Analysis

Flushing

- Flushing

- Flushing heating pipes

- Flushing coolants

- Air conditioner flushing

- Ventilation flushing

- Washing plate heat exchangers

- Flushing refrigeration systems

Disposal

Replacement

- home

- Blog (News)

- Antifreeze for gas boilers

Many boiler models that operate on gas fuel are designed to work with water and are incompatible with antifreeze. The use of non-freezing liquids contrary to manufacturer’s prohibitions threatens the failure of expensive equipment and voids the warranty of the gas boiler. Before purchasing the composition, be sure to make sure that the product will not harm the central device of the heating system.

When owners of private housing want to create a truly cozy and warm home, they usually use water as a coolant. Although the working fluid is widely available, it is not the best option for space heating systems. The thermal fluid includes a large number of impurities, and due to third-party substances, scale and corrosion appear in the boiler and pipes.

A serious disadvantage of water is its freezing point. When the temperature drops below 0 oC, the working fluid turns into ice and bursts the pipes from the inside, which leads to rupture. In houses where heating systems are used constantly, pipelines rarely fail. However, in buildings that are rarely used, the likelihood of an accident is very high.

To avoid equipment damage, antifreeze should be poured into the heating system instead of water. If the boiler operating rules allow this, there is no reason to continue to use an unstable working environment. Antifreeze liquids transform into ice at very low temperatures and are optimal for heating systems that operate intermittently.

Anti-corrosion and anti-scale additives are added to antifreezes. The substances prevent the formation of deposits, which impede the flow of the working medium, and significantly increase the service life of the equipment. Thanks to these properties, antifreeze liquids are excellent for situations where radiators must remain warm regardless of the frequency of use of the home.

Types and properties of heat-carrying liquids

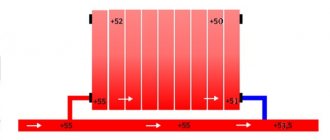

The working fluid of any water system - the coolant - is a liquid that takes a certain amount of energy from the boiler and transfers it through pipes to heating devices - radiators or underfloor heating circuits. Conclusion: the efficiency of heating depends on the physical properties of the liquid mediator - heat capacity, density, fluidity, and so on.

In 95% of private houses, ordinary or treated water is used with a heat capacity of 4.18 kJ/kg•°C (in other units - 1.16 W/kg•°C, 1 kcal/kg•°C), which freezes at a temperature of about zero degrees. The advantages of traditional heating fluid are availability and low price, the main disadvantage is the increase in volume when frozen.

The ice that forms in the cold literally splits pipes, boiler heat exchangers and radiators. To prevent the destruction of expensive equipment due to defrosting, 3 types of antifreeze made on the basis of polyhydric alcohols are poured into the system:

If you need to order high-quality installation of engineering systems (heating, water supply), please contact DESIGN PRESTIGE by phone +7 , and we will install the system at a professional level in accordance with high quality standards.

- Glycerin solution is the oldest type of non-freezing coolant. Pure glycerin is a transparent liquid of high viscosity, the density of the substance is 1261 kg/m³.

- An aqueous solution of ethylene glycol - dihydric alcohol with a density of 1113 kg/m³. The starting liquid is colorless and is inferior in viscosity to glycerin. The substance is toxic, the lethal dose of dissolved glycol when taken orally is about 100 ml.

- The same, based on propylene glycol - a transparent liquid with a density of 1036 kg/m³.

- Compositions based on the natural mineral - bischofite. We will analyze the characteristics and features of this chemical separately (below in the text).

Reference. Any non-freezing heating fluid contains a dye that gives the chemical a distinctive color. Poisonous ethylene glycol is usually colored red or yellow, propylene glycol is green (less often blue). Glycerin antifreeze is given a pink tint or left transparent. This classification is not mandatory and is not always observed.

Anti-freeze products are sold in two forms: ready-made solutions designed for a certain subzero temperature (usually -30 ° C), or concentrates, which the user dilutes with water himself. Let us list the properties of glycol antifreezes that affect the operation of heating networks:

- Low crystallization temperature. Depending on the concentration of polyhydric alcohol in an aqueous solution, the liquid begins to freeze at a temperature of minus 10...40 degrees. The concentrate crystallizes at 65 °C below zero.

- High kinematic viscosity. Example: for water this parameter is 0.01012 cm²/s, for propylene glycol - 0.054 cm²/s, the difference is 5 times.

- Increased fluidity and penetrating ability.

- The heat capacity of non-freezing solutions lies in the range of 0.8...0.9 kcal/kg °C (depending on concentration). On average, this parameter is 15% lower than that of water.

- Aggressiveness towards some metals, such as zinc.

- The substance foams when heated and quickly decomposes when boiling.

In order for antifreezes to meet operational requirements, manufacturers add additive packages to glycol solutions - corrosion inhibitors and other elements that maintain antifreeze stability and reduce foaming.

Heating a country house: types. Use of furnaces, water, gas and electrical systems

If you are planning to equip your dacha not only as a place for a seasonal stay, but also for living in the winter, one fireplace as a heating source is not enough. But how to choose heating for a country house so that it is as efficient as possible and at the same time affordable? Next, we will try to answer this question and consider possible options for heating a country house.

For year-round living in a country house, a high-quality heating system is necessary.

Types of heating

All existing types of heating primarily differ in the type of energy carrier on which they can operate.

The most common options for heating a country house are:

- On gas;

- Electricity;

- Solid fuel;

- Liquid fuel.

In addition, there are several types of heating methods for a country house:

Air heating circuit

In many ways, the choice of heating type depends on the following factors:

| Fuel availability | Does the village have gas or electricity, is it possible to stock up on firewood or other solid fuel, etc. |

| Proximity to communications | Communications include primarily power lines and gas pipelines |

| Building characteristics | The area that needs to be heated, the level of heat loss, etc. |

When deciding how to heat a country house in winter, you should familiarize yourself with the features of each system.

In particular, it is necessary to pay attention to such aspects as:

- The price of the fuel on which the system operates;

- Cost of system elements;

- Installation cost or option to install yourself.

Next, we will take a closer look at the features of different types of heating.

Bake

Bake

Heating a country house using solid fuel using a stove is a fairly common option. If the dacha is used in late autumn and early spring, then it can be heated with a stove.

However, such heating cannot be called ideal, as it has quite a few disadvantages:

- The oven takes up a lot of space;

- It is necessary to ensure a supply of fuel;

- It is very difficult to install a stove with your own hands; moreover, this procedure requires serious reconstruction of the house.

