Brick chimneys necessarily require additional insulation. High-quality insulation of a brick chimney means significantly extending its service life.

This is explained by the fact that insulating a brick chimney allows you to create conditions under which condensation will not settle on its walls, i.e. the dew point is placed outside the brick pipe.

If you answer the question of whether it is necessary to insulate a chimney, in the negative, significant differences in the temperature of the outside air and that located inside the chimney will lead to the formation and settling of condensate on the internal walls of the pipe. When it comes into contact with the surface of the wall, the moisture will absorb all the fuel combustion products deposited on the walls. As a result of complex chemical processes occurring in this case, one of the elements deposited on the walls becomes sulfuric acid, leading to premature failure of the pipe.

It is necessary to decide how to insulate a brick chimney pipe and what materials to use before completing the roofing work.

To perform insulation work, it is necessary to use materials that fully meet fire safety requirements. It is better to carry out the specified work directly at the construction stage.

What causes a chimney to deteriorate?

The thermal insulation of a chimney does not always guarantee its long service life and full satisfaction of all your expectations.

Quite often, when doing insulation with your own hands, pipes can soon begin to collapse, lose their tightness, and become deformed. There are certain reasons for this, the most common of which you can find below: Even basalt insulation for a chimney, if the pipe itself is incorrectly positioned or the installation process is violated, may become unsuitable. In this case. Increased dampness occurs in the system

Excessive humidity is caused by the settling of warm air vapors on the inner surface of the system, which in turn form condensation, which leads to destruction; Without knowing how to insulate a chimney, it is important to remember that during the use of a heating unit running on solid fuel, the surface and materials are exposed to various sulfuric, carbonic, and nitric acids, which can also cause destruction. This is especially likely if you use the fireplace or stove irregularly, with a lot of downtime.

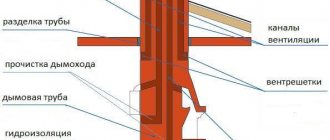

Correct exit and securing of a pipe when passing through a brick wall of a house

We suggest you read: Is a vapor barrier necessary when insulating a house with mineral wool?

Areas of application of asbestos products

Asbestos pipes, initially considered suitable only for the construction of reclamation systems, are now used much more widely. They began to be used:

- during the construction of non-pressure sewerage;

- as casing pipes when constructing wells;

- in sanitary and technical water supply systems;

- when creating drainage systems, storm drainage systems;

- as formwork for bored columnar foundations;

- and during the construction of ventilation systems and smoke exhaust ducts.

The great popularity of the material is explained by its advantages when comparing asbestos products with metal pipes. Asbestos cement is not threatened by corrosive processes. It has a small coefficient of linear expansion, which is acceptable when heated. The cost of asbestos pipes is quite affordable.

Important points in the construction of a furnace

In order for the water circuit to function with maximum efficiency, not only the heating water system must be properly designed, but also the furnace itself. Just maintaining order is not enough

Full compliance with furnace construction technology is important

Foundation

Its type and thickness depend on the size of the stove. It is recommended to install a massive classic Russian stove on a solid strip foundation. For smaller modern heating structures, a concrete pad one and a half ten centimeters thick, sometimes on a frame made of reinforcement, is sufficient.

Brick

For external walls, ceramic refractory bricks are used. For the base - his own, possibly second-hand. Experts recommend that you always line the inner surface of the firebox with fireclay stone. For a more presentable appearance of the facade, it can be laid with facing bricks right away or this finishing can be done later.

Solution

The mortar for masonry is prepared traditionally: sand is mixed with clay, diluted with water and a little cement is added for strength. You can purchase a ready-made cement-based masonry composition with special additives.

Masonry

The main condition for a strong structure is the presence of high-quality ligation of seams. They must not coincide under any circumstances. It is ideal when the seams of the bottom brick row fall under the middle of the bricks lying in the next row. To do this, starting the rows, alternate whole bricks and their halves.

Stoves with a water heating body have a fairly simple and understandable design. They are popular due to their low cost and ease of use. And if you don’t like using natural gas to heat your home or don’t have access to a gas network, this heating option should be considered first. Built by a good craftsman, such a stove never disappoints its owners.

Why insulate the chimney pipe from the outside?

Chimneys are made from various materials. It can be either refractory brick or metal, asbestos cement, reinforced concrete.

