From the author: Hello, dear readers! If you need a table showing the volume of water in a heating radiator, then most likely you live in a private house. Residents of apartment buildings rarely need this information, since they cannot in any way influence the level of battery filling - and this, in fact, is of no use, since the relevant organization is in charge of everything. The only knowledge you need in this case is the level of pressure that a particular radiator can withstand. You can get this information from the corresponding article on our portal.

As for private houses, the picture is different. An autonomous heating system, its creation, maintenance - all this depends solely on the owners of the home. In this matter, every detail is important: the material of the pipes, the power of the heating boiler, the type of radiator and much more. All this must be taken into account when arranging the heating system.

And not the least factor is how much coolant you need to fill it. A lot depends on this:

- weight of a filled radiator. For example, this point is very relevant for cast iron batteries. They themselves are not distinguished by low mass, and when filled with coolant they become even heavier. Considering that the batteries are hung on the wall, you can understand that their weight should be treated with some care,

- calculation of the power of the heating boiler and circulation pump. Naturally, these indicators depend on how much coolant the equipment will have to work with. Roughly speaking, if the boiler is designed for 50 liters, and you put a hundred liters into the system, then to heat such a volume the device will have to work hard, which will lead to its rapid failure and poor heating of all elements of the heating system,

- selection of radiator size. To do this, you need to take into account what type of circulation will be used in your heating system. In the case of a natural radiator, it must be large and, accordingly, contain a considerable amount of liquid. In the case of forced circulation, you can not pay much attention to the size of the batteries, since the pump will successfully deliver the coolant to all final targets, maintaining the required heating level,

- working with antifreeze. This composition is often used to fill the heating system. There is a lot of information on our portal about the advantages of this approach, and if necessary, you can easily find it. Let us remind you of this: to fill the system, antifreeze must be diluted with water. Naturally, for this you will need to know exactly how much of the finished coolant will go into the system. Firstly, this way you can purchase exactly the right amount of antifreeze. Secondly, you can properly dilute it with water so that the concentration is at the proper level,

- selection of expansion tank. It is clear that its volume also depends on the total amount of liquid in the heating system.

Naturally, for all this you need to take into account how much coolant is needed to fill each element of the heating system: the heating boiler, pipes and radiators. In principle, you can take any necessary technical indicators from the documentation that comes with all these elements.

How much water is in one section of an aluminum radiator, methods for calculating volume

Nowadays, replacing old cast-iron batteries with new models has become not a tribute to fashion, but a vital necessity. Concern for the safety of the heating system and attempts to reduce the cost of utilities have led to more and more consumers choosing aluminum radiators, which differ from other types of heaters in both technical characteristics and price. One of the important parameters is the volume of the heating radiator.

Parameters of aluminum radiators

The technical characteristics of heating batteries are the first thing a consumer pays attention to before purchasing. The most important indicators of a truly high-quality product are:

- The level of heat transfer of one section, since it depends on:

- First, how many elements are needed to heat one room.

- Secondly, how warm the room will be thanks to the radiator.

- Thirdly, what will the microclimate in the room be like?

- Resistance to water hammer and operating pressure of an aluminum radiator.

- Cost of the finished product.

The volume of one section of an aluminum radiator indicates its power and largely depends on how it was manufactured.

If the aluminum battery was made by pressing, then its parts were connected using glue, which makes it vulnerable. Such a radiator is not afraid of corrosion, but increased pressure can damage it.

The capacity of one section of an aluminum radiator, regardless of the method by which it was produced, is almost the same, but the fact that the cast model is stronger and more durable, heats up faster and can be adjusted in size puts them in first place in sales.

Types of coolants

As a rule, the question of what coolant is used in a centralized heating system is not asked, since water always flows through the heating pipe there. Another thing is autonomous heating, where you can choose the best option for a particular house, taking into account the climate of the region where it is built.

Why is radiator volume important?

Calculating how many liters are in one section of an aluminum radiator is important for several reasons:

Considering how many factors are affected by the volume of heating batteries, this parameter should be taken into account when choosing aluminum products.

Calculation of the volume of an aluminum radiator

There are two ways to determine the capacity of a heating battery:

This, although a very labor-intensive method, is the most reliable and accurate, since manufacturers can overestimate or underestimate the parameters of their products in the technical documentation.

