The development of technology has led to the replacement of classic wood stoves with boiler units. In addition to firewood and coal, gas, oil, diesel fuel and even electricity began to be used as fuel. Recently, energy for autonomous heating systems has been additionally obtained using solar panels and geothermal installations. Considering that hydrogen is an inexhaustible source of energy, you can try to assemble a hydrogen generator with your own hands to produce environmentally friendly fuel.

DIY hydrogen generator

How does hydrogen heating work?

The essence of this type of heating is the chemical reaction of electrolysis, in which water is divided into molecules of hydrogen and oxygen. As a result, Brown's gas or, as it is also called, detonating gas, is formed. During this chemical reaction, heat is released, which is used for heating. By adjusting the boiler power, you can achieve the required temperature in the room you are heating.

In order for hydrogen heating to work, the following conditions are necessary:

- Free flow of water. As a rule, tap water is used, however, distilled water can also be used. The volume of liquid required directly depends on the power of the boiler.

- Availability of electricity. Electricity is required for the electrolysis process to occur.

This device is considered the most environmentally friendly of all heating methods, since steam is released during operation, which does not harm the environment. And to operate, you only need electricity, and to reduce costs, it is possible to operate on solar energy, that is, draw energy through solar panels.

Essence of the question

Water heating

Some people get confused and believe that in fact the correct name for such a system is water heating, and the prefix “steam” remains from past times, when heating was carried out by industrial boiler houses that produced large volumes of steam. In fact, today there are boilers that provide space heating by converting liquid into two physical states. The strengths of this solution are:

- double heat transfer - by convection and infrared radiation;

- minimal losses in the heat exchanger when transferring energy from the source;

- high reliability;

- there is no danger of the system defrosting during the cold season;

- Possibility of use at any time of the year;

- long service life without failures.

Advantages and disadvantages of hydrogen heating

- One of the most obvious advantages can be considered an endless amount of fuel, since it is water. There is no need to mine coal, firewood or other natural resources to generate heat.

Low electrical energy consumption - Low electricity consumption. For example, a device with a power of 40 kW consumes 0.44 kW per hour; a hydrogen boiler is considered the most economical, unlike other heating methods.

- High degree of environmental friendliness, there are completely no emissions that harm the environment, since only steam is released during operation.

- High efficiency of about 94%; no other type of heating provides such heat transfer.

- Low noise level during operation.

- Does not require installation of a chimney and its subsequent maintenance.

- There is no need for a burning flame.

- The requirements for installation and installation location are much lower than for gas equipment.

- The disadvantage is that the gas produced has neither color nor odor, and if it leaks, it will be extremely difficult to detect. The temperature at which it ignites is 540 degrees, based on this it is classified as explosive.

Hydrogen release - Quite a high cost.

- There are very few specialists who inspect and certify cylinders.

- Constant replenishment of the catalyst is required.

- Difficulty in finding spare parts, this is due to low demand in the market.

Types of electrolyzers

Let's briefly look at the design features of the main types of water splitting devices.

Dry

The design of a device of this type was shown in Figure 2; its peculiarity is that by manipulating the number of cells, it is possible to power the device from a source with a voltage significantly exceeding the minimum electrode potential.

Flow-through

A simplified design of devices of this type can be found in Figure 5. As you can see, the design includes a bath with electrodes “A”, completely filled with solution and a tank “D”.

The operating principle of the device is as follows:

- at the entrance of the electrochemical process, the gas together with the electrolyte is squeezed into container “D” through pipe “B”;

- in tank “D” gas is separated from the electrolyte solution, which is discharged through the outlet valve “C”;

- the electrolyte returns to the hydrolysis bath through pipe “E”.

Membrane

The main feature of devices of this type is the use of a solid electrolyte (membrane) on a polymer basis. The design of devices of this type can be found in Figure 6.

The main feature of such devices is the dual purpose of the membrane: it not only transfers protons and ions, but also physically separates both the electrodes and the products of the electrochemical process.

