Life in a private house surrounded by nature is impossible without a high-quality and reliable heating system. But an autonomous heating system in a private house is a complex engineering structure that requires regular technological maintenance. If such equipment is not given proper attention, it begins to become clogged. This is primarily due to the fact that process fluids used in heating system pipelines contain many additives. With a constant flow of water, they are deposited on the walls of pipes and the internal surfaces of various heating system devices. All this slows down the normal movement of the coolant, and broken areas of scale and sediment layers can clog the system or cause breakdowns of the circulating pumps. To prevent emergency situations, routine maintenance is carried out on the heating system, one of which is hydropneumatic flushing.

The process of hydropneumatic flushing of the heating system

Hydropneumatic flushing and pressure testing of the heating system

Heating devices in a residential building are a complex structure connected to an autonomous or centralized network. Long-term and uninterrupted operation of engineering equipment depends on operating rules. If the conditions of use are not followed, the devices begin to become clogged and the quality of room heating decreases. To prevent breakdowns and for preventive purposes, mandatory hydropneumatic flushing and pressure testing of the heating system is required.

The importance of regular maintenance

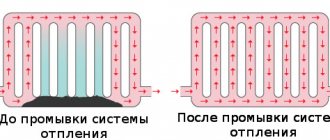

The accumulation of scale in pipelines not only reduces operating efficiency, but can also lead to an emergency. The smallest amount of deposits, 1 mm thick, reduces the level of heat transfer in an apartment building by 20%. The sediment is a specific insulator that retains energy. Layers can affect the internal surfaces of pipes and heating devices, causing corrosion processes and the formation of fistulas

To improve the quality of equipment operation, it is important to carry out hydropneumatic and hydraulic flushing at certain intervals, at least once a year

To determine the condition, diagnostics are performed. In apartment buildings, when replacing sections of the centralized network, scale and rust enter the pipeline, which is deposited in the devices. If the analysis is carried out independently, obvious signs include the following indicators:

- Whistling, gurgling and other sounds coming from devices.

- Long period of time for heating.

- Hot state of pipes with cold batteries.

- Increased energy consumption.

- Cleaning is also necessary when replacing the boiler.

When flushing internal heating systems using the hydropneumatic method, carried out by specialized organizations, a special procedure is noted. Equipment is inspected and its technical condition is assessed. Primary pressure testing in an apartment building should show a pressure with a minimum value of 2 atmospheres. This is necessary so that any detected defects are eliminated before work begins.

A clever meter that saves electricity Pays for itself in 2 months!

Professionals draw up a work certificate taking into account hidden procedures, for example, dismantling radiators of a heating system. By identifying the condition of the pipes and the amount of scale, the cleaning method is determined with the customer. Hydraulic technology is most often used, less often chemical cleaning is used. They draw up an estimate and sign an agreement, which includes deadlines for completion. After this, they begin cleaning, then carry out secondary pressure testing. This is necessary to check the functionality of the equipment in a residential building.

Why is regular maintenance essential?

In addition to the occurrence of emergency situations, the accumulation of scale in a pipeline heating system also sharply reduces its efficiency. Thus, just a millimeter of scale on the inner surface of a heating radiator reduces its heat transfer by 15 percent. Accordingly, in order to achieve a normal temperature in the house, you will have to increase the power of the boiler, and therefore increase fuel costs. In order not to incur extra costs, you need to clean the system.

The accumulated scale on the internal surfaces of the system has a much lower thermal conductivity than conventional metal used to make pipes. Scale is essentially a heat insulator - its thermal conductivity is 40 times less than that of metal. Even a thin layer of scale reduces the efficiency of the heating system to minimum values. Moreover, scale actively interacts with the metal of the pipes, which leads to increased corrosion and even the formation of fistulas.

Why is hydro testing necessary?

Hydrotesting – checking the integrity and tightness of the heating main. Testing allows you to timely detect leaks and gaps at the points of threaded connections of fittings and battery connections, which can lead to leakage and flooding. Hydraulic tests are a mandatory measure at the stage of preparing pipelines for commissioning.

The companies operating the structure are informed about the period of testing. The process is carried out by specialized companies whose employees have the necessary qualifications. Preparation of heat supply systems includes pressure testing of the main line and flushing of pipelines.

If you hire a contractor

If you order hydropneumatic flushing of heating systems from a service company, then specialists must first determine the scope and cost of the work. In this case:

- Calculations are made of the length of the flushed pipelines, the upcoming air and water consumption. The cost of the work is determined.

- A schedule of events is drawn up.

- A service contract is concluded.

- Equipment is imported, preparatory work is carried out, then hydropneumatic flushing and pressure testing are carried out.

- An act on flushing and testing the in-house heating system is drawn up. A technical guarantee is provided.

There is less work in a private house than in an apartment building, so the cost of cleaning is significantly lower. At the same time, work in the private sector can be quite complex due to the specific design features of thermal systems.

Methods for cleaning radiators

Chemical cleaning method for heating systems

During the chemical cleaning of parts of heating systems, their internal cavity is filled with special solutions. These include substances made from acid or alkali. They contain inhibitors. They are able to prevent metal corrosion, help preserve its internal part, and extend its service life.

heating systems. During work, old alkali and acid solutions should be drained. Such solutions are quickly neutralized. Acid components of an alkaline solution are added to them. This cleaning method is used when washing steel pipes. The composition of the reagents cleans the inside of the battery from rust and salt deposits.

