Actterm thermal insulation is characterized by a liquid structure, but at the same time it fully realizes its main function - it reduces the intensity of heat outflow . The substance is produced using advanced technologies; today 15 formulations have been developed. Each of the options has individual properties, which allows the use of different types of materials to solve various problems: insulation, protection against condensation, etc. Akterm paint is applied to the surface in the usual way - like any other paint and varnish composition, but at the same time the properties of the structure are improved.

Description and features of the composition

The product is available in the form of a liquid composition that looks similar to sour cream. After hardening, it forms a continuous layer on the surface, similar to foam material. This texture is formed after contact with air. The product is applied to the surface in two layers, after the first has completely dried.

The suspension contains:

- The filler is a microscopic hollow sphere made of silicone, glass and ceramics. Each hollow particle inside is filled with rarefied air and has a different diameter.

- The binding component is acrylic or latex, colored with a colored pigment. The manufacturer may add other components to the composition, in accordance with certain conditions of use.

Liquid heat insulator "Akterm Beton" is used on various surfaces: concrete, brick base, plaster, limestone. After application it acts as a reliable thermal barrier.

Advantages:

- a thin layer of coating, does not put additional load on the walls, does not hide the area;

- protects metal from corrosive processes;

- effectively protects against freezing;

- easy to apply;

- does not contain harmful impurities;

- has no foreign odor;

- protects against the appearance of fungus and mold;

- suitable as a finishing layer;

- anti-condensation paint is suitable for indoor and outdoor use;

- used in hard-to-reach places;

- no professional skills required.

Liquid thermal insulation is applied like regular paint, with a brush or roller. When working on concrete, use a spatula. On average, the layer dries within 24 hours.

See also

Pros and cons of airless painting, necessary equipment

Reviews about Akterm

Peter, 35 years old, Astrakhan. I spent a long time selecting Akterm insulation, the reviews helped me lean towards the Standard option. I liked that this is a universal composition - suitable for different materials. In terms of parameters, this paint is also a leader and is an excellent thermal insulator. Still, the rare insulation simultaneously protects from noise and moisture, and also does not make the structure heavier and lasts a long time. Alexander, 40 years old, Nizhny Novgorod. Liquid thermal insulation Akterm is immediately interested. I chose it for concrete, but I wanted to get something more than just insulation for load-bearing structures. As a result, I was not mistaken in my choice: the paint is applied in a thin layer, the adhesion is excellent, the parameters (sound, waterproofing) are completely satisfied.

Product range

The multifunctional product of the presented brand is available in various modifications. Depending on the type, the material acts as a heat insulator, reduces the risk of condensation and solves other problems.

“Akterm Anti-Condensate” is a special water-based coating that eliminates the appearance of condensation, the development of fungus and mold. Suitable for use in industry, construction and home use. Withstands temperatures of -60…+150 degrees.

“Akterm Standard” is a universal remedy. It is used on all types of surfaces. The product has heat and waterproofing properties, high-quality sound insulation, and energy saving. Can be applied to hot surfaces. Operating temperature +7…+45 degrees.

Expert opinion

Zakharova Irina Yurievna

Cleaning professional with 15 years of experience. Our best expert.

Ask a Question

Akterm Metal coating is used for thermal insulation of metal structures and furnaces with operating temperatures up to +190 degrees. Water-dispersion paint does not contain harmful substances, suitable for outdoor and indoor use.

Akterm Facade liquid insulation protects walls from freezing and reduces the risk of condensation accumulation. The product contains fungal inhibitors. The material is resistant to ultraviolet rays and has excellent vapor permeability.

Modifications of the Akterm series

Products of this brand are used at facilities for various purposes: industrial, private, commercial. Release form: multifunctional paint. It is used to insulate surfaces, but in addition the substance also solves other problems, for example, it reduces the risk of condensation or participates in the process of energy saving. The most common brands of Akterm liquid thermal insulation:

- Volcano;

- Standard;

- Concrete;

- Facade;

- Metal.

Each option implements different functions; accordingly, the scope of application for liquid materials of different brands often differs. Considering that these substances are produced according to different recipes, their operating conditions are specific. There are highly specialized materials. These include Akterm Anti-condensate, Hydrobofizer, Fire Protection, Metal.

Akterm Vulcan

This is a heat-insulating material that is produced on an organosilicon basis. It is a modified version of the standard insulation of this group and is designed for surfaces that are exposed to extreme temperatures -60...+450°C. The material of this brand is used to cover brick and metal . Scope of application: protection of chimneys, heat pipelines, process product pipelines, engine structural elements, roofs and other surfaces that are operated in aggressive conditions .

It is recommended to apply the substance in a layer of 1 mm . This is enough for the paint to provide the desired effect. When treating the surface, the material may lose its properties. To prevent this from happening, the application process is carried out at an air and protected surface temperature of -35...+35°C. Solvents: xylene and orthoxylene, 646.