Diaphragm

In cases where diffusion of electrolysis products between the electrode chambers is not permissible, a porous diaphragm is used (which gives such devices their name). The material for it can be ceramics, asbestos or glass. In some cases, polymer fibers or glass wool can be used to create such a diaphragm. Figure 7 shows the simplest version of a diaphragm device for electrochemical processes.

Explanation:

- Oxygen outlet.

- U-shaped flask.

- Hydrogen outlet.

- Anode.

- Cathode.

- Diaphragm.

Alkaline

The electrochemical process is impossible in distilled water; a concentrated alkali solution is used as a catalyst (the use of salt is undesirable, since this releases chlorine). Based on this, most electrochemical devices for splitting water can be called alkaline.

On thematic forums, it is advised to use sodium hydroxide (NaOH), which, unlike baking soda (NaHCO 3), does not corrode the electrode. Note that the latter has two significant advantages:

- Iron electrodes can be used.

- No harmful substances are released.

But one significant drawback negates all the benefits of baking soda as a catalyst. Its concentration in water is no more than 80 grams per liter. This reduces the frost resistance of the electrolyte and its current conductivity. If the first can still be tolerated in the warm season, then the second requires an increase in the area of the electrode plates, which in turn increases the size of the structure.

Homemade installation diagram

There is no unambiguous diagram of the device, since it can vary depending on the configuration with various sensors.

However, we can highlight a list of the required minimum components of this device:

- A vessel that is filled with liquid (electrolyte).

Set of plates for electrolyzer - A set of stainless steel plates between which, under the influence of electricity, water will decompose into hydrogen and oxygen (electrolyzer).

- Safety module.

- The combustion chamber.

- Heat exchanger.

And it all works in the following way: a special liquid enters an electrolyzer, in which gas is produced by splitting the liquid under the influence of an electric current. After combustion, water is formed, which is returned to the system. The container is made of high-alloy steel; the use of this material is due to its reliability.

There is a technological need to install a safety valve to relieve excess pressure from the system. The generated hydrogen then enters the combustion chamber. Having entered into a thermal reaction with O2, the gas produces heat, which flows through the radiator into the heating system of the room.

And the liquid that has formed in the chamber flows through a special tube into a vessel with an electrolyte, due to which self-ignition occurs through recirculation. Also, elements of a protective automatic system are added to this scheme for operational safety. Such as water level control sensors, temperature sensors, bypass valves, pressure control sensors in the system.

Model selection criteria

A hydrogen boiler for a home must be selected taking into account the following criteria:

- the heating power must meet the requirements of the heating system and coolant used, and also take into account the area of the heated premises,

- the dimensions of the combustion chamber must be equipped with the required number of heat exchangers, allowing the organization of several heating circuits,

- the electrical network in the building must be able to withstand the power consumption of the boiler,

- all structural elements of the boiler must be made of high-quality materials and have a sufficient margin of strength and wear resistance,

- The protection unit must be certified and comply with safety standards.

Example of a hydrogen heating boiler

Instructions for making a hydrogen boiler

In order to make a hydrogen boiler with our own hands, we need a hydrogen generator.

Homemade hydrogen boiler

To do this, you need the following tool:

- Sheet metal, high alloy stainless steel.

- Check valve.

- Bolt - 2 pieces, size 6 by 150, nuts and washers.

- Filter for liquid purification.

- Transparent hose or tube with a diameter of 8 mm.

- A container that closes hermetically. You can use a plastic container for storing food; take the volume 1.5 liters.

- Hose fitting 8 mm in diameter.

- A tool for carving metal, a carving grinder with a cutting disc is suitable.

Let's take a closer look at exactly what material needs to be used to make a homemade boiler. It is recommended to take steel 03*16N1, size approximately 0.6 by 0.6 meters, thickness 2 mm - this will be quite enough. Please note that it is necessary to use stainless steel, because the metal will come into contact with liquid, namely alkali. And the alkaline environment is the most aggressive.

Stainless steel sheet

Next, we will consider the assembly process step by step. Take a sheet of steel, place it on a flat surface and use chalk to make markings; we need to get 16 rectangles as a final result. Cut them using a grinder, make one corner of each plate beveled, this is necessary for attaching our burner.

