The cast iron potbelly stove POV-57 is an indispensable attribute for camping conditions. Such a heating device was developed by Soviet scientists in the 50s of the 20th century. Such an unpretentious heater will provide a comfortable temperature in tents, barracks and in the field. In addition to heating the room, the universal stove could be used to heat water and cook food - it was enough to place an aluminum mug, kettle, small saucepan or cans of canned food on the top of the body.

Equipment pov 57

About the disadvantages of an army stove

Like any other device or unit, a cast iron stove has its drawbacks.

One of them is the lack of ability to adjust operating modes and heating. Another disadvantage is, oddly enough, cast iron itself - a material that is difficult to withstand temperature changes. Therefore, it is necessary to heat the liquid with care and not to extinguish the firebox with water. And finally, the last negative point: when servicing the furnace, there may be cases of burns from the heated surface, the same factor can create a fire hazard if the surface of the housing comes into contact with flammable objects.

Of course, all this can be foreseen and the design can be modernized, eliminating these shortcomings. It’s not for nothing that cast iron stoves are still used, bringing a warm, cozy atmosphere to homes and cottages.

Making a stove from a barrel

If the master has an old metal barrel on his farm, he can use it to make a potbelly stove.

To do this, the location of the future firebox doors and ash pan is first marked on the metal surface, and the placement of the chimney opening is noted.

- The support legs are welded on the lower contour.

- Using a grinder, cut out all the intended holes and connectors.

The internal structure of such a stove model is no different from the classic version of a potbelly stove.

Army cast iron stove POV-57

The cast iron army stove stove POV-57 consumes a small amount of fuel, its consumption is quite economical. With one load of the firebox, the room will be provided with heat for 6–9 hours.

Design of an army cast iron "stove"

As the name of the stove suggests, its body is made of cast iron, a material characterized by good strength.

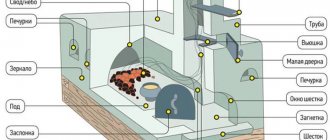

Quite thick walls retain heat well and ensure a long service life of the stove. To install such a device indoors, the construction of a foundation is not required. The ease of installation is explained by the rather simple design of the unit - a cylinder-shaped body is connected to a low stand. The front part of the stove is equipped with two doors: firewood is placed in the large opening, and soot and ash, which are formed after the combustion of solid fuel, are removed from the smaller opening. The housing cover is equipped with a chimney through which smoke is removed from the firebox to the outside. In addition, a vertically installed pipe provides an additional surface through which heat is radiated into the surrounding space. The air heated by burning fuel can circulate inside the furnace for a long time. The POV-57 potbelly stove has in its design special partitions with slots that hold it before being fed into the chimney. Characteristics and size

Dimensions (DxWxH): 330x330x525

Brand: Balezensky Casting and Mechanical src=»https://dymohod-msk.ru/wp-content/uploads/c/0/0/c0072e368d1812f3e1544e6e2a578b16.jpg» class=»aligncenter» width=»540″ height=»360″ [/img]

Advantages of the POV-57 military stove

Among the main advantages of the unit, the following qualities should be noted:

The weaknesses of the potbelly stove are manifested in the following points:

- there is no possibility of regulating operating modes and heating temperatures;

- strong heating of the housing increases the risk of fire of flammable objects located close to the stove, as well as burns;

- Forced extinguishing with water is not allowed due to cast iron’s intolerance to sudden temperature changes;

- it is difficult to heat more than 40 m2 with one stove;

- The heated room must be ventilated.

Requirements for installing a potbelly stove

The POV-57 cast iron stove is installed in a specially designated place. The most convenient angle for supplying the maximum amount of heat to the entire room is its corner part.

When installing a military stove, you should maintain a distance of 1 m from the nearest walls. It is necessary to protect the stove from proximity to nearby flammable objects and materials.

An important point is the insulation of the floor. To do this, you need to lay any refractory material, for example, a sheet of iron, under the POV-57 stove. Thermal insulation must also be provided at the point where the chimney exits to the outside.

You should not leave your military stove unchecked for even a minute. Until the cast iron body of the stove cools down, it is forbidden to leave the room for a long time.

— We purchased a potbelly stove specifically for heating the greenhouse at the end of winter - early spring, until the Siberian frosts subside. Seedlings planted in a room of 20 square meters developed well even when the outside temperature reached -25 °C. A two-layer film covering of the greenhouse and a chimney stretched through the entire building to provide the room with additional heat helped the stove cope with its task. We are pleased with our purchase and know that such a potbelly stove will serve us for a very long time.