- The house warms up unevenly; remote rooms are much colder than those close to the stove.

Boiler for water heating using solid fuel

Water heating

Perhaps water heating for a country house is the most common. Its principle is based on the fact that a heat source heats a liquid, which distributes heat throughout the system.

Most often, water is used as a coolant, however, in some cases, a country house is heated with antifreeze. The main advantage of water heating is the ability to maintain optimal temperature in the premises.

The simplest water heating scheme consists of the following elements:

- Fuel boiler;

- Heat transfer batteries;

- Expansion tank.

Another advantage of such a system is the ability to heat the house with any energy source, for example, wood or gas. The power of the heat supply source is selected in accordance with the area of the house.

Water circulation in the system can be carried out in two ways:

- Natural - circulation is carried out due to the difference in density of cold and heated liquid. Water or antifreeze is heated in the boiler, after which it moves through pipes to the heating radiators. Here the coolant is cooled and returned to the heat source via return lines.

This process is continuous. To achieve optimal water pressure, the boiler is located below floor level. This system is an excellent option for heating small buildings.

- Forced - the system uses a circulation pump, which ensures constant movement of liquid in the pipes, as well as uniform heating of all rooms. The disadvantage of such a system is that its uninterrupted operation depends on the availability of electricity.

Advice! If there is no power supply on the site, then renting a diesel generator for the dacha will help solve the problem.

Heating scheme with forced water circulation

It must be said that in a water heating system it is possible to supply hot water not only for heating, but also for domestic needs. For this purpose, double-circuit boilers are used, the design of which provides for the possibility of heating water for both purposes.

In addition, it is possible to heat a country house with your own hands, such as a “warm floor”, which can serve as a complement to traditional radiators or even as an alternative to batteries. In contrast, heated floors warm the room better and do not dry out the air.

Summarizing all of the above, we can highlight the following advantages of water heating:

- Low cost of equipment;

- Possibility of choosing energy carrier;

- High heat capacity of the carrier.

Along with the advantages, there are also some disadvantages:

- Difficulty in installing the system;

- Constant monitoring of equipment operation is required;

- System elements are susceptible to corrosion;

- The boiler takes up some space, although it is smaller than the oven.

A gas boiler

Gas heating

Separately, it should be said about gas heating, which also applies to water heating. It is perhaps the most convenient to use and effective.

Gas heating in a country house, made using modern heating equipment, can provide the house with warmth and comfort even in the most inclement weather.

The only disadvantage of this option is the need to connect to a central highway, which is not available everywhere. True, regular purchase of gas cylinders can be considered as an option.

Among the main advantages of such a system are the following:

- Affordable gas prices;

- Easy installation of the system;

- Ease of operation of the equipment.

- High heating efficiency;

- Environmentally friendly.

Convectors

Electric heating

Thanks to the direct transformation of electricity into thermal energy, electric heating systems for a country house do not require the installation of a coolant. You just need to install heating elements.

This heating technology is very popular in Europe. In our country, it is used less frequently, which is due to frequent power outages in rural areas, as well as the relatively high cost of electricity.

However, if there is no gas supply in a holiday village and there are difficulties in procuring solid fuel, then when deciding how to heat a country house, you can give preference to electric heating.

Currently there are four groups of such heating:

- Floor heating system;

- Convectors;

- Infrared heaters;

- Combinable devices.

In the photo - infrared heater

Among the advantages of electric heating, the following points can be highlighted:

- There is no need for special maintenance;

- Easy installation;

- The systems do not take up useful space in the room;

- Quiet and environmentally friendly.

As for the disadvantages, they include:

- Quite high costs of heating a house;

- Possible power outages;

- Wiring may need to be replaced prior to installation.

Advice! If you have purchased a summer cottage without buildings and do not know how best to equip it, you can pay attention to country houses made from block containers, which are quickly erected and have good thermal insulation properties.

Here, perhaps, are all the main heating methods that can be used in a country house.

Conclusion

There are quite a few options for organizing the heating of a country house with your own hands. Therefore, the choice should be based on the specific conditions in each individual case. This will allow you to organize heating most efficiently.

You can get more information on this topic from the video in this article.

Add to favorites Printable version

9dach.ru

About the pros and cons of glycol antifreeze

The main advantage of artificial coolants based on glycols is the preservation of the liquid phase at subzero temperatures. We list other positive aspects of using antifreeze in closed water heating systems:

- coolants do not contain calcium and magnesium salts, which form scale inside the heat exchangers;

- due to the penetrating ability of glycols, the effect of lubrication of moving parts occurs, ball valves and thermostatic valves do not sour, the fittings last longer;

- the boiling point of antifreeze 103-106 °C delays the moment of vaporization and airing in case of overheating of a solid fuel boiler;

- When the temperature drops below the freezing threshold, glycol solutions turn into a gel mass.

Note. The paragraph about scale implies that the “anti-freeze” is diluted with demineralized distilled water.

Let's clarify the last 2 points. Ordinary water, often poured into the heating system of country houses, begins to boil at 96-98 ° C, actively releasing steam. If the circulation pump is on the TT boiler supply, the steam phase penetrates the chamber with the impeller, water pumping stops, and the boiler completely overheats. A higher boiling point of antifreeze will delay the moment of the accident.

Unlike water, glycol hardened in the cold does not expand and does not destroy pipe walls. In the event of freezing, the only unit that will suffer is the forced circulation pump. The crystallizing gel will jam the impeller and the motor will burn out.

Unfortunately, there are plenty of disadvantages to non-freezing substances:

- Ethylene glycol is poisonous and requires careful handling and disposal of the solution. Glycerin and polypropylene glycol are harmless.

- The heat capacity of the “anti-freeze” is 15% less. To deliver the required amount of heat to the batteries, the liquid flow will have to be increased.

- The viscosity of antifreeze creates additional hydraulic resistance. You will need a more powerful and expensive circulation pump.

- Good turnover is a double-edged sword. Glycols penetrate through the slightest leaks, from which plain water cannot flow.

- Coolants and additives decompose during operation, losing their frost-resistant properties and forming flakes of sediment. The maximum service life of 1 refill is 5 years, then the heating is flushed and replaced.

- When using antifreeze, many gas boiler manufacturers void the warranty of the purchased product.

