BytTechService » Gas water heaters and boilers » Device » How the water unit of a gas water heater is designed, operating principle, typical malfunctions

The flow heater consists of several units. The operating principle of the device is simple, but individual blocks require special attention. In this article we will look at the water unit of a gas water heater. What kind of work it does, what materials it is made of and what its operating principle is, you will find out below.

Design and principle of operation of a geyser

A water geyser works on the following principle: water and gas enter the system when the hot water tap is opened. The ignition system is turned on, the gas in the combustion chamber is converted into thermal energy. The thermal energy then enters the heat exchanger.

A water geyser has a complex structure and consists of an outer casing, a combustion chamber, a water reducer, a heat exchanger, an ignition system, pipes, and a locking system.

The device housing is designed to protect the water unit and other built-in parts. The body gives the device a beautiful appearance, and it is made of steel or cast iron metal or metal-plastic. It also contains toggle switches that regulate the temperature and water pressure, and a display.- The main part of the gas water heater is the water block, another name for it is “frog”, water unit or water reducer. A water unit is installed inside the device in front of the heat exchanger and regulates the operation of the column depending on the volume of water entering the device. The water block of the geyser regulates the water supply to the system, directs it for heating through the heat exchanger and other elements, supplying users with hot water. The water reducer is made of brass, plastic and polyamide and consists of a base, a cover, a membrane, a Venturi nozzle, a temperature switch, a water flow and flow device, and a filter.

- The column heat exchanger contains thermal energy that heats the cold water circulating through the tubes. In a Junkers water column, the heat exchanger and the water unit cover are directly connected to each other. A little further from the heat exchanger is the water unit of the Ariston gas water heater.

- The combustion chamber can be closed or open. Its task is to convert gas into thermal energy.

- The ignition system consists of electric or piezo ignition.

- The pipes supply cold water and gas; they also have a valve for hot water outlet and a discharge valve.

- Some models are equipped with an emergency device shutdown system and system locking.

Water regulator for geyser Neva

Bulky water heaters are being replaced by new automated devices equipped with multi-level protection systems. One of these devices is the Neva gas water heater - a compact model, reliable, easy to operate, and with high power. But, like any device, the Neva geyser can work with minor disturbances. The cause of a malfunction is not always a manufacturing defect. Sometimes the problem occurs due to improper use of the device or ignoring the manufacturer's recommendations.

Knowing how the device works, you can fix the breakdown yourself . For those who are new to the device or it is under warranty service, this is not recommended.

How does the water regulator of the Neva column work?

The water reducer of a gas water heater consists of a base and a cover, between which a sealed membrane is installed. A plate is installed above the membrane. The plate is held by a rod coming from the regulator. The right nozzle contains a Venturi nozzle connected to the cover. The lid contains a steel ball, which is adjusted with a screw .

If excess water flow occurs through the regulator, then the entire flow is directed through the lower part. A slight increase in pressure in the main chamber of the regulator occurs due to the Venturi nozzle. It creates a local narrowing and the water pressure in the nozzle itself sharply decreases.

The cavity above the membrane and the nozzle are connected to each other through a channel. Under the membrane, pressure is formed as in a water pipe, and above it, it becomes slightly less. Due to this pressure difference, a force is generated that lifts the membrane with the plate and the rod . It is difficult to hold the rod with your hands, as its force becomes more than 50 kg.

If you close the hot water tap, the pressure in the Venturi nozzle becomes equal to the pressure in the water supply. The rod with the plate will lower due to the occurrence of equal pressure under and above the membrane.

Gas is supplied to the burner smoothly thanks to the retarder ball. When the membrane of the water unit rises and the water from above leaves, the retarder ball does not completely close the connecting section of the channel of the lid and the base.

The gas is quickly shut off when the membrane is lowered. Water enters the cavity above the membrane, and the ball moves to the left, clearing the way for the duct. The adjusting screw located inside can be rotated if you unscrew the sealed plug located outside. The gas will shut off faster if you tighten this screw.

The ball does not affect the operation of the device in any way and there is no need to remove it. In addition, incorrect adjustment and lack of it sometimes abruptly turns on the horse-drawn horse, making a popping sound.