On the other side of our plate, drill a technical hole for screwing in the bolts. Since we are making a “wet” electrolyzer, we only drill them on one side, pay attention to the fact that our device is the most efficient and simpler to implement.

In our case, each plate is completely immersed in the solution, and as a result, their entire area participates in the chemical reaction. Then assemble the structure from a plate and a bolt. To do this, put the first plate on the bolt and tighten it with a washer on each side, unfold the second plate so that its cut edge is near the bolt and fix it on top of the first plate.

To avoid them touching, place a piece of plastic between each of them. And then, assemble the entire structure in the same way. Then we need to make holes in the container large enough to accommodate the bolt. Insert the completed structure into the container and secure it. Use gaskets for tightness.

Ready electrolyser

Drill a hole in the lid and attach an oxygen tube with a fitting to it; use silicone to seal the connections. In order to check how tight it is, blow into the tube; if tightness is achieved, proceed to the next step. Make a second hole into which water will be poured.

After everything is assembled, perform a test switch on, connect any source to it, close the device, fill it with liquid, lower the other end into a jar of liquid to see bubbles. If you increase the voltage, the number of bubbles should increase.

Let's start making the boiler itself:

- Take a shaped tube with a diameter of 20*20 mm, cut it into 8 equal sections of 30 cm each.

- Then you need another pipe 40*40 mm, divide it into 3 sections, one 20 cm and two 8 cm.

- In a 20-centimeter pipe, make two holes 4 cm in size. Make them at the ends, weld the remaining two 8-centimeter tubes to them.

- Weld plugs on three ends, and fix the pipe on the remaining one, through which the hydrogen mixture will be supplied.

- Then determine the center of the cross of the resulting structure, measure 9 cm and make holes with a diameter of 15 mm at each end. You should have 4 holes.

Hydrogen heating in a private house - Weld pipes to them and install nozzles.

- Weld the 8 previously cut pipe sections. 2 pipes are welded to each end of the cross at right angles.

- Cut 3 square pieces from a steel sheet. In 2 of them, cut four holes with a diameter of 2 and 1 cm. It is necessary that these holes repeat the location of the nozzles.

- You need to take a tube with a diameter of 20-30 mm and cut it into smaller tubes of 40-45 cm each. Attach them to a square and weld them.

- Then we need a pipe with a diameter of 18 cm, 2.5 cm shorter than the welded tubes. Make one hole in it along the edges. We weld it to the cut square with smaller holes. Turn over the welded structure and install the 2nd square. The pipes must pass through the holes made. Weld everything.

- Weld the previously assembled unit with the burner.

- Weld tubes for liquid circulation to the previously made holes.

- Check the finished device, if a leaky solder is found somewhere, correct it.

- Install heat and flame sensors.

Generator operating principle

As an energy carrier, hydrogen truly has no equal, and its reserves are practically inexhaustible. As we have already said, when burned it releases a huge amount of thermal energy, incomparably greater than any hydrocarbon fuel. Instead of harmful compounds emitted into the atmosphere when using natural gas, the combustion of hydrogen produces ordinary water in the form of steam. One problem: this chemical element does not occur in nature in a free form, only in combination with other substances.

One of these compounds is ordinary water, which is completely oxidized hydrogen. Many scientists have been working on its splitting into its constituent elements for many years. It cannot be said that it was unsuccessful, because a technical solution for dividing water was nevertheless found. Its essence is in the chemical reaction of electrolysis, as a result of which water is split into oxygen and hydrogen; the resulting mixture was called detonating gas or Brown's gas. Below is a diagram of a hydrogen generator (electrolyzer) powered by electricity:

Electrolyzers are mass-produced and designed for gas-flame (welding) work. A current of a certain strength and frequency is applied to groups of metal plates immersed in water. As a result of the ongoing electrolysis reaction, oxygen and hydrogen are released mixed with water vapor. To separate it, the gases are passed through a separator and then fed to the burner. In order to avoid backlash and explosion, a valve is installed at the supply, allowing fuel to flow in only one direction.

