The high-tech Korean gas boiler Navien is a leader in the heating equipment market. Units with a wide range of power are produced for heat supply to houses with a main gas subscriber station. By design, they can operate on liquefied gas. The model range allows buyers to make a fine selection of equipment based on real technical conditions and financial capabilities. They have an impeccable minimalist design. The elegant appearance of the boiler fits into kitchens of any size and configuration.

Features of operation of Navien boilers

Navien - domestic double-circuit boilers with an open or closed combustion device are used for heating residential and public premises and heating water for domestic and technical purposes.

The boiler control is Russified and adapted to the real operating modes of Russian engineering systems.

The APS mechanism ensures a stable fuel combustion process with minimal consumption. The blower fan for supplying air and creating a working pressure of the gas-air mixture has different speed operating modes and allows the operator to control the rotation speed for complete combustion, preventing condensation.

Navien boiler equipment:

- Circulation pump;

- universal heat exchangers for the heating circuit and DHW system;

- security automation;

- expansion tank;

- selection of heating mode and timer to stop the unit;

- Navien boiler, installation and operating instructions.

The advantage of using a heating unit is that a burner with pre-mixing of the gas-air mixture has a modulation range of 30-100%.

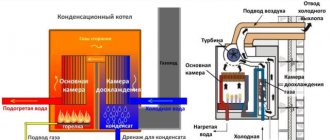

Design and main elements of the boiler

It is important to know your boiler in order to carry out basic maintenance. Although the model may vary from model to model, the main elements can be found in the case:

- combustion chamber;

- heat exchanger;

- expansion tank;

- gas burner;

- circulation pump;

- Control block.

Particular attention should be paid to the design of the lower part of the case, since this is where the inputs and outputs of the circuits are connected, and other important parts are located.

Navien boiler diagram

Closer to the wall there are 4 connecting pipes:

- Feed input.

- Return inlet (with safety valve).

- Hot water outlet.

- Cold water.

Next is a small gas supply pipe.

In front of the return inlet there is a hot water filter, and even closer there is a drain plug.

In front of the DHW outlet there is a make-up tap, through which the system is filled with water.

Specifications

| Indicators, units | NAVIEN Ace-13A Atmo | NAVIEN Deluxe-16K | NAVIEN Deluxe-20K | NAVIEN NCN-25K |

| Heating area, m2 | 98.0 | 128.0 | 160.0 | 220.0 |

| Condensing type | No | No | No | Yes |

| Thermal power, kW | 13.0 | 16.0 | 20.0 | 25.0 t |

| Combustion chamber | open (chimney) | closed (turbo) | closed (turbo) | closed (turbo) |

| Electrical power consumption, for own needs, kW | 110.0 | 150.0 | 150.0 | 130.0 |

| Min. t in the heating circuit, °C | 42 | 42 | 42 | 30 |

| Max. t heating circuit, °C | 80 | 80 | 80 | 95 |

| Max. pressure in the DHW system, bar | 8.0 | 8.0 | 8.0 | 10.0 bar |

| Max. t DHW, °C | 65 | 65 | 65 | 65 |

| Capacity (Δt=25°C), l/min | 9.0 | 13.6 | 13.8 | 14.0 |

| Capacity (Δt=35°C), l/min | 5.5 | 8.6 | ||

| Summer operating mode | Yes | Yes | Yes | No |

| Hot start mode | Yes | Yes | Yes | No |

| Efficiency, % | 86.0 | 91.0 | 91.6 | 98.2 |

| Nominal gas pressure in front of the boiler, mbar | 18.0 | 18.0 | 18.0 | 18.0 |

| Max. hourly gas consumption, m³/hour | 1.33 | 1.72 | 2.15 | 2.51 |

| Expansion tank capacity, l | 6.5 | |||

| Chimney diameter, mm | 130.0 | 60/100 | 60/100 | 80/125 |

| Price as of 07/01/2019 | 32780 rub. | 35200 rub. | 37880 rub. | 69800 rub. |

NAVIEN Ace-16K Turbo

Gas wall-mounted 16 kW is a compact design of a gas boiler for autonomous heating and hot water supply in houses with an area of up to 98 m2 with a remote control unit. Net power is 16 kW, average efficiency is 86%, and the highest fuel consumption is up to 1.33 m3/hour. DHW capacity - up to 5.5 l/min at t=35C.