When replacing the membrane, it is important to correctly reassemble the water heater. The membrane should not cover the connecting part of the cover channel and the base. A cover is installed on the base , aligned with the channel, then the regulator itself is installed into the column with a Venturi nozzle towards the outlet pipe.

The water unit of the Neva gas water heater is faulty, reasons

The water pressure is good, but the column does not turn on:

- The rod for the gas water heater has turned sour. It needs to be lubricated or cleaned.

- If the reason is a torn membrane, then it is replaced with a new one.

When you close the hot water tap, the water heater does not turn off immediately:

- The retarder ball is jammed or the channel in which it is located is clogged, it needs to be cleaned.

When you turn on a hot water tap, the water heater does not turn on immediately:

- The retarder ball is not adjusted correctly. The adjusting screw is tightened several turns.

The column goes out during operation or does not operate at full capacity:

- The membrane of the water unit has deteriorated. The membrane is replaced with a new one.

- If there is a filter at the inlet, it may be clogged and needs to be cleaned.

Cold water has normal pressure, but hot water has very weak pressure:

- Most likely, the mesh filter or nozzles are clogged and need to be cleaned.

This is interesting: Electric heated floor Which manufacturer is better to choose

1

Essential elements

Gas water heaters are flow-type heaters. They differ from a boiler in the absence of a container for heating the liquid - in the columns the temperature of the water rises as it moves through the pipes. These devices were developed at the beginning of the twentieth century. Of course, the new models have significantly greater functionality compared to the old-style speakers. However, their design and operating principle have not undergone significant changes.

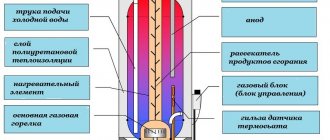

The design of a gas water heater is quite simple. The design of this unit consists of the following elements:

- 1. Ignition system and igniter. Required to start the burner.

- 2. Burner and combustion chamber. It is this structural element that provides thermal energy to the column.

- 3. Water side. Responsible for water supply.

- 4. Heat exchanger. With its help, thermal energy from the combustion chamber passes to the coil, in which the water is heated.

- 5. Chimney pipe. Necessary for connecting the unit to the chimney and removing combustion products.

These are the basic design elements that are present in all speaker models, for example Oasis, Iskra, Lviv VPG and others. The most significant differences between units are the presence or absence of various protection systems. The most common among them:

- 1.

Traction sensor. If there is no draft in the chimney, the column automatically turns off. - 2. Gas valve. The fuel supply will be shut off if the pressure in the line decreases.

- 3. Flame sensor. Gas will not flow into the unit when there is no fire for several seconds.

Columns are classified depending on the type of combustion chamber. Today there are units with an open and closed chamber. If with columns of the first type everything is clear and without explanation, then it’s worth saying a few words about the second. Their design includes an additional unit - a fan. It is designed to force air into the fuel combustion zone.

Most automatic speakers, equipped with a complex electrical control circuit, use batteries as a power source. However, there are also devices that receive power supply voltage from the network.

Design and principle of operation of a gas condensing boiler

Documentation

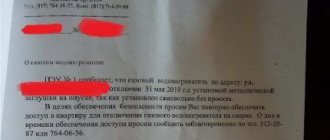

In order to install a gas water heater in an apartment or private house, you will need the following documents:

- Technical passport of the purchased dispenser or indication of the model in case of subsequent purchase of the unit.

- A report on the technical condition of the hood or chimney, drawn up by the exhaust and chimney duct inspection service.

- Project for placing new water heating equipment and connecting it to the gas and water mains in accordance with the technical specifications.

- An application submitted by the owner for the reconstruction of a premises with a water pump must additionally provide proof of ownership and a technical passport for the apartment.

- An application for installation work sent to the gas supply organization (Gorgaz) with a project attached.

The company engaged in the maintenance of the purchased gas water heater or specialists from the gas supply organization are required to perform the following actions when installing the equipment:

- Make a connection into the gas pipeline with the installation of metering devices and a shut-off valve.

- Hang the column with the flammable surface of the wall lined with insulating materials (tin in combination with asbestos or basalt sheets), connect a flexible gas supply to the unit.

- Connect the column to the chimney or exhaust system using a pipeline.

- Connect flexible hoses from the unit to the cold water main and hot water supply pipes.

