The characteristics of cast iron radiators differ from those characteristic of models made of steel and bimetallic raw materials. Models of such batteries, although old, still do not lose their popularity due to their quality and decent technical parameters. But the debate over which is better: old Soviet or improved modern models does not subside. To sort this out, we have prepared today’s article, in which we will look at the features of cast iron radiators, and in the table we will describe the technical characteristics of different models.

Types and features of cast iron structures

Cast iron batteries are heating equipment consisting of several sections. They are fastened together using special locks, the connection of which is strengthened using a reliable sealant.

Massive cast iron radiator on legs Source infradom.ru

There are single-channel and dual-channel designs. Basically, all cast iron batteries differ in their parameters: width, height, depth. Traditionally, all these dimensions depend on the number of sections used in one radiator.

The height of the device usually ranges from 35 to 150 cm. Smaller models are installed under the window sill in living rooms, and they try to install taller versions in rooms where there is nowhere else to install them except on the wall. It is believed that tall structures have a smaller number of sections, but are able to heat a large area due to their dimensions.

Large cast iron heating radiator with old paint Source remontnik.ru

On a note! Cast iron batteries can be painted with any paint, the main thing is not to apply too thick layers to it, as it may reduce heat transfer.

An indicator such as depth is also important. It can vary from 50 to 140 cm. This indicator determines whether these products can fit into the interior of the room.

Low cast iron battery with a protective case Source onlinetrade.ru

Why cast iron?

The first cast iron radiator has probably already celebrated its centenary. And to this day, cast iron heating radiators, the characteristics of which have been modified, have not lost their popularity. Cast iron is one of the most durable materials.

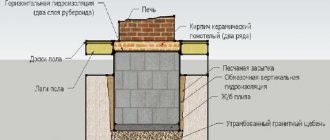

Installation of cast iron radiators

Humanity owes the invention of cast iron radiators to a Russian German with Italian roots, whose name was Franz San Galli. The first cast iron radiator appeared in the city of St. Petersburg. Of course, the device that this scientist invented was very different from the radiators we are used to. Since the German came up with his invention, he began to quickly get rich, while not sparing to share his invention with other countries.

Cast iron battery in retro style

More widespread use of cast iron radiators began in Russia only in the 20s of the last century. Such radiators in appearance and in their design were already closer to those to which Soviet people were accustomed.

Today, the competition for heating radiators in the global market is quite high, as other materials such as aluminum, bimetal, copper or steel have begun to be used for the manufacture of heating devices. However, the characteristics of cast iron heating radiators have not lost much ground and continue to be in demand.

Advantages and disadvantages of cast iron radiators

Several important features should be noted that will help you avoid making mistakes when choosing radiator units for heating a room. First of all, let's focus on the positive qualities:

- Even aggressive coolant is suitable. It is known that the water that enters the heating system when the equipment is started is not at all suitable for human use. It contains many technically dangerous impurities. Grains of sand, various heavy metals and alkalis accumulate in this liquid. So, if these alkalis have a long-term effect on the inner walls of the cast iron battery, then nothing will happen to them. If such an influence is exerted on bimetallic and steel structures, they will very soon become unusable;

- withstand high operating pressure. It is noted that the working pressure of cast iron radiators can reach 9 atmospheres or more. This indicator varies depending on the model and brand. Such structures are durable and wear-resistant, so they can withstand even strong water hammer. That is why they try to use cast iron radiator models when installing centralized equipment;

- long service life. Cast iron batteries can last for ten years, since they do not rust and are not exposed to chemical attack, which can cause the destruction of thinner metal walls;

- profitable price. Cast iron batteries are much cheaper than steel and bimetallic models despite their strength and durability. For example, if you need to buy radiators to heat several rooms, then it will be much more profitable to buy cast iron batteries.

Cast iron designer painted battery with legs Source realhomes.com

As for the minuses, the following several qualities should be highlighted:

- long heating. Indeed, a cast iron structure will heat up much longer than its bimetallic counterpart, since it has thick-walled sections. But such a unit also cools slowly. Accordingly, this minus can easily be turned into a plus;

- slow heat release. The room is not heated immediately when heating is started. Do not forget that a cast iron battery can heat not only air flows in a room, but also objects. Accordingly, from the moment of heating, objects in the room begin to emit heat, as a result of which it warms up much faster;

- huge weight. The more sections there are in a cast iron battery, the more they weigh. This interferes with basic installation. Therefore, you cannot start installing heaters alone. Please note - one section weighs at least 5-6 kilograms;

- a large amount of coolant is required. To properly fill the heating system, you need to take water at the rate of 0.9 liters per cast iron battery, while in a bimetallic or steel model it is enough to fill only 0.4 liters. Accordingly, one can consider that Soviet radiators are not economical enough;

- have an unaesthetic appearance. Really standard budget units are not attractive. You can also order designer options with interesting engravings and paintings. But for such models you will have to pay more than for standard options.