Vladimir, 43 years old, Barnaul

— I thought for a long time: what is better to buy? As a result, I installed an army cast iron stove-stove POV-57 in my brick garage of 15 sq.m. due to the fact that I often have to tinker with my rattle for a long time. It seemed to me safer than analogues during testing. Despite the fact that the heated stove at a close distance was even too warm, the opposite wall gave off a fair amount of cold. I thought that in this case the fan should be turned on to disperse the heat throughout the room.

Ivan, 37, Krasnoyarsk

— I remember the warmth of a potbelly stove from the days of my army service. The impressions were positive. They were placed in thin temporary modules. We heated it with coal then, because of the shortage of firewood. I served in a region with a temperate climate, so for a short and relatively warm winter, heating from a small potbelly stove was quite enough for us. The only downside I can mention is its weight. But the two soldiers did an excellent job of carrying, loading, and unloading the army potbelly stove.

Stanislav, 39, Rostov-on-Don

Increasing the number of pipe bends

Increasing the bends of the potbelly stove chimney

The tank at the outlet of washing machines will retain a certain amount of heat, but it will not be able to retain all the heat. A large amount of heat will continue to escape into the chimney.

Therefore, one of the improvements that provides additional heat retention is to increase the length of the outlet pipe. A long pipe running through the room, but with good exhaust, ensures the transfer of heat from its surface, which was previously lost.

Materials and tools

- several elbows that can be easily placed in the room after the potbelly stove,

- brackets for fastening pipe elbows,

- welding machine and metal processing tools.

Instructions

- First you need to mark the location of the pipe. It can pass with a large number of bends and zigzags, thereby ensuring maximum heat retention, without forgetting about the loss of exhaust draft.

- After marking the pipe laying location, it is necessary to install the pipe mounting brackets. Particular attention should be paid to the joints of pipe elbows and corners. Brackets must be made of heat-resistant materials.

- Lay the pipes to ensure a tight, hermetically sealed connection, and, if necessary, modify the elbows to ensure the pipe is laid along the marked route.

- Firmly secure the elbows in the brackets, check the working draft (burn newspaper in front of the pipe), check the tightness of the connections, connect the inlet elbow to the stove.

ADVANTAGES OF USING SOVIET STOVES

high level of efficiency (80%), the operation of the unit from one load lasts for 3-5 hours

Quick kindling in 10-15 minutes - heats up 2-3 times faster than other more modern stoves

Thick Soviet cast iron 8-10mm is a modern metal that is worse in quality than the old one. The walls of the furnace do not burn out or become deformed

Undemanding to fuel - The stove burns any solid fuel: firewood, coal, sawdust, construction waste, briquettes, peat

A rare item for decoration - a piece of Russian history can decorate your design and warm not only the body, but also the heart

Convenient transportation - It will not break or break on the road. The oven is mobile, you can move the oven from place to place

How to use?

The potbelly stove, although it requires constant monitoring, is very easy to use. In the upper compartment - the firebox, you need to load any ignition (paper and rags, wood chips or shavings), torches, and then, opening the ash door, light the fire. As soon as the flame starts, you need to load the firebox with good fuel: logs of hard wood and top with coal, briquettes, etc. Then the upper door is closed tightly, and the ash pan is covered so that a gap of about half a centimeter remains.

If the chimney is equipped correctly, the draft will ensure even burning of the fuel and uniform heating of the walls of the stove. This will take about 20 minutes, so after half an hour the room will be warm, and you can cook food on the oven lid.

Safety Recommendations

dry firewood and logs

What must be observed for safe operation of the potbelly stove:

- The stove must be installed on a non-combustible base;

- All objects and flammable surfaces must be no closer than 70-80 cm from the stove;

- You should not put more than three kilograms of fuel into the potbelly stove at one time;

- The firebox door should always be closed, except when loading firewood;

- It is prohibited to operate the stove if there is a problem with the exhaust pipe;

- Do not leave the oven running unattended for a long time or in the presence of small children;

- It is forbidden to touch the oven body while it is running or immediately after the flame in it has gone out; the entire surface heats up to a very high temperature;

- Do not leave or keep flammable objects or materials near a working stove.

If all the rules are followed, the potbelly stove will heat the room for a long time.

How to use?

The potbelly stove POV 57 is easy to use. The algorithm for lighting the stove is as follows:

- Place crumpled newspaper at the bottom of the oven reserve.

- Place brushwood, wood chips, and a small amount of basic fuel material on top.

- Make sure that the POV oven vent is half open.

- Set the paper on fire. If it burns too intensely, gradually cover the vent until the flame reaches the optimal size.

- Add fuel and close the oven door.

Try to use dry firewood

If you are about to use a new stove for the first time, first check the draft: a lit match is brought to the chimney, the flame and smoke should be directed strictly towards the chimney. If the draft is impaired, using the POV-57 potbelly stove is strictly prohibited.

