Warmth in housing is the basis of comfort, health and well-being. Taking into account that it takes 6 or more months to warm up, a properly thought-out heating complex also saves users’ finances. The calculator simplifies the calculation of heating radiators by area. In order to find out how to make a more correct calculation, we turned to the Miralex company, which specializes in heating and water supply systems.

Wall model Source kermi.net.ua

In private households, heating is individual, in high-rise buildings - general, but in any case, radiators form the basis. They are the ones who provide heating to the room, and energy consumption and temperature depend on their properties and quantity. The calculator allows you to calculate heating radiators by area by entering actual indicators into the fields. The counting procedure is carried out manually in simplified and detailed formats.

Types of radiators

The process of heating the air and maintaining its sufficient temperature depends on the batteries - metal, size, connection to the complex and their placement. Before calculating the number of radiator sections, you will need to find out the metal of manufacture.

Model range Source www.chipak71.ru

Indicators of various metals:

- A 350 aluminum - 138 W;

- A 500 made of aluminum - 185 W;

- S 500 made of aluminum – 205 W;

- L 350 made of bimetal – 130 W;

- L 500 made of bimetal – 180 W;

- Made of cast iron - 160 W.

Batteries are grouped according to their center length:

- 200 mm;

- 350 mm;

- 500 mm;

- 600 mm.

Steel

This type of coolant is characterized by its relatively low cost and aesthetic appearance. The design is integral and the number of sections is not adjustable. Steel walls are thin and require anti-corrosion protection. During operation, protection against water hammer and mechanical damage is necessary, since the seams can leak. Considering the low heat capacity of the structure, installing it in an apartment is impractical. In a private building, this option is more acceptable, since it is possible to independently regulate the degree of heating of the coolant.

Traditional equipment Source i.ytimg.com

Cast iron

Models with maximum heat transfer. Unlike Soviet radiators, modern ones are presented in decent design options, while retaining their positive properties.

This type of battery is practical and convenient:

- the number of sections can be adjusted;

- water hammers are not dangerous for them;

- the walls of the sections are little susceptible to corrosion processes;

- The device is suitable for any coolant.

Cast iron batteries are heavy and require high-quality installation and reliable fastening (wall-mounted and floor-mounted options are available).

In addition, batteries take a long time to heat up.

Aluminum

With high heat transfer, aluminum structures are lightweight. The appearance is elegant and varied, which allows them to be installed in any room. The structures can be either solid or prefabricated, consisting of several sections.

Since aluminum is susceptible to oxygen corrosion, the battery requires appropriate anti-corrosion protection. If available, this type of radiator surpasses all others in terms of performance characteristics.

Aluminum under the window Source pro-remont.org

The devices are installed in the private sector due to increased exposure to water hammer. With central heating this cannot be resisted.

Bimetallic

Made from two layers. External aluminum, has high heat dissipation. The second is made of an alloy that is not destroyed by corrosion. This design ensures long-term operation. However, the cost of these models is quite high, so it is important how to calculate the number of bimetallic radiator sections per room. They are characterized by stronger thermal conductivity than cast iron.

Calculation example

If you calculate how many sections of an aluminum radiator are needed for a room with an area of 20 m2 at a rate of 100 W/m2, then adjustment coefficients for heat loss should also be made:

- each window adds 0.2 kW to the indicator;

- the door “costs” 0.1 kW.

If it is assumed that the radiator will be placed under the window sill, then the correction factor will be 1.04, and the formula itself will look like this:

Q = (20 x 100 + 0.2 + 0.1) x 1.3 x 1.04 / 72 = 37.56

- the first indicator is the area of the room;

- the second is the standard number of W per m2;

- the third and fourth indicate that the room has one window and one door;

- the next indicator is the heat transfer level of the aluminum radiator in kW;

- the sixth is a correction factor regarding the location of the battery.

Everything should be divided by the heat output of one heater fin. It can be determined from the table from the manufacturer, which shows the heating coefficients of the carrier in relation to the power of the device. The average for one edge is 180 W, and the adjustment is 0.4. Thus, multiplying these numbers, it turns out that one section produces 72 W when heating water to +60 degrees.

Since rounding is done upward, the maximum number of sections in an aluminum radiator specifically for this room will be 38 fins. To improve the performance of the structure, it should be divided into 2 parts of 19 ribs each.