During operation of heating equipment, a large amount of combustion products and hot air masses move through the smoke channel. All this negatively affects the service life of the chimney, because... Corrosion processes are accelerated and the internal walls of the outlet channel are oxidized. If the pipes are made of metal, then there is also a high probability of a fire if there are errors during operation.

Most often, the chimney is damaged for a number of reasons:

- The presence of moisture in the chimney pipe means increased pressure and constant humidity. Due to the fact that the temperature inside and outside the chimney varies, moisture collects on the walls of the ducts, which negatively affects the condition of the structure.

- Chemical environment - when solid or liquid fuel burns, many aggressive substances appear that are dangerous to human health. If the chimney functions well, without failures, then all the formed substances are removed outside under the influence of natural draft. When the draft decreases and during the inactivity of the smoke exhaust structure, substances begin to accumulate on the walls of the smoke channel, this will lead to the pipe slowly beginning to collapse.

Insulating the chimney from the outside using modern thermal insulation materials significantly reduces the likelihood of damage and reduces the rate of corrosion processes.

Expert advice

Installation of thermal insulation of the boiler chimney must be carried out in compliance with installation norms and standards:

- the thermal insulation layer must be completely continuous, including in areas adjacent to the attic floor and roof elements;

- vapor barrier material is installed with the inscriptions facing out;

- the joining of sandwich pipe bends is carried out in such a way that the pipe of the lower bend fits inside the upper bend of the sandwich;

- external thermal insulation is carried out after the construction of the chimney, insulation from the inside is carried out during the process of its arrangement;

- if the roof is made of flammable building materials, then the chimney must be equipped with a spark arrester;

- All manipulations with mineral wool must be carried out using personal protective equipment to prevent particles from getting into the eyes and respiratory tract.

How to insulate a chimney pipe

The choice of materials for insulating pipes in the attic and outside is small, but to this list you can also add fibrous insulation, loose slag concrete, expanded clay, broken brick (construction rubble) and foam glass.

It makes no sense to compare the cost of these insulation materials, since each of them has its own physical structure, technical and operational characteristics. Therefore, how to insulate a chimney is chosen according to location. The main criteria are the material of the chimney in the house, the ease of work and the effectiveness of the result. We can only give general recommendations on choosing insulation:

- Do not use flammable insulation materials under any circumstances;

- Any insulation must be light, flexible and porous or loose;

- Even light thermal insulation can overload the roof elements, so there is no need to complicate the design.

In practice, several methods of attaching insulation are used, and they depend on the selected material. A pipe made of asbestos cement or metal (round) can be insulated from the outside with your own hands as follows: wrap it in mineral or basalt wool and secure it with clamps or wire, or put a metal casing on the fixed thermal insulation material. The second option: there is no need to wrap the pipe - it is covered with special cinder blocks of a special shape, and, if necessary, the top is insulated with mineral wool. More information about these technologies:

- Before insulating a metal or asbestos-cement pipe, purchase insulation with a thickness of at least 100 mm - any mineral or basalt wool will shrink when wrapped around the pipe, so a thick layer will not hurt. After attaching the insulation with clamps or soft steel wire, the thickness of the mineral wool layer should be at least 60 mm;

- When attaching a heat insulator with wire, it is prohibited to use wire in flammable insulation - electrical wires. As the chimney heats up, it can melt the insulation or even set it on fire. Even if the insulation does not catch fire, the physical parameters of the thermal insulation and the integrity of the insulation layer will be compromised;

- Instead of clamps or wire, you can wrap a sheet of galvanized or stainless steel around the pipe. The sheet should be no more than 1 mm thick so that it is convenient and easy to wrap and fasten the edges with rivets or screws. You can calculate the width of the sheet by finding out the circumference of the pipe, and it can be measured with a regular tape measure, adding 20-25 mm to the result for the overlap, where rivets or screws will be attached;

- The optimal height of such a sheet is more than a meter, so that a wind protection in the form of an umbrella can be conveniently mounted on top of it. It is advisable to roll the seam or protect it with bitumen mastic. If the seam is rolled, it is necessary to ensure that it looks inside the pipe - this way less rainwater and snow will get into it;

- The last step when insulating an external chimney pipe is the installation of a protective wind cone-umbrella, which will protect the chimney opening not only from turbulence, but also from precipitation.

