Solid fuel boilers with high efficiency, designed for heating water, heating residential premises, buildings for various purposes, can operate efficiently and effectively under any conditions. Their performance directly depends on the design features and the method of fuel combustion.

The parameter that determines the quality of heat transfer during operation is efficiency (coefficient of performance). This indicator displays the ratio of the energy released during long-term combustion to the useful heat released, which provides the entire system. It is expressed as a percentage, and the value depends on the quality of the boiler’s operation: the better the unit functions, the higher the efficiency.

Construction of a solid fuel boiler

The design of the solid fuel boiler is such that it can operate on both wood and coal. What is noteworthy is that to install these units you do not need to obtain an installation permit. In addition, they do not need frequent checks and examinations with the invitation of specialists. Typically the unit has a cylindrical or rectangular shape.

Components present in all boilers:

- Furnace or combustion chamber. Firewood is placed in it and then burned. Due to this, heat is generated.

- Blower (ash pan) is a hole that allows air to pass through to the combustion site. It is part of the firebox and is separated from it by a grate, through the cracks of which the slag remaining after the combustion of firewood pours out.

The operating principle of a new type of boiler is based on pyrolysis combustion of fuel. In them, the process of obtaining thermal energy is more complex, but effective.

In pyrolysis boilers, flammable gas is released, obtained during the decomposition of wood under conditions of lack of oxygen. This steam is mixed with air and burns with a torch in the heat exchanger zone. The design is equipped with a loading chamber and a firebox.

After placing coal or firewood in the loading chamber, the raw material enters through a ceramic burner into the combustion chamber, where a torch is located at the outlet. Adjusting the gas supply allows you to keep the coolant temperature at 65–68 ºС.

The heat exchanger is one of the most important components of a high-efficiency boiler. Heat is transferred through the walls of its tubes. By design, the heat exchanger resembles a coil, which is located in the flame zone of the combustion chamber. With new units, in most cases, it is designed so that the firebox itself is located inside the coil, thereby reducing heat loss.

Heat exchangers are divided into two types:

- Steel. Such units are quite lightweight, easy to install and inexpensive. However, their service life is about 10 years. Cannot be repaired.

- Cast iron. They are characterized by a long service life - over 20 years. Such boilers are resistant to corrosion. If one of the sections breaks, you can replace it with a new one.

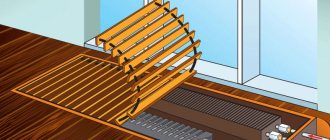

Differences from the rear chimney

The exhaust gas exhaust system of a horizontal (coaxial) configuration is mounted on boilers with a closed combustion compartment. Straight chimneys are combined with a fan unit and a forced-operation pressure pump. The main difference from the upper analogues is the horizontal placement of the outlet end on the street. Such structures are mounted on a heating boiler using an elbow, and are led out through the wall ceiling or roof to the side.

The upper chimney consists of a pair of round elements located inside each other, characterized by internal and external diameters.

Smoke is removed through a smaller cross-section pipe, and the outer part serves to suck in fresh air masses with further entry into the boiler.

What is efficiency

The efficiency factor of heating equipment is an indicator that is determined by the ratio of energy spent and useful heat entering the heating system for transportation to the room.

The efficiency percentage is calculated using the following formula:

q 1 + q 2 + q 3 + q 4 + q 5 = 100%

Explanation:

- q 1 is an indicator of the heat that was transferred to the coolant - water;

- q 2 - physical underburning - heat loss with exhaust gases;

- q 3 - chemical underburning - heat loss due to incomplete combustion of fuel;

- q 4 - heat loss during heat dissipation.

The efficiency of a solid fuel boiler will increase subject to optimized operation of the equipment.

High-quality installation, choice of raw materials, availability of ventilation and operating conditions significantly affect the efficiency indicator.

What does it depend on

Efficiency mainly depends on the loss of useful heat resulting from underburning of gases that are released during fuel combustion, as well as on the quality characteristics of the fuel and the amount of thermal energy released into the chimney.