When choosing the type of radiator, you should pay attention to the difference in the parameters of domestic and foreign manufacturers. Some indicators may look very attractive, but are not suitable for the centralized Soviet heating system

You also need to think in advance which coolant in the network will be used, and make calculations indicating its viscosity.

To summarize, we can say that the volume of an aluminum radiator is an important parameter that must be taken into account in order for the system to work truly efficiently in the future.

Types of coolants

- Water . The simplest and most accessible resource. Can be used in any heating systems. In combination with polypropylene pipes - an almost eternal coolant.

- Antifreeze . Used to fill systems of irregularly heated buildings.

- Liquids containing alcohol . An expensive option for filling the heating system. High-quality preparations contain at least 60% alcohol, about 30% water, and part of the volume is occupied by other additives. Mixtures of water with ethyl alcohol with different percentages. Non-freezing liquid (down to -30°C with an alcohol content of at least 45%), but dangerous: it can burn, ethyl itself is poisonous for humans.

- Oil . As a coolant today it is used in individual heating devices, but in heating systems it is abandoned: it is expensive and difficult to operate the system, technologically dangerous (long heating of the coolant to a temperature of 120°C and above is required). The advantage is that it really takes a long time to cool down, maintaining the temperature in the room, but the main disadvantage is the high cost of the coolant.

Low batteries

Radiators with a small center distance have the following advantages:

- they can be placed under a low window sill;

- they have maximum heat transfer per unit area.

Cast iron radiators

.

The dimensions of the MS-140M-300-0.9 heating radiator sections are:

- length 93 millimeters;

- depth - 140 millimeters;

- height – 388 millimeters.

Due to their smaller dimensions, the heat transfer of cast iron heating radiators is reduced - it is equal to 106 watts from one section at an operating pressure of 9 kgf/cm². Among foreign analogues, there are cast iron products with an interaxal distance along the connections equal to 200 and 350 millimeters; the power of a section of a cast iron radiator of this type is much higher.

Aluminum radiators

. For low batteries made of aluminum, both domestic and imported, the spread of the center distances is quite large. You can find radiator sizes of 150, 300 and even 450 millimeters. Since the possible section length starts from 40 millimeters, the device looks compact and unusual. Low aluminum heating radiators have height dimensions starting from 200 millimeters. The depth of many models compensates for the lack of the other two parameters and is 180 millimeters.

As for thermal power, it varies from a minimum of 50 watts per section to a maximum of 160 watts. The determining factor is the fin area of one section. At the same time, the change in dimensions does not significantly affect the operating pressure - low aluminum devices are designed for 16 atmospheres, and when testing - 24 atmospheres. Bimetallic radiators

. All the sizes of heating radiators that they have are also typical for aluminum heating devices. Thermal power is within the same limits. On sale you can find aluminum low radiators with heat output of 80 and 140 watts per section. The working pressure is 25-35 atmospheres.

Bimetallic low radiators, such as in the photo, have two nuances:

- among heating devices there are batteries not with solid steel cores, but with steel tubes placed between aluminum collectors. Their operating pressure, indicated by manufacturers, is usually 12 or 16 atmospheres;

- they often do not have vertically located channels and, in the case of a lateral connection, can be heated by the collectors due to the thermal conductivity of aluminum. The circulation of the coolant is ensured by the last section, since it is flow-through.

Steel panel radiator type 22: technical characteristics

Today, manufacturers of panel heating structures offer the following types of models:

- No. 10 has only one panel and lacks a convector and cladding.

- Type 11 has one panel and one heat exchanger.

- The steel radiator type 22 is in greatest demand among the population. Its characteristics indicate that it has two panels and two convectors. This is a more harmonious combination, since the product is obtained with high heat transfer, affordable price and low weight.

- Type 33 radiators are equipped with three heat exchangers attached to three panels. This is the most powerful and expensive type of steel panel radiators.

To quickly navigate the marking of steel products, you should remember that the first number in the number indicates the number of panels, and the second – convectors.

Panel radiator type 22 is considered the optimal choice for the following parameters:

- Their power varies from 576 W to 4115 W. This run-up is directly related to the height and length of the panels.