This insulation technology is the simplest, fastest, most economical and cheapest.

Conclusion

In conclusion, I would like to note that insulating the chimney will not solve all problems. After all, the chimney itself constantly needs timely maintenance. It is necessary to periodically inspect it, clean it and maintain it in proper condition.

If necessary, make proper repairs, which you now know how to do yourself. This will be the key to its high-quality, uninterrupted operation. And for you - a warm, cozy and safe home.

In the video presented in this article you will find additional information on this topic.

Types of chimneys

Pipes are made from different materials, which we will consider in more detail.

Brick

Classic brick chimneys for gas boilers are still in demand, regardless of their many disadvantages and weak thermal characteristics. At the same time, they meet sanitary standards and rules, which state:

- The pipe is made of fireclay bricks.

- To build the walls, a clay solution or special glue is used.

- To improve draft, the chimney rises above the level of the roof ridge.

Standards regulate the height of the pipe in relation to the roof ridge depending on the distance between them. Source kamin-estet.ru

- The masonry ensures tightness.

- At the internal hole, the deviation is no more than 3 mm per 1 m.

- To protect against precipitation, a deflector is installed on the head of the pipe.

The chimney can also have a mono design, which, due to low thermal characteristics, is repaired every 5-7 years.

Galvanized pipe

The “sandwich” type device today is the most effective option for chimney designs. The undoubted advantage of these chimneys is their resistance to aggressive environments and various mechanical influences.

The product consists of two pipes of different sizes, with one inserted into the other. Basalt wool is usually used as a filler between them.

Coaxial chimney

Currently, gas boilers use closed combustion chambers. Here, air enters and smoke is exhausted by a coaxial pipe. This is an original device, relatively recently introduced, but already very popular among users.

The non-standard solution lies in the supply of air through a pipe that removes combustion products. It turns out that one pipe performs two functions due to the design features.

A coaxial chimney is a pipe in a pipeSource rubankom.com

And its characteristic difference from ordinary pipes is the following... A smaller pipe (60-110 mm) is located in a larger diameter pipe (100-160 mm) in such a way that they do not touch each other.

At the same time, the structure is a single whole due to jumpers along the entire length and is a rigid element. The inner pipe serves as a smoke exhaust, and the outer pipe serves to supply fresh air.

Air exchange at different temperatures creates draft and sets the air mass in directional movement. The air in the room is not used during operation of the boiler, thus maintaining the microclimate in the room.

Ceramic

Such a chimney is a composite structure that includes:

- Smoke exhaust duct made of ceramic material.

- A layer of insulation or air space.

- Expanded clay concrete outer surface.

This complex design is due to several reasons. First, the chimney pipe is too fragile to be left unprotected.

The ceramic tube is always located inside some solid blockSource heatylab.com

Secondly, ceramics have high thermal conductivity, and therefore it needs reliable insulation. The inner round pipe has a smooth surface, while the outer one has roughness that does not affect the integrity of the product.

Typically, such chimneys are produced in lengths from 0.35 to 1 m, depending on the manufacturer. The connection of the inner and outer pipes occurs through a lock, which is a thinning in outer size at one end and an expansion of the inner pipe at the other end.

The expanded clay concrete outer surface is made of a square shape with a round hole inside. In addition, this product provides space for insulation, which is held in place by metal bridges. At the same time, they are fixed on the outer surface and make the pipe securely fastened.

Stainless steel

A steel gas chimney seems to be more reliable than a brick one. They are resistant to corrosion, immune to temperature fluctuations, and are not affected by increased air humidity and aggressive environments.

Stainless steel chimneySource pech-kamin.ru

In addition, such stainless steel pipes have a number of advantages:

- Long period of operation.

- Multifunctionality.

- Relatively low cost.

- Great strength.

- Possible implementation of a product of any complexity.

Chimneys made of this material are characterized by an assembly of modules, which allows the replacement of a damaged segment if necessary. The installation of chimneys is done using special outlets that allow them to fit harmoniously into certain roof elements.