To control the water level and timely replenishment, the structure is equipped with a special sensor, upon the signal of which it is injected into the working space of the electrolyser. Excess pressure inside the vessel is monitored by an emergency switch and a relief valve. Maintenance of a hydrogen generator consists of periodically adding water, and that's it.

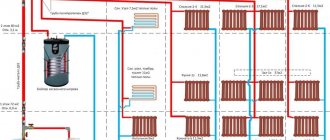

Sequencing

Steam solid fuel boiler

According to the markings in the diagram:

- The boiler is being installed. The room where it will be located must have a concrete base. If necessary, a small foundation is made.

- It is connected to the exhaust gas exhaust system.

- Emitters are suspended. To do this, hooks are used that are designed to support their weight. The place where they should be located was discussed above.

- Each radiator must be equipped with a Mayevsky valve for relieving air pockets.

- At a short distance from the boiler, at the highest point, an expansion tank is installed.

- A pressure gauge and a relief valve are installed at the boiler outlet, which will operate if the pressure exceeds the permissible limits.

- All components are connected to each other using pipes made of the selected material.

- If this is an open system, then a special tank and pump are installed at the end of the line.

- From the pump to the boiler there is a supply pipe of smaller diameter than the entire heating system.

- Before entering the boiler there is a filter that traps large particles.

- If gas is used as a carrier, then a rigid supply is made without any flexible hoses.

- The liquid is being refilled into the circuit.

- A test run of the system is carried out with a gradual increase in temperature to check integrity.

Heating installation

Hydrogen heating: myth or reality?

A generator for welding is currently the only practical application of electrolytic water splitting. It is not advisable to use it for heating a house and here's why. Energy costs during gas-flame work are not so important; the main thing is that the welder does not need to carry heavy cylinders and fiddle with hoses. Another thing is home heating, where every penny counts. And here hydrogen loses to all currently existing types of fuel.

Important. The energy costs for separating fuel from water by electrolysis will be much higher than explosive gas can be released during combustion.

Serial welding generators cost a lot of money because they use catalysts for the electrolysis process, which include platinum. You can make a hydrogen generator with your own hands, but its efficiency will be even lower than that of a factory one. You will definitely be able to get flammable gas, but it is unlikely to be enough to heat at least one large room, let alone an entire house. And if there is enough, you will have to pay exorbitant electricity bills.

Rather than wasting time and effort on obtaining free fuel, which does not exist a priori, it is easier to make a simple electrode boiler with your own hands. You can be sure that this way you will spend much less energy with greater benefit. However, DIY enthusiasts can always try their hand at assembling an electrolyzer at home in order to conduct experiments and see for themselves. One such experiment is shown in the video:

How to make a generator

A lot of Internet resources publish a variety of diagrams and drawings of a generator for producing hydrogen, but they all operate on the same principle. We present to your attention a drawing of a simple device taken from popular science literature:

Here the electrolyzer is a group of metal plates bolted together. Insulating gaskets are installed between them; the outermost thick plates are also made of dielectric. From a fitting built into one of the plates there is a tube for supplying gas to a vessel with water, and from it to the second. The purpose of the tanks is to separate the steam component and accumulate a mixture of hydrogen and oxygen to supply it under pressure.

Advice. Electrolytic plates for the generator must be made of stainless steel alloyed with titanium. It will serve as an additional catalyst for the splitting reaction.

The plates that serve as electrodes can be of any size. But you need to understand that the performance of the device depends on their surface area. The greater the number of electrodes that can be used in the process, the better. But at the same time, the current consumption will be higher, this should be taken into account. Wires leading to a source of electricity are soldered to the ends of the plates. There is also room for experimentation here: you can supply different voltages to the electrolyzer using an adjustable power supply.

As an electrolyzer, you can use a plastic container from a water filter, placing electrodes made of stainless steel tubes in it. The product is convenient because it is easy to seal from the environment by removing the tube and wires through the holes in the lid. Another thing is that this homemade hydrogen generator has low productivity due to the small area of the electrodes.