Important ! The model is equipped with a closed firebox with an outdoor cold air intake.

Deluxe Coaxial 16K

This is a wall-mounted model with a closed combustion chamber and two heating circuits. The turbocharged fan changes speed based on a signal from the built-in air sensor, which ensures complete combustion of fuel in the firebox, which reduces heat loss through flue gas emissions and increases the efficiency of the installation to 91%.

Benefits of Deluxe Coaxial 16K:

- High performance for hot water supply and heating;

- low contamination of the coolant in the heating system;

- low maintenance and repair costs;

- room temperature control;

- Russified control panel with a large LCD display;

- optimal balance of the gas-air mixture;

- innovative mode of modulation of the gas burner device;

- high-quality warranty service;

- easy setup of the Navien boiler;

- low cost of chimneys and gas transmission systems.

Warm home - Setting up DIP switches ien

Setting DIP switches ien

Boiler DIP switch settings ien

To set the factory settings of DIP switches for ien boilers, you need to set all the corresponding DIPs to the “Normal Operation Mode” position, set the smoke exhaust system, and the type of fuel; for correct operation, set the last three switches according to the power of your equipment.

Below is a breakdown of the parameters of DIP switches for ien boilers.

ien Prime

OFF position

| DIP switch no. | Description | |||||

| Function | ON position | |||||

| 1 | Commissioning | Commissioning | Normal operation mode | |||

| 2 | Job status | Maximum gas pressure | Normal operation mode | |||

| 3 | Minimum gas pressure | Normal operation mode | ||||

| 4 | Installation of chimney | FF | Coaxial | |||

| 5 | Selecting the fuel type | Liquefied gas | Natural gas | |||

| 6 | Country selection | Disabled | Normal operation mode | |||

| 7 | Normal operation mode | |||||

| 8 | Model installation | Normal operation mode | ||||

| 9 | Normal operation mode | |||||

| Performance | 13 kW | 16 kW | 20 kW | 24 kW | 30 kW | 35 kW |

| 10 | OFF | OFF | OFF | OFF | ON | ON |

| 11 | OFF | OFF | ON | ON | OFF | OFF |

| 12 | OFF | ON | OFF | ON | OFF | ON |

ien Deluxe

| DIP switch no. | Description | ||||||

| Function | ON position | OFF position | |||||

| 1 | Commissioning | Commissioning | Normal operation mode | ||||

| 2 | Job status | Maximum gas pressure | Normal operation mode | ||||

| 3 | Minimum gas pressure | Normal operation mode | |||||

| 4 | Installation of chimney | Disabled | FF | ||||

| 5 | Selecting the fuel type | — | Natural gas | ||||

| 6 | Model installation | Deluxe | Deluxe coaxial | ||||

| 7 | frequency Hz | 50 Hz | — | ||||

| Performance | 13 kW | 16 kW | 20 kW | 24 kW | 30 kW | 35 kW | 40 kW |

| 8 | ON | ON | OFF | OFF | OFF | OFF | OFF |

| 9 | ON | OFF | ON | ON | OFF | OFF | ON |

| 10 | OFF | OFF | ON | OFF | OFF | ON | OFF |

ien Ace/Atmo

| DIP switch no. | Description | ||||||

| Function | ON position | OFF position | |||||

| 1 | Commissioning | Commissioning | Normal operation mode | ||||

| 2 | Job status | Maximum gas pressure | Normal operation mode | ||||

| 3 | Minimum gas pressure | Normal operation mode | |||||

| 4 | Installation of chimney | FF | FF | ||||

| 5 | Selecting the fuel type | Liquefied gas | Natural gas | ||||

| 6 | Model installation | Model with DHW temperature sensor | Model without DHW temperature sensor | ||||

| 7 | frequency Hz | 50 Hz | — | ||||

| Performance | 10 kW | 13 kW | 16 kW | 20 kW | 24 kW | 30 kW | 35 kW |

| 8 | ON | ON | ON | OFF | OFF | ON | OFF |

| 9 | ON | ON | OFF | ON | ON | OFF | OFF |

| 10 | ON | OFF | OFF | ON | OFF | ON | ON |

Operating instructions for Navien gas boilers

This document is a mandatory appendix to the technical documentation provided by the manufacturer when registering the device in the retail chain. Operation is carried out from the control panel, the model offers many modes of use.

