Any heating equipment of absolutely all price categories has a limited resource. The service life of a gas boiler in the heating system of a private home depends on the complexity of the design, the materials used, production and assembly technology, the functionality of the automation and, of course, operating conditions. On average, gas boilers operate without problems for at least 7-10 years. In practice, there are models that have been in service for more than 17 years or, due to inappropriate operating conditions, 3-4 years.

In the article we will not only talk about the service life of models with different designs, but also determine what affects the service life of boilers and how it can be extended.

Service life of a wall-mounted boiler

This type of heating boiler is most in demand due to its low price and small size, but many buyers of such equipment do not know that they work much less than floor-standing options.

This is due to various factors:

- Almost all wall-mounted units are equipped with copper heat exchangers, in contrast to cast iron in floor-standing units. Copper makes the heating structure light, but it wears out quickly and requires a high level of purification of the circulating water. If this is not done, the copper will oxidize and the internal heating surfaces will become clogged with scale. From practice it follows that a copper boiler heat exchanger, even with good operation, can work for no more than 5-8 years, at a level of 12-18 for the cast iron version.

- A chimney with natural circulation cannot develop the power of the flame, so there is a temperature imbalance in the combustion chamber, leading to accelerated decommissioning of the unit.

- Wall-mounted boiler units generally have the lowest power and therefore operate with overload, which also significantly reduces the service life of a gas boiler in a private home.

Results

So, we can draw the following conclusions:

- do not save when buying a boiler; more expensive models will provide your home with uninterrupted heating for several decades;

- choose floor-standing models with a cast iron heat exchanger;

- engage only professionals for installation and maintenance of the boiler;

- Follow all operating rules established by the manufacturer.

By fulfilling all these requirements, your boiler will operate smoothly, economically and safely for several decades!

Service life of a floor-standing boiler

Floor-standing gas units last 5-8 years longer than wall-mounted ones. So, according to actual data, a steel heat exchanger can last 11-12 years, and a cast iron one can last 12-18 years.

Floor-standing devices practically do not function at full load, which prolongs the service life. And if the owner of a double-circuit heating boiler carefully carries out all routine maintenance and preliminary water purification, then such a gas boiler unit will serve him for at least an additional ten years. Many people remember Soviet cast iron boilers with a service life of 50 years.

The service life of a floor-standing gas boiler depends on the temperature conditions in the heating networks; at low temperatures, the flue gases cool down greatly.

At temperatures below 55 C, the condensation process begins in them, with the formation of acid, which penetrates the boiler heating surfaces and “eats away” everything in its path, from the chimney system to the firebox.

Therefore, if the manufacturer specifies a lower temperature limit for the return coolant, it must be maintained. In addition, when the condensation process occurs, it is necessary to additionally install condensate traps at the bottom of the chimney, which will significantly increase the service life of the floor-standing gas boiler.

Number of circuits

All models of gas boiler systems present on the Russian market are classified by the number of circuits.

…

- Single-circuit ones are designed only for heating the coolant circulating in the heating system.

- Double-circuit ones are designed for heating and creating domestic hot water at home.

Single-circuit installations are simpler and therefore more repairable. Double-circuit, they have a lot of design features that significantly increase the cost of maintenance and repair in the event of failure of its elements.

Important! Despite the widespread belief that simplicity is the key to reliability, the number of circuits of a heating unit does not in any way affect its lifespan.

Check out the Review of wall-mounted gas boilers https://oteple.com/obzory-nastennyx-gazovyx-kotlov/

Do you want to know how to install a wall-mounted gas boiler with your own hands?

Gas boiler Buderus 60 kW power and reliability

What determines the duration of work?

The service life of gas boilers is directly related to the model brand, correct installation and maintenance. Each boiler manufacturer sets a warranty period for equipment, which is determined by its technical characteristics, which affects the extension of life.

As practical data shows, the service life of Western assemblies is longer, followed by Russian and Korean units, and only then Chinese ones.

Boiler brand

Boiler units up to 24 kW in the price group from 40-60 thousand rubles. characterized by the highest service life from 12 to 18 years.

These include modifications from German companies: Vaillant, Viessmann Group and Buderus, Japanese Rinnai, French De Dietrich. Such devices use the best cast iron alloys, and the components are made using the latest innovative technologies.

The standard or manufacturer-declared operating life is calculated from the date of installation and first start-up of the equipment.