Types of pressure

The pressure in such radiators is: pressure testing and working. The first is often called maximum.

The pressure test determines how much load the radiator can withstand during severe water hammer. When checking, they try to create a load in the highways that will be close to the maximum. This figure ranges from 12 to 16 atmospheres.

And the working pressure shows the load that the coolant gives in the radiator circulation. Typically the load is 9 atmospheres, but this figure can range from 6 to 9.

Battery markings and specifications

There are many manufacturers who, as before, continue to produce cast iron radiators with excellent technical characteristics. In the table below we suggest considering the most common and high-quality designs, as well as familiarize yourself with what parameters they have.

| Brand | Working pressure, atm | Thermal power, kW | Heating area, m2 | Coolant volume, l | Dimensions, cm | Weight, kg |

| Konner Modern | 12 | 0,12-0,15 | — | 0,66-0,96 | 565x65x80 | 3,5-4,75 |

| MS-140 | 9 | 0,12-0,16 | 0,244 | 1,11-1,45 | 588x93x140 | 5,7-7,1 |

| World Cup 1 | 9 | 0,075-0,11 | 0,103-0,165 | 0,66-0,9 | 570x80x70 | 3,3-4,8 |

| World Cup 2 | 9 | 0,1009-0,1423 | 0,148-0,207 | 0,7-0,95 | 572x80x100 | 4,5-6,3 |

| World Cup 3 | 9 | 0,1083-0,1568 | 0,155-0,246 | 0,95-1,38 | 570x90x120 | 4,8-7 |

These technical characteristics are quite conditional. They may vary not only depending on the brand of the manufacturer, but also the time of production of the unit. Basically, they try to adhere to the standards stated in the table, according to which it is much easier to choose a cast iron radiator.

Calculating the number of sections

The number of sections of cast iron batteries is calculated on the basis that for heating 10 sq. m. requires 1 kW of thermal energy - taking into account the 20% reserve, a 1200 W battery will be required. Using the MS-140-500 cast iron battery as an example, we can choose a model with 7 or 8 sections (1120 or 1280 W). It is also necessary to take into account coefficients corresponding to the average air temperature in winter, the quality of thermal insulation, the number and design of windows, as well as their area.

Table for calculating the number of sections of a cast iron radiator depending on the heat transfer of one section, the area of the room and the height of its ceilings.

Additionally, coefficients corresponding to the height of the ceilings, the type of attic and the number of external walls are taken into account. For example, if there is high-quality thermal insulation, a reduction factor of 0.85 is applied - a similar factor is taken into account if there are windows with triple glazing. If there are two external walls, a coefficient of 1.2 is applied, if there are three walls, we take a coefficient of 1.3.

The presence of a heated attic allows you to apply a coefficient of 0.9, and if there is a living space above, a coefficient of 0.8 is applied. In rooms with ceilings three meters high, you need to take into account the coefficient of 1.05, and if you like high ceilings up to 3.5 meters, use a coefficient of 1.1 in the calculations. For a more accurate calculation, invite a heating engineer or use special calculators.

When performing calculations, do not forget to look at the technical data sheets of the radiators used and clarify the heat transfer parameter of one section.

How to correctly calculate the power of a cast iron battery for installing it in one room

In order for the radiator to please the owner with its efficiency, it is necessary to correctly calculate its power. Here it is necessary to approach the calculations as competently as possible. If this is not done, the heated room may turn out to be too hot or quite cool. We will tell you how to make calculations in this section.

Low-power compact cast iron radiator of a modern type Source eco-kotly.ru

Radiator disassembly

Advice! To perform this work, it is necessary to drain the water, remove and disassemble the heating device. This is best done in the summer when the heating system is not working.

Radiator key 1”, 10 sections, pitch 80 mm.

