The key element of the heating system is the circulation pump. With the help of this equipment, heat is evenly distributed throughout the room. Depending on the quality of the device, the water pressure and the efficiency of its heating will change.

Not all users know how to choose these devices correctly and what technical characteristics to pay attention to. At the moment, there are many manufacturers of this type of equipment. WILO circulation pumps for heating systems are in great demand among consumers.

Briefly about the Vilo company

The WILO Group is the world's leading manufacturer of pumping equipment used in households, utilities and industry. The company was founded back in 1872, when its founder, Louis Uplander, began producing hardware.

WILO is currently a leader in digital innovation. The company compares favorably with its competitors with highly efficient and energy-saving solutions, which allows it to produce high-quality equipment according to German standards. Now the enterprises of this company are open all over the world, their number reaches 60.

The VILO RUS division, founded in 1997, operates on the domestic market. Now it includes 30 branches. In 2016, we opened our own service center, which specializes in repairing WILO equipment.

Features of WILO brand pumps

The company's main goal is to create equipment that will make users' lives more comfortable. It is for this reason that all manufactured devices are characterized by reliability. Pumps can have different designs, applications and functionality. The entire model range has the main advantage of energy efficiency, which allows you to save money on electricity.

Advantages

In modern heating systems, natural circulation is most often used. But there are situations when forced transportation of coolant is required. To achieve this task, you need to know how to choose the right pumping equipment. The choice is influenced by many factors, but the most important is the power indicator, the intensity of the water supply will depend on it.

WILO products are characterized by the following performance advantages:

- Has no heat losses.

- Corrosion-resistant materials are used to manufacture equipment components.

- The system is controlled automatically. As a rule, models have a built-in thermostat, and an LCD display is provided to display all functions. If desired, you can switch to manual control, which is necessary to control the shaft speed.

- Even if a high-power model is selected, it will work almost silently.

- Compact sizes. This allows you to install the pump in the desired location without much difficulty.

- It is connected using spring terminals, which does not take much effort and time.

- The rotor and motor have a multi-stage protection system, which makes the unit immune to power surges.

The only disadvantage of modern pumping units is that they require electricity to operate fully. Therefore, it is not recommended to purchase them for areas where there are problems with the supply of electric current.

The devices are suitable for both heating systems and air conditioning. The model range includes dozens of different types that differ in characteristics and functionality. Therefore, choosing the right model for a specific task will not be difficult.

Prices for the range of WILO circulation pumps

circulation pumps WILO

Advantages of devices

Thanks to the special properties of the Wilo pump, the efficiency of the heating system increases significantly. In this case, thin pipes can be used, which, in turn, helps reduce material and fuel costs. Also, when using a pump, the volume of carbon dioxide that is released into the atmosphere is reduced, and the daily consumption of electrical energy is no more than 250 W.

Vilo pumps have many positive properties.

During operation, the working part of the pump is constantly washed by the pumped liquid, so there is no need for regular maintenance of the unit

The most important of them are the following:

- After water evaporates, there is no heat loss.

- The operation of the system can be controlled automatically. The device has a liquid crystal screen, a built-in thermostat and other elements that allow control. You can also manually switch the speed of rotation of the working shaft.

- Compared to many circulation pumps from other brands, Wilo devices are quite compact and therefore do not take up much space.

- The motor and rotor have a multi-stage protection system that helps prevent failure due to sudden surges in voltage in the electrical network.

- The motor operates silently, making it possible to install the device in residential buildings.

Wilo pumps are used in small rooms of several hundred square meters. The selection is carried out according to such parameters as power, volume of circulated water, room area and pressure height. The last parameter is the most important.

You can see how to distinguish an original pump from a fake in the following video:

Types of circulation equipment "VILO"

Many owners of suburban housing are faced with the problem of choosing equipment for efficient heating of a large area - up to several hundred square meters. The natural circulation created by a conventional heater is insufficient, because the pressure in such a system rarely exceeds 0.6 MPa.

This problem is solved in two ways:

- A closed system of large-diameter communications is being constructed. Here you need to take into account that the materials will not be cheap.

- A circulation pump is added to the system.

A more economical option is the second one. It will improve the circulation of coolant in the system, which will increase heating efficiency. Modern pumping units produced by the WILO brand come in two types, the features of which will be discussed below.