Boiler service life, from well-known boiler equipment companies

- AOGV, Russia, 10 years.

- Ariston, Italy, 8-10 years old.

- Baxi, Italy, 12-15 years old.

- Bosch, Germany, 12 years.

- Vaillant, Germany, 10-15 years.

- Viessmann Group, Germany, 15-20 years.

- Lemax, Russia, 11-14 years old.

- Navien, South Korea, 10 years old.

- Protherm, Slovakia, 10-12 years.

- Rinnai, Japan, 10-12 years old.

Incorrect boiler selection

An incorrectly selected boiler is the root cause of low service life and one of the very common mistakes of an uninformed buyer. Many of them believe that the more power, the better. In relation to energy equipment, this is not correct.

Excess power changes the temperature regime of heating in heating networks, due to which aggressive condensate appears on the walls of the firebox and pipes, which activates corrosion processes. The service life of such equipment decreases significantly.

In addition, moisture combines with soot in the flue gases to form tar and tar deposits that cover the heating surfaces of the boiler. The efficiency of such an installation decreases, as does the quality of heating, and the cost of heating also increases due to excessive fuel consumption. It is very difficult to clean such a unit, and sometimes you have to do it every week.

Heat exchanger material

This parameter is the main one in determining the service life; it is on this basis that manufacturers set warranty periods.

The most popular and inexpensive is a steel heat exchanger. Typically its wall thickness is 3-5 mm. Even with ideal water quality and proper maintenance, such a gas boiler will not be able to operate for more than 10 years. In fact, the probability of a heat exchanger burning out is much less, after about 5-8 years.

The cast iron heat exchanger is made with thicker walls; the metal is heat-resistant and resistant to corrosion processes.

The potential service life of such metal is up to 50 years. Although copper differs from steel in its anti-corrosion qualities, it also suffers from low service life due to the possibility of burning out.

Gas burner type

In domestic boiler installations, two types of burners are used: atmospheric and inflatable. Atmospheric, which are installed in units with natural flue exhaust in open fireboxes. These burners take combustion air directly from the room in which they are located.

Such a smoke exhaust system is structurally very complex, its operation is not stable and depends on many factors, for example, on the speed of the wind, which can clog the smoke exit from the chimney.

The poor quality of the chimney exhaust leads to the accumulation of soot in it, which further reduces the speed of the flue gases and violates the design temperature regime of the boiler, leading to premature burnout of its structural elements.

Inflatable or turbocharged burners are installed in modern closed-type devices with a coaxial chimney and do not have these disadvantages.

The speed of movement in the unit is set by a fan, air is taken from outside the room through the outer channel of the coaxial pipe, and flue gases are emitted into the atmosphere through the inner channel.

The operation of such a fan can be modulated to suit different boiler outputs from 30 to 100%, which significantly extends the service life.

Operation errors

Poor quality maintenance of boiler equipment can reduce its service life to almost zero; for example, if you feed the boiler with dirty water, it will not work without accidents for even a week.

Manufacturers of boilers who provide equipment with long service life require cleaning of the coolant: from mechanical type to softening systems.

Many began to equip units with factory cleaning systems. Those that do not have water purification systems, according to the manufacturers' requirements, must be periodically washed to remove scale deposits, according to the technology indicated in the technical documentation.

The following violations of operating rules also lead to premature wear of boiler equipment:

- high air humidity in the combustion chamber;

- negative internal air temperatures;

- violation of the rules for cleaning heating surfaces from soot and scale;

- replacement of factory equipment with homemade equipment;

- violations of hydraulic operating conditions in the heating system, including airing.

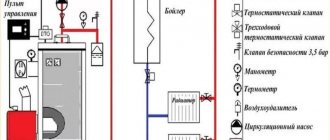

Mistakes made during installation

Low-quality installation of boiler units will lead to the fact that it will not be able to operate at stable conditions. In this case, air can collect inside the heat exchanger, and dust can be deposited on the surfaces of the burner device, which leads to a high level of wear.

A frequent root cause of unit malfunctions is considered to be incorrect installation of batteries and other elements of the heating network:

- If the batteries are installed with a counter-slope, air collects in them, which causes corrosion of the internal heating surfaces, both in the heating network and in the boiler.

- An incorrectly installed air vent will not perform its functions, the coolant will not circulate in the operating hydraulic mode, disrupting the temperature regime of the boiler and overheating the heating surfaces.