Glycol liquids are poorly compatible with electric boilers. Instructions for the use of various antifreezes categorically do not recommend filling systems operating in conjunction with electrolysis heaters with antifreeze. That is, for electrode boilers of the “Galan” type, a special coolant developed by the specified company is needed.

Under rare circumstances, antifreeze can release flammable gas that breaks through the automatic air vent. Example: the heat source is an electric boiler, the heaters are Chinese-made aluminum radiators. Heating glycol causes a complex chemical reaction and gas formation.

TOP 12 Best electric heating boilers for home

Rating of the most economical and reliable electric heating boilers for a private home. Models are presented with durable heating elements, properly functioning safety automation and effective temperature control. Such boilers do not require complicated installation. There is no need to install a chimney, supply and exhaust ventilation or allocate a room for them. Modern models of heating element modifications have a built-in security system and other necessary elements and components, so to create a simple heating system you do not need bulky boiler piping. Below we will consider the methodology for calculating boiler power by area of the house, calculate energy consumption indicators in seasonal terms and give several ways to save energy.

To choose an electric heating boiler, you need to select the correct power and inspect the electrical wiring. The cross-section of the power cable must correspond to the load. Models up to 3.5 kW are connected directly to the apartment outlet. More powerful electric heating boilers operate through automatic protection devices, which are responsible for controlling the current strength.

The installation of electric boilers with a power of up to 10 kW does not need to be coordinated with Energonadzor. This is done only when connecting a multi-tariff meter in order to save electricity on the price difference between the day and night tariffs. For boilers with a power of more than 6 kW, it is necessary to organize a three-phase connection (380 V).

Content

How to choose a good product, what to pay attention to. Overview of selection criteria

Which boiler is better: gas or electric?

When a gas main runs along the street, it is not customary to think about which boiler is better to install for heating a house: gas or electric? By default, developers choose the first option. However, such a decision is not always justified. In many cases, installing an electric boiler is much more convenient and profitable.

| Aspect under consideration | A gas boiler | Electric boiler |

| Connection to an energy source (gas pipeline, electrical networks) | To connect to the gas main, you need to collect a package of documents, submit an application, receive technical specifications, order a project, and carry out installation work. Each stage requires going through bureaucratic obstacles, money and time. | When installing boilers that match the allocated power, approvals are not required. |

| Boiler installation conditions | A separate boiler room is required, a long list of requirements for which is clearly stated in SNiP standards. In order to comply with everything, sometimes you have to reconstruct the house. | A separate boiler room is not required. The boiler can even be placed in the kitchen. The only condition is that the cross-section of the electrical cable matches the power load. |

| Ventilation ducts and chimneys | The installation of a complex ventilation system with the removal of combustion products is required. Additional cash costs. | The operation of the equipment does not involve open flame. No chimney installation required. |

| Boiler installation | Performed only by gas service specialists. Payment according to established prices in the region. This is the case when “bargaining is not appropriate.” | You can install the electric boiler yourself. But it is better to invite an electrician who will ask for an adequate amount for his services. |

To summarize: at the initial stage of connecting a gas boiler, a lot of bureaucratic approvals are required, the fulfillment of a huge list of requirements, the blow to the family budget is very sensitive. The price of a gas boiler is 2-3 times higher than an electric boiler of similar performance. We will add a fee for mandatory maintenance of each gas installation in the house. It will take more than one year until the costs are compensated by paying utility bills. Or maybe they won’t be compensated. You need to understand that the price of gas has long been out of budget, and electrical appliances have undergone a revolution in terms of energy efficiency.

Calculation of boiler energy consumption per hour, day, month

To dispel the myths that an electric boiler will require exorbitant costs for utilities, let’s calculate how much electricity this unit actually consumes. An electric heating boiler in a modern technological design provides 99% efficiency. At full load, when it is not particularly insulated, and it is -15 outside the window, a 9 kW unit should theoretically consume 9.091 kW per hour.

Further calculations show the following:

- Energy consumption per day: 9.091x24 = 218.2 kW.

- In monetary terms, at a tariff of 3.89 rubles per 1 kW hour, the payment per day will be: 3.89 x 218.2 = 848.8 rubles.

- Energy consumption per month: 30 x 848.8 = 6,546 kW.

- In monetary terms, the monthly payment will be 25,463.9 rubles.

- Energy consumption for the heating season (from October 15 to March 31) will be 136 x 218.2 = 29,675.2 kW.

In monetary terms, payment for the season will be 848.8 x 136 = 115,436.5 rubles.

Calculations were performed for severe winter conditions and, accordingly, 24-hour full load of the boiler. In fact, no one pays that amount. In reality, the boiler will be loaded at an average of 55% during the heating season. The automation is designed so that it will turn on for about 12 hours a day. As a result, the heating of an ordinary brick house of 75 sq. m. in a temperate continental climate, a 9 kW boiler will cost 9-15 thousand rubles. per month.

The two best ways to reduce electric boiler consumption

The energy consumption of a home boiler depends on many factors:

- Climatic conditions. Where the heating season is shorter, winters are milder, heating costs (for any type of fuel) will be lower.

- Energy efficiency of the building. High-quality double-glazed windows, thick walls, an insulated attic and other heat-insulating measures will reduce heat loss.

- Desired room temperature. By reducing demand by 1 degree, you can save up to 5% of electricity.

- Coolant quality. Hard, frequently changed water forms scale on the heating element, and the boiler’s heating performance decreases.

- Heat transfer level of radiators. Optimal performance when installing an electric boiler is guaranteed by bimetallic radiators. Steel and cast iron batteries are not recommended.

- Availability of a circulation pump. This piping element eliminates all the shortcomings of the water heating device.

When all these parameters are optimized, but you want to save even more, you can resort to two methods:

- Connect a programmable room thermostat to the boiler, which allows you to reduce energy consumption when the owners are away and increase the room temperature during those time periods when people are in the house. Before purchasing a thermostat, you need to make sure that the appropriate contacts are available on the unit. In some models, such automation is already built-in.

- Install an electric meter that allows you to divide your electricity consumption into two or three time zones. Accordingly, configure the unit to operate at a time when the tariff is minimal. The costs of purchasing, designing and installing the meter are recouped in one season.

Boiler power supply

Features of connecting to the power supply depend on the power of the unit:

- Installation of boilers from 10 kW is carried out under the control of the energy supply organization.

- Boilers with a power of 7 to 10 kW are connected to a 380 Volt network through a panel with an RCD.

- Units with a power of up to 6-7 kW are connected through a residual current device.