"Navien" mounted boiler operating instructions, structure and description of functions:

- Power (POWER) - on / off;

- combustion (COMBUSTION) displays the combustion process;

- pump (PUMP) status of the network circuit circulation pump;

- hot water (HOT WATER) - water heating temperature;

- low level (LOW LEVEL) - emergency water level in the circuit;

- overheating (OVERHEAT) – unacceptably high water temperature;

- sensor (SENSOR) – sensor malfunction;

- reset (MISFIRE) mode on the panel to factory settings.

Warm home - Setting up DIP switches ien

Setting DIP switches ien

Boiler DIP switch settings ien

To set the factory settings of DIP switches for ien boilers, you need to set all the corresponding DIPs to the “Normal Operation Mode” position, set the smoke exhaust system, and the type of fuel; for correct operation, set the last three switches according to the power of your equipment.

Below is a breakdown of the parameters of DIP switches for ien boilers.

ien Prime

| DIP switch no. | Description | |||||

| Function | ON position | OFF position | ||||

| 1 | Commissioning | Commissioning | Normal operation mode | |||

| 2 | Job status | Maximum gas pressure | Normal operation mode | |||

| 3 | Minimum gas pressure | Normal operation mode | ||||

| 4 | Installation of chimney | FF | Coaxial | |||

| 5 | Selecting the fuel type | Liquefied gas | Natural gas | |||

| 6 | Country selection | Disabled | Normal operation mode | |||

| 7 | Normal operation mode | |||||

| 8 | Model installation | Normal operation mode | ||||

| 9 | Normal operation mode | |||||

| Performance | 13 kW | 16 kW | 20 kW | 24 kW | 30 kW | 35 kW |

| 10 | OFF | OFF | OFF | OFF | ON | ON |

| 11 | OFF | OFF | ON | ON | OFF | OFF |

| 12 | OFF | ON | OFF | ON | OFF | ON |

ien Deluxe

| DIP switch no. | Description | ||||||

| Function | ON position | OFF position | |||||

| 1 | Commissioning | Commissioning | Normal operation mode | ||||

| 2 | Job status | Maximum gas pressure | Normal operation mode | ||||

| 3 | Minimum gas pressure | Normal operation mode | |||||

| 4 | Installation of chimney | Disabled | FF | ||||

| 5 | Selecting the fuel type | — | Natural gas | ||||

| 6 | Model installation | Deluxe | Deluxe coaxial | ||||

| 7 | frequency Hz | 50 Hz | — | ||||

| Performance | 13 kW | 16 kW | 20 kW | 24 kW | 30 kW | 35 kW | 40 kW |

| 8 | ON | ON | OFF | OFF | OFF | OFF | OFF |

| 9 | ON | OFF | ON | ON | OFF | OFF | ON |

| 10 | OFF | OFF | ON | OFF | OFF | ON | OFF |

ien Ace/Atmo

| DIP switch no. | Description | ||||||

| Function | ON position | OFF position | |||||

| 1 | Commissioning | Commissioning | Normal operation mode | ||||

| 2 | Job status | Maximum gas pressure | Normal operation mode | ||||

| 3 | Minimum gas pressure | Normal operation mode | |||||

| 4 | Installation of chimney | FF | FF | ||||

| 5 | Selecting the fuel type | Liquefied gas | Natural gas | ||||

| 6 | Model installation | Model with DHW temperature sensor | Model without DHW temperature sensor | ||||

| 7 | frequency Hz | 50 Hz | — | ||||

| Performance | 10 kW | 13 kW | 16 kW | 20 kW | 24 kW | 30 kW | 35 kW |

| 8 | ON | ON | ON | OFF | OFF | ON | OFF |

| 9 | ON | ON | OFF | ON | ON | OFF | OFF |

| 10 | ON | OFF | OFF | ON | OFF | ON | ON |

Starting the boiler

After all installation work has been completed and pressure testing has been carried out, the first commissioning start-up of the boiler equipment is carried out. All work is carried out by service center workers with the preparation of appropriate documents, which in the future will preserve the manufacturer’s warranty obligations.