- The steel radiator type 22 can withstand operating pressure from 6 to 10 at a test pressure of 12 atmospheres. Although heating structures made of steel are quite strong, they are best used in closed autonomous systems. If you need to connect to a centralized heating system, you need to calculate the power of the panels in advance and purchase a device taking it into account. This disadvantage can be compensated if the thermal output of steel radiators type 22 is controlled by a pressure reducer.

- Steel panel heaters are easy to install.

- The maximum length of these radiators (3000 mm) allows them to be used even if there is a large window in the room.

- For each room separately, you can purchase a heater that matches its area.

- The service life of steel radiators from foreign and domestic manufacturers is 10 years, but this is not the limit if all the nuances of operation are observed. For example, the purity and pH of the carrier plays an important role in their quality and durability. If you install filters, then steel heating radiators type 22 (the characteristics confirm this) will give off their heat longer than stated in the data sheet.

Even if you take the smallest size of steel radiators of this type, you can see how different their power ratings are. For example, with a height of 300 mm and a length of 400 mm, it will be 576 W, while for a product of the same length, but with a height of 500 mm, it will be 823 W.

Steel radiator 22 type 500x1000 mm has a power of 2057 W. These indicators are not the same for different manufacturers.

The volume of water in an aluminum, cast iron, bimetallic heating radiator

There are many reasons why you may need to know the volume of water in a heating radiator. The easiest way is to look at the specifications, instructions or other documentation for the product. But what to do if it is not there?

From this article you will learn how many liters of water are in one section of a heating radiator, depending on its model and dimensions. We will also tell you how to calculate this indicator for non-standard models.

How much water is in one section of a cast iron radiator?

Cast iron batteries differ in section height, depth, power and weight. For example, the MC 140-500 model has a height of 50 mm and a depth of 140 mm. Basically, the volume of water in the cast iron section of the radiator is affected by its height.

The most common is the MS series. Depending on the manufacturer, the volume of coolant may vary, so there is a slight scatter.

Volume of one section of the MS brand (in liters)

- MS 140-300 – 0.8-1.3,

- MS 140-500 – 1.3-1.8,

- MS-140 – 1.1-1.4,

- MS 90-500 – 0.9-1.2,

- MS 100-500 – 0.9-1.2,

- MS 110-500 – 1-1.4.

Cast iron batteries of the ChM series are very popular. The model marking indicates the number of channels, height and depth of the section. For example, ChM2-100-300 has a height of 300 mm, a depth of 100 mm, and water circulates in it through two channels.

Volume of water in one section of the ChM brand (in liters)

- World Cup1-70-300 – 0.66,

- World Cup1-70-500 – 0.9,

- World Championship2-100-300 – 0.7,

- World Championship2-100-500 – 0.95,

- World Championship3-120-300 – 0.95,

- World Championship3-120-500 – 1.38.

Water volume in one section of an aluminum radiator

There are dozens of manufacturers of aluminum heating radiators, the products of each of them differ in the design and size of the internal channels. Therefore, we can only approximately say how much water is in one section of an aluminum radiator.

The main difference between the models is in height, so here is a list of the most common sizes (data are given in liters):

- 350 mm – 0.2-0.3,

- 500 mm – 0.35-0.45,

- 600 mm – 0.4-0.5,

- 900 mm – 0.6-0.8,

- 1200 mm – 0.8-1.

For non-standard sizes, you can use the formula (V – volume in liters, h – height in meters):

V = hx 0.8

The result will be approximate, but if you don’t have the equipment specifications at hand, you can use the obtained value. This way you can determine how much water is in one fin of an aluminum battery with an error of no more than 20%.

Please note that the capacity of an aluminum heating radiator may decrease over time due to corrosion. It is formed due to water with poor alkalinity or acidity. Also, the volume of liquid in an aluminum radiator may be reduced due to silting.

How much water is in one section of a bimetallic radiator

As with aluminum, there are many options for manufacturers and brands of bimetallic radiators. Their structure, appearance, and channel diameters differ in the same way.

The volume of water in a bimetallic radiator depends on its height and is (in liters):

- 35 cm – 0.1-0.15,

- 50 cm – 0.2-0.3,

- 60 cm – 0.25-0.35,

- 90 cm – 0.3-0.5,

- 120 cm – 0.4-0.6.