- After unscrewing the fittings, the radiator is removed from the mount and placed on a sheet of plywood to prevent contamination of the floor.

- We unscrew the blind plugs.

- We unscrew the nipples that connect the individual sections of the radiator. First you need to determine the distance the key should go into the battery. To do this, the key is applied to the outside of the device, and the distance to the nipple is marked with a pencil on the key. After this, the key is inserted into the radiator up to the mark and the nipple is unscrewed.

Advice! Sometimes corrosion completely corrodes the openings for the key, then dismantling the section is completely impossible. In this case, it is recommended to cut the joints of the sections with a grinder, then heat the thread with a blowtorch and unscrew the nipple.

Features of radiators with decorative design

Cast iron radiators, made with a specific design in mind, are not characterized by maximum efficiency during operation, since their characteristics are somewhat lower.

Cast iron radiator with a small amount of decor Source remontnik.ru

For example, the heat transfer of such structures is insufficient, since there is an additional decorative layer of paint on the surface, which retains heat. The power of such units is significantly less, since in order to emphasize the aesthetics of the room, the batteries are made in a compact shape.

There is also a possibility of a drop in hydraulic resistance inside the structure. This is due to the increased compactness of the sections. Therefore, it is often difficult to choose.

Designer cast iron radiator in a metallic shade Source dmworld.ru

Beautiful cast iron radiator in an antique style Source retro-lux.ru

Positive and negative sides

Cast iron radiators have a huge number of positive aspects. Among them, the most significant are:

- Low hydraulic resistance, thanks to which the coolant passes through the radiator without significant interference

- Scale and salt deposits do not harm the heating system

- Resistance to chemical reactions

Among the negative aspects are:

- Not the most beautiful and presentable appearance

- It is very difficult to regulate the temperature in the room

- Complex connections between fins make cleaning difficult

- Weight and impressive dimensions make you think about reliable fastening

Inertia is an advantage and disadvantage of cast iron radiators at the same time. Batteries are very difficult to warm up. However, after turning off the heating system, they will retain and release heat for a long time.

Review of popular brands of manufacturers and their prices

High-quality cast iron casting, the original shape of the sections, and the stylishness of the patterned ornament create the unique attractiveness of the new type of cast iron batteries. Their price is higher than standard models. At the same time, the antique design of heating devices organically complements the classic, Gothic or English style of room decor.

The cost of products is significantly influenced by the scale of production. Some radiators are made only to order, which significantly increases their price compared to standard “Soviet”-style products. For example, one MS-140 section produced by the Nizhny Tagil Boiler and Radiator Plant can be purchased for 380 rubles.

Retro Style

A Russian brand that produces several collections of cast iron radiators in various styles: Empire, Rococo, Classicism, Baroque. Provides battery painting services according to customer preferences. You can choose imitation antique silver, Gzhel, red gold, bronze and other options.

The cost of one section of a vintage two-channel Retro Style Anerli is 16,367 rubles.

A battery of 5 low-profile multi-channel Retro Style Bolton sections can be purchased for RUB 19,219.

The Retro Style Chester cast iron radiator costs 41,696 rubles for 5 sections.

Prices for Retro Style cast iron battery models

cast iron batteries Retro Style

Guratec

The high-quality heating devices made in Germany are designed in a retro style. The surface of the sections is protected by a powder paint coating that is resistant to mechanical damage. Before being sent to consumers, products are tested on hydraulic stands.

The Guratec radiator of the Fortuna series, priced from 140 euros per section, is decorated with a beautiful vine ornament, and the range also includes products with images of dragons, lions and angels. The patterned surface of the batteries, painted to match the decor, will decorate a classic interior.

Prices for Guratec cast iron battery models

Guratec cast iron batteries

Roca

The representative of the Spanish industry has a hundred-year history of development. The first products were released in 1917. The company produces a variety of heating devices from aluminum, steel, cast iron with a retro-style design. The popular Epoca model is a battery of 6 cast iron sections, which sells for 29,420 rubles.

Demir Dokum

The factories of the Turkish manufacturer are equipped with automated production lines in accordance with modern European standards. Now you can buy in Moscow any of six models, which are presented in different standard sizes.

The products are distinguished by excellent performance characteristics, have a magnificent appearance, so they can decorate any interior. One section of the Demir Dokum Historic model costs 3,981 rubles.