When starting the Navien boiler, the instructions must be followed impeccably. Sequence of work:

- The circuits are filled with water through the unit’s make-up unit, built into the structure, with a special tap at the bottom next to the tap water inlet.

- Monitor the pressure gauge; when the pressure rises to 2.0 atm, close the tap.

- Remove air pockets. At the first start, it is performed in manual mode, and at subsequent starts, through an automatic system. They start the process from the most distant battery, opening the Mayevsky tap, and alternately go through all the points of the heating circuit.

- After etching the air plug, the pressure in the circuit will drop, so re-filling will be required.

- Discharge the air mixture from the circulation pump.

- To turn on the unit, press the “Power” button.

- The electric ignition will work and the unit will start, after which it is necessary to adjust the temperature regime.

Draining water from the boiler and hot water supply system

If the boiler is not planned to be used for a long time (especially in winter), it is recommended to drain all water from the heating and hot water circuits. What to do:

- The unit is de-energized and the gas valve is closed.

- The valves of the heating system (2 pieces) and cold water are closed.

- The tap that is usually used opens (above the sink, for example) and drains hot water from the system.

- The tap in the DHW system is closed.

- A plug is opened at the bottom of the housing and water from the heating is drained.

Settings

“Navien” is programmed for winter (heating and DHW) and summer (DHW) operating modes - with the “Snowflake” and “Sun” icons. The network temperature is adjusted on the LCD remote control when the “radiator” icon on it is lit. In some options, the “Heating Mode” is started, in others the knob is turned. A flashing LED records the set water temperature.

If the icon just lights up without pulsating, the actual temperature in the network is displayed. By selecting the icon, use “+” or “-” to increase or decrease the temperature. After a couple of seconds the LED will stop flashing and show the actual temperature. They regulate the heating temperature from 40.0 C to 80.0 C. If it is set incorrectly, an error code will be displayed.

Note! The DHW temperature is adjusted in the same way, only on the remote control there are pictograms with a tap, the range is from +30 to +60 C.

Operating modes

Like many heating appliances, Navien boilers have winter and summer operating modes. On the display, the mode change button is indicated by the “Snowflake” and “Sun” icons.

By pressing this button again, you can change the options:

- Winter mode activates heating and hot water supply.

- Summer is only hot water supply for household needs.

You can adjust the coolant temperature on the remote control when the heating radiator icon lights up on the display.

In some models, to do this you need to press the “Heating Mode” button, in others you need to turn the knob with this icon.

A flashing radiator icon means that the numbers you see show the set temperature of the coolant.

If the “radiator” just lights up, the actual temperature in the heating is displayed.

Having selected “radiator”, you need to press the “+” or “-” keys to increase or decrease the temperature. A few seconds after the desired temperature is set, the radiator icon stops blinking, and the display will show what temperature the coolant is now, and the device will begin to gradually heat it (or cool it) to the selected one.

Tips and recommendations for operating the Navien boiler

The main advice from experts regarding the safe operation of the boiler:

- The room where the unit is located must have good ventilation.

- The unit must have a separate independent connection to the electrical network.

- The boiler must operate in a fully assembled and protective housing.

- The user is prohibited from independently repairing the gas equipment of the boiler.

- The boiler must undergo an annual inspection by representatives of Gorgaz.

- The boiler owner must periodically check the joints of the boiler and the gas pipeline for leaks with a soap solution.

Additional Information. If leaks occur, immediately turn off the gas valve, ventilate the room and call the emergency gas service.

Navien gas boilers have been used by Russian consumers for a long time. They have rightly earned the trust of customers. The lightweight layout with the widest range of modern water heating functions allows you to choose these models from a large list of offers on the heating equipment market.