To calculate the volume of a section of a bimetallic radiator of non-standard height, use the formula (V – volume in liters, h – height in meters):

V = hx 0.35

This will give you an approximate value, which may vary within 20%.

How to calculate consumption

The value represents the amount of coolant in kilograms that is consumed per second. It is used to transfer temperature to the room through radiators. To calculate, you need to know the boiler consumption, which is spent on heating one liter of water.

Formula:

G = N / Q, where:

- N - boiler power, W.

- Q—heat, J/kg.

The value is converted to kg/hour, multiplied by 3600.

Formula for calculating the required volume of liquid

Refilling of pipes is required after repair or reconstruction of the piping. To do this, find the amount of water needed by the system.

Usually it is enough to collect your passport data and add it up. But you can also find it manually. To do this, consider the length and cross-section of the pipes.

The numbers are multiplied and added to the batteries. The volume of radiator sections is:

- Aluminum, steel or alloy - 0.45 l.

- Cast iron - 1.45 l.

There is also a formula that can be used to approximately determine the total amount of water in the harness:

V = N * VkW, where:

- N - boiler power, W.

- VkW is the volume that is sufficient to transfer one kilowatt of heat, dm3.

This allows you to calculate only an approximate number, so it is better to check the documents.

To get a complete picture, you also need to calculate the volume of water held by other components of the piping: expansion tank, pump, etc.

Attention! The tank is especially important: it compensates for the pressure that increases due to the expansion of the liquid when heated. First of all, you need to decide on the substance used:

First of all, you need to decide on the substance used:

- water has an expansion coefficient of 4%;

- ethylene glycol - 4.5%;

- other fluids are used less frequently, so the data should be looked up in a reference table.

Formula for calculation:

V = (Vs * E)/D, where:

- E is the expansion coefficient of the liquid as stated above.

- Vs is the estimated flow rate of the entire piping, m3.

- D is the efficiency of the tank, indicated in the device passport.

Having found these values, they need to be summed. Typically, four volume indicators are obtained: pipes, radiators, heater and tank.

Using the data obtained, you can create a heating system and fill it with water. The filling process depends on the scheme:

- “Gravity flow” is performed from the highest point of the pipeline: a funnel is inserted and liquid is released. This is done slowly and evenly. First, open the tap below and place the container. This helps avoid the formation of air pockets. Used if there is no forced current.

- Forced - requires a pump. Any one will do, although it is better to use a circulation one, which is then used for heating. During the process, you need to take readings from the pressure gauge to avoid increasing pressure. And also be sure to open the air valves, which helps with the release of gas.

How to calculate the minimum coolant flow

They are also calculated as the liquid consumption per hour for heating the premises.

It is found during the break between heating seasons as a number that depends on the hot water supply. There are two formulas used in the calculations.

If there is no forced circulation of hot water in the system, or it is turned off due to frequency of operation, then the calculation is performed taking into account the average flow rate:

Gmin = $ * Qgr / [(Tp - Tob3)*C], where:

Qgsr is the average value of heat that the system transfers per hour of operation during the non-heating season, J.

$ is the coefficient of change in water consumption in summer and winter. It is taken to be equal to 0.8 or 1.0, respectively.

Tp - supply temperature.

Tob3 - in the return when the heater is connected in parallel.

C is the heat capacity of water, taken equal to 10-3, J/°C.

Temperatures are taken equal to 70 and 30 degrees Celsius, respectively.

If there is forced DHW circulation or taking into account water heating at night:

Gmin = Qtsg / [(Tp - Tob6)*C], where:

Qtsg is the heat consumption for heating the liquid, J.

The value of this indicator is taken equal to (Ktp * Qgsr) / (1 + Ktp), where Ktp is the coefficient of heat loss by pipes, and Qgsr is the average power consumption for water per hour.

Tp - supply temperature.

Tob6 - return measured after the boiler circulating liquid through the system. It is equal to five plus the minimum allowable at the point of water collection.