The efficiency indicator depends on a number of factors:

- technical condition of heating equipment;

- load on the heating system;

- quality of fuel used by heating equipment.

Why is the efficiency higher in steel boilers?

In steel boilers, unlike cast iron ones, the efficiency will always be higher, since they require little energy input to heat a certain volume of water to the required temperature.

Steel is a less brittle material than cast iron, so in metal heating units it is possible to design a combustion chamber of a more complex geometric shape. Due to this, the heat exchange area increases, which leads to increased efficiency.

Steel units are characterized by fewer technological limitations. They allow you to increase efficiency by improving the design: adding convection channels, cooled grates, and increasing the reliability of the heat exchanger.

Due to high-quality insulation, steel boilers retain heat better. Two days after the unit is turned off, the temperature of its walls decreases by only 20 degrees.

Types of liquid fuel

For imported liquid fuel boilers, the passport specifies the type of fuel according to the EL DIN 51603 standard with characteristics similar to diesel fuel with the Russian Euro-4 standard. Important indicators are density 0.86, viscosity at 20 degrees C - 6.0, sulfur content 0.005 and ash content 24 mg/kg

The average liquid fuel boiler consumes 1 kg of liquid fuel per hour for every 10 kW of power, and when operating for 100 days at full load, and another 100 days at half load, a 15 kW boiler for a house of 100-150 m² will require a reserve of about 5 tons of fuel. A competent choice of equipment, primarily the type of boiler and burner, will help correct this amount, but the type of fuel also affects this figure.

| Light heating oil |

Boiler houses often use heating oil, namely light heating oil. It is close to diesel in viscosity and degree of purification, but differs from it in price, since it does not comply with the cetane number, cloud point and other parameters important for automobile engines, and this affects taxation and the product becomes cheaper. The sulfur content is not regulated in it and it can be more than 0.7% (for diesel fuel - no more than 0.2%), higher viscosity (0.835-0.84 mm²/s) and lower density (0.82 kg/l ). In general, since there are no standards for heating oil in GOSTs, its quality lies entirely with the manufacturer, and it is better to do a laboratory analysis before purchasing. Many large and reconstructed refineries have abandoned the production of heating oil, for example, the Tyumen Antipinsky Refinery still produced it until 2013-2014, and today it produces only stable gas gasoline and heating oil. The closest supplier for residents of the south of the Tyumen region has so far been found in Kurgan; fuel is supplied from neighboring regions. The cost of heating oil is 5-7% lower than the cost of diesel fuel.

| Fuel oil |

Dark heating oil is even more viscous (8.0 mm²/s versus 3.0-6.0 mm²/s in diesel fuel) and its sulfur content is even higher - up to 1.1%. This type of heating oil is intended for combustion in furnaces with preliminary evaporation; it is unacceptable for modern imported heating boilers; it simply does not burn in them.

Fuel oil in Russia is produced in the M40, M100, M200 grades and it differs mainly in viscosity and the presence of diesel fractions in the M40 grade, which ensure a lower pour point. M40 fuel oil, often intended for use in domestic boiler houses, hardens at +10 and this allows it to be transported under favorable conditions without heating, but in winter heating will be required in any case. The temperature for M40 fuel oil at the point of withdrawal from the tank must be maintained at least 60 degrees C, and for M100 grade - at least 80 degrees.

| Waste oil burner |

Waste oil as a type of fuel for boiler houses is of interest primarily to owners of service stations or directors of large motor transport enterprises, where the turnover of used oil is large and it is possible to create a supply of it. In general, this fuel is equivalent in combustion efficiency to diesel, and if we are talking about the utilization of our own resource, the cost of which is zero, then this is a very attractive type of fuel. Even if your reserves of waste are not enough, you can buy it at a good price and the cost of heating with waste oil is the second most profitable after heating with gas. Burners for processing are produced by Kroll (Germany, originally it was a burner for rapeseed oil, but adapted for the needs of the Russian market for processing), DanVex (Finland), Hiton, Euronord EcoLogic, NORTEC.