Korean-made Navien heating boilers are popular in our country. They are reliable and at the same time affordable in price. Due to the great demand for these devices, setting up a Navien gas boiler is a pressing issue among buyers.

Possible malfunctions and ways to eliminate them

Navien error codes:

- 01 – overheating (check if the pump is working and if the filter is clogged).

- 03 – no gas (check if the tap is open).

- 04 – false flame signal (check the serviceability of the gas valve, replace the electrodes or board).

- 05 – 06 – Short circuit on the temperature sensor or open circuit.

- 09 – problems with the fan.

- 10 – problems with smoke removal (check the operation of the fan, whether the chimney is clogged, whether the fan pipes are connected correctly, gusty wind could also be the cause).

- 013 – Short circuit on the OM flow sensor.

If the boiler does not give any errors, but works much worse, the reason may be a clogged filter or an airy system.

Navien boilers, like any other equipment, require good care and proper handling. Regular checks and service control will help avoid breakdowns.

Installation of an internal electrical network is an important stage in the arrangement of a new building. Electricity in a private house with your own hands - how to do the wiring correctly? Read the advice of professionals.

Design features of Navien gas boilers

Manufacturers of Navien produce devices of different capacities, floor-mounted, wall-mounted and with a hot water supply function. They can be connected both to a centralized line and to gas cylinders. The units have a modern appearance that allows them to fit into any home interior. Navien gas boilers are equipped with a safety group, which includes:

- modulating turbocharging;

- protection against coolant freezing;

- SMPS chip that protects against power surges;

- temperature sensor control panel, which allows you to adjust the operation of the unit to certain circumstances.

The most common model of Navien gas units is Deluxe, so let’s look at them in more detail.

Advantages and disadvantages of Navien Deluxe

Boilers have been sold on the world market for more than 30 years. They have gained popularity due to their reliability and functionality. The high level of safety of gas equipment is ensured by several protection systems:

- From freezing of the heating system, during prolonged shutdown of equipment in the cold season.

- From destructive operating modes of the electrical network, during power surges.

- From low operating conditions of the gas network.

- From emergency operating conditions of the water supply system, when the coolant pressure decreases to 0.1 bar.

The safety group of the Navien boiler contains primary sensors for temperature and pressure, a control pressure gauge and a safety relief valve against excess pressure in the heating circuit. To protect the internal surfaces of water heating from scale, a filter is installed to purify water from hardness salts.

An SMPS chip is built into the electronic board of the boiler control system, which protects the boiler equipment from fluctuations in the network +/- 30% of the normal voltage of 220V.

Among the minor disadvantages of this brand of heating sources, Russian users include the rather high price, energy dependence and complex installation of a gas boiler, which must be carried out by a specialized organization.

Setting up a Navien gas boiler

Next, we’ll look at how to set up a Navien Deluxe gas boiler with your own hands. Manipulations are carried out using a remote control with a built-in room temperature sensor.

Heating settings

To set the heating mode and set the coolant temperature, hold down the button with the image of a radiator until the same icon appears on the screen. If the “radiator” picture blinks, it means that the set coolant temperature is displayed on the screen. If the symbol does not flash, the actual water heating level is displayed.

Navien wall-mounted gas boilers - model range, pros and cons

How they work and what are the advantages of Navien Ace gas boilers

To set the desired temperature, use the “+” and “-” buttons with the “radiator” icon flashing. The possible range is from 40ºC to 80ºC. Once the temperature is set, it will be automatically saved. The “radiator” icon will blink for a few seconds, after which the actual temperature of the coolant will be displayed on the screen.

Heating with air temperature control

To set the desired air temperature in the room, you need to hold down the “radiator” button until the image “house with thermometer” appears on the screen. It means “Heating with room temperature control” mode.

When the “house with thermometer” symbol is flashing, the desired room temperature is displayed on the screen. When the icon is not flashing, the display shows the actual room temperature.

When the icon is flashing, using the “+” and “-” buttons, the desired level of heating in the room is set, adjustable in the range of 10-40ºC. The temperature is then automatically saved and the icon stops flashing.