Does the stove stand idle for a long time (for example, when the owners leave the dacha, the warehouse is closed, the summer kitchen is not used in winter)? Experts advise preserving the product: covering the outer walls of the potbelly stove with a thick layer of chalk. This will protect the cast iron from corrosion.

Where can I buy?

Today, hundreds of specialized stores offer POV-57 military stoves. You can order a stove online from another city - the goods will be delivered within a few days (depending on the remoteness of the client’s locality).

If you want to save money, you should buy a used army stove, not a new one. On advertising sites like Avito, potbelly stoves with different service life are sold. If the stove has been used for less than 5 years, the price is reduced by 20-30%. If the stove is more than 10 years old, it is sold at a discount of 60-70% of the cost of a new product.

Attention: the service life of a potbelly stove is half a century; it is not recommended to buy a stove older than 50 years

Still have questions?

Get a free consultation from our warehouse manager Fill out the form and we will call you back within 15 minutes!

Advantages and disadvantages

If we talk about the disadvantages of POV-57 stoves, then they mainly consist of an unsightly appearance, which, however, in the corresponding interior will be mistaken for a retro style or loft. Also a disadvantage will be the large weight of the structure and the general fragility of cast iron, which is afraid of sudden temperature changes. Maintainability is also not at a high level - the crack can be soldered, but this is ineffective. You should also handle the product carefully, as its surfaces become very hot, which can lead to serious burns.

And now about the advantages:

- The high heat capacity of cast iron allows the stove to accumulate heat and release it even after the firewood has completely died out for at least an hour;

- Fast heating and moderate wood consumption when used correctly;

- Possibility of transportation and use in field conditions, unlike stationary furnaces;

- Ease of installation and use, unpretentiousness regarding the types of fuel used - you can burn anything;

- Durability - high-quality Soviet cast iron is not afraid of corrosion, which determines the duration of operation.

Old potbelly stoves POV-57 are in high demand today along with their steel counterparts, and in some cases their installation is completely justified. Affordable price and ease of maintenance, complete autonomy, versatility and original appearance - all this speaks in favor of potbelly stoves.

This is interesting: Butakov furnaces: design review

Why modernize?

The potbelly stove is a very simple heating device, although today it is deeply modernized. Such a stove, which has become a favorite solution for heating small country houses, can have not only a single-chamber, but also a two-chamber design. A modernized potbelly stove can provide heat even to houses where residents live permanently.

The simplicity of design and manufacture makes it accessible to purchase and use. In addition, a significant advantage for the construction of such a structure is the absence of a foundation. But, despite so many positive properties, the potbelly stove also has significant disadvantages:

- Its efficiency is quite small, the simplicity of the design carries with it an inherent drawback - a huge part of the heat from the potbelly stove “flies into the chimney”.

- To work with such a stove, strict safety requirements must be observed, since falling combustion elements can damage nearby premises and even lead to a fire.

- To heat a room with a potbelly stove, it is necessary to consume a significant amount of fuel elements, which is due to the fact that this type of heating is used only for short-term operation.

But this is not a reason to be discouraged; over the years, our “Kulibins” have found several simple but effective ways to increase the efficiency of a potbelly stove. In this article we will look at the modernization of the stove design itself.

Disadvantages of a cast iron stove

Currently, this stove can be safely called a rarity.

Using such a stove has its disadvantages:

- the oven cannot be called an absolutely fire hazard;

- there is no automatic mode of operation, and therefore the owner himself has to light it, add fuel, clean it, etc.;

- used only for heating small rooms - up to 20 m3;

- high-quality heating occurs only in the room in which the potbelly stove is located;

- lining the furnace body with bricks increases heat transfer, but negatively affects the condition of the metal;

- before leaving, you must wait until the cast iron stove has completely cooled down to avoid emergency situations;

- It is possible to release a toxic odor that appears as a result of fuel combustion.

Important information: the room in which the stove is installed must be ventilated.

You may want to learn about cast iron wood-burning stoves for summer cottages and their structure.

Tips on fireplace stoves for long-term burning may be useful. Read about it here.

Design and principle of operation

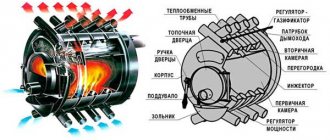

What is the difference between the Loginov Potbelly stove and other metal stoves? The point is the L-shaped blower. The ash pan door is replaced with pipes welded perpendicularly. The edge of the horizontal pipe is tightly welded, and the edge of the vertical pipe has a thread for a plug. There are holes made on the thread - by screwing the plug you can reduce the air flow, thereby regulating the combustion process.