Experts take the numerical value of the coefficient Ktpiz from the following table:

| Types of DHW systems | Loss of water by coolant | |

| Taking into account heating networks | Without them | |

| With insulated risers | 0,15 | 0,1 |

| Insulated and with towel rails | 0,25 | 0,2 |

| Without insulation, but with dryers | 0,35 | 0,3 |

Important! The calculation of the minimum flow rate can be found in more detail in building codes and regulations 2.04.01—85

Storage and wear processes

In order to reduce the risk of deterioration of battery performance during long-term storage, you must adhere to the following rules:

- do not allow complete discharge;

- storage temperature is not lower than -20 °C and not higher than +30 °C;

- charge annually for 48 hours;

- The battery surface must be clean to avoid self-discharge.

The main processes that destroy a lead-acid battery:

- Sulfation is the formation of crystals of lead salts. They are deposited on the plates and prevent the normal passage of current.

- Corrosion is an oxidative process that destroys the lead electrodes of a battery.

- Shedding - the active mass in the cells of the positive electrodes loses normal adhesion to the base and falls off.

- Adhesion defects also lead to the sliding of the powdery contents of the conductive plates.

Failed batteries cannot be repaired and must be recycled. Vapors of heavy metals can cause serious harm to humans and the environment, so artisanal smelting of lead from batteries is life-threatening.

Answers from experts

Chairman:

5 square meters

Verik:

cast iron heats, and aluminum transfers heat to the water in the radiator.. 350 mm is a stretch of 8 squares

Truculentus:

The passport for the radiator indicates the thermal power of one section of the radiator (for sectional batteries) or the same indicator of the entire radiator. This indicator differs for different manufacturers.

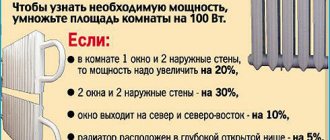

In practice, an approximate calculation is usually used, based on the fact that for heating 10 sq.m. a normally insulated room with a ceiling height of up to 3 m requires 1 kW of thermal power (100 W/sq.m). For corner rooms (2 external walls), rooms with large windows (or several windows), the obtained value is increased by 20-25%.

Grandfather Au:

look at how many watts it is according to the instructions, divide by 100, multiply by 0.8 and you will get square meters (the same with any radiator)

Vladimir Petrov:

As I understand it, 350 is the interaxial distance and how many sections there are. Look on the Internet in the section. There are a bunch of batteries there, you can take their power rating data. And then consider about 150 watts per square meter. I have about 14 square meters on the terrace at my dacha. m there are two batteries of 12 sections 350mm. I took it with a reserve. The windows are large, 2400 x 140, two of them; I have a winter garden there. It's even hotter when it's minus 25 outside.

Pretzel:

For 10 square meters of a house there is approximately 1 watt. at 24, respectively, 2.4 watts. One section is approximately 150-200 watts. Approximately 12-15 sections are needed. I have a house of 120 square meters, sections 5+5+5+10+5 = 30 second floor and 7+5+5+5=22 + warm floor first floor

Truculentus:

To heat a typical room in a 1 m³ panel house, 0.041 kW of thermal energy is required. To heat a room in a brick house with wall insulation (mineral wool, foam plastic) and installed double-glazed windows on 1 m³, 0.034 kW of thermal energy is required. A double-glazed window will reduce heat loss by 15-20%; accordingly, the number of sections can be reduced. If the room is corner, then heat loss will be approximately 20% greater. For premises built in accordance with the latest building regulations, 0.020 kW of thermal energy is required per 1 m³. Any radiator has information about the thermal power on the packaging or in the included insert.

Frosya Burlakova:

You can approximately determine how many radiator sections are needed if you multiply the area of the room by 100 and divide by the heat transfer of the section (according to the passport) in W. It should be remembered that the obtained value is approximate and a number of factors are not taken into account (heat losses of the room, heating network parameters and types of radiator connections). 15 approximately

uncle Ivan:

At least 14, and it is better to install two blocks of 8 sections.

Andrey:

There is not enough data for a correct answer. Please indicate: 1. the difference in temperature between your comfortable temperature and the minimum winter temperature for your region. 2. the amount of heat loss from the surfaces of the heated room 3. the rate of air exchange from the room to the street and adjacent rooms 4. Connection diagram for radiators. 5. how many windows are there in the room? 6. Estimated temperature of the supply and return pipelines. 7. circulation speed and coolant type. 8. Thermal power of the section declared by the manufacturer and at what temperature conditions. 9. You can also add pressure in the system, but this is nitpicking since the effect on heat transfer is insignificant. We are waiting for the data and will immediately issue an accurate answer.