Features of hydrogen heating

To generate heat in your home, you can use various energy sources. There are also quite unusual options among them - for example, hydrogen fuel. Currently, hydrogen heating is rarely used by domestic consumers due to some difficulties in obtaining raw materials.

However, this method is still considered the most environmentally friendly and provides heating for large rooms. And the costs of such heating will be, although higher compared to the use of gas as an energy carrier, but noticeably lower compared to the operation of solid fuel and electric boilers.

Features of hydrogen heating

For the first time, home heating using hydrogen was developed by Italian inventors. The device they created created virtually no noise and did not emit harmful substances into the atmosphere. At the same time, the temperature inside the boilers was low, and the equipment could be made not from cast iron or heat-resistant steel, but from ordinary metal and even plastic.

The “classic”, low-temperature version of hydrogen heating is the release of heat during the formation of water from hydrogen and oxygen. Although there is also a technique that involves the reverse process - the splitting of water molecules to create hydrogen fuel that burns in boilers.

Boilers running on hydrogen do not need a special system for exhausting combustion products into the atmosphere. After all, the process produces only steam, which is harmless to the environment. And obtaining raw materials is practically no particular problem, unlike energy carriers such as gas, diesel fuel and pellets.

Costs when using hydrogen heating will only go to electricity for the generator.

Advantages and disadvantages

The spread of hydrogen heating systems is facilitated by a number of advantages of this method:

- Environmental cleanliness of emissions.

- Work without the use of fire (only for conventional low-temperature systems). Since heat is not produced by combustion, but as a result of a chemical reaction. The combination of hydrogen and oxygen leads to the production of water, and the energy released goes to the heat exchanger. In this case, the coolant temperature does not exceed 40 degrees, which is an almost ideal mode for a “warm floor” system.

- The use of hydrogen fuel saves money for the owner of a private home.

The only more profitable method in terms of operation is gas heating, which is not always available for suburban housing.

Also, the use of hydrogen reduces the costs of hydrocarbons such as oil and gas, which are non-renewable resources.

True, the technique also has disadvantages. Firstly, hydrogen is quite explosive and, as a result, difficult to transport, although this problem exists only for the low-temperature version.

Secondly, there are few specialists in our country capable of correctly installing such boilers and certifying hydrogen cylinders.

Principle and device

Hydrogen heating is based on the release of a significant amount of thermal energy resulting from the interaction of oxygen and hydrogen molecules. The process is characterized by the large size of the container required for its flow and high efficiency (>80%). For proper operation of the equipment it is necessary:

- connection to a source of liquid, the role of which is most often played by the hydrogen system;

- availability of power supply, without which it is impossible to maintain electrolysis;

- periodic replacement of the catalyst, the frequency depends on the performance and design of the boiler;

- compliance with safety requirements) although compared to gas heating there are much fewer of them due to the occurrence of all reactions inside the boiler, and only visual control of the process is required from the user).

However, given that it is unlikely to be possible to create equipment such as a low-temperature hydrogen installation for heating a house with your own hands, an alternative method is most often used - producing hydrogen and using it as an energy carrier. This option will be more affordable and will provide a higher coolant temperature in the heating system (the same as gas).

System assembly

Hydrogen heating systems include hydrogen generators, burners and boilers. The first is necessary to decompose the liquid into its components (with or without the use of catalysts to speed up the process). The burner creates an open flame, and the boiler serves as a heat exchange device. All this can be purchased at the appropriate stores, but the same system created by yourself, as a rule, works more efficiently.

The hydrogen generator can be assembled in several ways. To make it, you will need several steel tubes, a tank to house the structure, a pulse-width generator with a power of 30A or higher, or another power source. In addition, during assembly you cannot do without a container for distilled water.

The liquid from which hydrogen will be released is supplied inside a sealed structure, where there are stainless steel plates (the more of them, the more hydrogen is produced, although additional electricity is also consumed), adjacent to each other.