Cleaning heating systems using hydraulic pneumatics

This method of cleaning the heating system is recognized as the most universal, inexpensive and most popular. This cleaning method requires using a lot of water. In autonomous heating systems, all internal parts are washed only with cold water.

Flushing sequence

using hydraulics:

- start the heating system in reset mode;

- a stream of air is directed to the coolant of the system, which will quickly clean the internal structures of the battery from scale and formations;

- if there are risers in the heating system, then they are washed; if the heating system is cleaned by the tenant himself, then the risers should be washed individually. This is done in order to flush the radiator itself.

According to the drawn up agreement, and this is necessary to check the quality of flushing, it is necessary to carry out control coolant intakes

. Such work is carried out in the thermal unit, in other parts of the system. This is done for the equipment acceptance committee, which will sign the equipment acceptance certificate. She can always make sure the water is clean and free of impurities.

The topic of this article is documentation of flushing the heating system. We are interested in drawing up an estimate, concluding a contract and drawing up a report.

In addition, the criteria by which the work performed is assessed are also interesting.

Do-it-yourself chemical washing

For chemical cleaning, it is important to select the correct preparation and carefully study the instructions before starting work. To clean the heating system in a private home yourself, you need:

- pump;

- container for liquid;

- cleaning product;

- hoses.

Most chemicals are diluted with a certain volume of water before use. If you wish, you can purchase ready-made liquid in stores, which is the best option for flushing a small system. For large stand-alone systems, it is recommended to purchase a concentrate. The cleaning procedure is as follows:

- draining water from the heating network;

- filling the treatment station tank with the prepared composition;

- switching on using pump pipes and filling the heating system elements with a chemical composition.

It usually takes 2-3 hours to destroy scale. Circulation is carried out until there is no sediment in the filter container. It is mandatory to flush the heating system with water to completely remove the chemical reagent.

Please note that used chemical solution must not be poured down the drain.

When carrying out work, pay attention to safety precautions with chemicals. Precautionary measures:

- When working with the solution, it is imperative to wear gloves;

- the concentration of the reagent can be very dangerous for humans, so before starting work it is necessary to protect the mucous membranes with a respirator.

The main advantages of this method are

- High-quality removal of lime deposits and rust on the inner surface of pipes.

- There is no need to completely dismantle the heating system.

- Uniform heating of radiators after flushing.

- Reduced fuel consumption and, as a result, savings.

- Extending the life of the heating system.

What is flushing and pressure testing?

Flushing and pressure testing of heating systems is carried out in cases where the layer of deposits in the pipes becomes too large for them to continue to function. As a preventive measure, such events are rarely carried out, since this pleasure is quite labor-intensive and expensive. For hydropneumatic flushing, acid solutions are used that remove plaque from the walls of the pipeline to the outside. Metal particles cling to the inner walls of the pipes, thereby reducing their diameter. It leads to:

- increased pressure;

- increasing the coolant speed;

- decrease in efficiency;

- increased costs.

What is pressure testing of a heating system - this is an ordinary test, based on the results of which we can say whether it is safe to use such equipment or not, and whether it can withstand the required loads. After all, no one wants to become a victim of circuit depressurization and end up as a patient in the burn department. Pressure testing of the heating system is carried out in accordance with SNiPs. It is a mandatory procedure. After it, a document is issued confirming the technical serviceability of the circuit. Here are the main cases when pressure testing of a heating system is carried out:

- when assembling a new circuit and putting it into operation;

- after repair work has been carried out;

- preventative checks;

- after cleaning pipes with acid solutions.

Pressure testing of the heating system is carried out in accordance with SNiP No. 41–01-2003 and No. 3.05.01–85, as well as the rules for the technical operation of thermal power plants.

From these rules it is known that such an action as pressure testing of the heating system is carried out either with air or with liquid. The second method is called hydraulic, and the first is manometric, also known as pneumatic, or bubble. The rules for pressure testing a heating system state that water tests can only be carried out if the room temperature is above five degrees. Otherwise, there is a risk that the water in the pipes will freeze. Air pressure testing of the heating system eliminates this problem; it is carried out during the cold season. In practice, hydraulic pressure testing of the heating system is used more often, since everyone is trying to complete the necessary scheduled work before the onset of the heating season. In winter, only the elimination of accidents, if any, is carried out.

You can start pressure testing the heating system only when the boiler and expansion tank are cut off from the circuit, otherwise they will fail. How to pressurize a heating system:

- all liquid from the circuit is drained;

- then cold water is poured into it;

- as it fills, excess air is released from the circuit;

- after water has accumulated, a pressure blower is connected to the circuit;

- How pressure testing of a heating system occurs - the number of atmospheres gradually increases. In this case, the maximum test pressure should not be higher than the tensile strength of different circuit elements;

- High pressure is left for some time and all connections are inspected. You need to look not only at the threaded connections, but also at the places where parts of the circuit are soldered.