Rapeseed oil as a type of fuel is not yet widespread in our country, although from 1 hectare you can get 1 ton of diesel fuel, 25-30 tons of green fodder for livestock, honey (rapeseed is an excellent honey plant) and the land will also be prepared for future crops, since rape is a green manure crop. culture. If you have your own rapeseed oil, the cost of a ton of diesel fuel is approximately 1,600 rubles, and this is an excellent alternative to diesel fuel with a cost of about 23,000 rubles) European boilers, in particular the German Buderus Logano, successfully operate on diesel fuel and rapeseed oil.

Diesel fuel is the most expensive type of liquid fuel for a boiler room; it is divided into summer, winter, interseasonal and arctic based on operating temperature. Most imported boilers are designed to run on diesel fuel. Since the production of diesel fuel is regulated by two GOSTs - 305-82 and 52368-2005, and there is also the Technical Regulations of the Customs Union of 2011, there is confusion in the names, but the average buyer of fuel for an individual boiler room can remember several important points. One of them is that summer diesel fuel is stored longer, it can be purchased for future use and is used down to -5 degrees C. Winter and Arctic diesel fuel has a limited shelf life due to additives in the fuel; it is expensive and unenvironmentally compatible to burn. For heating, it is advisable to choose Euro diesel fuel; it has higher efficiency during combustion, better technical characteristics and meets environmental requirements.

At the same time, if it is impossible to place a container with diesel fuel in a heated room, only winter or even arctic fuel will remain viscous outside the building at subzero temperatures, and this must be taken into account when planning a liquid fuel boiler room.

So, after clarifying the question of what type of fuel the liquid fuel boiler room will be supplied with, you can move on to choosing equipment for its storage (tank) and combustion (boiler with burner).

Operating rules affecting the boiler efficiency value

To ensure that heating equipment always works properly, experts recommend adhering to the basic operating rules that affect the efficiency of the boiler.

In this case, it is necessary to strictly follow these points:

- Select only the optimal modes of blowing and operation of the hood.

- Monitor combustion intensity and completeness of fuel combustion.

- Constantly monitor the amount of drift and failure.

- Assess the condition of surfaces that heat up when fuel burns.

- Clean equipment regularly.

Boiler selection criteria

Before installing a heating system, you need to decide on the type of boiler, find out what power equipment is needed to heat the entire area of the room, and choose the type of fuel.

When choosing, you should pay attention to the following criteria:

- Boiler power / useful volume of the loading chamber. This indicator indicates how much fuel can be loaded into the combustion chamber and how often this will need to be done. With the same dimensions, cast iron products demonstrate increased power.

- Dimensions. Cast iron equipment with the same power as steel equipment will be more compact and will require on average 19% less free space for installation.

- Type of fuel. It is advisable to purchase boilers made of high-alloy durable steel if coal will be used as the main fuel. To use firewood, the ideal option would be a unit with a cast iron chamber.

- Unit weight. A cast iron boiler weighs approximately 17% more, so the price for delivery and installation of this device will be significantly higher.

- Impact strength. Steel is more ductile than cast iron and therefore the risk that a metal boiler will receive damage and cracks during loading or transportation is several times lower.

- Durability. The service life of a solid fuel unit is 10–20 years. The duration of operation depends on compliance with the manufacturer's recommendations. In practice, with proper maintenance, any device can work much longer.

- Price. Steel units will have a lower price compared to cast iron products of the same class and power. The technology for processing sheet steel is less labor-intensive.

- Service. Cleaning heat exchangers in steel boilers is easier than cleaning cast iron products.

You can also make a homemade solid fuel boiler.

Minimum required power

An accurate calculation of the boiler's heating output is carried out by a heating engineer based on SNiP 2.04.01-85. However, in domestic conditions, for an average uninsulated or weakly insulated house with a masonry of 2 bricks and a ceiling height of 2.7 m, the minimum required power is calculated from the rule of 1 kW per 10 m2, we also recommend laying a 20% reserve.