With dry rotor

Such devices are used in long-distance heating systems. Between the pump motor and the rotor there are sealing rings, the operation of which is designed for 3 years. During operation, the rotor does not come into contact with the coolant. Thanks to this, the device is reliably protected from corrosion and requires virtually no maintenance. The advantage of dry rotor pumps is their high level of efficiency, reaching 80%.

It should be borne in mind that this type of product is quite noisy, so they are installed in a specially designed room. It is important that there are no foreign particles in the liquid that could damage the O-rings.

With wet rotor

With the help of such models, country houses where heating systems are of short extent are heated. A distinctive feature is the presence of a rotor and impeller, which is necessary to accelerate the movement of the coolant. The rotor itself rotates in a liquid, which additionally serves as a coolant for the mechanism.

When installing such pumps, it is important that their shaft is located in a horizontal plane - only under such conditions will water always remain in the housing.

Glandless rotor pumps have the following advantages:

- almost no noise during operation;

- have a built-in mechanism for switching the rotor rotation speed;

- are reliable;

- characterized by a long service life;

- do not require additional maintenance;

- easy to set up and repair.

The efficiency of these installations does not exceed 50%.

Connecting the device

Heating efficiency and uniform distribution of heat throughout the rooms is ensured by a properly selected circulation pump

It is important to install it correctly, a lot also depends on this

Self-installation does not require professional knowledge, but there are several important points.

Connection point

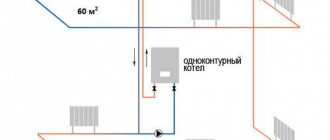

It can be installed on any section of the circuit, but professionals recommend choosing a return pipe.

Photo 4. Diagram of the heating system. The circulation pump is installed on the return circuit.

Installation in a heating system

The water is shut off, the pipes are cut according to the installation length of the product. Before installation, check in which position, horizontal or vertical, the pump should operate. The joints are then sealed and tightened. They think about connecting to the power grid in advance.

Filters

It is recommended to install additional coarse filters; this will protect the device from accidental ingress of particles and significantly reduce the likelihood of failure.

Separate pocket

Sometimes, for ease of maintenance and repair of the pump, installation is carried out in a separate pocket. For this, an additional branch of half a meter in length is created. Valves are installed at the ends, which allow you to disconnect the device from the general circuit at the right time. In this case, there is no need to shut down the system - the valves are closed, the pump is removed from its place and sent for repair, and the structure continues to operate.

Photo 5. Special pocket for the circulation pump. There are valves at the edges of the structure.

Types of pumps by number of speeds

The design of each pump provides a certain number of speeds. The performance of the equipment depends on this parameter. WILO products are available in single and multi-speed, allowing you to choose the product for your specific system.

Single speed

Such models are not regulated in terms of operating speed. If you turn them on, they will only work at maximum power. These products are the simplest from a technical point of view and affordable, since the design does not contain additional elements - regulators. This option is convenient in situations where the pump must operate at maximum power - as a rule, these are common cases, which is why such products are very popular.

Multi-speed

Thanks to the presence of several speeds, the user can choose the intensity of operation of the pumping equipment. For example, in some situations it is not necessary for the device to operate at full power, and a reduced speed is set. This leads to energy savings and less wear on the working mechanism.

Modern equipment can have 3 or even 4 speeds, so the user himself decides in which mode the pump will operate. More speeds are not found.

Scope of application

Since pumps for a wide variety of purposes and capacities are produced under the Vilo brand, the scope of use of the equipment is also very diverse. This:

- Heating - closed circuits in forced systems.

- Water supply – maintenance of private houses, wells.

- Sewerage - the outflow of waste liquids from buildings located away from the central branch of the sewer system, the drainage of cesspools.

- Storm drainage – pumping out groundwater, draining basements and cellars during floods.

- Construction – work with technical, contaminated water at construction sites.

- Homestead farming - watering from a well, borehole, nearby pond and barrels.

The company also produces pumping stations and additional accessories for pumps.

Marking

For each model of manufactured equipment, in addition to the instructions, a special plate is attached, on which all the necessary technical designations are applied. If you know how to read them, it becomes clear for what purpose the pump is used, its performance characteristics and much more.

Several models of WILO pumps are currently available:

- Star-RS (RSL, RSD) - heating systems, air conditioning, refrigeration;

- Star-E - industrial heating models with electronic control;

- Star-AC - refrigeration and air conditioning;

- Star-Z - hot water supply;

- Star-ST - solar thermal systems.