Pressure testing of a heating system with air is even easier. Just drain all the coolant, close all the outlets in the circuit and force air into it. But this way it is more difficult to determine the malfunction. For example, if there is liquid in the pipes, then at high pressure it will ooze through a possible gap. It is easy to determine visually. But if there is no liquid in the tubes, then there is nothing to come out except air. In this case, a whistle may be heard.

And if it is not audible, and the pressure gauge needle indicates a leak, then all connections are coated with a soap solution. To make it easier, you can check not the entire system, but by dividing it into segments. In this case, it is easier to carry out pressure testing of heating pipes and determine possible places of depressurization.

Process description

During washing, dirt, deposits, limescale, scale, and rust are removed. To ensure successful cleaning, a number of calculations and preliminary steps are performed:

- Pipeline parameters: length, diameter.

- Air flow and pressure.

- Carrier speed and pressure.

- Measurements of individual groups of risers.

- Checking the presence of shut-off equipment.

- The need to add chemicals for older systems.

- Dismantling equipment that may be damaged by high pressure.

If the pipeline length is short, pipes are inserted at the inlet and outlet. The first is needed for reverse movement, the second is used to drain dirty water. If there are large lines, pumps are connected to the operation to increase the speed of the carrier and in case of insufficient compressor power. There are two methods of hydropneumatic flushing of the heating system:

1. Filling method.

The technology is considered quite complex, since the process involves filling with liquid, then compressed air is supplied every 15 minutes. A compressor is involved in the work. Using water hammer, deposits are removed from surfaces and dirt is lifted from the bottom of the radiators. The coolant with impurities is released through the drain valve of the system. Washing is carried out in several stages until the equipment is completely free of scale. The method is very effective, but difficult to implement, so it is better to entrust the processing to specialists.

Cleaning the heating system involves simultaneously pumping liquid and air through all areas. Before supplying water, it is necessary to close the collection valve; when the compressor is running, unscrew the drain pipe. Passing through all pipes and appliances, the mixture cleans them and then drains. The procedure is carried out continuously until clear liquid comes out. In difficult cases, when washing, chemical reagents are included in the cleaning mixture. An alkali or acid is added to the water, which can dissolve the deposits. Work can be carried out without the participation of a compressor; dirty water comes out when the pump is connected. The amount of funds depends on the length and diameter of the system elements. The method is considered fast and effective, but is not suitable for washing aluminum units, as there is a risk of destruction of the walls from chemicals.

We recommend: Flushing the heat exchanger of a gas boiler: the most detailed instructions for doing it yourself, choosing liquids and other means for descaling, the cost of equipment and specialist services

Pressure testing is carried out after cleaning the heating pipes using the hydropneumatic method. The procedure is necessary to identify defects and lack of tightness as a result of washing. The system is filled with water at a slow pace, while the operating pressure should be from 2 to 8 atmospheres, depending on the number of storeys of the house. The parameter is saved for half an hour and checked by connecting a pressure gauge to the inlet pipe. If the meter shows the minimum value, there is a leak that is found and repaired. To do this, drain the water, make repairs, then refill the system until the pressure gauge readings improve.

Cleaning heating pipes using hydropneumatic flushing is a requirement in preparation for the season. Unfortunately, the frequency of the procedure is not always observed, which often leads to equipment failure and an accident on the highway. After choosing a method of implementation, it is necessary to agree with specialists about crimp testing. This will help identify possible defects and places of depressurization.

What is flushing and pressure testing of a heating system?

Flushing the pipes is necessary for the normal operation of the heating system.

Work to prepare and resume uninterrupted heating operation guarantees trouble-free coolant flow.

Flushing

If the radiators in your apartment begin to heat worse than before, there are several reasons:

- poor boiler performance;

- pump failure;

- airing of pipes.

Over many years of operation, debris, scale particles, and rust accumulate in pipes, heating devices, and collectors. Growing inside, they clog the passage hole for the coolant; the porous structure reduces the heat capacity of the metal parts of the heating devices.

Consequences of blockages:

- burnout of the heat exchanger, requiring its replacement;

- temperature difference in batteries;

- noise in the pump with subsequent failure;

- boiler breakdown.

To eliminate and prevent contamination, washing is performed.

Mineral deposits can completely block the movement of coolant

A decrease in heating efficiency occurs for 2 main reasons:

- The appearance of mineral deposits. Non-galvanized pipes readily accept calcium and magnesium salts on the surface. Such problems do not arise with galvanized pipes.

- Sludge growth in pipe sections with low coolant flow rates. Multi-section cast iron radiators are susceptible to this phenomenon. The dependence is proportional to the increase in volume and number of sections.

- special hydropneumatic equipment;

- chemical reagents.

The basis of chemical reagents is acid.

Crimping

This procedure is designed to check the hydraulic system for weak points. Tests are carried out using overpressure water circuit or pneumatic method.

Signs that a flush is needed

For the normal functionality of the heating system, nothing should interfere with the movement of the coolant through the channels constructed for it.

It can be diagnosed by carefully monitoring the operation of the entire system and the appearance of a number of indirect signs:

- warming up of the system takes longer than before (for autonomous heating systems);

- the operation of the boiler is accompanied by uncharacteristic sounds;

- increased gas or electricity consumption; the temperature in different parts of the radiators varies significantly;

- radiators are noticeably cooler than supply pipes.