Vulcan paint is offered in the form of a viscous substance. If you use it without preparation, the consumption will increase. It is necessary to bring the liquid insulation to working viscosity; to do this, add a solvent approved by the manufacturer. Only in this case will the material retain its properties. The surface is covered several times with Vulcan brand insulation. Each layer should dry naturally for 2 hours.

Areas of application

Thermal insulating paints are used in various industrial areas and everyday life. In addition to its main purpose, the coating protects the surface from corrosion, does not allow moisture to enter, and reduces heat loss by up to 90 percent.

Areas of application of Akterm liquid heat insulator:

- insulation of external and internal walls of residential and industrial buildings;

- processing of external seams in panel buildings;

- insulation of wall seams of easily erected structures;

- protection of loggias, balconies, basements;

- insulation and insulation of windows;

- thermal insulation of vehicle interiors;

- insulation of floors, walls, ceilings from freezing;

- insulation of pipelines, heating mains, ventilation systems;

- processing of the external part of water transport.

Rules of application

The liquid suspension is applied in a thin layer of 0.5-1 millimeter to any surface. After drying, the material acts as a thermal barrier. The operating air temperature should be within +7...+45 degrees with a relative humidity of 65 percent.

See also

Types of wood primers and rules for applying them before painting

When treating a small surface area, the suspension is applied using a spatula or paint brush. At industrial facilities, liquid heat insulation is applied using a special installation using the spray method. When working with equipment, use an appropriate nozzle made of carbide material.

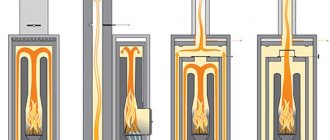

How it works?

Liquid thermal insulation Asstratek, after application according to instructions and polymerization, is a system of hollow microscopic bodies assembled into a thin carpet - a kind of air “bubbles” in a durable ceramic shell. Like any porous material, thermal paint prevents heat transfer from the painted surface. Insulation also partially reflects thermal energy in the infrared spectrum, returning it towards the radiation source.

Despite its hydrophobicity, the polymer coating is vapor-permeable, which allows it to be freely used in residential areas and for insulating “breathable” surfaces.

Types of thermal insulation in the Asstratek line:

- Universal is a water-soluble composition with wide application. For most work on thermal insulation of housing or industrial facilities, it will be enough to buy universal thermal insulation. In terms of cost, this is the most inexpensive paint in the presented range.

- Universal BC (all-season) based on organic solvents is frost-resistant. During transportation and during use, it does not change its characteristics even in frosts down to -30 ° C. It also has excellent weather resistance and is immune to sunlight.

- The facade is a water-soluble composition of high viscosity, due to which liquid insulation for walls does not spread over vertical surfaces.

- Decor-acoustic - textured thermal insulation that can improve acoustic characteristics. It has found wide application in the interior decoration of studios, concert halls, museums and other specialized premises.

- Metal – with an increased level of anti-corrosion protection of metal surfaces.

| Station wagon BC | Station wagon | Facade | Acoustic decor | Metal | |

| Packing, l | 20 | 3; 10; 20 | |||

| Price, rub/l | 495 | 415 | 430 | 445 | 445 |

Instructions for applying thermal insulation:

1. Prepare the surface as for painting - remove dust, rust, remove delamination, repair cracks and chips.

2. Prime the base with any composition suitable for the purpose. If the metal surface being treated has a temperature above +80 °C, the same Asstratek insulation should be used as a primer, diluted by 20-25% with water to reduce consumption.

3. After stirring the suspension until smooth, spread it in a layer no thicker than 0.5 mm and leave for a day until it dries. Exceeding the specified thickness will lead to swelling and the frozen liquid thermal insulation will crack.

4. Repeat the application process at the required time intervals until an insulation layer is obtained that corresponds to the thermal engineering calculations. As a rule, 5-10 layers may be required for effective thermal insulation, so insulation will take about a week.

If it is necessary to paint with a paint brush, layers should be applied up to 0.2 mm thick, giving each layer sufficient time to dry to touch. After 2-3 passes with a brush, the first technological layer of 0.5 mm should form.

The instructions for using insulation do not allow applying paint to lime surfaces, as well as to substrates heated above +120 °C at the time of painting. For Decor-Acoustic and Facade coatings, the limit is +60 °C.

Analogs

There are many varieties of thermal paints on the construction market, differing in composition, characteristics and manufacturer.

Similar products from Akterm Beton include:

- "Bronya Universal" - suitable for treating surfaces of any material. The product is used for insulating pipelines, ventilation systems, furnaces, and work tanks. Apply a product to prevent condensation. Exceptions are surfaces where the temperature exceeds 140 degrees.

- "Bronya Nord" is a liquid insulation that can be used at sub-zero temperatures. Also suitable for application to any surface. Operates at temperature conditions of -60…+90 degrees.

When choosing a heat insulator, pay attention not only to the pricing policy, but also to the properties of the material. “Akterm Concrete” stands out among other analogues due to its ease of application and low labor costs.