Safety regulations

The passage of a pipe through the ceiling of a bathhouse is regulated by SNiP 41-01-2003. This document states that:

- the passage of the bath pipe in the ceiling should be located at a minimum distance of 350 mm from flammable structures and 250 mm from difficult to flammable elements;

- It is considered ideal to leave this distance not closed (air). However, such a design will lose a large amount of heat;

- the specified distance is filled with non-combustible materials;

- the hole must be covered with metal sheets (stainless steel is more often used, which does not spoil the appearance of the room);

- the pipe in the bathhouse through the ceiling and roof should not have joints. This factor must be taken into account when designing a chimney;

- the maximum length of the pipeline passing through the ceiling or roof should not exceed 1 m;

- The chimney should not be attached rigidly to the ceiling or roof.

As the temperature rises and falls, the pipe may expand and contract slightly, respectively. A strong fastening will lead to deformation of the pipe or passable ceiling.

Selection of thermal insulation material

The following materials can be a heat insulator:

basalt or mineral wool. The insulation can withstand heating up to 600ºС. The main disadvantages are: the release of formaldehyde, since the material contains resins and the instability of protective qualities when wet, which is possible in the event of condensation formation;

Basalt wool

expanded clay The material has excellent properties. When wet, expanded clay quickly restores its functions. However, to arrange the ceiling, you will have to additionally install containers in which the material will be located;

Middle fraction expanded clay

mineralite The material consists of cement, cellulose and mineral fillers. Minerite tiles can withstand temperatures up to 600ºC. When heated, it does not emit harmful substances, and when exposed to water, it does not lose its properties;

Minerite insulation

- asbestos. It is a good insulating material, but when heated strongly it releases substances harmful to humans;

- sand or clay. The materials were used as heat insulators earlier, before the advent of modern insulation materials. However, some experts prefer to use natural materials rather than artificial ones.

Minerite is considered the most optimal insulation.

Pipe joint insulation

To make the joints airtight, use:

- high-strength sealants that can withstand large temperature changes;

- special clamps made of the same material as the chimney.

To ensure draft, there should be no more than 3 to 4 pipe connections in the chimney duct. A chimney consisting of 3 elbows is considered optimal.

The role and functions of insulation

People living in areas with harsh climatic conditions often face the problem of rapid destruction of the chimney. The reason for this is sudden temperature changes, the appearance of condensation, freezing, and then subsequent defrosting of the walls of the chimney saturated with moisture. Thanks to high-quality thermal insulation, of course, it will not be possible to avoid the appearance of condensation, but it will protect the chimney from freezing and thereby extend its service life.

Among other things, warm flue gases, passing through a cold pipe, are noticeably cooled, but at the same time they heat the walls of the chimney. The level of thrust depends on the heating time of the walls. If it is insufficient, carbon monoxide returns back to the heating device, and from there - inside the house, which is fraught with very disastrous consequences, including poisoning. To avoid this, it is necessary to perform high-quality insulation of the smoke duct. Thanks to it, the pipe will warm up faster, and fumes will escape through the least resistance.

Advice! To achieve the most efficient heating of the chimney, it is advisable to construct it from stainless steel. The steel pipe heats up very quickly - in just 2-5 minutes.

What material to use

First of all, it is important to choose a material that will not contain toxic substances, can safely contact the pipe, and is not affected by fungus

It is recommended to note that the material can be found on construction markets in the form of rolled rolls, sheets, slabs and mats

Thermal insulation cylinder

The use is relevant if the chimney is in the form of a metal structure. It consists of two pipes of different diameters: the first is smaller, acting as a chimney pipe.

Thermal insulation cylinder

Stainless steel is used as the main material. It withstands the effects of acidic substances, which often form on the inside of the chimney. To carry out lining, the pipe must have a large diameter of 6-10 cm, which will act as a casing. Basalt insulation is poured into the free space. Some craftsmen make this material themselves at home, or purchase it at construction markets.

Mineral wool

The material is suitable for insulating chimneys and stoves. This is due to the fact that the insulation is able to favorably withstand even the highest temperature fluctuations, exposure to chemicals, and is also used as internal or external insulation.

There are 4 types of insulation depending on the use of material, structure, length or thickness: slag wool, fiber, stone, basalt. Thermal insulation and chemical properties depend on the structural features. If you plan to carry out furnace insulation from the outside, it is better to use basalt mineral wool. This is a material that is optimally suited for brickwork, since basalt has low thermal conductivity, is heat-resistant, and does not contribute to the spread of mold or mildew.