However, weak or uneven heating of batteries is not always a sign of clogging. Perhaps they were aired out. In such a situation, it is enough to release the air lock through the Mayevsky tap.

Without regular flushing of heating systems, pipes become overgrown, their flow area decreases, resulting in an increase in hydraulic resistanceIn houses with a central heating system, its flushing should be carried out by employees of the heat supply company. In a private home, this procedure is carried out by the owners or invited specialists.

For example, in centralized heating systems, the coolant must undergo a water treatment cycle, which reduces the degree of contamination. True, this rule is not always followed. And the system itself is often in its third or fourth decade of operation, and the amount of waste circulating inside increases every year.

But for both centralized networks and autonomous systems, it is recommended to flush annually. Which, by the way, is confirmed by the requirements of building codes. This period is considered critical for the accumulation of debris inside the circuit, which significantly reduces operating efficiency.

If the system is not flushed before the start of the heating season, the pipeline becomes clogged and appliances and heating equipment fail prematurely.

Hydroflushing, how and why

Hydropneumatic flushing of a heating system is based on simultaneously supplying air under pressure in a certain amount and water to sections of pipelines. The water-air mixture that is formed in this case cleans the heating communications thanks to multiple pulses performed by the flushing compressor.

Pulses in pipeline water create small bubbles, which gradually destroy deposits on the walls of heating communication pipes.

In order for the washing process to be successful, it is necessary to perform the following calculations:

- Length of pipelines that will be flushed;

- Air flow and pressure determined based on pipe diameters;

- Water speeds and flow rates.

Typical scheme for carrying out work

Preparation

For the hydroflushing process to be successful, you need to take an individual approach to each heating system and take into account its features.

Ideally, before the process it is necessary to carry out preparatory measures:

- Inspect all heating communications;

- Determine sections of pipelines (risers, groups of risers) that will be washed separately and break them down into stages;

- If necessary, you need to install shut-off valves to block sections of pipelines and remove washed deposits from the heating system;

- Make calculations of air and water consumption to obtain the required result after washing;

- Determine the need for hydraulic testing (pressure testing) of pipelines.

Connected equipment to the elevator

After all the preparatory measures have been carried out, the heating systems are hydroflushed until the water-air mixture becomes lighter. After washing, repeated pressure testing is performed.

The quality of the flushing performed is assessed by the reduction in the hydraulic resistance of the heating system, which is determined after and before hydraulic tests.

Method for cleaning the heating system

A pipe with a diameter of twenty to forty millimeters is inserted into the supply. The pipe is equipped with shut-off elements and check valves. Next, you can begin to supply water and compressed air to the system.

If you had to deal with a small system, then it is possible to supply water and air through existing pipes. If there is excess water, it can be discharged through drain taps or a drain pipe can be specially installed for this purpose. If there is an elevator, then the cone and glass are removed before washing.

Dismantled heating elevator

Compressed air is supplied to the heating pipelines thanks to a compressor, which you can see in the photos and videos in our gallery. The compressor produces air with a pressure of about 0.6 MPa. To prevent the flushing liquid from entering the compressor receiver, you need to install a check valve on the pipeline. Pressure gauges with a scale of up to one megapascal are installed on the supply and return pipes.

The washing itself can be carried out using two methods:

Flow-through. The heating supply pipelines are first filled with water with the air collector valve open. After filling the pipes, the valve is closed and the supply of compressed air begins. Both the air and water mixture are simultaneously supplied to the pipelines.

Flushing is stopped when clean water begins to flow through the pipe. After this, the water is drained into the drain. This method is used to clean heating and hot water systems;

Filling method. With this method there is some consistency in actions. To begin with, the pipelines are filled with water and the valve is closed. Compressed air is supplied to the second pipe for fifteen to twenty-five minutes, depending on the diameters of the pipes and contaminants.

After the air supply has stopped, close the valve and drain the water through the drain pipe. Upon completion, the system is rinsed several times with clean water.

Heating system diagnostics

To identify the need for hydropneumatic flushing of the heating system, it is necessary to carry out an initial diagnosis. It can be carried out at home, without resorting to the services of expensive specialists. It is based on the diagnostic results that it is necessary to decide on flushing. In addition, after routine maintenance, gently subject the heating system to anti-corrosion treatment - this will reliably protect the walls of the pipelines for the next operational period.

So, the main signs that your heating system needs hydropneumatic flushing are the following:

How is hydropneumatic flushing carried out and what equipment is needed?

The main essence of hydropeneumatic flushing of a heating system is cleaning the pipeline system and heating radiators using compressed air pressure . In this case, the coolant remains in the system, that is, water. The beginning of this process sharply increases the speed of fluid movement in the system, and compressed air gives the water increased turbulence, that is, uneven movement and the formation of turbulence. Under the influence of a mixture of air and water, scale and deposits formed on the internal surface of the system are loosened, carried away by the water-air flow and removed from the pipes and radiators to the discharge point.

The discharge point for loosened deposits in this type of flushing is the drain pipe or a specialized tap. If these elements are missing in the heating system, they must be inserted before starting cleaning.