MurYska:

oh wow, what sophisticated answers)))))) we thought so for 2 square meters 1 section, now in the apartment it’s 28-30C in the winter before the renovation it was 20-22

Grandfather Au:

per square meter you need 100 watts, especially in a panel house! DO NOT take aluminum - especially if the high-rise building breaks! and they don’t like our water very much

Smirnov Vladimir:

The required number of sections is determined by the formula: S rooms * H ceilings * window coefficient (35 - if double-glazed windows, 40 - if regular windows) / section heat transfer = number of sections. Aluminum radiators have a heat output of 190 watts

Valentina Bryzgalina:

The locksmith spoke. “What’s the point of installing many sections, if the pressure is small, it will not push through to the end. “This often happens, because (zheki, reu) have big savings on this. I changed batteries and wanted 10-12 pcs. put in a room of 18 sq. m. As a result, they installed 8 pieces, the circulation is good, it’s warm. Aluminum ones last 6 years.

Ivan Krasnoshchok:

I used the table, see the Kermi website. about (only in English letters) is very convenient and sensibly written.

Egor Lvov:

why do you want it?

Easy way

There is another way to determine the volume of coolant, which does not require the possession of any information. Everything is extremely simple. Close all the caps on the battery and fill it with water using a measuring container. At the same time, naturally, you count how much liquid got in.

At the end of the procedure, drain everything accumulated from the radiator. Of course, all these operations must be performed either in the bathroom or in the yard so as not to flood the house. Based on the obtained indicator, you can easily navigate the total volume of coolant for your heating system. Good luck!

In accordance with applicable law, the Administration disclaims any representations and warranties that may otherwise be implied and disclaims liability in relation to the Site, the Content and its use. More details: https://seberemont.ru/info/otkaz.html

Was the article helpful?

Tell your friends

Modern models of heating radiators

For mounting on walls, various manufacturers have developed new models made of gray cast iron; their weight is much less than the old classic models.

For example, let's describe the Czech heating radiator Viadrus STYL 500. How much does 1 section of this heating radiator weigh? And how much will the mass of the entire structure be? The weight of 1 section is 3.8 kg. water holds 0.8 liters, so the weight of one radiator section with water will be 4.6 kg. With a heat flux of 140 W, to heat a room of 20 m2, 14 sections will be required; the corresponding weight will be 64.4 kg with water. Thus, this figure differs by 40% less than that of the classic MS 140 sample. If this value is divided into two parts (32 kg each), then we can conclude that installation on walls made of modern materials, including porous concrete, It is quite possible to carry out without additional fasteners.

An even lighter design was developed by Russian manufacturers. Their heating devices are offered under the EXEMET brand. The MODERN model has the following weight characteristics:

One section from this manufacturer weighs 3.2 kg, heat output is 93 W. To heat a room of 20 m2 you will need 22 sections, then the total weight will be 70.4 kg. These parameters are not bad, especially considering that the company produces models with possible installation on the floor.

A few words about the vintage cast iron battery. Its weight exceeds the Soviet model, which can reach 14 kg. These heating devices look very much like the old ones that were installed in residences and estates back in the 19th century.

The EXEMET FIDELIA model weighs 12 kg, heat dissipation is 156 W, the total mass of the device for our example is simply monstrous - 154 kg. The complex issue of installation is irrelevant here, since the first and last sections are equipped with legs for placing the device on the floor.

So, in order to ensure uninterrupted service for the heating system, you cannot ignore such important indicators as the weight and volume of the battery section. Thanks to the correct calculation of the load on the fastening elements, you can count on reliable installation and long-term operation of the device.

Answers from experts

Chairman:

5 square meters

Verik:

cast iron heats, and aluminum transfers heat to the water in the radiator.. 350 mm is a stretch of 8 squares

Truculentus:

The passport for the radiator indicates the thermal power of one section of the radiator (for sectional batteries) or the same indicator of the entire radiator. This indicator differs for different manufacturers.