- Upon completion of the work, the Gorgaz specialist must set up and start the dispenser, seal the gas meter and draw up a report on putting the unit into operation.

The cost of installing a gas water heater at home by private specialists will cost about 3,000 rubles; gas supply companies, depending on the region, carry out the connection at their own prices.

Rice. 10 Recommended spacing and placement of insulation

2

Operating principle

Having become familiar with the design of geysers, it will be easier to understand the operating principle of these units. When fuel burns, thermal energy is released, heating the heat exchanger. Most often, this part of the burner is made of copper or special alloys with high thermal conductivity.

Around the heat exchanger there is a coil, which is also made of materials with high thermal conductivity. As a result, it heats up and transfers thermal energy to the water. After this, the hot liquid enters the pipeline. To remove combustion products, the unit is equipped with a chimney.

It is worth considering separately the operating principle and design of the gas water heater reducer. This is one of the most important design elements, since its main task is to start the column and supply water. The node works as follows:

- 1. When the tap is open, water flows into the water reducer of the gas water heater.

- 2. In one of the chambers of the device, pressure begins to increase, which sets the membrane in motion, which, bending, pushes out the plate.

- 3. The plate acts on the water rod, which moves the gas block pusher.

- 4. This triggers the switch, which starts the control unit, and it gives the command to ignite the unit.

- 5. At the same time, the gas valve is released, opening the fuel supply.

If a flame appears, a special sensor turns off the spark plug. When the hot water tap closes, the pressure in the two chambers of the reducer is equalized and the gas valve shuts off the fuel supply. The principle of operation of a battery-powered geyser is no different from units powered from the mains.

Depending on the ignition method, the columns are divided into three types:

- 1.

Manual. First you need to open the fuel supply, then manually light the fire using matches or a lighter. - 2. With piezo ignition. Unlike the first type, the burner is ignited using a button that activates the piezoelectric element.

- 3. Automatic machines. These units are fully automated and designed as efficiently as possible.

The structure of a gas boiler and the principle of its operation

3

Recommendations for maintenance and repair

All elements of the column structure are subject to destruction due to various factors. Any gas equipment requires regular maintenance. If defects are identified during maintenance work, they must be eliminated as quickly as possible. Of course, some repair work should be entrusted to a professional, but some can be done independently.

The principle of operation of a double-circuit gas boiler

3.1

Dismantling and adjusting the gearbox

You must first turn off the fuel and water supplies. Only after this can you begin to carry out preventive or repair work. To remove the gearbox, you need to perform several steps:

- Water is drained from the heat exchanger;

- using an adjustable wrench, the gas and water pipelines are disconnected from the column;

- If no mistakes were made at the previous stages, the gearbox can be easily dismantled.

Depending on the model of the unit, changes may be made to its design. To avoid problems when dismantling the water reducer, you must first disconnect all pipes and parts that make the work difficult. The housing should be easy to remove; no physical effort is required.

To adjust the gearbox, you must use special bolts located on the back side of the unit. Most often, the unit is already prepared for operation at the factory and does not require additional configuration. It is not advisable to adjust the unit unless absolutely necessary.

3.2

Cleaning the water unit

This event must be held at least once every 12 calendar months. When unscrewing the fastening bolts located on the unit cover, you must be careful not to damage the folds. When the cover is removed, it is necessary not only to clean the internal space of the gearbox, but also to perform the following procedures:

- 1. All solid residues must be removed from the bottom of the part, and the coarse water filter must also be rinsed.

- 2. It is advisable to lubricate the rod with grease or castor oil.

- 3. If you suspect that the gasket has lost its former elasticity, it also needs to be lubricated.

With regular maintenance of the unit, its service life can be significantly extended. Most often, the rod seal and membrane fail. The first element must be replaced once every 3 years, and the second - after the appearance of ruptures or microcracks. In addition, during intensive work the spring for returning the rod to its original position may break.

Having carefully studied the design and principle of operation of the gas water heater, you can carry out all preventive measures yourself. If you don’t have confidence in your own abilities, then you should turn to professionals for help. When working with the unit, you must strictly follow the instructions.

This is interesting: What wire cross-section is needed for 15 kW 3 phase to enter the house

Why does the burner burn weakly or turn off?