- Connection of 3.5 kW electric boilers is possible through a regular outlet.

The wires are pulled into an electrical pipe or simply placed in a plastic case. The cable with copper core and vinyl insulation VVGng is considered the most reliable.

There is a direct relationship between the cable cross-section and the power of the electrical installation. If the load is higher than permissible, the insulation will begin to melt, leading to a short circuit and fire. To calculate the boiler current, you need to divide the power of the heating element (indicated in the passport for the unit) by the network voltage.

Calculation for a 6 kW boiler:

Calculation for a 9 kW boiler:

Boiler power and its calculation

In the simplest method for calculating the required power of an electric boiler, the area of the heated room is taken as the basis. By default, it is assumed that to heat a room of 10 square meters. m. with standard ceilings of 2.5-2.7 m, you need to spend 1 kW of power. If the ceilings are higher, a correction factor should be derived: the actual ceiling height must be divided by 2.7.

Next you need to apply the climate coefficient:

- for southern regions 0.7 – 0.9;

- for central Russia 1.2 – 1.3;

- for the Far East and North 1.5 – 2.

For private households, the resulting value is multiplied by 1.5. If the boiler will be used to organize hot water supply, a power reserve of 25-30% is added.

Example calculation for a private house of 75 sq. m in the Krasnodar region with standard ceilings for a boiler that will be used for heating and hot water supply:

- 10 x 75 = 75 W = 7.5 kW

- 7.5 x 0.7 = 5.25

- 5.25 x 1.5 = 7.8 kW

- (8x30):100=2.4 kW -30% power reserve.

- 7.8+2.4=10.2 kW

We have previously written about:

Types of electric boilers

According to the type of water heating, all electric boilers are divided into the following types:

- Heating elements. The most common type. A tubular electric heater (TEH), protected by a dielectric, is heated by electricity and transfers heat to the coolant. The number of heating elements required depends on the power of the device. The downside is the appearance of scale on the heating element and, as a result, a decrease in productivity.

- Electrode (ionic). More economical type. The coolant acts as a current conductor. Electrical energy is supplied to the two electrodes, which passes through the electrolyte and, due to the potential difference, causes it to heat up. These are reliable and safe units, the disadvantage of which is the expensive coolant. Electrodes need to be changed from time to time. A prerequisite for connection is the presence of grounding of the boiler and the entire water circuit.

- Induction. Complex units that have been used for household purposes not so long ago. The main components of the system are the induction coil and the core with coolant inside. The boilers do not have the disadvantages of heating elements and ion boilers. They are durable, compact, economical, fireproof, but heavy and very expensive.

Connection type (220 and 380V)

According to the type of connection, electric boilers are divided into two groups:

- Operating only from a regular power supply of 220 V. Units with a power consumption of up to 3.5 kW can be connected directly to an outlet, more powerful ones directly to the panel.

- Operating from a three-phase network with a voltage of 380 V. These can be boilers with any power consumption. Since private homes do not often have three-phase networks, such a connection is justified for powerful units that cannot work with a 220 V network.

Many models up to 6 kW provide two types of connection - to 220 V and 380 V networks.

Number of circuits

Depending on the tasks performed, boilers are divided into two types:

- Single-circuit, which work only to heat the room.

- Double-circuit, which can solve the issue of providing hot water supply.

The second type of boiler can work in conjunction with a boiler or in instantaneous water heater mode. For a family of 2-3 people, a capacity of 10 l/min is sufficient. To ensure that hot water can be supplied directly to the kitchen sink and shower, this parameter must be increased to 15 l/min.

Power regulation and boiler control system

The power of the electric boiler can be adjusted in steps, that is, by half power or by a quarter. Fine tuning is carried out by shut-off valves on radiators. Smooth adjustment is provided in expensive models where a rheostat is installed. There are the simplest models without the ability to change power.

The automation system, which is designed to maintain the temperature set by the user, can be made in two versions:

- A mechanical thermostat shuts off the coolant flow or opens the contacts of the electrical network when the coolant temperature reaches the desired limit. When it falls, the boiler turns on.

- Electronic thermostats. They include a remote sensor, which is attached to the radiator, and a control unit. Temperature settings are more accurate, but the price of the boiler is much higher.

Automation functionality

In modern electric heating boilers, electricity consumption can be reduced by programming the operating parameters of the unit for a day or a week in advance. This allows you to set a lower temperature when the owners are at work and intensively heat the house at night, when there is a lower electricity tariff.

If there is no such functionality, you can connect a high-tech electronic room thermostat to the boiler, which focuses on the air temperature in the room, and not the temperature of the coolant.

Modern automation is able to adjust the operation of the boiler to external weather conditions. When installing a boiler in a country house, the function of protecting the heating system from freezing is useful.

Boilers for houses up to 60 sq. m.

Teplodom i-TRM SILVER StS 6 6 kW single-circuit

Average price: RUB 20,300

When connecting an external water meter with a pulse output, the boiler will turn off without operator intervention if the flow in the heating circuit stops for some reason.

- durable heating element made of stainless steel;

- the ability to participate in a cascade connection paired with other boilers;

- presence of an input for an external thermostat and weather-compensating automation;

- maintaining operability at extreme voltage values.

With a 3-phase connection, the boiler has another advantage - it automatically selects the priority phase to even out the load on the electrical network.

EVAN EPO 6 6 kW single-circuit

Average price: RUB 12,550

- electric heater made of high-quality stainless steel;

- emergency thermal switch that turns off the boiler when the coolant temperature reaches 92;

- possibility of connecting an external thermostat;

Unlike the previous model, EVAN EPO 6 does not have such rich functionality, but the price of the unit is much lower.

Teplodom iTRM-6 SILVER 6 kW single-circuit

Average price: RUB 13,900

The Teplodom electric boiler is equipped with a rich set of useful functions, and has a huge price advantage among similar models. The triac electronics used in this unit operate silently and are resistant to surge voltage surges. Steel heating elements have a special chemical coating that extends their service life. The frost protection system, emergency shutdown and self-diagnosis allow the device to remain operational for a long time.

- presence of an input for weather-compensating automation;

- advanced digital, LED and sound indication;

- intelligent power modulation with phase selection.

This electric boiler is suitable for a private home or cottage as a main or backup heat source. The boiler can be connected to 220 V or 380 V electrical networks.