Specialists cut the sheets to suitable sizes. The material is wrapped around the pipe, and then the insulation is secured with wire. If it is necessary to install sheets of greater thickness, then a metal grid is used, which is fixed throughout the entire area.

Gaps must be sealed. As a rule, a special substance or tape is used for this purpose. Brick is suitable as cladding.

EPPS

The optimal solution is if the chimney is made of brickwork. It has increased durability and is completely waterproof. Category G2 includes Technoplex, Penoplex. Thermal insulating and fire-resistant classes G3, G4 are considered to have lower ratings. For use in coal or wood stoves. The inlet gas temperature can reach 600 degrees. Non-flammable glue is often used for polystyrene foam boards. Stripes and free space are eliminated by insulation.

EPPS

Plaster

A brick chimney can be insulated from the outside using plaster and a special metal mesh. This option is considered one of the most common, since heat loss ranges between 25%. First you need to secure the reinforcement and apply a layer of plaster on top of it. It's better to use several layers.

As soon as the composition dries, to add aesthetics, it is recommended to paint it so that the structure is in harmony with the main color of the building. It is also recommended to use an anti-corrosion compound.

Thermal insulation made of basalt

It is customary to distinguish two types: cylindrical (where the internal diameter ranges from 18-89 mm, the cuts are longitudinal, which allows for convenient installation), semi-cylindrical (the range of used diameters is more than 89-273 mm, consists of two shells).

To carry out installation, you do not need to remove part of the chimney. For this, bandages are used to make the longitudinal joint isolated. In addition, there is no need to use a box for protection.

Stainless steel casing

Suitable for metal or asbestos pipes, the design will be the best choice. The diameter must be at least 5 cm larger than the main pipe. Basalt insulation is used to fill the empty space. If there is empty space left, it is usually filled with cement. It helps protect the pipe from sudden temperature changes.

Stainless steel casing

Cinder concrete

Using the material, parallel walls are built in relation to the main frame. However, a small space should remain during the work. The seams must be reinforced with wire. The free gap is filled with clay or gypsum.

Thermal insulation options

Before you start work, you need to decide on the insulation material. You can use almost any, you just have to take into account that the chimney heats up to high temperatures, which means the insulation must be heat-resistant and non-flammable.

- Mineral, basalt or glass wool. The most commonly used material. Sold in mats or in rolls. The material is non-flammable, has good thermal insulation properties, and often has an additional waterproofing layer in the form of a thick film. It is worth considering that cotton wool, when wet, loses most of its thermal insulation properties and gradually collapses. Outdoors, the structure should be protected with a casing made of metal or other material.

Bulk insulation. These are broken bricks, expanded clay, sand and other materials. In this case, you also cannot do without a casing. It is built around the chimney, the free space is filled with insulation. Retains heat well and is cheap.

- Metal foil. Shields heat and cold, reducing temperature differences. Used as an additional layer with fiber insulation.

- Ready-made cylindrical insulation with a foil screen.

It has different diameters, which greatly facilitates solving the problem of thermal insulation. The insulation is placed on the pipe and secured with clamps or construction tape. Cinder concrete slabs. Most often used for thermal insulation of brick pipes. The slabs are attached to the walls of the structure, after which they are covered with plaster mortar. - Plaster mortar. Prepared from special heat-resistant mixtures. For greater efficiency, the solution is applied in three layers, each layer thicker than the previous one. For effective insulation, the thickness of the plaster must be at least 4 cm. It is applied to a reinforcing mesh that serves as a frame.

It is not recommended to use foam plastic for thermal insulation of chimneys due to its flammability.

The choice of insulation method depends largely on the material of the chimney. It is also necessary to take into account the strength of the structure on which the structure will be installed. Heavy thermal insulation can over time push through the ceiling and cause its deformation.

Video: professional advice on choosing fiber insulation

The choice of insulation depending on the wall material and finishing method

Brick walls

For a brick house, any insulation for the external walls of the house is suitable. But each type of finishing has its own recommendations for insulation technology.

Facing brick

If facing brick is chosen as the outer finishing layer, and the load-bearing walls of the house are also made of brick, then both foamed or extruded polystyrene foam and stone wool can be used as insulation. When using stone wool, it is necessary to provide a ventilated air layer so that water particles evaporate freely - this will help to avoid the walls getting wet.