To make it clearer, let's look at an example.

WILO Star-XX 25/1-5 YY:

- Star — equipment type;

- eXX - for which systems it is suitable;

- 25 - indicator of the internal diameter of the pipe;

- 1–5 - possible pressure, measured in meters;

- YY - single- or three-phase electric motor.

These are the basic parameters found in the device name.

What else is indicated in the labeling:

- brand logo;

- product number and production date;

- model;

- Class F - indicator of resistance to heating of the coolant;

- IP - pump protection level;

- PN - permissible operating pressure;

- Tmax—maximum operating temperature level;

- SV0 — availability of software (if additional functionality is connected, then this parameter is of great importance);

- P1max, P1min - permissible temperature ranges;

- Imax, Imin - current required for operation;

- 1–230 V - voltage.

These designations are the most common and, based only on them, you can already make the right choice of equipment. All other characteristics are indicated in the product passport.

Drain TMW 32/11

This Wilo pump model is a vortex drainer made from various materials. The device is capable of pumping slightly polluted water (meaning those in which the diameter of the pollution particles does not exceed 1 cm).

Brief technical characteristics of the circulation pump Vilo Drain TMW 32/11:

- The maximum depth at which it can be used is 3 m.

- This device has overheat protection. In 60 minutes of operation it will be able to pump 15 cubic meters. meters of water.

- As the name implies, the head height of this device is 11 m, cross-section is 165 mm.

Its average cost is 10,500 rubles.

As a rule, choose a pump

Many users do not know what equipment parameters to pay attention to when choosing.

Many factors affecting the operation of the heating system are taken into account:

- Required amount of heat. There are many important conditions at play here: room area, ceiling height, number of storeys, number of windows and doors, as well as the material used to make them. The insulation factor of the basement and attic is also taken into account.

- Climatic conditions of the area. When choosing, you should take into account the minimum air temperature, frequency of wind loads and other features.

- Design of a heated structure. The thickness and material of the walls, floors and ceilings are taken into account. The presence of a ventilation system in the house is of no small importance.

In short, there are many criteria that should be taken into account when selecting effective equipment. If skills and knowledge are not enough, you should contact specialists.

Also taken into account: the number of installed batteries, boiler power, features of the water distribution scheme. Another important indicator is pressure. To determine it, they are based on the total hydraulic resistance of the system. As a rule, this parameter is indicated at the design stage of the house.

If the living area is small (less than 3000 m2), then this makes the choice easier:

- 200 m2 - WILO Star RS 25 2;

- 350 m2 - Star RS 25 4;

- 520 m2 - Star RS 25 6 or RSD 30 6;

- 700 m2 - Star RS 25 7 or 30 7.

All manufactured equipment operates almost silently and does not require maintenance. In addition, ease of control is achieved through built-in automation.

General and basic characteristics of circulation devices of heating systems

Basically, all heating systems use circulation pumps; they help supply fluid and are installed inside the housing. The general and main parameters of such products are:

- Performance - it shows how much liquid the circulation pump can pass through itself in one hour of operation in the heating system. It all depends on the hydraulic resistance of the line.

- Pressure is another word for hydraulic resistance. It is used to determine the maximum height to which the pump will raise the entire column of water.

- Connecting dimensions are usually selected as follows: selection should be made taking into account the diameter of the connected heating pipes, as well as the length of the housing.

- Maximum temperature. The main task of such pumps is to pump heated coolant. It is better to choose a device that can withstand a maximum temperature of up to 110 degrees.

- Manufacturer - this parameter is also important in work. It is best to buy products from reputable suppliers.

Choosing a circulation pump - rules?

When you have received the required parameters of the desired product, you can begin choosing a model. It may seem that, purely theoretically, absolutely any pump is suitable, which is in no way inferior to the technical characteristics of those already calculated. When choosing, it is necessary to take into account the following recommendations from experts:

- You should try to study the model you like as best as possible. It is best to choose a pump whose operating point is usually closest to the graph.

- It is necessary to choose a pump that does not have very high performance, as it will consume unnecessary unnecessary electricity and also create unnecessary noise.

- Performance should be calculated based on the maximum load at the lowest outside temperature. If you think that the pump consumes too much energy, then choose a less powerful one.

- Nowadays, all modern devices have three speeds. By switching them, the operation of the entire heating system can be optimized.