In the container, under the influence of current, the process of splitting water molecules into oxygen and hydrogen occurs, after which the latter is fed into the boiler where the burner is installed. If the current is supplied not from the network, but from a PWM generator, the efficiency of the system increases.

Materials used

The heating system usually uses distilled water, to which sodium hydroxide is added in a proportion of 10 liters of liquid per 1 tbsp. l substances. If it is unavailable or difficult to obtain the required amount of distillate, the use of ordinary tap water is also permitted, but only if it does not contain heavy metals.

As the metals from which hydrogen boilers are made, it is permissible to use any type of stainless steel - ferrimagnetic steel, to which excess particles are not attracted, would be an excellent option. Although the main criterion for choosing a material should still be resistance to corrosion and rust.

To assemble the apparatus, tubes with a diameter of 1 or 1.25 inches are usually used. The burner can be purchased at the appropriate store or online service.

If you choose the right materials and carefully study the heating circuit, manufacturing the installation and connecting it to the boiler is not difficult.

Some points of application

First of all, I would like to emphasize that the usual method of burning network gas or propane is not suitable in our case, because the combustion temperature of HHO exceeds the similar properties of hydrocarbons by more than three times. As you understand, structural steel will not hold such a temperature for a long time. Stanley Meyer himself recommended using a burner of an original design, the diagram of which is given below.

Scheme of a hydrogen burner designed by S. Meyer

The whole trick of this device is that HHO (indicated by the number 72 in the diagram) passes into the combustion chamber through valve 35. The burning hydrogen mixture rises through channel 63 and at the same time carries out the ejection process, entraining outside air through the adjustable holes 13 and 70. Under the hood 40, a certain amount of combustion products (superheated steam) is retained, which penetrates through channel 45 into the combustion column and mixes with the burning gas. This makes it possible to reduce the combustion temperature many times.

The second point that I would like to draw your attention to is the liquid that should be poured into the installation. It is best to use prepared water that does not contain heavy metal salts. The best option is distillate, which can be bought at absolutely any automotive store or pharmacy.

For successful operation of the electrolyzer, potassium hydroxide KOH is added to the water, at the rate of approximately one tablespoon of powder per bucket of water

The best option is a distillate, which can be bought at absolutely any automotive store or pharmacy. For successful operation of the electrolyzer, potassium hydroxide KOH is added to the water, at the rate of approximately one tablespoon of powder per bucket of water.

During operation of the installation, the main thing is not to heat the generator. As soon as the temperature increases to 65 degrees Celsius or more, the electrodes of the apparatus will become contaminated with by-products of the reaction, due to which the productivity of the electrolyzer will become less. If this does happen, then the hydrogen cell will need to be disassembled and the deposits removed using sandpaper.

And the third thing we place special emphasis on is safety. It must be remembered that the mixture of hydrogen and oxygen was called explosive for a reason. HHO is an unsafe chemical that can cause an explosion if not handled properly. Follow safety rules and be especially careful when experimenting with hydrogen. Only in this version will the “brick” that our Galaxy consists of bring warmth and comfort to your home.

Safety rules must be followed not only when installing a hydrogen generator. When assembling and operating the bioreactor, you also need to be very careful, because biogas is explosive. Read more about this type of installation in the following publication: https://aqua-rmnt.com/otoplenie/alt_otoplenie/kak-poluchit-biogaz.html.

We hope you find this post inspiring and roll up your sleeves to start building a hydrogen fuel cell.

. Of course, all our calculations are not considered the ultimate truth, however, they can be used to create a working model of a hydrogen generator. If you want to completely switch to this heating supply option, then the question will need to be studied in much more detail. Perhaps your installation itself will become the basis, thanks to it the redistribution of energy markets will end, and cheap and environmentally friendly heat will enter every home.

Feasibility of the technique

The reason for installing a hydrogen heating system in a private home may be the lack of natural gas and the availability of electricity. At the same time, the costs of providing the building with heat are lower compared to the use of electric heating devices.

In addition, there is no need for pipes to remove combustion products. It turns out that a hydrogen installation can be used in country houses as an independent or additional heating equipment.