Pie of insulation of a brick house with stone wool with brick cladding.

Wet facade

According to the rules of construction and design (clause 8.5 of SP 23-101-2004), the layers must be arranged so that the vapor permeability of the inner layer is less than that of the outer one. That is, the insulation should not interfere with the removal of moisture from the walls of the room. If you adhere to this rule, then mineral wool is best suited in this case due to its high vapor permeability. However, brick walls do not have high vapor permeability, so polystyrene foam can be used to insulate them, followed by applying a plaster layer.

Pie of insulation of brick walls with polystyrene foam followed by arrangement of the plaster layer.

Ventilated facade

If wall panels or large porcelain stoneware slabs are chosen as cladding for brick walls, which are mounted on a ventilated facade, then it is recommended to use stone wool as insulation.

Pie of insulation of brick walls when installing a suspended ventilated facade.

Wooden walls

Houses made of logs or timber are insulated using both the suspended ventilated facade technology and the wet facade technology. In both cases, it is recommended to use stone wool as insulation.

Insulation of wooden walls with stone wool.

Walls made of aerated concrete blocks

Wet facade

If you follow the rule that the vapor permeability of building structures should increase from inside to outside, then to insulate load-bearing walls made of aerated concrete blocks, it is best to use stone wool.

Pie of insulation of walls made of aerated concrete blocks with stone wool, with the arrangement of a plaster facade.

However, aerated concrete is not wood, rot cannot occur in it, and if the inside of the room is well ventilated, then the use of polystyrene foam is allowed for external insulation of aerated concrete walls.

Pie of insulation of walls made of aerated concrete blocks with polystyrene foam, with the arrangement of a plaster facade.

Facing brick

If facing brick is chosen as the exterior finishing of aerated concrete walls, then it is possible to use both stone wool and expanded polystyrene as insulation. In the case when the insulation is made with stone wool, it is necessary to provide a ventilation gap between the insulation and the brickwork. This will allow moisture to evaporate from the insulation.

Pie of insulation of walls made of aerated concrete blocks followed by finishing with facing bricks.

Basic methods of insulation

We have already discussed the insulation of a metal chimney in particular above. Determine what the casing in the ceiling and on the roof will be made of

Pay special attention to places of insulation near the outlet of the pipe; in those places the greatest temperature difference is observed

Method of insulating a steel chimney

There is no particular difference between the insulation of a stainless steel channel and a similar one

Also pay attention to the transition directly in the house, as well as in the insulated part of the roof. Often, many owners are careless about arranging a channel in the attic, but in most cases it is from there that the fire begins to spread

According to the advice of many experts, it is better to completely thermally insulate the channel in an unheated room.

Gas boiler flue insulation

In this case, the same places that were discussed above need to be insulated. You can use the same materials for this as for solid fuel boilers. That is, opt for basalt or asbestos-cement slabs, with a layer of “stainless steel” covered on top.

Types of insulation

The following requirements apply to the insulation for the chimney pipe:

- the material must be available for DIY installation;

- it must be non-flammable;

- it should be suitable for insulating your type of chimney.

We recommend that you read: How to install water supply for personal use and watering at the dacha using HDPE pipes with your own hands

Three types of chimneys are common:

- brick;

- steel;

- asbestos.

Each pipe has its own best type of insulation:

- Fireproof mineral wool (basalt thermal insulation). This insulation can be used for any type. To install the shell of an iron pipe with high-temperature operation, crumbly non-flammable basalt wool is used, since the metal has the greatest thermal conductivity. The shell design is available in finished form (sandwich) or can be assembled with your own hands.

- Plaster. A classic type of insulation for brick chimneys. Suitable for stoves using any fuel.

- Broken brick or slag. The available material is poured into the gap between the outer wall of the chimney pipe and the mounted insulating casing. The disadvantage of this design is its heavy weight.

- Extruded polystyrene foam (EPS). A special thermal insulation material that is used to insulate brick chimneys or other structures that have a square or rectangular shape. Not suitable for classic wood or coal stoves, since the heating temperature of the chimney exceeds the operational characteristics of the material; to put it simply, the polystyrene foam will melt.