For example, for the house described above with an area of 150 m2, the minimum required power of an oil-fuel boiler will be (150/10) * 1.2 = 18 kW.

Review of popular models and prices

Manufacturers produce various types of heating units designed for a certain power, as a result of which there are some restrictions on the size of the heated area. A review of popular models and prices of solid fuel equipment allows you to determine which product is best installed in a private home.

Candle 18 AREMIKAS

The fuel for this unit is peat briquettes or sawdust. This device uses a special combustion method, in which only 10–20 cm of the bottom layer of the load is burned. The resulting smoke, with the help of a distributor, directs hot air into the combustion chamber.

When choosing any boiler operating mode, the efficiency will always be high. Thanks to the unique design of the equipment, you can save fuel even in winter.

Advantages of the Candle 18 AREMIKAS boiler:

- Stable and optimal operating mode. Minimum - 7 hours, maximum - 34 hours.

- Adjusting the water temperature using the air draft regulator.

- Only a 10–20 cm layer of solid fuel burns, so when the water circulation in the circuit is turned off, its temperature will increase by only 12–16 ºС.

- Ash removal is carried out 2-3 times a month, as it does not interfere with the combustion process.

- Compact size.

On the Russian market, the cost of this unit ranges from 54 to 95 thousand rubles and depends on the characteristics of the model.

Prices for solid fuel boilers AREMIKAS

solid fuel boilers AREMIKAS

Zota Mix 40

To operate the domestically produced Zota Mix 40 model, coal and wood are used as the main type of fuel, and gas and liquid serve as backup sources. To change the type of power source for a pellet boiler, remove the ash pan door, and for a gas boiler, open the combustion chamber flap and install the burner. The unit can also operate using electricity. It is possible to install heating elements made of stainless steel.

The water jacket is located along the entire contour of the boiler, including under the ash pan. The design allows the bunker to be cooled and not subject to deformation, provides additional heat removal and improves liquid circulation.

Achieving maximum efficiency is facilitated by the boiler’s ability to maintain an operating pressure of 3 atm, which also guarantees safe operation of the heating system. The level can be increased to 4 atm. for a short time. The unit is equipped with a pressure gauge for monitoring water temperature and pressure, as well as an automatic draft regulator.

Main characteristics:

- Capable of heating an area of up to 400 m2.

- Boiler power - 40 kW.

- The fuel used is solid.

- By type of installation - floor-mounted.

- The minimum service life is 15 years.

- The firebox body is steel.

- The average price is from 45 to 48 thousand rubles.

Technical characteristics of ZOTA MIX:

| Name | ZOTA “Mix”-20 | ZOTA “Mix”-40 | ZOTA “Mix”-50 |

| Rated thermal power, kW | 20 | 40 | 50 |

| Water chamber capacity, l | 50 | 120 | 140 |

| Pressure atm. not more | 3 | ||

| Efficiency, % | 80 | ||

| Fuel | coal, firewood, gas, diesel fuel | ||

| Power of the heating element, kW | 3–9 | ||

| Dimensions, mm | 475 x 415 x 1015 | 580 x 490 x 1265 | 680 x 490 x 1265 |

| Firebox (depth), mm | 300 | 400 | 500 |

| Chimney, mm | 150 | 180 | 180 |

| Pipe (height), mm | 6000 | 9000 | 9000 |

| Weight, kg | 140 | 195 | 235 |

Prices for solid fuel boilers ZOTA

solid fuel boilers ZOTA

Alpine Air Solidplus-4

This model is completely independent of electricity. The boiler can be installed in private houses and cottages, which are located in places where there are no power lines. The service life of this unit is over 15 years.

Pros and main features of ALPINE AIR Solidplus-4:

- Supplied ready-assembled with a warranty.

- There is a built-in thermostat.

- Mechanical control.

- High heat transfer efficiency.

- Durability of structural elements.

- Protection against freezing and overheating is provided.