If the heating system with liquid coolant has an elevator, it must be dismantled before flushing to avoid damage.

The air in the heating system is supplied from a compressor to create a powerful water-air flow with turbulence. This device should show a pressure of 0.6 MPa at the outlet. In order to prevent water from entering the compressor receiver from the system, a check valve is installed at the point where it connects to the pipeline system.

A good compressor with a powerful and uniform air supply supplies the pipelines with a water-air mixture, which loosens and knocks down scale deposits inside the pipes. The compressor must operate in a uniform pulse mode, creating not just a constant flow of air, but a series of air-water shocks. This is how the turbulence that loosens the scale is formed.

A smart solution is to use a compressor that can add disinfectants and cleaning agents to the air flow. In addition, such a device must be protected from spontaneous shutdown, be quite compact and, preferably, have an alarm about the level of the flushing liquid being consumed and the displayed pressure parameters.

Signs of air locks

The first sign of air in the system is poor heating of the batteries. The battery warms up unevenly, not enough, and if any sounds appear in it, then the answer is clear - the air in the heating radiators is preventing the circuit from working properly. If the radiators have a bottom connection, and its upper part is cold, then air has accumulated in such a radiator and bleeding the air from the heating radiator will restore normal operation.

Removing air from heating circuits

There is a lot written on the Internet about what needs to be done and how to remove air from a heating battery. For open heating systems with an expansion tank, this problem is not relevant. In such systems, the air exits independently through a tank located at the highest point of the circuit. Problems with some radiators may arise, especially if the slope is chosen incorrectly. Such air bubbles are removed using Mayevsky taps or automatic air vents.

For closed systems with forced circulation, the problem of how to get rid of air in the heating system is also completely solvable. Air is removed from the batteries manually by opening the Mayevsky tap. If you hear a hissing sound when you open it, then the actions are correct and there is air in the system. The air must be released until water appears at the outlet of the Mayevsky tap.

Such accumulations of air can completely stop the circulation of water in the system. If the installation of problematic areas of the circuit, for some reason, cannot be changed, then a heating system air bleed valve is installed in such problematic areas to bleed it.

Features of aluminum radiators

An unpleasant phenomenon is sometimes observed in aluminum radiators. The radiator material reacts with water. As a result, gases are constantly formed and must be constantly removed from the radiator, and how to remove air from a heating battery is described above. To avoid the problem described above, it is enough to buy and install aluminum radiators with an internal anti-corrosion coating. The correct solution would be to replace the aluminum radiator with a bimetallic one.

Flushing chemicals

Chemical compounds are used to remove scale, which forms mainly on the internal surfaces of steel and copper pipes. These solutions prevent foaming of the coolant, which provides protection against corrosion processes and thereby increases the life of the circulation pump.

The chemical used changes color. The active composition is colored red, and the spent one has a yellow-orange tint. To prepare a water-based solution, you will need to use 10-30% of the chemical. It is prohibited to drain the waste into the sewer; the composition must first be neutralized.

Test Tools

To test the system for resistance to high pressure, a special device is used, which is called a pressure tester. It is a pump capable of creating pressure inside the system up to 60 or 100 atmospheres, depending on the type of mechanism. There are 2 types of pumps: manual and automatic. They differ only in that the second option stops pumping itself if the pressure reaches the desired level.

The pump consists of a tank into which water is poured and a plunger pump with a handle that moves it. On the body of the mechanism there are taps to block the pressure supply and pressure gauges to regulate the pressure. There is also a tap on the tank that allows you to drain the water that remains in the tank.

The principle of operation of such a pump is similar to a conventional piston analogue, which is used to inflate tires. The main difference is the cylindrical piston made of steel. It is fitted tightly inside the housing and a minimum gap is created, which makes it possible to pump up pressure up to 60 atmospheres.

Manual blowerSource amazon.com

For hand pumps, the biggest disadvantage is that such pressure testing of pipes will take a very long time due to pumping the system with water. This process can take several hours, since large systems that have radiators will need to be filled manually.

Automatic devices work on a similar principle, but when the pressure limit is reached, they turn off themselves. They also require electricity to operate, so manual ones are more suitable for places where there is no power supply yet. Automatic pumps can pump pressure up to 100 bar, and industrial devices up to 1000 bar.

Electric version of the compressor Source ngenix.net

What is hydropneumatic flushing?

The essence of the method is that compressed air is supplied under high pressure into a system filled with water. A seething water-air mixture (pulp) is formed, which loosens the scale deposits and carries them through the drain into the sewer. For greater cleaning efficiency, air from the compressor is supplied in pulses and jolts. The pulsation of such water-air “blows” is adjustable and can be changed step by step. Flushing continues until the water at the outlet of the circuit becomes clear. After completing the work, it is necessary to check the system for leaks - carry out a pressure test, because after descaling, leaks may occur in some pipeline connections.

For apartment buildings, the frequency of hydropneumatic flushing of central heating systems is determined to be 1 year (SNiP 3.05.01-85). In private homes, autonomous heating systems should be flushed only if there is a real need for it. That is, heat transfer has noticeably deteriorated, energy consumption has increased, and cold areas are easily detected on heat exchangers. You can flush the system purely for preventive reasons, but it is not cheap (if you order it from a specialized company).