- Incorrect slopes in the natural chimney system will contribute to soot deposits in the internal channels, a decrease in the size of their cross-section, a drop in the aerodynamic speed of the flue gases, which will contribute to overheating of the firebox and heat exchanger, as well as the possible release of carbon monoxide into the room.

Installation method

There is a direct relationship between the service life and the type of gas heat generator, which can be floor-mounted or wall-mounted.

- Floor-standing, more monumental and powerful. Their construction uses materials that are resistant to high pressure and temperature.

For heat exchangers of floor-standing boilers, steel and cast iron are used, which have high strength characteristics.

- Mounted (wall-mounted) – lighter and more compact. The small dimensions and weight of the device are due to the heat exchanger material.

- As a rule, wall-mounted boilers use a copper heat exchanger, which, due to its high heat transfer, has smaller dimensions and weight. But copper is fragile and susceptible to corrosion, which leads to fairly rapid failure of the heat exchanger, especially with irregular maintenance.

You should know that steel heat exchangers, like copper ones, are susceptible to corrosion. That is why most of the leading manufacturers in this market segment use high-quality stainless steel to produce steel heat exchangers. Cast iron coils are not susceptible to corrosion, but are very sensitive to pressure changes. Both factors affect the lifespan of the boiler.

What do you pay attention to when choosing

The choice of boiler unit is made independently by the buyer, so you need to know what the service life depends on. For gas units, it is initially interconnected with design features and correctly selected power.

A lack of thermal power leads to an increase in the load on the heat exchanger, burner device and circulation pump.

Excessive power is considered no less problematic. It triggers the clocking process of the automatic boiler, when it begins to quickly turn on/off. In practice, it has been proven that unsteady conditions cause increased wear.

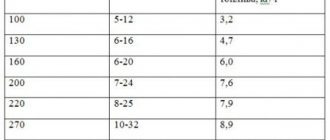

Therefore, it is important to correctly determine the thermal power of the boiler before purchasing. For this, a practical ratio is used: for 10 m2 of heated area, take 1 kW of power and take a power reserve of 10-15%.

For example, to heat a house with a heated area of 200 m2, you will need a unit with thermal power:

200/10Х1.15= 23 kW

Boiler installation price category

As a rule, the retail price of a boiler is one of the indicators of its reliability. Condensing heating systems belong to the most expensive category of heating equipment.

With proper operation and regular maintenance, the declared life of such units is 30 years. This is due to the use of high-quality materials, which are necessary when obtaining thermal energy from combustible fuel and condensate.

Convection boiler equipment usually falls into the middle price category. The average lifespan of installations of this type declared by the manufacturer varies from 10 to 15 years. In convection heat generators, thermal energy is obtained exclusively through gas combustion, which leads to higher temperature loads on materials.

…

Steam models

This category of boilers is designed to generate steam. Most plants that use steam in the process require high pressure. Therefore, the performance of such equipment consists of temperature and pressure indicators. For the most part, gas industrial steam boilers are units that, through fire tube structures, generate steam with a productivity of at least 0.25 t/h. Depending on the requirements of the enterprise, you can choose models with higher power. As a rule, the maximum reaches 55 t/h. Pressure indicators, in turn, can be up to 30 bar, and temperature conditions can be up to 300 ºС. Modern models are distinguished by their ability to operate on various types of liquid and gaseous fuels. When choosing, it would not be amiss to take into account additional equipment in the form of deaeration devices, dispensers and bubblers.

If the system fails

The set of devices is a single security system, and the blocking function is directly performed by several sensors. The most dangerous option is the spontaneous extinguishing of the burners and igniter, which can provoke an accumulation of gas in the room, and therefore the danger of an explosion is high.

If for some reason the sensors do not work, then in this situation your actions are clear - stop the gas supply manually, i.e. close the valve. To find the cause of the failure and quickly resolve it, contact gas services. This is not an option when you can “try” to solve the problem yourself - the risks are too great! The intervention of a specialist is not even discussed!

Maintainability of the heat exchanger

As noted above, the heat exchangers of modern gas boilers are made of: copper, stainless steel, cast iron. According to reviews, under the right operating conditions, the service life of a steel heat exchanger in a gas boiler is 15-20 years, and a cast iron one up to 30 years. The life of a copper coil is limited to 5-10 years.