Review of popular models and their costs

The WILO brand produces a wide range of pumping equipment for heating country houses. All models differ in many parameters: power, pressure, coolant temperature and other characteristics.

Star

The equipment in this line is used in domestic conditions and is suitable for organizing a heating system in a small house.

There are two series:

- Star RS . This includes 12 models, labeled from 15-4 to 30-8. Heat-resistant cast iron is used to make the body. Parts that come into contact with the coolant during operation are made of stainless steel. Star RS adjustment is manual, and these pumps allow you to create pressure up to 10 bar. The maximum throughput is 6 m3 per hour.

- Star RSD . These are more functional devices. With their help, you can increase the pressure in the system. Devices connected to such a pump can last longer. In addition, the module can be simultaneously connected to two circuits at once. The device is equipped with a special switch necessary for adjusting electric motors. The weight of the device is only 5 kg, but it is capable of providing the required pressure for a house with an area of 750 m2.

We should also highlight the model 15 WILO Star Z Nova, which is used for recirculation in hot water supply systems. The pressure and performance of each model vary. The price of these devices starts at 3,600 rubles.

Top

This category of pumps is used in heating systems of large cottages and apartment buildings. Thanks to their high performance, they can be connected to systems where the heating area does not exceed 1400 m2.

A distinctive feature is the presence of thermal insulation, so the device is suitable for outdoor installation. The maximum operating pressure is 10 bar.

The following models are produced:

- R.L. and S. _ These are the most productive devices with a wet rotor, which are equipped with one or two motors. Connect to a single- or three-phase network. The three-speed pump is equipped with a mechanical switch.

- Z. _ By purchasing this unit, you don’t have to worry about the quality of the coolant. Often the Z 15 TT 1 model is chosen, which is not afraid of calcium or magnesium deposits. There are no strict requirements in terms of installation location.

- TOP . These are basic devices, the number of which is more than 50. They differ in flange size and performance.

In a word, if you need an appliance for a large home, you should pay attention to the Top series, where you will definitely find a suitable model. You can buy a circulation pump for heating WILO at a price of 15,150 rubles.

Stratos

This is a relatively new invention in the field of pumping equipment. The key feature is the built-in LCD display, which is used for control. The screen displays the necessary information about the operation of the device. The line was created taking into account the fact that the pumps will be installed in large heating systems. Connection to a boiler with a power of 25 kW or more is possible.

Main features:

- power adjustment from 2 to 48 W;

- the presence of a night mode, during which a minimum of electricity is consumed;

- automatic adjustment of operating parameters, for which the controller must be connected to a room thermostat.

Among the list of models there are 2 interesting ones: one with a bronze body and increased productivity (16 bar). This line performs best in energy-saving systems. The cost starts from 10,485 rubles.

Yonos

These are models equipped with an electronic control unit and air protection. An additional function is to remove solid deposits from liquids. Switching modes is mechanical. If you need to achieve efficiency, the device is switched to automatic mode. The display panel displays operating information: what is the pressure in the system, how much electricity does the pump consume, and so on.

This series is one of the latest released by the company, therefore it has absorbed all the positive qualities of its predecessors. The price of these modern devices is from 8900 rubles.

BAC family

This line represents pumps operating with a dry rotor. This is a single-stage centrifugal unit that can be used as a circulation unit. Such models, in particular, are used in equipping residential buildings, as well as industrial infrastructure and agriculture. The working medium can be both cold and hot water. Since the Wilo BAC heating circulation pump does not provide for passive lubrication with a working medium, you should initially prepare for regular maintenance. True, if we are talking about pumping clean water, then the list of such measures may be limited to checking connections and technical and operational parameters.

Installation features

Installation can be done using different methods.

There are 2 schemes:

- Single-pipe. The coolant is constantly consumed, while temperature differences are insignificant.

- Two-pipe. With high drops and variable flow rates.

Before starting installation work, study the instructions for the product in detail. It is also important to choose the installation location, namely, there must be access to the device for maintenance. Most often, equipment of this type is installed in front of the boiler. Installation on the supply is not relevant, since there is a possibility of creating a vacuum.

Installation steps:

- The remaining liquid is drained from the system.

- The pipeline is being cleaned.

- The pump itself and auxiliary fittings are being installed.

- Liquid is poured into the system, from which excess air is removed.