- The burner does not turn on - reasons:

- insufficient water pressure;

- improper operation of the ignition wick;

- bad traction.

lack of spark;

In all of these cases there is no flame. If the column turns on, it is only temporarily and after repeated opening of the DHW tap.

- problems with the water unit (frog), the membrane has failed or the rod needs maintenance;

insufficient water pressure in the pipeline;

If the flame burns unevenly, has a red-white hue, protrudes beyond the heat exchanger, and there is a stable water pressure, it is necessary to clean the outer part of the radiator. In automatic gas water heaters, failure to modulate the burner flame indicates a malfunction of the programmer in the control unit.

- In a littered chimney duct, lack of air circulation leads to the accumulation of flue gases. Problems with draft affect the operation of the burner; there is no flame or burns unevenly.

Other malfunctions of flow-through heaters

In addition to the problems listed above, speaker owners have to deal with the following problems:

- weak sparking, sometimes single discharges slip through, the gas does not flare up;

- ignition is accompanied by a strong bang;

- after closing the DHW valve, the burner continues to operate until the electromagnet cuts off the fuel supply due to strong heating (at the command of the sensor);

- spontaneous ignition after connecting to a power source;

- insufficient heating;

- Water is leaking from the water heater.

Advice regarding weak discharges on electrodes. If the batteries and contacts are in order, try cleaning the ends of the electrodes and adjusting the gap between the needles and the plane of the burner (the value is indicated in the technical data sheet of the product). If there is no result, call a specialist - most likely the reason is in the pulse block.

Problems with sparking cause popping noises - gas has time to accumulate in the combustion chamber before a sufficiently powerful discharge is formed. If the spark remains weak, the fuel-air mixture ignites when it reaches a high concentration, which is accompanied by a micro-explosion. There have been cases where the pops damaged the heat exchanger, disrupted seals and normal contact in the electrical circuits of the sensors.

Continuing heating after turning off the water is a rather dangerous malfunction. If it coincides with a failure of the overheating sensor, a vapor phase will form in the heat exchanger that can rupture copper tubes and honeycombs. The reason is the jamming of the “frog” rod that opens the gas valve. How to repair:

- Remove the water module according to the instructions above.

- Disassemble the “frog” and remove the plastic plate.

- Unscrew the nut (or screw) in the left half of the membrane chamber and remove the pusher.

- Change the seals, thoroughly clean all parts from deposits, including the spring monostat (located on the right side of the “frog” behind the membrane).

Recommendation. Before assembly, check how freely the rod moves inside the new seals. For details on disassembling and repairing the speaker, watch the video:

Spontaneous start of heating without turning on the water is a consequence of sticking of the pusher. When the burner of the device does not turn off and the thermostat trips, the user temporarily turns off the power source. Since the rod remains pressed, after the power supply is restored, the column turns on itself, without opening the DHW tap. The “treatment” method is described above.

The reason for low heating is total contamination of the main elements of the unit - the heat exchanger and burner. The column needs to be completely disassembled and serviced; it is better to entrust such work to a specialist. In case of burnout and leakage, the heat exchange unit must be removed and properly soldered, which is not always possible to do at home.

Typical unit problems

Most often, the unit fails due to poor quality water. Potassium and magnesium impurities settle and clog device parts. Pressure drops in pipes also have an effect. It has been proven that 80% of gas heater failures occur due to failure of the water-gas unit.

Study the main signs and causes of breakdowns.

The water pressure is normal, but the burner does not light

- Check the membrane. The rubber element quickly wears out, breaks, and leaks. It is better to install a silicone membrane instead of the old element.

- The rod is stuck and won't budge. Perhaps he got used to it. Lubricate this area and the oil seal with grease to restore operation.

The cold flow is quite strong, but the hot flow is weak

- The mesh filter is clogged with small debris and rust. Remove and clean the part.

- The nozzle at the entrance to the unit is clogged. Cleaning is also carried out.

When opening the mixer, the column does not start immediately

- The retarder ball channel is clogged. The elements are disassembled and cleaned. The ball is located in the unit cover.

- The retarder ball is not adjusted correctly. You need to tighten the adjusting screw.

After closing the taps, the device does not stop working

- The ball is jammed or its channel is clogged.

The equipment does not operate at full capacity and may go out during operation.

- The membrane was damaged. The faulty element needs to be replaced.