Law of conservation of energy ↑

Everything in nature is interconnected. If something has arrived somewhere, it means it has left somewhere. This folk wisdom simplifies, but generally correctly describes the law of conservation of energy. Hydrogen, when burned, releases thermal energy. But to produce gas by electrolysis, you will have to spend a certain amount of electricity. Which, in turn, is largely obtained through the generation of heat when burning other types of fuel. And if we take the clean thermal energy necessary to generate electricity and the energy that hydrogen will provide during combustion, even the most advanced installations result in double losses. We literally throw away half the money. And these are only operating costs, but you should also take into account the cost of very expensive equipment.

AeromodellerII wind-hydrogen airship project. Belgian engineers painted a beautiful picture, all that remains is to back it up with specific economically feasible technologies

According to the INEEL research laboratory, in US industrial hydrogen generators the cost of one kilogram of hydrogen was:

- Electrolysis from an industrial power supply - 6.5 usd.

- Electrolysis from wind generators - 9 usd.

- Photoelectrolysis from solar devices - 20 usd.

- Production from biomass - 5.5 usd.

- Conversion of natural gas and coal - 2.5 usd.

- High-temperature electrolysis at nuclear power plants - 2.3 usd. This is the least expensive method and the furthest away from home conditions.

Moreover, even the best hydrogen generator at home will be noticeably inferior in efficiency to an industrial one. With such prices, there is no reason to talk about any serious competition for hydrogen fuel compared not only with cheap natural gas, but also with expensive electric heating, diesel fuel and even heat pumps.

Advantages and disadvantages

Professionals highlight the following advantages of hydrogen heating:

- No fire. Thermal energy is generated during a chemical reaction that does not require combustion of any type of fuel.

- Consistency of temperature indicators. The coolant is maintained at a temperature of +40 C throughout the entire time the boiler is put into operation.

- Versatility of use. There are no restrictions for forming a system in any building.

- Practicality. The low temperature of the coolant guarantees no burns, and a home craftsman with minimal tool skills can install the heating circuit.

- Environmentally friendly. During operation, the device does not emit harmful gases, combustion products, waste particles and slag. The boiler emits neutral gas that does not pollute the atmosphere.

The scheme pays for itself in 3-3.5 years, provided it is used as a constant and main source of heat. The only alternative may be gas heating, but despite the cheapness of fuel, connecting to the main line is not always possible.

The disadvantages include the high explosiveness of hydrogen, so it is important to ensure all levels of safety when using raw materials and transporting fuel only in low-temperature conditions. It is precisely because of the difficulties in supplying hydrogen that such a heating scheme is used quite rarely today.

What is a hydrogen generator and how it works

The device has another name - an electrolyzer; it functions through physical and chemical processes. A hydrogen generator for home heating looks like several metal plates that are immersed in a container filled with distilled water. Despite the simplicity of the circuit, the electrolyzer is capable of generating large amounts of energy.

The process is as follows: an electric current passes through water between metal plates of different polarities (anode-cathode), this leads to the splitting of the distilled liquid into molecules of hydrogen and oxygen. If the area of the metal elements is large, a lot of electric current passes and the volume of gas increases. The housing where the plates are immersed must be equipped with terminals for connecting a power source - electric current, as well as a sleeve where the generated gas is directed.

Historical aspect

The fact that hydrogen energy can be used to its advantage was noticed a very long time ago. The legendary healer Paracelsus, during his experiments, noted that the combination of certain substances leads to the formation of bubbles. At first, the scientist decided that it was simple air, but later it turned out that it was hydrogen - a colorless gas that, under certain conditions, exhibits explosive functions.

Science does not stand still, and today hydrogen is used in various industries, including for heating residential and industrial premises. The technology is actively developing, and today there are even cars that move using hydrogen energy. This scientific innovation has attracted the interest of millions of people, and the topic of using hydrogen for home heating is only becoming popularized.

Scientists have already proven that hydrogen is not only effective, but also very common and easily accessible. The only difficulty arises in the fact that it has to be extracted from various chemical compounds, mainly from ordinary water.