For proper installation, circuit preparation is required. Thanks to it, the device will be able to continue working even if the power is turned off. The diameter of the main pipe and the bypass must be different.

By following these recommendations, even a novice master can handle the installation:

- To achieve maximum performance, the shaft of the device must be in a horizontal plane.

- The terminal box is installed on top.

- There should be a ball valve on each side of the pump, which is necessary for subsequent maintenance.

- The system must have a filter that removes small particles from the coolant.

- There should be a valve on top of the bypass line to remove air.

- The presence of shut-off valves is necessary to prevent water from leaking.

- An expansion tank is provided for an open heating system.

- To improve performance, the connection points of the device must be properly sealed.

Proper installation in compliance with all rules and recommendations is the key to efficient operation of pumping equipment.

Qualified Installation

Having your pump system installed professionally by a certified technician or professional facility can help avoid many problems, protect your drinking water, and prevent contamination. When carrying out work, the installation company must use only products that have a mark of conformity with standards received from an accredited certification organization. And you can't go wrong if you choose products from Wilo.

Our advice

- Have work on your drinking water pipeline done only by specialized companies.

- Careful and rational handling of warm water saves time and energy.

- To protect and conserve our drinking water supplies, never pour toxic substances or waste down the drain.

- Repairing a dripping faucet will not only save you a lot of hassle, but it will also reduce your costs and be a positive contribution to sustainable use of resources. Over a year, more than 1,000 liters of drinking water can flow through a dripping faucet.

- If you have not used the pipes for a long time and the water in them has stagnated, you can use it to water flowers without any problems.

Recommendations for operation and maintenance

Various problems may arise during operation of the circulation pump. The design of WILO products is so simple that you can service them yourself, without the help of professionals.

Frequently encountered problems and ways to solve them:

- The shaft stopped rotating. These pumps operate so quietly that it is impossible to immediately determine the cause of the breakdown. To identify a malfunction, a special shaft rotation tester is used. If the scale shows no movement, the device must be disconnected from the power supply. This situation sometimes occurs during long periods of inactivity or when a foreign object gets inside the camera. In any case, you will have to disassemble the pump and unscrew the shaft, and then remove foreign particles from it.

- A creak appeared. Most often this happens when the system heats up. A squeaking sound is heard when the engine pulley begins to come into contact with the starter plug. To eliminate this problem, it is enough to install a gasket on the plug. If this does not help, then the part of the pulley that rubs against the bushing can be sawed off, but not more than 3 mm.

- The pump stalls. Usually the reason lies in the formation of scale, which needs to be cleaned with a brush. If the system has a coarse filter, this problem practically does not arise.

- Pump vibration. This indicates that the bearings need to be replaced. The appearance of vibration may also indicate a drop in pressure, which should be increased. Sometimes reducing the viscosity of the coolant helps.

- Low water pressure. The problem indicates that the device is not connected correctly. This can happen if the filter is dirty, the water pipes are faulty, or there is a large amount of glycol in the coolant.

These emergency situations occur extremely rarely and are most often due to improper connection of equipment. In any case, they can be fixed simply and without the use of special tools.

Blitz tips

- Do not purchase equipment significantly more powerful than necessary. A unit with greater productivity will not be energy saving;

- The selection must be made according to a previously made calculation. If this does not work, consult the equipment sales points;

- Installation is best done via bypass;

- If the installed equipment will remain inoperative for a long time , periodically put it into operation by short-term start-up;

- Remember that all electrical equipment must be grounded.

How to recognize a fake

WILO is a popular equipment, so now you can often stumble upon a fake. If the product is original, it is covered by a warranty. A separate category is the Chinese WILO pumps, whose service life is only 2–3 years, while the original can last up to 15 years.

How to visually identify a fake:

- The original packaging has a cubic shape with high-quality glossy paint. Fakes are placed in a rectangular box.

- A sticker is attached to the original device; for fakes, the article number, serial number and other data are printed.

- The serial number is not stamped on the body of the counterfeit device.

- On the original the arrow showing the direction of water movement is large, on Chinese products it is small.

In addition to visual qualities, you should also pay attention to the internal design.

Differences:

- The rotor and stator are marked on their housings, indicating the serial number and date of manufacture.

- In original models, the upper part of the device is detached from the rotor, which makes the device repairable.

- Electronics must also be marked.

These are the key points by which you can distinguish the original from a Chinese fake.