Loginov's original potbelly stove

It is important to make a plug with a slight play, so that expansion of the metal when heated will not cause problems. A screen is welded to the sides and back on the stiffeners to increase efficiency

Without such screens, it is extremely uncomfortable to be near the stove - the temperature is too high and can cause burns. The firebox door is also threaded. A 200mm pipe serves as the firebox opening, and a plug with a handle 220mm in diameter is screwed onto this pipe.

12918027525f238194e21c71fdf01c56.jpe

You can see more details about Loginov’s potbelly stove in this video:

Modification

N. Pyankov’s model is distinguished by the presence of an additional combustion chamber. Unlike more complex designs of slow combustion stoves, the Pyankov potbelly stove is manufactured even faster, the model proposed by Loginov. It is enough to weld steel sheets 140-160 mm long to the back and front walls of the furnace at different distances from the top. The distance between the sheets should be 80mm. The grate is installed 80mm from the bottom. Pyankov moved Loginov’s firebox door to the top of the stove and began using it as a hob.

It will not be difficult for a good master to evaluate all the advantages and disadvantages of the two drawings. If desired, you can make a new model of a potbelly stove using only these two developments, changing the rectangular shape to a round one.

An example of a homemade design (in this photo there is a modernized Pyankov stove), but there is practically no difference in the manufacturing process.

Design Features

The main function of the stove is to heat the room (house, garage, warehouse).

The Soviet stove is entirely metal. Soviet craftsmen improved the existing stove model and put it into mass production. True, they made it more for the army. But due to the fact that the stove perfectly coped with its functions, it became widely used by workers and peasants.

Because of their simplicity, Soviet potbelly stoves are wear-resistant and repairable.

The design of the Soviet potbelly stove is quite simple, it consists of:

- furnace body,

- grate,

- bottom,

- top cover,

- fire door,

- vent door.

Furnaces were produced at 2 factories:

- TEMZ, LMZ plant;

- Plant named after L.M. Kaganovich.

Appearance of a Soviet potbelly stove

Technical specifications:

- Years of production: 1952-1957;

- Manufacturing material: cast iron SCh10-SCh15;

- What you can use to burn: wood, coal, pellets, briquettes and sawdust;

- Firebox: 30 liters;

- Heating area: up to 40 m2;

- Dimensions (LxWxH, mm): 330x330x600;

- Smoke hole diameter - 125mm;

- Weight: 65 kg.

We do not recommend choosing stoves manufactured after 1960, because poor quality cast iron was used in those years.

Photo 1

Photo 2

Conclusion

A potbelly stove is one of the most reliable and common helpers for both summer residents and owners of garages or utility rooms and change houses. Moreover, you can not only purchase it, but also make it yourself. Manufacturing does not require any complex and hard-to-find materials, as well as very specific skills.

To improve the potbelly stove, we considered several types of modifications: attaching 2 tanks from a washing machine welded together; making an ash pan; mesh with stones; increasing the number of pipe bends. These improvements will increase heat retention and improve the operation of the stove.

Design of an army cast iron "stove"

As the name of the stove suggests, its body is made of cast iron, a material characterized by good strength.

Quite thick walls retain heat well and ensure a long service life of the stove. To install such a device indoors, the construction of a foundation is not required. The ease of installation is explained by the rather simple design of the unit - a cylinder-shaped body is connected to a low stand. The front part of the stove is equipped with two doors: firewood is placed in the large opening, and soot and ash, which are formed after the combustion of solid fuel, are removed from the smaller opening. The housing cover is equipped with a chimney through which smoke is removed from the firebox to the outside. In addition, a vertically installed pipe provides an additional surface through which heat is radiated into the surrounding space. The air heated by burning fuel can circulate inside the furnace for a long time. The POV-57 potbelly stove has in its design special partitions with slots that hold it before being fed into the chimney.

Characteristics and size

Weight (kg): 45-47 Power (kW): 2 Dimensions (DxWxH): 330x330x525 Chimney (mm): 115 Brand: Balezensky casting-mechanical src=»https://dymohod-msk.ru/wp-content/uploads /5/8/e/58e3ebe8ded6fec2eeb5cb2b5dd785a0.jpg" class="aligncenter" width="640″ height="427″|fcw3qayjh5a| alt=”Cast iron army stove-stove POV-57″ src=”https://dymohod-msk.ru/wp-content/uploads/d/0/e/d0e1fe9dad0f5412eed1953b13a6131a.jpg” class=”aligncenter” width=”540 ″ height=”360″[/img]

Washing machine tubs

Many have noticed that when the stove is burning, sheaves of sparks often fly out of the chimney. This means that the fuel did not burn out completely and left the working chamber, taking with it most of the thermal energy. So, one of the first ways to improve a potbelly stove is to create a working chamber where small coals will burn out and heat will be retained.