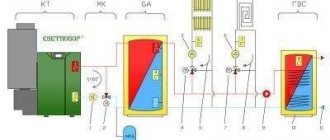

In single-circuit heating heat generators, one coil is installed, which transfers the thermal energy obtained from fuel combustion to the coolant. Depending on the design, two-circuit boilers can have two heat exchangers (primary and secondary) or one bithermic.

- In the first option, the primary coil is responsible for heating the coolant and is installed in the upper part of the boiler installation (above the burner). The secondary one is responsible for creating the hot water supply.

- Bithermic has a “tube-in-tube” design. The coolant for the heating system moves in the space between the outer and inner tubes; Water flows through the inner tube of the heat exchanger to provide hot water supply.

Any heat exchanger is susceptible to scale formation. This is especially true for devices through which hard tap water circulates. The separate coil can simply be washed or the damaged section replaced.

In a bimetric heat exchanger, scale forms much faster than its separate counterpart. Deposits that appear in the inner tube of such a device are almost impossible to eliminate. Heat transfer will gradually decrease, which means that in order to maintain the desired water temperature, it will be necessary to increase the volume of fuel burned. Constant operation of the boiler unit in this mode will significantly reduce its service life.

It should be understood that repairing a bithermal heat exchanger is practically impossible; a complete replacement of the entire module is required. And this is a rather expensive process that can cost up to 50% of the initial cost of the heating installation.

We recommend watching the video.

In it, a manufacturer’s representative talks about the types and varieties of heat exchangers used in boiler systems

Type of gas burner device

In a gas boiler, thermal energy is obtained by burning fuel. To create and burn a gas-air mixture, a burner is used, which can have two versions:

- Atmospheric.

- Burner with forced air.

In the first type of device, the formation of a mixture of air and gas is carried out naturally through draft.

In the chamber of an atmospheric boiler, gas combustion does not occur completely: combustion products remain on the air duct, electrodes, and heat exchanger, which reduce the efficiency of heating the coolant. Thus, a boiler unit with an atmospheric burner operates under a higher load, which significantly reduces its service life.

The design of pressurized burners provides for the presence of two chambers: in the first, air and fuel are mixed; in the second, the direct process of combustion of the mixture occurs.

In turbocharged boilers (equipped with forced-air burners), the fuel burns completely, which increases efficiency and reduces the load on the unit. This fact gives us the right to conclude that turbocharged boilers have a slightly longer service life compared to their atmospheric counterparts.

Which brand of geyser is better?

It is difficult to give a definite answer to the question of which geyser is best to buy. The favorites among manufacturers are Mora Top and Vaillant. They use the most durable materials available to create the most durable speakers. If you have broad financial opportunities, it is recommended to give preference to the models of these companies, since their devices provide maximum safety.

Modern domestic speakers (Neva, Ladogaz) are designed taking into account the needs of users from the CIS. They are often equipped with additional filters and scale protection, since they have to interact with hard water. The absence of additional costs resulting from transportation reduces the cost. A low price is not a sign of poor quality, since domestic companies try to produce universal devices suitable for most users.

Before purchasing, it is recommended to further read other indicators, speaker reviews and customer reviews. Each manufacturer has unsuccessful and good models in their line. The best geyser should cope with the available water pressure, provide the required temperature and have a long service life.

Other tips

The living room with the kitchen can be combined and decorated with various shortcomings

It is important to calculate and anticipate everything in advance. Decorators and craftsmen share tips that will help avoid problems during repairs and furnishings: The result depends on how detailed the project is drawn up.

Oddly enough, it is worth taking into account the growth of loved ones and relatives. It is also recommended to calculate the approximate number of possible guests. You can get rid of food smells by installing a strong hood or ventilation system.

The result depends on how detailed the project is drawn up. Oddly enough, it is worth taking into account the growth of loved ones and relatives. It is also recommended to calculate the approximate number of possible guests. You can get rid of food smells by installing a strong hood or ventilation system.

Small models are more suitable for housewives who do little cooking

If you plan to have a sleeping place in the living room, then it is important that the ringing of appliances and other kitchen utensils is not heard. Silent dishwashers and other appliances will come in handy

In addition, you can install a sliding door and install a soundproof partition. If there is sensitivity to ultraviolet radiation, the owners hang thick curtains made of light-proof fabric. If household appliances do not match the direction of the interior, they are hidden behind furniture or put away in kitchen cabinets. When installing luminaires and lamps, they are guided by several criteria

It is important that the light falls evenly throughout the entire space. Especially bright lighting is preferable in the kitchen area and where the dining table is installed. In the living room, designers create a subdued atmosphere using wall sconces and table lamps.