Find out useful information about aluminum batteries on our website:

Simple calculation

Connecting heating to high-rise buildings, the number and location of devices is made on the basis of complex technical calculations. They are produced by specialists based on SNiP 41-01-2003. Regulatory rules stipulate, for example, how many sections of a bimetallic radiator are needed per 1 m² of area:

- in the center -100 W;

- in the north – 150-200 W;

- in the south - 60 W.

Different types of radiators for a home heating system Source stroy-podskazka.ru

SNiP stipulates how many battery sections are needed per square meter of building area, taking into account the composition of the alloy:

- bimetal – 1.8 sq. m;

- aluminum – 2.0 sq. m;

- cast iron - 1.5 sq. m.

The user can make an approximate calculation independently. The purchased radiator comes with a user manual. It contains device data and power. Using these indicators, you can calculate radiator sections by room area using the template:

room area (in sq. m) X100 W / section power (numbers in instructions)

The data obtained are used with heated floors above and below, not on a corner, in a brick building, with a distance to the top of up to 3 m.

Calculation by volume

For wall heights of more than 3 meters, size calculations of heating radiators are used. For 1 sq. m of housing:

- for buildings made of panel blocks - 41 W;

- for buildings made of brickwork - 34 W.

Sample:

Heat transfer = room area X wall height X standard power (41 or 34).

Connection Source build-experts.ru

The resulting total is divided by the standard output of the section and the required number is obtained.

See also: Catalog of companies that specialize in the installation of stoves and fireplaces

Example of a simple calculation

In calculations, the average option of 1300 W is accepted. It is added by 20% and leads to a higher value. Thus, they buy a device with a power of 1600 W. If 1 section is 160 W, then 10 pieces will be required.

To find out how many sections of a bimetallic radiator are needed for 18 m² with a wall height of 2.7 m, we substitute the numbers:

18 X 100=1800 W.

Then the required complex is selected. The consumer can buy a device of a suitable size, with a length from 0.8 to 2.0 m and a height of 0.3-0.6 m.

Then you need to decide on the metal.

Bimetallic device Source bulbul.ua

Accurate calculations with many parameters

It is difficult to make such calculations. The above formulas are valid for a normal room in central Russia. The geographic location of the house and a number of other factors will introduce additional correction factors.

- The final formula for a corner room should have an additional factor of 1.3.

- If the house is not located in the middle zone of the country, the additional coefficient is described by the building codes of this territory.

- It is necessary to take into account the installation location of the bimetallic radiator and decorative elements. For example, a niche under a window will take 7%, and a screen up to 25% of the thermal power of the battery.

- What will the room be used for?

- Wall material and thickness.

- How much do frames and glass cost?

- Door and window openings introduce additional problems. Let's look at them in more detail.

Walls with windows, street and doorways, change the standard formula. It is necessary to multiply the resulting number of sections by the heat transfer coefficient of the room, but it must first be calculated.

This indicator will be the sum of the heat transfer of the window, doorway and wall. All this information can be obtained by contacting SNiP, according to your type of premises.

https://youtube.com/watch?v=nSewFwPhHhM

Detailed calculation

The number of sections of heating radiators can be calculated taking into account additional coefficients. The standard power is assumed to be per 1 sq. m 100 W. Additional indicators that affect the atmosphere in the building are taken into account:

Heat transfer = area X 100 X K1 X K2 X K3 X K4 X K5 X K6 X K7 X K8 X K9 X K10

Each coefficient affects the thermal conditions of the room.

K1 – the number of walls in contact with street temperatures, where:

- for one surface, take 1;

- with two surfaces – 1.2;

- with three – 1.3;

- with four walls in contact with the atmosphere - 1.4.

In this case, the corner rooms will be the coldest.

K2 is an indicator that takes into account the relationship to the poles. Surfaces in the shade will be cooler because they are not exposed to the heat of the sun's rays:

- northern surface -1.1;

- east side -1.1;

- southern surface -1;

- western surface of the building -1.

Installation with large glazing Source openstroi.ru

See also: Catalog of house projects with a fireplace

K3 is an indicator showing the degree of insulation. In addition to standard construction, residents can insulate walls with special products both outside and inside, reducing heat loss.