A common method of such an improvement is to install two washing machine tanks welded together, which will act as a kind of car muffler.

Materials and tools

To make this structure we will need:

- first of all, two whole tubs from old washing machines,

Washing machine tubs

Instructions

To properly attach 2 tanks from a washing machine welded together, you must follow a simple guide:

- First, you need to weld two washing machine tanks together so that after welding they form a single container resembling a large cylinder.

- After welding, clean the weld seams and bring the single tank to a marketable condition.

- The next step is to make one hole at opposite ends of the tank, the size matching the diameter of the furnace outlet pipes. Carefully clean out the holes made.

- Insert the outlet pipe elbow into these holes, but so that the pipes inside the tank are at different levels, as if overlapping each other.

- Seal one connection between the pipe and the tank and clean it. Make the second hole in such a way that it fits tightly around the pipe, which will be directly inserted into the potbelly stove. There is no need to weld the second hole, as it will later be useful for removing carbon deposits inside the tank.

Upgrade with washing machine tanks

This simple improvement will allow you to retain a large amount of heat, which previously simply flew away into the chimney.

Cast iron wood burning stoves

A brick stove is effective, but it takes up a large area, takes a long time to warm up, and independent installation requires special knowledge. A steel heating unit does not always withstand high temperatures. The cast iron stove - the simplest and most economical option for a heat source for a summer residence - does not have these disadvantages. Wood is usually used as fuel, but other materials can be used. The efficiency of the device exceeds 60-80%.

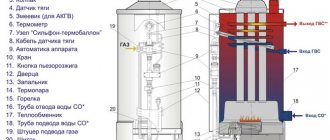

Design and operation

The design of the potbelly stove is as practical as possible. The body rests on legs, there are two doors (cast iron or glass) in front for supplying firewood and removing ash, and an all-metal chimney pipe (at least 5 m) is attached to a special hole on top. Hot air in a potbelly stove always rushes upward. The design of the cast-iron stove is such that the heated streams do not immediately come out - first they go through a kind of labyrinth. Circulation of hot air provides greater heat transfer.

For these purposes, the chimney is moved to the side, and a partition with a gap on the opposite side is attached between it and the flame. Firewood is placed through the door into the housing and the flame is lit. When burned, the fuel heats the potbelly stove, which in turn transfers heat to the room. Ash waste enters the pallet through special holes or a mesh, thanks to which the volume of the working space is not reduced.

Thus, a cast iron stove can be used to heat small rooms, garages, trailers, as well as houses or even city apartments. In some cases, a cast iron stove serves as a vital source of heat, in others – as an interior decoration. For example, the POV-57 potbelly stove is extremely practical and compact, capable of heating a room of 20 m2, and devices produced by the Godin brand are rightfully considered a work of art.

The process of installing a potbelly stove

First of all, you need to choose a location for the heat source. The distance from the stove to the nearest wall cannot be less than 1 m. It should be remembered that a cast iron stove for temporary housing must be under control and visible at all times; it is forbidden to leave the building until the metal has cooled down. Under no circumstances should a wood stove be placed close to flammable objects.

The safest cast iron stoves have a chimney consisting of one section. If this length is not enough, connecting elements is allowed. In this case, the lower pipe fits tightly into the upper section. A thermal barrier is installed at the point of contact between the chimney and the wall or roof. A layer of non-combustible materials (sheet metal, etc.) is placed under the stove and near the firebox door.

Those who want to save money are thinking about how to make a potbelly stove out of cast iron with their own hands. The easiest way to make a rectangular structure. For this you will need: metal sheets more than 3 mm thick, a chimney pipe, 5x5 cm corners, a burner cover.

- The details are drawn out: hob, walls, bottom, grate, two inner plates.

- In the front wall of the future cast iron stove, two rectangular holes are made - the future firebox and ash pan.

- Two openings are cut out in the upper surface - for the burner and the chimney.

- Legs are attached to the bottom of the cast iron stove.

- Corners are welded at the intended location for attaching the grate. They will serve as brackets.

- The grate is made in the form of a grid of reinforcement, or a metal sheet is taken as its basis, in which many round holes are made.

- In the upper part of the cast iron stove, measure 16 cm from the hob and weld a plate 8 cm long less than the depth of the stove to the front wall.

- Similarly, install the same metal sheet to the rear surface.

- All parts are connected by welding, the joints are reinforced with corners. Doors are installed in front of the cast iron stove.

- The chimney pipe is welded and the seams are cleaned.

- If desired, heat-resistant paint is applied to the stove.

- The structure is installed on a fire-resistant coating, the chimney is insulated in places of contact with the surfaces of the building.