Boilers up to 100 sq. m

Protherm Slope RAY 9 KE /14 9 kW single-circuit

Average price: RUB 48,317

- the ability to fill the system with antifreeze liquid and hard water;

- three stages of water heating;

- contains the entire installation complex (expansion tank, pump, automation).

This model has an interface for connecting various remote control and monitoring devices, so the boiler will be an excellent choice for a country house in which residents do not live permanently.

STOUT SEB-0001-000009 9 kW single-circuit

Average price: RUB 39,823

In second place in the rating is a beautiful, energy-efficient European-assembled boiler, which has received many good reviews from users. Unlike the previous model, special “climate” automation is already built in here. Thanks to the synchronized operation of the external and internal sensors, the set temperature in the room is maintained with an accuracy of 0.1 degrees. Statistics for the last hours are saved in the device’s memory, where you can see how the temperature is maintained and how many heating elements are used. This information will help evaluate how energy is consumed and adjust the operation of the boiler.

- emergency shutdown of the unit when operating parameters are exceeded;

- 6 operating modes, including hot water option;

- intelligent change of power levels.

This model performs well in combination with other boilers when they are connected in series to increase the total power or create different heating zones.

EVAN EXPERT 9 single-circuit

Average price: RUB 50,800

The electric boiler from the Russian manufacturer is equipped with stainless steel heating elements from the Czech company Backer. The operating algorithm of the device is based on an analysis of indoor and outdoor temperatures, which ensures economical energy consumption. The control unit reacts to changes in the climatic environment and selects the optimal coolant temperature and the desired power level.

- multi-stage protection system (against overheating, high pressure, power surges);

- programming mode, with which you can set the temperature by day of the week and hour;

- expanded service capabilities for independent monitoring of the performance of each control unit.

The multifunctional device can be connected to a “warm floor” system. A remote control module can be connected to the unit.

EVAN Warmos-IV

- power: 9.45 kW

- heating area: 94.5 sq.m

- number of circuits (if any): single-circuit

- Efficiency: 99%

Average price: RUB 22,690.

EVAN Warmos-IV is the best single-circuit electric boiler with a heating element. It is used only for heating the room, the maximum power is 9.45 kW, it allows you to heat an area of up to 94 square meters. Efficiency is high - 99%. Wall mounting, electronic control system. Equipped with a power indicator and a thermometer. Protected from overheating, freezing will be prevented. Weighs 27 kg. The manufacturer promises the product will work for 10 years.

- simplicity and functionality;

- favorable price-quality ratio;

- Purified water can be used as a coolant.

Boilers 100-150 sq. m

Protherm Slope RAY 14 KE /14 14 kW single-circuit

Average price: RUB 50,882

A wall-mounted electric boiler is used for heating and organizing hot water supply when a boiler is connected. Users can configure up to four power levels. It is possible to connect a remote control and a weather-dependent automation unit. Thanks to the LED indication and liquid crystal display, it is convenient to monitor the temperature and control the operating status of all components.

- automatic protection against overvoltage, freezing, water hammer;

- built-in expansion tank and pump unit with float air vent;

The efficiency of this unit is 99.5%. This is a convenient and economical boiler option for installation in an apartment, private house or country house.

Vaillant eloBLOCK VE 14 14 kW single-circuit

Average price: RUB 56,304

The electric boiler from the German brand is equipped with rich energy-saving functionality. The microprocessor control unit provides automatic temperature control, protection against overloads in the electrical network, freezing of the boiler and boiler. Power supply is supplied from a three-phase alternating current network with a voltage of 380V.

- possibility of connecting an indirect heating water heater;

- compatibility with Warm Floors systems;

- effective pump anti-blocking system;

- presence of a BUS bus for connecting weather-compensated automation.

The boiler has a modern design. Despite the powerful electronic filling, it has the simplest possible control panel and can be an excellent alternative to gas heating.

EVAN S2 12 12 kW single-circuit

Average price: RUB 22,440

- the design of the heating element on a threaded connection simplifies the replacement procedure;

- The emergency sensor turns off the unit at a temperature of +92±3℃.

EVAN Next 12

Average price: 12,350 rub.

EVAN Next 12 is a single-circuit boiler with a heating element. The power of the heating system is from 6 to 12 kW. Heats up to 120 square meters. Efficiency is high - 99%. Mechanically controlled. The boiler is installed on the wall. There are two power levels. Three-phase mains voltage. The product is protected from overheating. Weighs 8 kg. The manufacturer promises 10 years of operation.

- low noise level;

- compactness;

- low price;

- Ease of Management.

Electric boilers for houses up to 200 sq. m.

Protherm Slope RAY 18 KE /14 18 kW single-circuit

Average price: RUB 54,292

A high-quality unit from a European manufacturer demonstrates high efficiency throughout its entire service life. The device is equipped with a durable cylindrical copper heat exchanger. The multifunctional LCD display displays the temperature of the coolant in the heating circuit and boiler, as well as information about faults. This powerful heating device uses a 380 V three-phase power supply to operate.

- intelligent connection of heating elements;

- powerful safety unit (thermal fuse, frost protection);

- an effective diagnostic system for checking the functionality of all components.

The electric boiler looks elegant; such a device can be placed in a visible place without damaging the interior.

Reko 24P 24 kW single-circuit

Average price: RUB 36,200

A powerful 24-kilowatt boiler performs its tasks automatically with the ability to manually adjust the power. Special sensors monitor the temperature of the water in the circuit and the environment. It is permissible to use antifreeze intended for household heating systems as a coolant. The pressure in the main circuit should not exceed 2.5 bar. A simple control panel and LED display make it easy to monitor the operation of the device.

- the ability to program temperature by day of the week;

- built-in electricity consumption meter;

- Manufacturer's warranty on the heat exchanger is 8 years.

Despite its impressive power, the boiler is small in size. In maximum power mode, this unit can be used to maintain a comfortable microclimate in a room up to 240 sq. m.

EVAN Warmos-IV-21 21 kW single-circuit

Average price: RUB 33,130

- increased safety due to an emergency shutdown system;

- durable stainless steel heating elements with rotation when turned on.

The unit operates stably and does not require complex maintenance. Users have no complaints about its reliability and durability.