Is this crimping necessary?

Let's start with the basic concepts. What is a home heating system? Unless you have electrical panels, then most likely this is a line of pipes with coolant circulating through them. In order for it to move within the system, by default the coolant must be in a liquid state. And liquid, as you know, always strives to find a way out of a confined space. If circulation is disrupted for some reason, the entire system stops working.

PHOTO: pp.userapi.com High-quality heating is the result of constant monitoring of the integrity of the entire system PHOTO: kliningovyj-raj.ru And if the tightness of the main line is broken, then, in addition to the lack of heat, you may also be faced with the need for emergency repairs to your apartment and even those of your neighbors

There is only one simple way to check for possible disturbances in the operation of the main line - increase the pressure in the system so that connection defects are detected, which should be paid attention to before starting the heating. Thus, pressure testing is an actual pressure test of the heating main before the operating season

To check the system for leaks, the pressure should be increased by 20-80%. The percentage of pressure increase depends on the equipment installed in the line. After all faults are detected during pressure testing, the necessary repairs are made and the tightness of the system is restored.

PHOTO: zamena-radiatora.ru All this takes time, so do not postpone the procedure until the last days before the start of the heating season

Things to remember before cleaning

Flushing the heating system using hydropneumatic technology should be carried out with the following initial measures:

- Calculation of the largest and smallest p needed for cleaning;

- Carrying out hydrotesting and pressure testing, if necessary;

- Establishing the need to use chemicals, since for outdated structures, cleaning the OS using this method without them may not deliver the required result;

- Measurement of hydraulic resistance of the configuration. After cleaning, the quality of the method is determined by the difference between this value “before and after”;

- Establishing places in the pipeline for cleaning, installing a stop fitting to limit them;

- If the structure has a water jet lift, the cone and sleeve must first be removed from it;

It should be noted that the use of this technique greatly reduces waste, and the profitability of using OS increases. This cleaning method is less expensive than overhauling the entire pipeline. But in terms of effectiveness it is in no way inferior to him.

The price category for the operation will depend on whether you will perform it yourself or go to professionals. In the first situation, it is less expensive to rent special equipment, since the cost of a new supercharger is quite high. If you entrust it to specialists, the cost of cleaning will be much lower.

Rules and procedures for carrying out different types of washing

Hydropneumatic flushing technology

The technology for flushing a heating system using the hydropneumatic method involves injecting compressed air into a pipeline filled with water. The resulting air-water mixture moves at high speed, thereby “loosening” and separating existing deposits from the surface of the pipes and removing them beyond the contour.

Hydropneumatic heating flushing using disinfectants

Hydropneumatic flushing is carried out in two ways. The first option involves a flow circuit. First, the system is filled with water - the air collector valve is open, after filling the valve is closed. Then, using a compressor, compressed air is pumped in and the drain pipe is opened. As a result, the resulting water-air mixture passes through all heating devices and then drains. The washing process continues until clean water flows from the nozzle.

The second washing option is carried out using a different algorithm. When the system is filled with water, the air collector valve is closed. Then, compressed air is pumped into the pipeline through the backup pipe for 10-15 minutes, after which the dirty liquid is drained through the drain pipe.

Chemical flushing: an alternative to major repairs

Chemical cleaning of heating systems is based on the use of alkaline and acidic solutions. The washing procedure consists of introducing a chemical solvent and a corrosion inhibitor, which protects the metal from oxidation, instead of a heat agent. The reagent, circulating in the system, dissolves scale and deposits on the walls of the pipeline. Before draining the liquid, a neutralizer is added to reduce the toxicity of the drug.

We compare the results before and after hydrochemical cleaning

The composition of the solution and the exposure time of the product are calculated individually, taking into account the contamination of radiators and pipes, and the material from which they are made. The advantage of this method is the possibility of carrying out the procedure during the heating season without turning off the heating. As a rule, one cycle is enough for high-quality cleaning.

Cleaning with chemical solutions extends the service life of the heating system by 10-15 years and significantly increases the efficiency of radiators. The effect of flushing is equated to a major overhaul, while its costs are 10 times lower than repair work.

The disadvantages of chemical washing include the high toxicity of the drugs. This method cannot be used for systems with poor seals and thin pipes, the walls of which may not withstand the effects of concentrated reagents. This aggressive method is prohibited for aluminum batteries!

Pneumohydropulse washing is an effective hardware method

Pneumohydropulse cleaning is carried out without dismantling the system using a special pneumatic device. The impact of the device leads to the formation of a pulsed kinetic wave and cavitation bubbles in the coolant, which, when collapsed, create shock waves. All this increases the pressure in the pipes and radiators and leads to the cleaning of their walls from all types of deposits and washing out contaminants from the system.

Device for hydropneumatic pulse cleaning

Work using a pneumatic-hydraulic pulse apparatus can be carried out at any time during the heating season. The technique does not require dismantling or turning off the heating and allows you to work with pipes with a diameter of up to 150 mm. This method is safe for all metals, as it does not involve exposure to caustic substances.

Flushing heating systems is a complex technological process with a lot of subtleties and nuances, so it should be carried out by professionals with sufficient experience and the necessary equipment.