A basic army cast iron stove can be made from a pipe or barrel.

Manufacturers and cost

1. Thorma (Slovenia).

It produces the most simple, inexpensive, but nevertheless high-quality models of potbelly stoves. Most of them are equipped with a “clean glass” system, secondary combustion of flue gases. The average cost of devices for small dachas is 25,000 rubles.

Grid with stones

Modernizing a potbelly stove with a mesh with stones is quite one of the most common improvements. Almost everyone had a bath and steamed in the steam room. There you saw a set of stones that warm the air in the steam room.

The principle of this modernization method is similar. It is necessary to line the potbelly stove with stones, which continue to retain heat for a long time. It is worth remembering that you should not use galvanized material for manufacturing, since when heated, toxic fumes are released into the air.

Materials and tools

For this event we will need:

- a set of good stones (you can use high-quality clay bricks), preferably of medium size, similar to those you came across in the steam room.

- dense metal net, you can use a chain-link net.

- if you plan to do it like an adult, then you will need fittings and a welding machine.

Instructions

Making this improvement is simple:

- It is necessary to make a frame of metal mesh (or reinforcement) near the stove, which will not block access to the technological openings of the potbelly stove.

Precautionary measures

It is strictly forbidden to use flammable materials and metals with low melting points to create this improvement. Also, this structure should ensure free maintenance of the potbelly stove, not block access to the firebox, to the ash pan, and not interfere with the removal and replacement of outlet pipes.

Rules for installing a potbelly stove indoors

When choosing a place to install the stove, you need to take into account that there must be a safe distance between the structure and wall surfaces, furniture, and flammable objects. It must be placed in an open place that can be seen from anywhere in the room, because... The operation of a potbelly stove requires constant supervision.

The stove supports are made of metal, they get quite hot, so there must be a non-flammable surface underneath them. In addition, sparks may fly from the firebox, which requires a protective floor covering in front of the firebox door. Usually a sheet of metal or tin is used, but the floor can also be tiled. It is strictly forbidden to place a potbelly stove on linoleum, carpet, parquet, or plank floors.

When installing a chimney, it is necessary to ensure that there are no connecting points of pipe parts in the room where people may be. If this is not possible, then care should be taken to ensure the tightness of the joints. The fuel storage is equipped separately, as far as possible from the stove to prevent accidental fire. Where the pipe passes through the wall, you need to install a thermal barrier made of brick.

The model with a glass door is installed on a platform made of natural stone. During installation, all fire safety rules were observed. It turned out beautiful and reliable

When choosing a potbelly stove for your dacha, it is better to choose a long-burning or double-burning model. These are the most economical stoves that use fuel as efficiently as possible. If your budget allows, purchase a design with thermal glass. This will make it easier to monitor the operation of the stove and create an ideal atmosphere in your dacha for a good rest.

Modernization methods

The design features of the stove do not allow for major changes, of course, unless you decide to make a small home nuclear reactor out of it, but all the proposed improvements are aimed at only one thing - heat preservation. During operation, the stove easily loses heat through the pipe; the thinness of the walls quickly transfers it, but does not allow it to be stored for a long time. The direct-flow furnace consumes a large amount of fuel, and its properties are aimed at consuming charcoal raw materials.

To modernize and increase efficiency, it is to obtain the greatest amount of heat with the same fuel combustion.

There are four main and simple methods for upgrading a potbelly stove, the use of which will significantly reduce heat loss:

- Attaching 2 tanks welded together from a washing machine.

- Making an ash pit.

- Grid with stones.

- Increasing the number of pipe bends

Let's take a closer look at them.

Advantages and disadvantages

POV-57 stoves have the following advantages:

- Compact dimensions, allowing you to equip a small room.

- Strong, durable oven material. The army cast iron stove POV-57 has been operating for over half a century (subject to the operating rules).

- Used for 2 purposes: warming up rooms, cooking food using the cooking method.

- Cools down slowly, retains heat longer after turning off the oven (4-5 hours).

- When installing dampers and screens, the efficiency of the furnace increases (+5-10%).

POV-57 has disadvantages that should be taken into account:

- Warming up a room larger than 40 sq. meters with a potbelly stove POV will not work.

- Lack of possibility of installing automation on the stove.

- Fire safety is low compared to other types of stoves; constant monitoring of the operation of the potbelly stove is required.

- The stove body gets very hot, you need to be careful not to get burned.

Important: the POV cast iron potbelly stove does not tolerate sudden temperature changes. Do not extinguish the fire by pouring cold water - this will lead to cracks in the stove body

Installation Requirements

The POV-57 stove is placed indoors on a fire-resistant surface (especially important if the potbelly stove does not have long legs). Experts recommend installing a cast iron system on tiles or sheet iron

It is convenient to place the oven in the corner of a house, garage, or shed. It is better not to place it in the center of the room, so as not to accidentally touch the walls and get burned. There should be at least 1 meter from the wall to the body (if there are wooden walls around). It is strictly prohibited to keep flammable materials within 1.5 m of the device.