Setting the hot water temperature

To set the hot water temperature, you need to hold down the “water tap” button until a similar flashing symbol appears in the right corner. You can then set the desired hot water temperature between 30ºC and 60ºC. The settings will be automatically saved and the “water tap” symbol will stop flashing.

Note! In the “Hot water priority” mode, the water heating temperature is regulated differently.

Now let’s look at how to configure the Navien Deluxe gas boiler in the “Hot water priority” mode. To activate it, hold down the “water tap” key until the “faucet and light” symbol appears on the screen. Now you can set the desired temperature using the “+” and “-” keys. While the DHW temperature is changing, the “water tap” icon should flash above the “tap and light” symbol.

The “Hot water priority” mode involves preparing a supply of water at a given temperature even if it is not in use. It allows you to supply heated water to the consumer a few seconds earlier.

Away Mode

The “Away” mode means the gas boiler operates only for preparing hot water. To switch the unit to this mode, you need to press the button that shows an arrow and a water tap. The “water tap” symbol that appears on the screen means that the “Away from Home” mode is set. The actual temperature in the room is displayed next to it.

Note! This mode is convenient for use in the warm season, when hot water supply is necessary, but there is no need for heating.

Setting the Timer mode

The “Timer” mode is necessary to set the time for stopping the operation of the gas boiler within the range from 0 to 12 hours. The unit will work for half an hour, turning off for the specified interval.

To set the “Timer” mode, hold down the “radiator” button until the “clock” symbol appears. When the icon is flashing, use the “+” and “-” keys to set the interval time. The set value is saved, the “clock” stops blinking, and the display shows the actual air temperature.

Boiler circulation pump Navien 13-40K

Circulation pump for gas boiler NAVIEN:

- Ace 13-40K

- Coaxial 13-30K

- Atmo 13-24A

- Deluxe 13-30K

Code NAPU9GLPST36 30000469A

Made in Korea

- Description

Description

Circulation pump for gas boiler Navien 13-40K

Responsible for the circulation of coolant in the system.

If the pump in the Navien boiler is faulty, the boiler will not work either for heating or for heating hot water.

It is most likely that if the circulation pump of the Navien boiler fails, the boiler will generate an error associated with overheating of the boiler and lack of coolant circulation in the system. Although, of course, a malfunction of the boiler pump is a probable, but not the only cause of overheating of the Navien Ace boiler, and only a qualified service specialist can accurately determine the cause of the Navien gas boiler overheating error directly when diagnosing the boiler.

Checking the serviceability of the circulation pump of the Navien Ace, Deluxe, Atmo gas boiler: If the circulation pump of the Navien boiler has stopped rotating, check the following: - Disconnect the circulation pump plug by turning the screwdriver counterclockwise and check the condition of the circulation pump rotor to see if the pump is jammed (in certain cases conditions, the pump may “stick” - use a flat-head screwdriver to force the axis to turn.

If you suspect that the Navien pump has power problems, you need to check the following: - Using a tester, check whether the pump is receiving power. Is 220V voltage coming from the controller? -Check the pump coil for an open circuit. Measure the resistance at the coil terminals. A resistance value of less than 0.3Ω is considered normal.

-If there is no power supply to the pump, replace the controller (electronic board of the boiler).

If, as a result of the check, you find out that the pump on your Navien Ace, Deluxe, Atmo boiler does not work, then you need to replace the pump.

REPLACING THE NAVIEN BOILER PUMP:

1) Remove the drain plug connected to the pump and remove the connecting connector.

2) Remove the connecting clip from the pump.

3) Remove the nut from the heating water inlet pipe connected to the circulation pump.

4) Remove the old pump and install the new one.

Attention! In Navien brand gas boilers, you can only use the original circulation pump! Its article number is 30000469A NAPU9GLPCT36, NAPU9GLPCT16. It is not possible to replace a Navien boiler pump with a circulation pump from another manufacturer.