Hydrodynamic type of flushing

The heating flushing scheme in this way involves active action of water on scale and deposits. This happens thanks to a stream of water, which is directed under extreme pressure to the desired area.

Water is supplied through special nozzles of the required size and diameter. This type of washing is more expensive than chemical washing, but the result is much more satisfactory.

Scheme of using the hydrodynamic method of cleaning the heating system. Click to enlarge.

This type of flushing is best suited for batteries made of cast iron. Removing scale from cast iron using chemicals is very problematic due to the properties of the material itself, and sometimes even impossible.

However, the hydrodynamic system does an excellent job in such cases.

Another undoubted advantage is the environmental friendliness of such washing, since no acids or solvents are used. But only water.

To achieve the desired effect, specialists must have a special mechanism that will create a pressure of two hundred or more atmospheres.

Naturally, all scale is removed solely by exposure to water. No additional liquids or reagents are needed.

But here, too, everything is not as simple as it seems. Before flushing using this method, you must take the radiator to a service center. There it will have to be treated with a special liquid so that the layer that needs to be removed becomes softer and more pliable.

Only after this can the walls be treated with a jet of water operating under pressure. Using this method, you can remove almost everything: grease, scale, rust, dyes, carbon deposits, etc.

Instructions for flushing the heating system

Pneumatic pulse cleaning scheme

There are 2 main methods for flushing the heating system, namely:

- using special hydropneumatic equipment;

- using chemical reagents.

Flushing using the hydropneumatic method

Hydropneumatic flushing of heating systems - instructions

Hydropneumatic flushing of heating systems - instructions

This method is actively used by domestic housing offices and is quite effective. You just need to do everything in accordance with technology.

The principle is extremely simple: first, water is discharged from the system, then it is supplied back. A special pneumatic pump is used to “adjust” the water flow. As a result, under the influence of a fairly powerful pressure, scale and other deposits peel off, and when the water is drained, they are removed from the system.

To carry out this procedure yourself, you will need a pneumatic pump capable of pumping up a pressure of more than 6 kg/cm2.

The sequence of actions is as follows.

Before starting work, you must turn off all taps

The end fittings are unscrewed using a wrench

First step. We close the return valve.

Heating system line diagram

Second step. We connect the pneumatic pump to the valve installed after the valve.

Third step. We reset the return line.

Fourth step. Let the pneumatic pump build up pressure above 6 kg/cm2 and then open the valve to which it is connected.

Fifth step. We close off all the risers one by one. We do this so that no more than 10 risers are blocked at one time. Compliance with this rule will make the washing procedure as effective as possible.

Sixth step. We switch the system to reset in the opposite direction. To do this we do the following:

- close the discharge and close the valve connected to the pump, and turn off the device;

- close the open valve, and then open a similar one on the “return”;

- we reset the heating system. To do this, connect the pneumatic pump to the valve in the opposite direction, then open the valve and turn on the pump. The liquid will move in a different direction.

You can determine the required duration of rinsing by eye. Has clear clear liquid started coming out of the system? We can finish! Return the gates and valves to their original positions and turn off the pump.

Prepare a suitable container to collect dirty water. If you wish, you can connect a hose to the battery and ensure that the dirty coolant is discharged into the sewer.

Chemical wash

Chemical pipe flushing diagram

This method can be used only in two cases, namely:

- if it is necessary to clean a heating system with natural circulation, built using steel pipes. It is advisable to use chemical reagents in situations where, for any reason, there is no desire to flush the entire system. Most often, blockages are deposited in heat exchangers. The system can silt around the entire perimeter. In the second case, chemical washing will not be of much use;

- if it is necessary to restore the old heating system. Over decades of operation, pipes can become clogged and overgrown so much that the power of the pneumatic pump will not be enough for effective cleaning. It would, of course, be possible to use a more powerful pump, but no one can guarantee that the pipes will not burst under such pressure.

Important! If the pipes are very old, with traces of corrosion and deformation damage, flushing may not have any positive result. Chemical reagents will simply dissolve the rust, causing the pipes to start leaking

The only effective solution in such a situation would be to replace worn-out lines.

Wash reagent

The principle of flushing is simple: instead of coolant, a special solution containing acid and alkali is poured into the system. Then the mixture is circulated for 2-3 hours (if it is not the natural circulation line that is being cleaned, you will need to connect a pneumatic pump for this), after which it is drained and the pipes are filled with standard coolant.

Reagents for flushing and protecting heating systems

Important! According to the requirements of SNiP, such reagents are prohibited from being discharged into the sewer system. The best option is to neutralize the used mixture using a special composition

You can buy it in the same place where you buy the washing solution.

Never use such chemical mixtures to clean aluminum pipes. If the products remain intact after such washing, they will serve significantly less.

It is recommended to carry out mandatory flushing of the system of a private home at least once every 7 to 10 years.

SP-OM

The complex product of the SP-OM brand is used for flushing heating systems, heat exchangers, boilers and any other heat exchange equipment. Can be used in open and closed heat exchange circuits. "SP-OM" does not destroy aluminum and polymer elements of the system, as well as rubber gaskets. It has proven itself well on an industrial scale. There are various brands of SP-OM designed for specific operating conditions. Manufacturer's website - https://spomcom.ru/

SP-OM Pros

- effective removal of scale, rust and other deposits;

- wash-in-place;

- does not corrode rubber gaskets and seals;

- prevents corrosion of ferrous metals;

- may further include a corrosion inhibitor;

- Can be used with aluminum parts.