Installation example

This is the wrong way to install the oven! There are flammable materials around and the oven is not on a stand.

Popular factory models

If you need an inexpensive stove for your dacha, check out our detailed review of the most outstanding and interesting models of cast iron potbelly stoves. We will consider both foreign samples and Russian-made stoves.

Potbelly stove POV-57

Before us is one of the simplest and most affordable cast iron stoves. It will allow you to give your dacha warmth, and in sufficient quantities. The stove is designed to heat small rooms with a volume of up to 40 cubic meters. In some ways it looks like a barrel, but in fact it is cast iron, as evidenced by its impressive weight - approximately 45-47 kg. Its design is collapsible, so it can be quickly cleaned of dirt. The cast iron stove-stove POV-57 can operate on a variety of types of solid fuel - traditional firewood, fuel briquettes, European firewood and much more. The efficiency of the device is 80%, which is quite a large figure. Its cast iron body accumulates and retains heat, providing a soft return. You can cook food on the top of the stove. In addition, it can easily be called a long-burning stove - on one load it burns for up to 5-6 hours.

Please note that this cast iron stove was created for the military - this is another plus in the treasury of its undoubted advantages

Termofor Fire-battery 5B

Quite an interesting cast iron stove for a summer house and any country house, pleasing with its affordability and pleasant design. It can warm up a room with a volume of 100 cubic meters. Thermal power is 6 kW, firebox volume is 35 liters. On top we see a small hob. At the bottom there is a box for collecting ash. On the front panel we see a large loading door with a handle that remains cold at all times. The door itself is equipped with a small viewing window. The cast iron stove Termofor Fire-battery 5B is equipped with a slot convector, which further increases its efficiency. The potbelly stove drives air through itself, thereby heating it throughout its entire volume. For normal operation of the stove, you will need a chimney with a height of at least 5 meters. Another interesting feature of the unit is the presence of a small heat exchanger in it, which serves to prepare hot water - for this purpose an external tank is connected to it. The most striking drawback is the limited length of the firewood, which is 29 cm.

META Gnome 2

Before us is a somewhat clumsy cast-iron stove for heating the dacha. Here we see a simple cast-iron body, covered with metal sheets, forming a kind of convector. There are two doors at the front - one of them closes the ash pan, the second closes the combustion chamber. In the upper part there is a hob, next to which the chimney is visible. The power of the potbelly stove is 5 kW, thanks to which it can heat a room with a volume of up to 80 cubic meters. The META Gnome 2 cast iron stove got its name due to its miniature size. The model turned out to be good, but rather scary - there can be no talk of any design here. The potbelly stove is well suited for use in the country house and garage. The only thing that confuses you is the small volume of the firebox - you will have to add more and more firewood to it quite often.

Blist ZAR

The Blist ZAR cast iron stove combines excellent technical characteristics and an attractive design with a ceramic finish. With a power of 8 kW, the potbelly stove easily heats volumes of up to 130 cubic meters. The stove is equipped with a wide door with a loading window and a large ash pan. There is also a small compartment for storing firewood. The body of the potbelly stove is somewhat rounded, with decorative inserts visible on the sides. A special feature of this cast iron stove is that it is lined with fireclay. Among the shortcomings is the lack of a hob, which would definitely come in handy here. But this potbelly stove is presented in several color finishes, thanks to which it can easily fit into any interior.

Operating a potbelly stove

Using a potbelly stove involves alternating cycles of its kindling, which include:

- fuel loading;

- ignition of loaded fuel in the stove;

- heating the stove (its beneficial use for heating people and premises);

- cleaning ash from the ash pit and combustion chamber.

The most important stage is the loading of fuel, which must be placed in an order that facilitates its ignition. First, paper and thin dry branches are laid, with larger dry chopped logs on top of them. Coal is loaded, as a rule, from above onto already well-lit firewood. To restore draft, quite often you will have to disassemble the chimney and clean its pipes and elbows of accumulated soot. Also, the draft in the stove must be regulated by a damper damper, or by changing the length and position of the chimney pipes.

Thus, powered by solid fuel, which can be found almost everywhere, a hand-made mobile potbelly stove made of metal will become a reliable help to the zealous owner in many difficult life situations.