Thermal insulation reduces heating requirements:

- masonry of walls with a thickness of two bricks without additional insulation - 1;

- masonry walls with a thickness of one brick without additional insulation – 1.27;

- with additional insulating material - 0.85.

K4 is an indicator indicating the temperature regime of the area. Temperatures vary greatly in different regions. For the indicator, information from the hydrometeorological service about the lowest temperatures is used:

- from -10 °C the indicator is 0.7;

- from -15 °C the indicator is 0.9;

- from -20 °C indicator 1.1;

- from -25 °C indicator 1.3;

- below -35 °C – 1.5.

K5 – takes into account the height of the walls in the room. To heat a larger volume, more power will be required:

- with a standard indicator of 2.7 m - 1;

- from 2.8 to 3 m – 1.05;

- from 3.1 to 3.5 m – 1.1;

- from 3.6 to 4.0 m – 1.15;

- more than 4 m - 1.2.

Six-section model Source 4geo.ru

K6 - takes into account the temperature in rooms above and below the calculated one. Apartments on the top and first floors will require greater heat transfer. It should be taken into account that it is prohibited to install a heated floor system in multi-storey buildings. It can be insulated using special materials at the request of the owners. The attic is made warm in private households.

Applicable indicator:

- cold, unheated room above -1;

- insulated surface at the top – 0.9;

- heated room above – 0.8.

K7 is an indicator that takes into account heat leakage through the surface of the glass.

Even modern metal-plastic windows allow heat to pass through and this factor must be taken into account when calculating heating. Wooden frames have high heat loss rates:

- wooden frame material and two glasses - 1.27;

- metal-plastic frames with double glass – 1;

- double-glazed window with two glasses and argon as a filler or two-chamber – 0.85.

Not only the material of the window frames matters, but also the size of the glazing surface.

Design solution Source stkc-ufa.ru

How to calculate heat loss?

To fully calculate the heat loss of a room or an entire house, you will need to collect a large amount of information about the structure. The calculations themselves can be performed manually using SP 50.13330.2012 or in any online calculator.

- We calculate the area of the windows, take the area with the frame. If there are two windows in the room, then add up the total area.

- We measure the total length of the external walls, and then multiply the resulting value by the height of the ceiling.

- Subtract the area of the windows from the area of the walls.

- We calculate the floor area to determine heat losses through infiltration (blowing through technological openings).

- You need to know the type of windows: for example, double-glazed windows, a regular double-glazed window, etc.

- We determine the material of the external walls. For example, brick with mineral wool insulation.

Heat losses through internal walls and partitions are usually not taken into account.

- To determine heat losses through the floor, you need to know the design of the first floor: floors on the ground, floors above the technical underground or basement, etc.

- To calculate losses through the ceiling, you need to know the structure of the ceiling and its perimeter.

If there is a “warm” attic or a heated floor above the first floor, then when calculating for the first floor, losses for the ceiling are not taken into account. Energy leaks through the floor are taken into account only on the first floor. If heat loss for an attic is calculated, then instead of the ceiling, energy loss through the roof is added.

In private houses, the greatest heat loss occurs in the attic floors, since it is in contact with the roof. The least power is required to heat rooms on the second floor if there is a “warm” attic above them. The ground floor is usually colder due to the entrance door and losses through the floors.

Calculation depending on the type of radiator

When studying the components of heating systems in an online store, the calculator calculates heating radiators per area online.

Data is provided for each model. The figure is sometimes given not in W, but as coolant flow. You can recalculate: 1 l/min is considered as 1 kW of power.

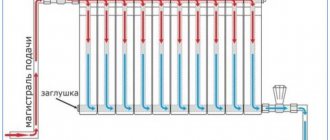

Single pipe system

There are some special features when using a system with a single-pipe connection. A cooler coolant reaches the device installed further. In order not to count the temperature individually, a simplified procedure is used.

If you have a single-pipe system in your home, the Gibax brand has special connection modules Radiplekt Therm and Radiplekt, which, thanks to the minimum number of connections, will make the system as reliable as possible. These are modules with automatic or manual temperature modes. Also, these modules will help you maintain optimal indoor air temperature thanks to automatic or manual control.