In practice, an approximate calculation is usually used, based on the fact that for heating 10 sq.m. a normally insulated room with a ceiling height of up to 3 m requires 1 kW of thermal power (100 W/sq.m). For corner rooms (2 external walls), rooms with large windows (or several windows), the obtained value is increased by 20-25%.

Grandfather Au:

look at how many watts it is according to the instructions, divide by 100, multiply by 0.8 and you will get square meters (the same with any radiator)

Vladimir Petrov:

As I understand it, 350 is the interaxial distance and how many sections there are. Look on the Internet in the section. There are a bunch of batteries there, you can take their power rating data. And then consider about 150 watts per square meter. I have about 14 square meters on the terrace at my dacha. m there are two batteries of 12 sections 350mm. I took it with a reserve. The windows are large, 2400 x 140, two of them; I have a winter garden there. It's even hotter when it's minus 25 outside.

vyachko:

Based on the empirical average ratio of 1 kW per 10 sq. m area, then. For example, for a room of 20 square meters. m you need a battery with a total power of 2 kW. One section of an aluminum radiator with a center distance of 500 mm at a temperature difference of 70 degrees produces 140...200 W (need to be clarified for the specific brand of radiator). For 2 kW we get somewhere around 10…14 sections.

Vyacheslav Koshelev:

and there is nothing more to answer...

BOSS:

Read SNiP heating engineering. The number of radiators depends not so much on the area, but on the heat loss of the room (on the correctness of the chosen enclosing structures: walls, floors, ceilings). Everyone protects a private house from the evil one... (from money in his pocket). If you insulated and built it correctly... then consider it as written above... if not, then refer to the calculator and SNiP.

Farit Gafuanov:

in short, one section, two squares, to be sure, take two more sections

Andrey:

Find out the rated thermal power of the section (all manufacturers indicate it for a supply of 90 degrees) divide 90 by the calculated supply temperature, you will get a reducing coeff. Using the tables, determine the approximate heat loss of one square meter of your walls and multiply by their outer area. , add the heat loss of the Windows (tabular data multiplied by the area), add the heat loss of the ceiling, depending on the type of insulation or the presence of neighbors above, they vary greatly. Add heat loss to supply and exhaust ventilation. Set up a winter regional co-off. air temperature and indoor temperature that is comfortable for you. Based on this temperature difference and the amount of heat loss in the room, you determine how many kilowatts are required to maintain this temperature, divide these kilowatts by the actual power of the section and find out the minimum number of sections. The principle is simple; The more sections and the lower their temperature, the more efficient the heating.

Irina Manaeva:

1 section for 2-3 sq. m.

Oleg Khrebtov:

I always put 1 section at 1.5m. sq. Enough even in severe frosts..

MIKA:

BOSS said everything correctly, we calculate the heat loss of the premises

Maria:

Take it with a reserve - you can tighten the valves. It wouldn’t hurt to put it in the corners either - outside corners and at the entrance for a pillow.

Gennady Skvortsov:

It’s nice to read the opinions of experts, I would like to add only about the priority location under windows and entrance doors

Pavel Pavlov:

bet the more the better... be realistic - if you are not an expert, why the hell will you calculate possible heat losses and other bullshit, it is better to proceed from what pressure you have in the pipe - how many sections it can push through. but it will be hot, turn down the heat, and this again saves gas...

What should the dimensions be?

In order for the heating radiator to give off maximum heat (in this case we are not talking about its thermal power, but about the efficiency of its operation), the dimensions must be as follows:

- The length should be more than 70-75% of the width of the window opening.

- The height should be such that there is 8-12 cm between the floor and the battery, and 6-12 cm between the window sill and it.

If the recommendations are not followed, the operation of the aluminum radiator will be accompanied by heat loss. Therefore, even if he can provide the necessary for a room with an area of 20 square meters. m 200 watts of heat, then due to incorrect dimensions there will be insufficient heat in the room. After all, part of it may be lost under the windowsill or used to heat the floor.

When the length is less than 70% of the width of the window opening, the battery will not be able to create a thermal curtain capable of blocking the movement of cold air entering through the window. The consequence of this situation will be the appearance of cold and warm zones in the room. Also, the windows will be constantly covered with steam. And even the power of the heating radiator, which is greater than the need, cannot become a “magic wand”.