Design of an army cast iron stove

Since the times when the POV-57 stove was used only by military spacecraft (Red Army), its characteristics and design have not changed in the carriages and warehouses of the Ministry of Railways of the USSR. It is still made of gray cast iron - an alloy of iron, carbon, graphite. For potbelly stoves, the following grades of cast iron are used: SCh 10, 15, 25, 30, 35. The higher the number in the name of the material grade, the more durable, heat-resistant, and corrosion-resistant the device will be.

The main elements are made from cast iron in the POV-57 furnace; here is the structure of the furnace:

- Furnace body.

- Potbelly stove lid (removable).

- Grate (removable).

- Oven bottom (removable).

- Fire door.

- Blower door.

The body of the potbelly stove has the shape of a barrel, less often the base is made rectangular. The stove is placed on 4 legs. If there are no legs included, then before installing the POV-57 you will have to take care of constructing a fireproof base.

On the front part of the body of a military stove-stove there are two doors. One is needed for laying fuel material. Combustion products (ash, soot) are removed through the second door. At the top of the stove there is a steamer. A chimney is mounted to it, removing carbon monoxide.

When purchasing a potbelly stove, it is important to ensure that there is a metal plate with slots between the firebox and the firebox. It guarantees air circulation inside the furnace body, increases the efficiency of the device

If you want to speed up the heating of the room and reduce fuel consumption, it is recommended to install side screens (there are none in the design of a standard stove): metal sheets are attached to the stove with long screws so that there are gaps of 5-6 cm in length between them and the walls of the potbelly stove.

A real army stove

Potbelly stove in various painting options

How to make a Loginov potbelly stove with your own hands?

Making a Loginov potbelly stove does not require special tools or materials. The master must be able to weld, cut and rivet metal, and strictly adhere to the diagram.

Tools

When working with metal you will need the following tools:

- Grinder for cutting metal.

- Welding machine and accompanying protective equipment.

- Gun for riveting metal.

- Tool for cutting threads of different diameters.

- Drill and drill bit for metal.

Materials

Materials for making a Loginov potbelly stove:

- Sheets of metal with a thickness of at least 3 mm, with a total area of 1.35 m2.

- Iron rods 45cm long – 6 pcs.

- 100mm pipe for chimney. The length depends on the height of the room.

- Pipe 80mm and 30mm for blower and outlet.

- 200mm pipe about 10cm long for the firebox door.

- Plug 220mm.

- The metal angle for the legs is about 1.2 meters, depending on the intended height of the structure.

- Rivets 6 pcs.

Step-by-step instruction

- Cut the metal into the required pieces in the form of a rectangle according to the diagram (above, in paragraph Diagram and drawing).

Prepare the leaf pieces

- Cut holes for the firebox door and ash pan in the pipes and sheet metal for the front of the stove, and also make a hole for the chimney pipe in the top sheet.

- Cut threads on the ends of the 200mm and 30mm pipes, inside the firebox door and the vent plug.

Carve pipes

- In the 30mm pipe in the thread area, drill holes in a circle in a checkerboard pattern. There should be no holes outside the thread.

- Weld a blower from 80mm and 30mm pipes according to the diagram, weld the edge of the 80mm pipe. Make a plug for the blower.

The blower can also be upgraded as in this photo

- Weld the sheets of metal together, weld the chimney outlet, fuel door and ash pan to the holes.

Weld the body

Weld the remaining parts to this body

- Weld iron rods onto the walls of the stove.

- Place the stove on its feet by welding a metal corner. Cut the corner legs and bend them as in the diagram.

- Weld the screen. Using a special gun, rivet the sheets together as in the drawing, bending the sheet of metal at the back of the screen.

- Weld the chimney pipe at the smoke exhaust point.

Weld the chimney

- Check for defects, assemble and remove the chimney to the street.

- Perform a test fire. If the stove does not smoke and has good draft, then the work is finished. The oven is ready for use.

How to install it in the house?

Just like the design, the operation of the folk stove itself does not require any special skills. In order for its operation to be not only effective, but also safe, it is better to follow a few simple rules.

- The distance between the stove and nearby objects and walls should be at least 30 cm, and preferably 50 cm.

- The chimney of a potbelly stove should go exclusively to the street.

- Use stainless steel pipes with a diameter of 130 mm;

- The chimney must not be combined with any other ventilation.

- The outlet of the pipe (walls or ceiling) must be insulated with non-flammable materials.

- It is advisable to install this potbelly stove on a weak foundation, but there is no possibility - no problem.

- Provide fire safety equipment. A box of sand will do just fine.

The USSR potbelly stove will only please you if you provide for these little things in advance.

An ordinary stove in a classic design only heats well one room with an area of about 40 square meters. If you help her, the heat will remain for a long time.

Insulated walls, ceilings, windows, and the use of thermal insulation materials will significantly reduce fuel costs and save money. The room heats up quickly. The main task is to keep warm.