Multi-level stretch ceilings with LED strip also look good in this room. Moisture-resistant finishing materials are more durable and easy to clean. Thus, they retain their appearance for a long time. The kitchen combined with the living room combines:

In the living room, designers create a subdued atmosphere using wall sconces and table lamps. Multi-level stretch ceilings with LED strip also look good in this room. Moisture-resistant finishing materials are more durable and easy to clean. Thus, they retain their appearance for a long time. The kitchen combined with the living room combines:

- personal tastes of the owners;

- reliable finishing materials;

- current design ideas;

- convenience;

- trends. The best photos of kitchen living room design

About execution and isolation

Industrial gas heating boilers are usually horizontal. To maximize heat retention inside, the surface of the combustion chamber is insulated with insulating material from the outer walls. The layer retains heat and protects the outer walls from overheating. This helps prevent burns from contact with heating equipment.

Replacing a gas boiler in a private house - documents you will need

Boiler maintenance, as well as its installation, is carried out only by specialized employees of government agencies, for example Gorgaz

Gas boiler AOGV and AGV are a responsible and important part of housing, therefore only the relevant authorities have the right to replace them, and then with the knowledge of the authorities

To replace a boiler in a private home, you will need to draw up some documents that will need to be submitted to government authorities so that the new device can be legalized. This procedure must be followed so that there are no problems with the relevant authorities later. The owner will be able to collect all the documents independently or seek help from a special specialized organization.

Required documents:

- Certificate that meets all safety standards;

- DVK inspection report;

- Technical data sheet and instructions for the boiler;

- A contract that will provide a service guarantee for 1 year;

- The project and the changes made to it.

Having all these documents in hand, you can go to the city gas department for permission. Your project must be approved, and only then proceed to replacing the boiler. While you wait for permission, you can choose a suitable model that will meet all your requirements and ensure uninterrupted heating operation.

Checking the tightness of gas channels

After installing the water heater, you need to check the gas pipes for leaks. If you have a gas analyzer, this greatly simplifies the procedure and improves the quality of the test. If this device is missing, then you can use the old method.

To do this you will need regular soap, a jar and a brush. The soap is dissolved in the jar to form a liquid emulsion. Next, using a brush, the emulsion is applied sequentially to the pipe joints. As you apply, you need to monitor the appearance of bubbles in the treated areas. If they appear, the leak must be eliminated.

Before testing for leaks, you must take the necessary safety precautions. Be sure to turn off all electrical appliances

Under no circumstances should you check for gas leaks using fire. This is dangerous and may cause an explosion. There is no point in risking your life and the lives of your neighbors.

Gas equipment requires regular inspection and periodic cleaning. You can clean the dispenser yourself, but if you have no experience at all in servicing such systems, it is better to contact a company that has entered into an agreement with you for the supply of gaseous fuel and maintenance of the devices involved.

How to prevent explosion of gas equipment?

To protect your home and prevent emergencies, it is recommended to purchase gas equipment in specialized stores.

All technical devices, including geysers, are certified by Gosstandart of Russia. Without this permit, gas appliances are not allowed for domestic use.

In a specialized store, when purchasing, you are required to provide a “certificate of conformity”. If the equipment is not of domestic production, it is worth asking whether the dispenser has been tested and certified in Russia. Take a look at the technical data sheet of the wall-mounted gas boiler and see what security systems it is equipped with.

Purchasing a instantaneous gas water heater at specialized outlets is a guarantee of quality. In addition, you can subsequently contact the center in case of a malfunction of the device and the need to replace it if a manufacturing defect is detected.

To prevent breakdowns, it is recommended that gas workers inspect the device annually. You should also study the instructions for the purchased device, which indicate under what conditions the device can operate and how to operate it correctly. The connection should be trusted only to specialists from the gas service with which the contract has been concluded.

Components and parts must be regularly cleaned of soot and debris. If problems are observed during ignition or malfunctions are detected (the column slams), call a specialist. Any technique, even potentially dangerous, if used correctly and constantly monitored for functionality, will not cause trouble or lead to dire consequences.