Therefore, if the window is 2 m wide, then the length of the battery should be at least 1.4 m

Of course, in order to select a device with such a length, you will need to take into account sections of different heights and their heat transfer. The calculation may take a long time, but it is worth it

Aluminum radiator section power

Many people note that in the formula for calculating the number of sections, you can substitute the power of the heating radiator section that the manufacturer indicated in the technical documentation. This idea is correct when a coolant with a temperature of 100 °C circulates in the heating system and is cooled to 80 °C. The fact is that manufacturers indicate the heat transfer of the battery under the condition ΔT = 70 °C. They calculated this indicator based on the formula:

- where t1 represents the inlet coolant temperature,

- t2 is the coolant outlet temperature,

- t3 represents the room temperature of the house.

ΔT = 70 °C only when the coolant has the above temperature levels and t3 = 20 °C.

After that, they take a special plate in which the manufacturer indicated the heat transfer of the radiator at different ΔT, and look for the resulting indicator. Next to it is a correction factor. For example, for ΔT = 50 ° C it is 0.65. This figure is multiplied by the power of the radiator section. Next, the obtained result can be substituted into the formula indicated at the very beginning.

Conclusion

The correct operation and efficiency of the heating system, as well as the optimal operation of other elements of the system, depend on the accurate determination of the full volume of the heating system. The most important thing in correctly determining the volume of the heating circuit is that each heating boiler is designed for a certain volume of coolant. If the volume of the heating system is excessive, the boiler will work constantly. This will significantly reduce the service life of the heating device and entail unplanned costs. The volume of the heating circuit must be calculated correctly.

Calculation example

If you calculate how many sections of an aluminum radiator are needed for a room with an area of 20 m2 at a rate of 100 W/m2, then adjustment coefficients for heat loss should also be made:

- each window adds 0.2 kW to the indicator;

- the door “costs” 0.1 kW.

If it is assumed that the radiator will be placed under the window sill, then the correction factor will be 1.04, and the formula itself will look like this:

Q = (20 x 100 + 0.2 + 0.1) x 1.3 x 1.04 / 72 = 37.56

- the first indicator is the area of the room;

- the second is the standard number of W per m2;

- the third and fourth indicate that the room has one window and one door;

- the next indicator is the heat transfer level of the aluminum radiator in kW;

- the sixth is a correction factor regarding the location of the battery.

Everything should be divided by the heat output of one heater fin. It can be determined from the table from the manufacturer, which shows the heating coefficients of the carrier in relation to the power of the device. The average for one edge is 180 W, and the adjustment is 0.4. Thus, multiplying these numbers, it turns out that one section produces 72 W when heating water to +60 degrees.

Since rounding is done upward, the maximum number of sections in an aluminum radiator specifically for this room will be 38 fins. To improve the performance of the structure, it should be divided into 2 parts of 19 ribs each.

Find out useful information about aluminum batteries on our website:

Critical stage: calculating the capacity of the expansion tank

In order to have a clear idea of the displacement of the entire heating system, you need to know how much water is placed in the boiler heat exchanger.

You can take averages. So, on average, a wall-mounted heating boiler contains 3-6 liters of water, while a floor or parapet boiler contains 10-30 liters.

Now you can calculate the capacity of the expansion tank, which performs an important function. It compensates for the excess pressure that occurs when the coolant expands when heated.

Depending on the type of heating system, tanks are:

- closed;

- open.

For small rooms, the open type is suitable, but in large two-story cottages, closed expansion joints (membrane) are increasingly being installed.

If the tank capacity is smaller than required, the valve will release pressure too often. In this case, you have to change it, or install an additional tank in parallel.

For the formula for calculating the capacity of the expansion tank, the following indicators are needed:

- V(c) is the volume of coolant in the system;

- K is the coefficient of water expansion (the value is taken as 1.04, based on the water expansion rate of 4%);

- D is the expansion efficiency of the tank, which is calculated by the formula: (Pmax – Pb)/(Pmax+1)=D, where Pmax is the maximum permissible pressure in the system, and Pb is the pre-pumping pressure of the compensator air chamber (parameters are indicated in the documentation for the tank );

- V(b) - expansion tank capacity.

So, (V(c) x K)/D = V(b)