- Compact sizes.

- Temperature control.

- High efficiency. Minimum amount of harmful emissions.

- Smooth power control.

- Low heat losses.

- It works on the principle of three-pass circulation.

- The chamber material is high-quality cast iron.

- Will last almost 50 years with proper use.

- Universal design.

- Resistance to corrosion process.

- Economical work.

- Easy to maintain and manage.

There are models on sale that are characterized by different power, volume of combustion chambers and number of sections, so it is always possible to choose the best option for a private home.

Characteristics:

- Brand country: Türkiye.

- Installation type: floor-standing.

- The power when using firewood will be 25.5 kW, coal - 17 kW.

- Open combustion chamber. Number of sections - 4.

- Cast iron heat exchanger.

- Dimensions: 107 x 52 x 47 cm.

- Warranty period: 3 years.

- Price: 45,150 rub.

Upper chimney design

A simple vertical system for solid fuel boilers is assembled without stepped sections or horizons. In difficult cases, deviations and straight inlays no longer than 1 m, laid with a slight slope, are allowed.

In such configurations with branches, an accelerating segment is introduced to start the traction. In this case, the heating structure is connected vertically or horizontally.

Discharge pipes start from the boiler, length - at least 1 m, connect a direct adapter for input. Failure to comply with these recommendations causes a lack of traction. The deficiency is compensated by increasing the height of the entire structure.

Upper chimney installation.

How to make efficiency high

There are many methods for increasing the efficiency of solid fuel equipment. Each of them helps to increase this parameter from 3 to 7%.

The most effective ways:

- Using quality fuel. If possible, it is necessary to use only dry and high-quality raw materials for heating the room.

- Regular removal of ash. If it is not possible to purchase expensive, high-quality fuel, it is necessary to clean the chimney more often.

- Ventilation of the room. Since the combustion process occurs in the middle part of the unit, it is necessary to ensure a stable flow of fresh air into the room where the equipment will be located.

- Reducing heat loss. If a residential building gives off heat faster than it heats up, purchasing higher quality fuel or even new boiler equipment will not give the desired result. Therefore, it is necessary to insulate the living space, install new windows made of wood or plastic, and reliable doors.

- Installation of auxiliary devices. To heat the house evenly, you need to use a circulation pump. This method is very effective and helps increase efficiency. If the old unit does not cope with the task of heating the house, then you can purchase an inexpensive boiler and install it in a cascade. Additional equipment can be used when the old one alone cannot cope with the heating task. You can find out Vilo pumps for heating at the link.

Advantages of fuel briquettes

The main advantage of briquettes is that the combustion temperature is 1.5-2 times higher than that of firewood. At a humidity of 20%, the calorific value of wood is 2500-2700 kcal/kg, briquette - 4500-4900 kcal/kg.

And there are simple and logical explanations for this:

- Briquettes have low humidity. The lower the humidity of the firewood, the higher its heat transfer. Normal wood moisture content when properly stored is 15-20%. For briquettes, the humidity is 4-8% and is achieved through forced drying - a mandatory stage in their production.

- Briquettes have a high density

. Why does oak firewood burn hotter than poplar wood? Because of the density. The density of oak is 0.81 g/cm3, poplar is 0.4 g/cm3. That is, each cm3 of oak contains more useful and combustible woody matter than poplar. Briquette density is 0.95-1g/cm3. Their combustible content per unit volume is even higher than that of oak. Accordingly, the calorific value is higher.

Low humidity and high density are the key to the success of briquettes. If you dry firewood to a moisture content of 4-8%, then its calorific value will be comparable to briquettes.

Other advantages of briquettes:

- Take up less space.

- Burn more evenly and longer.

- Made from waste. If you care about the environment and the environment.

- Due to low humidity, briquettes emit less soot and pollute the chimney less.

- How to clean soot from a chimney? Simple ways to remove soot from a chimney at home.

- Does the firewood burn poorly and there is a burning smell in the room? Read these reasons for backdraft in a chimney.