If you discover a malfunction and decide to do the repair yourself, read below on how to remove the gearbox.

Setting details

These devices have only one geyser temperature regulator. Thanks to it, the heating temperature and power are adjusted. The self-diagnosis system evaluates the operation of the components when turned on. If there are problems, the red light comes on and the device is blocked from starting. Then it is necessary to adjust the water pressure.

Then you need:

- Remove batteries from the compartment;

- Turn off the microswitch;

- Provide a source of electricity;

- Turn on the hot tap and turn on the microswitch;

- The pressure on the burner should be maximum;

- After saving the settings, the orange lamp will turn on.

In other columns, the water temperature is adjusted by turning the toggle switch and controlling the strength of the water flow.

Important! When adjusting, it is prohibited to exceed the maximum temperature specified in the instructions.

Unfortunately, it is impossible to easily set the settings according to the instructions. Each system has different meanings. If you have difficulties setting up the gas water heater temperature regulator with your own hands, you should turn to professionals.

Distinctive features of the speakers

When choosing a device, you should pay attention to the operating principle of the Neva gas water heater. It has a good automatic protection system against accidental flame extinguishing

The heat exchanger in Neva should not overheat, and the system controls temperatures. The column is reliably protected from excessively high pressure. If the control system becomes faulty, the Neva’s security system will turn off the operation of the mechanism. A plus is the presence of auto-ignition when pressed. The system operates on batteries.

The main advantage is the outlet water temperature, which does not change. This installation is considered the main guarantee of safe use of the system. There is no danger of burns from hot water.

The operating principle of the Neva gas water heater makes it possible to install it even in the smallest apartments. It meets all regulatory requirements. And the durability of its use depends on the attention and diligence in the work of the apartment owner.

There are other brands. For example, the operating principle of the Astra gas water heater differs little from the Neva mechanism. This unit is widely available and can always be found in stock. The speaker is considered reliable, so many people are happy to buy this device. It is easy to set up; all you need to do is follow the step-by-step instructions. The advantage of this speaker is that you can always find spare parts for it on the market. The unit is distinguished by its affordable price. Almost anyone can afford it.

It is believed that the operating principle of the Electrolux geyser is quite simple. It has an electronic ignition system. In it you can find an indicator that shows where you can find out the water temperature. This speaker comes with a three-year warranty.

An important detail is that the heating element does not contain lead.

It is worth paying attention to the operating principle of the Oasis gas water heater. This model is in wide demand on the market and has good reviews

Many people are interested in what the principle of operation of the geyser draft sensor is. This element is necessary to promptly notify residents of a possible fire hazard. If the remains of the combustion process do not go up the chimney, but end up in the rooms, then you need to check the draft sensor of the gas boiler. It may be different. When installing it, it plays a significant role what type of camera is installed in the room. It can be open or closed.

If the material from which the sensor is made exceeds the specified expansion standards, then the sensor should operate, thereby saving it from overheating.

Repair and maintenance of gas-water unit

Hard water, constant thermal load and other factors destroy the structural components of the column over time. Any gas consuming equipment requires regular maintenance. And if defects are identified, carry out immediate repairs.

The design of the gas water heater water reducer has a simple internal structure. Everything is easy to understand. If desired, you can repair the geyser frog or carry out preventive maintenance without calling a technician.

How to remove a frog from a gas water heater

First you need to turn off the water and gas supplies. After this, work is carried out in the following order:

- drain the water from the heat exchanger - for this purpose it is better to use a tap or mixer located significantly below the water heater;

- disconnect the gas and water supply pipelines (an adjustable wrench will be required);

- Now you can remove the water unit of the gas water heater; if everything is done correctly, the frog should be easily dismantled.

The design of the gearbox may differ depending on the model of the flow column. In order for the removal of the water block to be successful, it is necessary to unfasten all parts and pipes suitable for the main structure. The housing can be easily removed; no physical effort is required.

Cleaning the water unit of a gas water heater

Held at least every year. There are several fixation bolts on the frog cover. When unscrewing, care must be taken not to damage the folds. After removing the cover or disassembling the gearbox into two parts (depending on the model of the column), the internal space is cleaned and the structural parts are serviced:

- when cleaning the gearbox, scale and solid residues settled at the bottom of the unit are removed, and at the same time the coarse mesh on the inlet pipe is cleaned;

- the rod can be lubricated with castor oil or grease;

- The gasket can also be coated if it feels rough to the touch and has lost its elasticity.