Video: How to choose a good electric heating boiler

New mineral coolants

We decided to highlight the description of these liquids, since they are made based on the natural mineral - bischofite. The substance is a magnesium salt of hydrochloric acid, the full name is magnesium chloride hexahydrate. The manufacturer declares the following characteristics of the finished antifreeze, designed for a minimum temperature of minus 30 degrees:

- the color of the aqueous solution is light yellow, the density is 1117...1250 kg/m³;

- boiling threshold - 116 °C, freezing point - minus 30 °C;

- specific heat capacity - 0.77 kcal/kg •°С (3.23 kJ/kg•°С);

- thanks to the additives, there is no foaming and no aggressive effect on various seals - silicone, paronite, EPDM and BMS rubber;

- the substance is not toxic;

- In terms of viscosity and fluidity, the drug is very close to glycol chemicals.

Reference. The product appeared on the market after 2010. The price of liquid as of 2022 is about 1 USD. e. per liter of finished coolant (-30 ° C).

Compared to traditional glycol analogues, mineral antifreeze benefits due to its high boiling point, cost and health safety. The negative point is the increased density and low heat capacity, 23% worse than that of water.

The practical use of the coolant has revealed a number of shortcomings, as evidenced by reviews from homeowners:

- The fluidity of the solution is extremely high. There have been cases where antifreeze penetrated through the soldered joint of polypropylene pipes.

- Upon contact with air, the liquid fraction quickly evaporates, leaving a noticeable salt build-up. Similar phenomena are observed in heat exchangers and pipelines where air bubbles have penetrated.

- The substance reacts with bare metal on welds. Stalactites of iron and salt form inside the system, reducing the flow area and clogging the mud traps.

- In case of overheating, antifreeze turns into a slurry of unknown color.

User responses about this type of “anti-freeze” can be read on the well-known construction forum: https://www.stroimdom.com.ua/forum/showthread.php?t=157650

Taking into account the experience of users, we do not dare to recommend mineral antifreezes for use in heating systems of private houses. Perhaps over time, manufacturers will eliminate the above problems and the magnesium chloride solution will be able to compete on equal terms with glycols.

TOP 15 Electric Boilers for Home Heating | Rating 2021 + Reviews

To protect against overheating and freezing, these electrical appliances are equipped with special automation. Some models can be designed to use not only water, but also antifreeze as a coolant.

The boiler can be single- or double-circuit. The latter is a kind of hybrid of a single-circuit boiler and a boiler. The water heating device can be a tubular electric heater (TEH), induction coils or a specially designed electrode group (ion boilers). Please note: when connecting electric boilers, be sure to use grounding!

The rating below of the best electric boilers presents single-circuit heating elements solutions. They are divided into categories according to the method of connection to the electrical network.

Single-phase boilers (220 V)

The heating elements and heat exchangers of such flow-through boilers are most often made of ordinary stainless steel. Mostly for this group, the wall mounting method is used (in this case, the height of the ceilings must be taken into account), but some products may also have floor mounting.

Choosing an “anti-freeze” for heating

Tip number one: buy and fill in antifreeze only in extreme cases - for periodic heating of remote country houses, garages or buildings under construction. Try to use water - regular and distilled, this is the least troublesome option.

When choosing a frost-resistant coolant, follow the following recommendations:

- If your budget is limited, take ethylene glycol from any well-known brand - “Teply Dom”, Dixis, Spektrogen Teplo Coolant, Bautherm, Termo Tactic or “Thermagent”. The cost of the concentrate -65 °C from Dixis is only 1.3 USD. e. (90 rubles) per 1 kg.

- If there is a danger of antifreeze getting into household water (for example, through an indirect heating boiler, double-circuit boiler), or you are very concerned about the environment and safety, buy harmless propylene glycol. But keep in mind: the price of the chemical is higher; a ready-made Dixis solution (minus 30 degrees) will cost 100 rubles (1.45 USD) per kilogram.

- For large heating systems, we recommend using premium class HNT coolant. The liquid is made on the basis of propylene glycol, but it has an increased service life of 15 years.

- Do not buy glycerin solutions at all. Reasons: sedimentation in the system, too high viscosity, tendency to foam, a large number of low-quality products made from technical glycerin.

- Electrode boilers require a special liquid, for example, HNT-35. Before use, be sure to consult with a representative of the manufacturer.

- Do not confuse automobile antifreezes with chemicals used in heating systems. Yes, both formulations are glycol-based, but the additive packages are completely different. Engine coolant is not compatible with residential water heating.

- For open and gravity-flow heating systems, it is better to use water, or, in extreme cases, propylene glycol diluted at minus 20 °C.

- If the heating distribution is made with galvanized pipes, there is no point in purchasing glycol mixtures. The substance will deal with zinc, lose the package of additives and quickly degrade.

Clarification. It is not profitable to use frost-resistant liquid for an open heating system. Hot antifreeze will evaporate into the atmosphere through the expansion tank, the antifreeze will have to be constantly topped up, and money will be spent. It is unacceptable to pump in ethylene glycol, since its vapors are toxic.

There is a lot of debate about the harmfulness of ethylene glycol compounds, including on the pages of construction forums. Without denying the harmful effects of the chemical on human health, let us draw attention to a convincing fact.

Homeowners whose closed systems are installed well have been using inexpensive glycol for years without any problems. Let's listen to the expert's opinion in the video:

Filling the heating system with liquid

Experts say that there are two ways to fill a closed system with liquid:

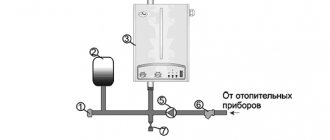

- using a pump. The liquid should be pumped from a barrel or tank. In this case, be sure to use a pressure gauge. The injection should be stopped when the pressure reaches 1.5 Bar (we are talking about a private house no higher than 2 floors). The pump is connected to the make-up or drain pipe through a check valve. All air valves should be opened,

- manually. You will have to fill the finished coolant through the air vent on the riser (this is the highest point of the system). Reviews claim that this method is more labor-intensive. As in the first case, it is necessary to connect a pressure gauge and open all air valves. Manual pumping and deflation of air must be done until you see the desired pressure reading on the pressure gauge.

From this video you will learn how to properly fill the heating system in a private home with antifreeze:

Instructions for use

If your system previously ran on water, switching to antifreeze will not be easy. Theoretically, radiators with a boiler can be emptied and filled with cold-resistant coolant, but in practice the following will happen:

- due to lower heat capacity, the output of batteries and the efficiency of heating rooms will decrease;

- due to viscosity, the load on the pump will increase, coolant flow will drop, and less heat will reach the radiators;

- antifreeze expands more than water, so the capacity of the old tank will not be enough, the pressure in the network will rise;

- To improve the situation, you will have to increase the temperature on the boiler, which will lead to excessive fuel consumption and increased pressure.