Prices for Demir Dokum cast iron battery models

cast iron batteries Demir Dokum

Conner Modern

The products of the Russian manufacturer in the Art Nouveau style have good heat transfer rates. Products are manufactured using modern technologies. At a very affordable price, domestic cast iron radiators are not inferior to European ones in terms of workmanship. The cost of the Modern-500 series model of six sections is 4080 rubles.

How to choose cast iron heaters

When choosing radiators, we follow the standard algorithm. We determine the required thermal power, calculate the number of sections, and assemble heating devices for each room from them. Then - the purchase of heaters, installation kits and control valves.

What type of radiators is better to choose:

- For heating technical, utility and utility rooms of a private house, the MS-140M series or its variants are quite suitable.

- In residential premises, “accordions” are clearly inappropriate. Buy nicer “aluminum-look” batteries.

- If your budget allows, install designer appliances - domestic or imported, there is practically no difference. Find out the weight of the sectional heater in advance and consider the installation method - wall or floor.

Vintage taps for retro batteries from Carlo Poletti

- Conventional ball valves and balancing valves are not suitable for retro radiators purely visually. We need similar Carlo Poletti fittings.

- Place any batteries you like in a private cottage; they will easily withstand the pressure of an autonomous system.

- What devices are best for an apartment? The answer depends on the method of heat supply. With a centralized supply, it is not recommended to install cast iron due to periodic testing of the network. If the pressure “jumps” to 12 bar, the sections may crack.

Note. Before purchasing radiators, you can contact the heat supply organization and formally request the operating parameters of the pipeline network. But if the pressure is exceeded and the cast iron is destroyed, you will suffer losses that are difficult to compensate.

MS-140 – main parameters

Today, of all the models that were installed at one time in apartment buildings, the most popular of them remains - MS-140. The lowest center distance had cast iron radiators 300 mm, and the highest - 800 mm. Currently, factories produce only batteries of two parameters - MC 500 and 300.

Basic indicators:

- Working pressure 9 atmospheres.

- Heat dissipation up to 175 W.

- Consists of two-channel sections.

- The cast iron radiator 500 has a height of 50 cm and a width of 9.8 cm.

- The coolant volume is 1.35 l.

- Heating of the coolant up to +130 degrees.

Thanks to these parameters, the MS-140 is in demand among the population. A significant role in this is played by its low cost and high reliability, proven over decades.

Operation of modern radiators with water

There are 7 characteristics that distinguish cast iron from other metals:

- Durability

The resource of the device is exhausted for a very long time, since it is capable of performing its function efficiently for 50 years or more.

In some cases, no repairs are carried out during this period. Considering the low cost, the result is a cheap system that requires almost no maintenance costs.

- High heat dissipation

Among other materials, cast iron transfers the temperature of water into the environment better than others. This is due to the ribs of the sections located vertically. The design and parameters of the metal allow the radiators to work for a long time even if the boiler is turned off or the latter loses its quality operation.

- Ability to withstand high heat

Cast iron batteries can easily withstand temperature increases up to 130-140 degrees , which makes it possible to use water vapor as a working substance. Although this is unreasonable, and such values are redundant.

- Modern radiators have a high safety margin

The container of the devices is protected from external physical damage. The internal part of the system can withstand operating pressure up to 18 atm . This helps with hydraulic tests during which large pressure values are applied.

- Corrosion protection

The latter is possible due to the iron contained in the alloy. To neutralize this problem, the inner walls are coated with a special substance. Thanks to the drug, oxygen released from the steam during strong heating does not interact with the metal. Then, as it cools, it combines with hydrogen again, becoming a liquid.

- High hydraulic resistance

The indicator depends on the diameter of the pipes that supply water to the radiator. For cast iron, the value is high, so there is no need to use a circulation pump. The liquid forces itself to travel through the system quite easily.

Attention! The device supports operation with any type of coolant. Both water and mixtures containing glycol can be poured into the cast iron piping.

- Low cost of the device and ease of installation

Cast iron have built-in connections: you just need to hang the battery on hooks that are embedded in the wall and connect it to the pipes.

This method of fastening is reliable, guarantees the absence of leaks, and reduces the risk of water hammer. The latter can sharply increase pressure and cause irreparable damage to the device.

The system is connected to the piping with threaded connections , which is safer than welding. This also allows you to combine different metals, such as cast iron sections with steel pipes. Despite the ease of installation, it is recommended to invite a specialist.