One-piece design Source highlogistic.ru

First, calculate as for a two-pipe system, and then add the required number of radiator sections. The percentage of heat reduction at the connecting joints determines the number of additional sections. The drop in heating temperature is typically assumed to be 20% at a more distant junction.

Calculation of the number of sections of heating radiators, analysis of 3 different approaches, examples

Correct calculation of heating radiators is a rather important task for every homeowner. If an insufficient number of sections is used, the room will not warm up during the winter cold, and the purchase and operation of too large radiators will entail unreasonably high heating costs. Therefore, when replacing an old heating system or installing a new one, you need to know how to calculate heating radiators. For standard premises, you can use the simplest calculations, but sometimes it becomes necessary to take into account various nuances in order to obtain the most accurate result.

Video description

Additionally, see how to connect radiators to a one-pipe system:

Using old metrics

When carrying out repair work and replacing previous heating equipment, you can use the previous data. If the temperature level during the heating season is satisfactory, then the thermal power remains the same. Old batteries will lose 10-15% of their thermal conductivity over time due to internal corrosion. Therefore, the new ones will require a smaller number of sections with a similar battery material.

When installing devices in designer versions, you should approach the installation with special care. Unconventional solutions significantly change the air heating system.

Corner design Source remkasam.ru

Additional recommendations

To give batteries an aesthetic appearance, they are often masked with special screens or curtains. In this case, the heating device reduces heat transfer, and when calculating the required number of sections, another 10% is added to the final result. Since most modern radiator models have a certain number of sections, it is not always possible to select batteries taking into account the calculations performed. In this case, it is recommended to purchase a product whose number of sections is as close as possible to the desired one or slightly more than the calculated value.

Useful tips for properly arranging your heating system

Bimetallic radiators come from the factory connected in 10 sections.

After calculations, we got 10, but we decided to add 2 more in reserve. So, it's better not to do it. Factory assembly is much more reliable and comes with a warranty of 5 to 20 years. Assembly of 12 sections will be carried out by the store, and the warranty will be less than a year. If the radiator leaks soon after this period ends, repairs will have to be carried out on your own. The result is unnecessary problems.

Let's talk about the effective power of the radiator. The characteristics of the bimetallic section indicated in the product passport are based on the fact that the temperature pressure of the system is 60 degrees.

This pressure is guaranteed if the temperature of the coolant in the battery is 90 degrees, which does not always correspond to reality. This must be taken into account when calculating the room radiator system.

Below are some tips for installing the battery:

- The distance from the window sill to the top edge of the radiator should be at least 5 cm. Air masses can circulate normally and transfer heat to the entire room.

- The radiator needs to lag behind the wall by a length of 2 to 5 cm. If reflective thermal insulation is attached behind the battery, then you need to purchase extended brackets that provide the specified gap.

- The bottom edge of the battery is supposed to have a distance of 10 cm from the floor. Failure to follow the recommendation will worsen heat transfer.

- A radiator mounted against a wall, and not in a niche under a window, must have a gap of at least 20 cm with it. This will prevent the accumulation of dust behind it and help heat the room.

It is very important to make such calculations correctly. This determines how efficient and economical the resulting heating system will be.

All the information given in the article is aimed at helping the average person with these calculations.

Increased heat transfer efficiency

When the radiator heats the internal air of the room, intense heating of the external wall in the area behind the radiator also occurs. This leads to additional unjustified heat losses.

To increase the efficiency of heat transfer from the radiator, it is proposed to fence off the heating device from the outer wall with a heat-reflecting screen.

The market offers many modern insulating materials with a heat-reflecting foil surface. The foil protects the warm air heated by the battery from contact with the cold wall and directs it inside the room.

For proper operation, the boundaries of the installed reflector must exceed the dimensions of the radiator and protrude 2-3 cm on each side. The gap between the heating device and the thermal protection surface should be left 3-5 cm.

To make a heat-reflecting screen, we can recommend isospan, penofol, alufom. A rectangle of the required dimensions is cut out of the purchased roll and fixed on the wall at the location where the radiator is installed.

It is best to fix the screen that reflects the heat of the heating device on the wall with silicone glue or liquid nails

It is recommended to separate the insulation sheet from the external wall with a small air gap, for example, using a thin plastic grid.

If the reflector is joined from several parts of insulating material, the joints on the foil side must be sealed with metallized adhesive tape.