Addition. After filling the liquid, the old connections sealed with flax and paint are guaranteed to flow.

In order for heating to function normally using a chemical coolant, you need to calculate in advance or remake the existing system according to the new requirements:

- Select the capacity of the expansion tank at the rate of 15% of the total volume of liquid (water was 10%);

- The pump performance is assumed to be 10% more, and the generated pressure is assumed to be 50% more. Let us explain with an example: if previously there was a unit with a working pressure of 0.4 Bar (4 meters of water column), then use a 0.6 Bar pump for antifreeze.

- In order to operate the boiler in optimal mode and not raise the temperature of the coolant, it is advisable to add 1-3 (depending on power) sections to each battery.

- Pack all joints with dry flax or use high-quality pastes - sealants such as LOCTITE, ABRO or Hermesil.

- When purchasing shut-off and control valves, consult with the seller about the resistance of rubber seals to glycol mixtures.

- Pressure test the system again by filling the pipes and heating equipment with water.

- When starting the boiler unit at negative temperatures, set the minimum power. Cold antifreeze needs to be warmed up slowly.

Advice. The total amount of coolant is easy to calculate - the cross-sectional area of the pipe is multiplied by its length, the capacity of the boiler and radiators is indicated in the product data sheets. Find out how to properly place and connect the expansion tank in our separate publication.

The concentrated coolant must be diluted with water, ideally with distillate. Do not rely on an excessive reserve of frost resistance - the more water you add, the better the heating will work. Recommendations for preparing coolant:

- For heating elements, electric and gas double-circuit heat generators, prepare the mixture at minus 20 degrees. A more concentrated solution may foam upon contact with the heater, and carbon deposits will form on the surface of the heating element.

- In other cases, mix the components at freezing point according to the table below. Proportions are indicated per 100 liters of coolant.

- If there is no distillate, first conduct an experiment - dilute the concentrate in a jar with plain water. If you see a precipitate of white flakes - a product of the decomposition of inhibitors and additives, this water should not be used.

- A similar check is done before mixing antifreeze from two different manufacturers. It is unacceptable to dilute ethylene glycol with propylene composition.

- Prepare the coolant immediately before pouring.

The maximum service life of any antifreeze substance in pipes and heating radiators is 5 years. At the end of the specified period, the liquid is drained, the system is flushed twice and filled with fresh antifreeze.

How to choose and make heating for a summer house

Country houses are used for recreation, not for permanent residence. However, in early spring or late autumn it becomes cold in any room. Therefore, heating the dacha becomes a necessity. Otherwise, it will not be possible to stay in the house for the night. This can be inconvenient due to the fact that the road to the holiday village sometimes takes a long time, and sometimes it is inopportune to return on the same day.

There is another significant advantage of a heated dacha, for example, for those who have children: you can have a winter picnic with the kids outside the city during the New Year holidays. How to make heating for a dacha with your own hands, and which scheme is best to choose for this, we will consider further.

Heating in a brick house

Which houses are best suited for heating devices?

Depending on the building materials, a temporary dwelling may or may not be suitable for heating. For example, wooden houses built from panel panels cool down very quickly. Such a structure must be additionally insulated. Don’t forget about fire safety when installing heating in a wooden country house.

Heating in a wooden house

Another thing is houses built of brick, shell rock or concrete. They are permanent buildings and are ready for year-round visits. The choice of heating scheme in such houses depends on the communications passing nearby.

Suitable heating options for a summer house, their pros and cons

Conventionally, they can be divided into three types:

- oven;

- water;

- electric.

Modern stove heating is achieved using a cast iron or steel stove.

We will not consider a furnace made of refractory bricks, since it should be taken into account at the design stage and installed together with the construction of internal walls.

If you have to choose heating in your dacha without gas, then this option turns out to be the most economical. The advantage of this type of heating is the ability to heat the room to an optimally comfortable temperature in just 40-50 minutes. Stove heating has disadvantages: it is necessary to periodically (approximately every 4-6 hours) add fuel and clean the ash pan from combustion products; you also need to control the draft.

However, this device has undoubted advantages: simplicity and speed of installation, no need to worry about equipment failure, freezing and rupture of pipes, as in water heating.

Cast iron stove

The second type is water (steam) heating. In terms of comfort and design, it can be compared with a city one. The principle of water country heating is that the coolant - hot water (or antifreeze) is preheated in the boiler - passes through pipes into radiators or convectors and releases heat, heating the rooms. The disadvantages of such heating are the complexity of the circuit and the need to purchase expensive equipment. The advantages of this type of heating: comfort of use and the ability to choose one of the available boilers:

- gas;

- electric;

- solid fuel.

It should be noted that gas heating boilers for dachas, although preferable, require mandatory approval before installation from the gas service.

The simplest type of country heating is electric. This is implemented by installing heaters, convectors or warm infrared floors. Pros: their installation does not require major repairs, the equipment does not require maintenance, it connects and works as needed. Cons: in case of power outages, it is better to have an alternative heat source, for example, the same stove.

Infrared floors

How to choose the right heating system for your dacha

The first step is to determine the availability of fuel. If there is a gas main nearby, it would be a sin not to take advantage of it. Gas is one of the cheapest types of fuel. Accordingly, gas heating for a summer house is the best option in terms of quality and affordability.

If the networks do not pass close, then solid fuel and electricity remain. It is better to give preference to either a cheaper or safer type. Much depends on the materials from which the house is made.

For example, it is unsafe to install stove heating in a wooden house, since materials located near the stove may ignite. At the same time, infrared floors are best installed under laminate, since wooden floors have high heat-insulating properties. In addition, they dry out from heating and become deformed over time.

Total:

- For a house made of brick or concrete, water or stove heating is more suitable;

- For a wooden house it is better to install water or electric heating. When using the oven, you should take safety precautions and carefully isolate it from heated metal surfaces.

Stove heating: installation rules

This heating installation in a country house has some limitations. It is best to install a cast iron firebox in utility rooms or living rooms, choosing walls at least 500 mm thick adjacent to the interior rooms. It is not recommended to install stoves in bedrooms to avoid carbon monoxide poisoning. It is not advisable to install the firebox in a draft, between adjacent windows or doors: otherwise it will start to smoke. It is not recommended to hammer into a wall if there is no chimney; it is better to complete it.