The circulation pump for the Navien boiler Navien Ace, Deluxe, Atmo 30000469A NAPU9GLPCT36, NAPU9GLPCT16 is sold only assembled.

buy a circulation pump for a gas boiler Navien 13-40K 30000469A NAPU9GLPCT36, NAPU9GLPCT16 in our online store. You can buy it from us at an affordable price and with prompt delivery throughout Chelyabinsk and Russia

How to increase the time between starting and shutting down a gas boiler?

If there is a problem with frequent switching on and off (“clocking”) of a gas boiler, you can change the difference between starting and stopping the unit. This is possible using the Navien engineering menu:

- Turn off the remote control and press two buttons “+” and “-” at the same time.

- A number from 2 to 20 appears on the display. Usually 8 or 10.

- Use the “+” and “-” keys to increase the delta value between start and shutdown.

- After 5 seconds, the remote control goes out.

- The boiler is turned off and then turned on again.

. and without construction experience

My works for 2022.

How I set up the Navien boiler, hysteresis on the burner

The boiler heats up, life goes on, but something told me that everything is not so rosy, first of all, a mistake was found among many buyers of gas boilers, they all buy with a reserve of power “just in case,” well, I, like everyone else, I took it with a reserve, with a reserve for hot water supply and frosts, i.e. It turned out that in warm weather outside, the Navien boiler continues to cycle , which is very unfortunate for it, and can lead to breakdown, first of all, there may be a breakdown of the ignition system , since it constantly lights the boiler, and most often wears out, this is not for me I want to.

As an inquisitive researcher, with a stopwatch in my hands, I studied the cycles of the boiler in different modes of its operation, in warm weather, in cold weather, and decided to test the capabilities of the boiler at work depending on the temperature in the room, for this I selected the room mode in the boiler settings.

At first everything was happy, the boiler obediently stood up, waiting for the set temperature to drop, but the joy was short-lived, cold was already creeping across the floor (the heat from the radiators, which cut off the cold air from my many windows, disappeared, and the house became not very comfortable, in the upper part the room where the remote control for the boiler, in which the temperature sensor is located, hung. It was in a warmer zone, we immediately understood that this was not suitable for us, at first there were thoughts of hanging the remote control down, closer to the floor, but, firstly, this is inconvenient for control, secondly, it can be ruined by domestic cats, thirdly, the boiler may not turn off at all, trying to catch up with the temperature below, when it is already hot in the middle part of the room in height.

The room temperature test did not pass and was not suitable for me, at the same time I remembered the person who connected the gas, who advised that the boiler should not be turned on in this mode.

Time passed, but the cycles did not give me peace, and one day it occurred to me, while regularly observing the boiler, that the hysteresis (delta) in the turn-on-switch-off segment of the gas boiler was probably too small, and I would like the boiler to drive the coolant longer to a higher level. low CO temperature, but it was unclear how to do this, I certainly know how to program, but programming languages for this boiler are inappropriate, and I don’t have equipment to connect to the “brains” of the boiler, and one day, purely by chance, I came across one well-known forum for a person who knows how to do this, and with the help of only one remote control, by entering the engineering menu of the Navien boiler!

This is literally what needs to be done. to change the delta between boiler start-stop.

1. With the Navien boiler remote control turned off, press the + and - buttons for 5 seconds

2. The number 8 or 9 or 10 will appear on the remote control display (for me)

3. Again, use the + or - buttons to change the value (this is delta) in the range from 2 to 20 (I set it to 12)

4. We wait 5 seconds, after which the boiler remote control goes out

5. Turn off the boiler by removing the plug from the socket for at least 10 seconds

6. Temperature difference value saved

Having done all this, I immediately realized the difference, the intervals between starts and stops of the boiler increased, although it raised the delta by only 2 degrees!, a useful thing, the engineering menu of the Navien boiler!

Cleaning the heating water filter

Filters collect all the impurities contained in the water.

They need to be cleaned periodically, for this:

- Drain the water (see previous paragraph).

- Wait until the equipment cools down completely.

- There is a filter located not far from the drain plug. To remove it, first remove the mounting bracket, then pull out the filter itself.

- It must be rinsed under pressure with clean water.

- Then reassemble in reverse order.