Regular maintenance of the frog will extend the life of the instantaneous gas boiler and ensure its smooth operation.

Which components should be replaced?

The gearbox contains several elements that are constantly exposed to mechanical pressure and poor quality water. At each service, the functionality of the following components is checked and replaced:

- rod seal - replacement of the seal is necessary on average every 3 years to protect the gas valve from moisture;

- membrane - replacement of the gasket is necessary when it ruptures, as well as when microcracks appear;

- rod and components - the spring that brings the rod to its original position fails after intensive use after 4-5 years.

For maintenance, it is better to use ready-made branded gaskets for the gearbox. The membrane is usually sold separately, but if you wish, you can purchase a factory repair kit with all the components that need to be replaced.

How to adjust the reducer on a gas water heater

Setting up the water unit will help optimize gas flow and water pressure at the outlet of the column. Adjustment of the water reducer of an instantaneous gas water heater is carried out using bolts located on the back side of the unit. Usually they are set in factory conditions, which is sufficient for normal operation of the column.

If you need to adjust the water pressure, the bolts are loosened a little. The DHW pressure at the outlet should increase. Adjustment of the gas water heater reducer is not carried out unless absolutely necessary. It is better to have the work performed by a gas service representative.

After the maintenance is completed, the water unit is installed back. Check for water and gas leaks. The column is launched and used as usual.

How to repair a “frog” with your own hands?

Hard water, exposure to high temperatures and other factors gradually cause the elements of the water block to wear out. If any damage is detected, it is necessary to urgently repair the problematic part.

If desired, you can repair the water block of a geyser yourself, since its design is quite simple. Before doing this, it is important not to forget to turn off the fuel and water supplies.

If you need to adjust the pressure of the device, you need to twist the special bolts located on the back of the block. Then the water is drained from the heat exchanger; for this purpose, a tap located below the water heater is used. Disconnect the gas and water supply pipelines. Now the “frog” can be removed. The design of the water block may vary slightly depending on the model. In order for the removal of the water unit to be successful, all pipes and wires should be disconnected from it.

Turning on the device

The first step is to install the batteries. To do this, open the battery compartment and install them, observing the polarity. Then you need to open the cold water and gas valves. Open the hot liquid tap on the nearest faucet.

At the moment when the liquid flows through the water unit, a spark ignition occurs and, thanks to this, the burner ignites. If it is turned on for the first time or after a long period of inactivity, air may accumulate in the gas line; in order to remove it, you will need to open the mixer several times, hold it for a minute, and then close it.

If the burner ignites, you need to turn the water pressure adjustment lever (located on the right) to the right, this will make it possible to turn on the Vektor JSD 20 device when the liquid pressure in the system has decreased.

Required water pressure

The minimum pressure required to turn on the selected column is indicated in the equipment documentation

Paying attention to this parameter is especially important when installing a heater in old houses built in the 60-70s, since the pressure in their pipes is often insufficient for the heater to operate. If the manufacturer states that the minimum requirement is a pressure of more than 0.15 bar, then in an old building there may be problems with the functioning of this column

Another point is the ability of the column to withstand the hydraulic shock that periodically appears during water supply. This is the name for a short-term increase in pressure in pipes, which can cause leaks and damage to connections. With a value in the range of 11-12 bar, the column is able to withstand such changes.

Security sensors

A geyser can be dangerous, because it is connected simultaneously to water and gas mains, each of which individually can pose a threat.

If there are problems with the gas or water supply, safety sensors turn off the operation of the column, and special valves will shut off the water or gas supply.

Typically, geysers can withstand voltages of up to 10-12 bar, which is 20-50 times higher than normal pressure in pipes. Such sharp jumps are possible with so-called hydraulic shocks.

But if the pressure is lower than 0.1-0.2 bar, then the column will not be able to work. You need to carefully study the instructions and specifications before purchasing to understand whether the dispenser is optimized for low water pressure in pipes in the CIS countries and whether it will work properly. And vice versa - will it withstand sudden changes in pressure, which, alas, is also not uncommon in our conditions.