Stove heating scheme

It is correct to place the firebox on a brick bed laid in three rows, especially if it does not have a stand. A chimney made of sheet material or cast iron is installed above the stove. To avoid fire, you need to cover the pipe with thermal insulation at the points of contact with the ceiling and roof. Depending on the model, such a stove heats an area from 15 to 90 square meters. m. It can be installed in one day, if you do not use decorative finishing.

Water heating of a country house

This type of heating is the most comfortable due to the fact that the heat emanating from the radiators is distributed evenly throughout the room. It is advisable to choose it for houses with an area of 100 m2 or more, when stove heating is not enough and electric heating is expensive.

Scheme

This do-it-yourself dacha heating scheme boils down to the following: water is heated in the boiler, which begins to circulate with the help of a pump, flowing through the pipes into the radiators. To prevent the liquid expanding from heating from rupturing the pipes, it is necessary to connect a container to the system - an expansion tank of an open or closed (membrane) type.

Water heating circuit

It is possible to install a water heating system without a pump - of the forced type, but it is less reliable and not justified, since heating the room with its help is many times slower. Sometimes it takes a day for the room to get a little warmer. Therefore, we will not consider it.

Equipment

So, to set up the system you will need to purchase:

- radiators (according to the number of windows in the house), the selection of sections is taken in the calculation of 1 piece. by 1.5-2 m2;

- pipes suitable for them (determine the footage in accordance with the diagram);

- expansion tank calculated at +10% of the heating circuit volume;

- pump (calculated that 1 m2 will require 100 W of energy);

- shut-off valves, corresponding keys;

- level, pencil;

- gas, electric or solid fuel boiler depending on the availability of fuel. As an interesting option for a summer residence, you can consider a pyrolysis or gas generator boiler. Its efficiency is achieved up to 92% due to the fact that after burning the wood releases gas, which is ultimately also used as fuel. Thus, from one bookmark the boiler operates uninterruptedly for 12 hours.

The most suitable heating radiators for summer cottages are aluminum or biometallic. They weigh little and heat up quickly. They are easy to transport with your own transport and connect to polypropylene pipes, which look decent, are inexpensive and do not require painting.

Installation recommendations

When placing radiators on brackets, it is necessary to maintain a distance of at least 70 mm to the window sill, 100 mm from the floor and 30 to 50 mm to the wall. The film is removed from the batteries after installation. For aesthetic reasons, it is better to install supply pipes level. The expansion tank is located next to the boiler, the pump in front of it.

It should be taken into account that when the house is not heated, the water in it will freeze, which can lead to rupture of pipes and failure of the system. To prevent this from happening, it is recommended to either drain the water when leaving or fill the containers with antifreeze.

Electric heating

Installation of heaters and convectors

The easiest and fastest way to keep warm in a country house is to turn on the convector or infrared emitter. A very good option for a summer residence is electric radiators. These devices very quickly raise the room temperature to a comfortable level.

Electric heater

Convector heater

Infrared heater

One could stop at this equipment if it were not for health concerns. The fact is that in a cold room your feet freeze more than outside. Therefore, it is better to install heated floors in the house. They allow you to warm up much faster after a long stay in the fresh air, and therefore there is less chance of catching a cold.

Installation of heated floors

You can install infrared heated floors at any time of the year, even on old flooring. Using this method, installation of heating for a dacha is carried out without much difficulty. To do this, you need to purchase infrared film (one of the best manufacturers - Caleo), heat and waterproofing, thermostat, coating (preferably laminate). The following steps should be followed:

- clean the floor surface, it must be perfectly flat;

- install a thermostat in the wall;

- lay thermal insulation (preferably Izolon) and secure it with construction tape;

- lay the film strips in accordance with the instructions (the area where the furniture will be should be left without an emitter);

- fasten them together;

- Insulate cut areas with bitumen tape;

- connect electrical wires to the edges;

- bring them to the thermostat; check the system for serviceability;

- lay waterproofing;

- cover the floor with carpet or laminate.

Recommendations on how to save on heating a country house

Connecting infrared film to electricity

It has been observed that heat leaks affect the speed and efficiency of heating rooms. Up to 20% of the heat usually escapes through old wooden double-glazed windows. Through cold walls - up to 40%, through doors - up to 20%, through the floor - 10%. Accordingly, if before the onset of cold weather you fix leaks and insulate the walls, then within an hour you will be able to feel in a country house just like in a city apartment.

And further. The most economical heating for a dacha in terms of fuel consumption is gas. Therefore, if it is possible to connect to the highway, then it is better to choose it as a priority.

Video: types and heating options for a summer residence

https://www.youtube.com/watch?v=5H6Of05jB2s

teploguru.ru

Finally, about coolants for electrode boilers

Electric water heaters of this type operate on the principle of a “soldier’s boiler” consisting of two blades connected to a 220 volt network. Water simultaneously serves as a coolant and electrolyte; heating occurs due to its conductivity, which depends on the content of magnesium and calcium salts.

This is why electrode boilers do not work with distillate and significantly lose power with under-salted water. According to the passport of the Galan heater, the resistance of the working fluid should be no more than 3200 Ohms per 1 cm.

If you pour regular ethylene glycol into an electrolysis heat generator, the substance will enter into a chemical reaction, foam and lose additives against corrosion and scale formation. The problem can be solved in 2 ways:

- A special antifreeze designed for electrode-type units is purchased. Special additives that resist foaming are dissolved in the working environment.

- A saline solution of the required concentration is prepared, as shown in the video below. Such water will begin to crystallize at a lower temperature, although it cannot be compared with antifreeze in terms of frost resistance.

You should pay attention to the preparation of tap water - pass it through a filter and let it sit for 1-3 days. A good solution is to buy a corrosion inhibitor separately and add it to the coolant for the heating system in advance.

The operating principle of this type of heating equipment

A lot has already been said in various materials about what the operating principle of long-burning solid fuel heating equipment is based on. The achieved effect is due to a fundamentally different method of fuel combustion in the combustion chamber. Due to the multi-stage combustion process, complete burnout of the fuel mass loaded into the boiler is ensured. In this case, wood gas is released in large quantities, which does the main work of heating the coolant.

For reference: the units operate on the basis of pyrolysis, the process of generating volatile flammable compounds obtained from wood as a result of exothermic reactions. During the smoldering process of fuel, wood (pyrolysis) gas is formed, which, when interacting with hot air, ignites. This technique is also called gas generators.