Minuses

Consultation and services of a flushing specialist may be required.

SP-OM

Metalin T is a product made on the basis of hydrochloric acid. Removes heavy lime deposits, rust products and organic matter in heating systems made of steel or non-ferrous metals. It is a non-flammable substance. After adding an alkaline neutralizer, the waste is allowed to be drained into the sewer. Packaged in concentrated form in containers from 1 to 30 liters.

Metalin T Pros

- non-flammable;

- quick cleansing.

Minuses

- after neutralization with alkali, discharge into the sewer system is allowed;

- not used for treating surfaces made of aluminum and its alloys.

Used in the treatment of pressure boilers, tubular heat exchange devices, boilers, condensers, pipelines in industry and domestic conditions. Removes various types of contaminants, in particular limestone and corrosive deposits. Ideal for washing plastic, metal and rubber pipes. Cleans carefully and does not have a negative effect on the structure of the seals. Not recommended for cleaning systems with surfaces made of aluminum and derivative alloys. Preliminary testing on treated stainless steel surfaces is also recommended.

4a293175f1908eda01bbc87f7b3a4bf3.jpeSYNTILOR Watesup Pros

- does not affect the structure of metals;

- concentrated product;

- high efficiency even at low operating temperatures (20–35°C);

- does not damage seals and rubber gaskets;

- contains an inhibitor.

Minuses

cannot be used for products made of aluminum and derivative alloys.

Heating system cleaner SYNTILOR Watesup

Deoxyl-3

Deoxyl-3 is an acid-type product for chemical cleaning of pipelines in heating and water supply systems. It is packaged as a concentrate in 20 liter containers. The liquid is not flammable and belongs to toxicity class 3. For a greater cleaning effect, it is advisable to use the Deoxyl NO additive together with the drug. Foaming is neutralized by the Foral PG additive. The liquid is quite aggressive, so when working with it it is recommended to protect the skin and respiratory organs with protective equipment. Use strictly according to label instructions.

Deoxyl-3 Pros

- completely removes scale-corrosion deposits regardless of the design features of the equipment;

- biodegradable;

- after washing, the spent working solution can be drained into the sewer;

- The composition includes various inhibitors that prevent metal etching and the appearance of corrosion. Inhibitors not only remove deposits, but also protect the metal.

Minuses

The liquid is aggressive (work with it only with protective equipment).

Which system flushing products would you choose or would you recommend purchasing?

Deoxyl-3

75.00 % ( 3 )

Save your voting results so you don't forget!

To see the results you need to vote

Stages of crimping

The work is carried out at the following frequency:

- when starting a new system;

- annually after the heating season;

- after flushing or repairing the heating main with replacement of pipes.

For apartment buildings, preparation is as follows:

- Inspection of shut-off valves in elevators, central pipes, risers. On cast iron valves, the seals are changed, the paronite gaskets between the connection flanges are renewed, and unusable bolted connections are replaced.

- Using visual observation, pipes and fittings are examined for the presence of cracks, chips, corrosion, and defects. Make repairs if necessary.

- Check the thermal insulation of risers and main pipes in basements.

Pressure testing after pressure cleaning is necessary to identify possible leaks

Crimping procedures and testing are carried out taking into account the parameters of heaters and heating equipment indoors. Regulations allow the use of operating pressures of up to 6 bar for cast iron heating radiators. When they are in the walls, the maximum is 10 bar.

Hydraulic tests are carried out as follows: the system is checked as a whole, then a pressure higher than the working one is applied to the thermal unit.

According to Rules 115 clause 9.2.13., tests are carried out at a pressure not lower than:

- 1 MPa - elevators, heaters for heating and hot water systems;

- 0.6 MPa - cast iron and steel heating radiators;

- 1 MPa - convector, panel heaters;

- working pressure plus 0.5-1 MPa for hot water supply;

- pressure recorded in the manufacturer's instructions for air heaters.

The test pressure in steam systems is selected by the manufacturer from maximum to operating minimum:

- minimum - not lower than 0.2 MPa, but not less than 1.25 working;

- the maximum is established by strength calculations according to standards;

Crimping occurs at temperatures from + 5 degrees. If negative - in emergency cases.

If there is no visible leak, but the pressure drops, the pressure gauge shows problems in hidden places

Crimping stages:

- Filling the system with cold water. During work, the temperature of the liquid is no more than 45 degrees. The pressure increases gradually. Control is carried out using a pressure gauge.

- Once the set pressure is reached, the system remains at rest for about 30 minutes.

- During downtime, an inspection is carried out for leaks in pipes and batteries. Make sure there are no leaks. A method of control is to place toilet paper in dangerous places or wrap pipes with it. When there are leaks, spots of water and silt are visible.

- Control occurs according to the readings of the pressure gauge. The leak occurs in a place inaccessible to observation. A drop in pressure will warn of this.

Upon completion of pressure testing, a certificate of fitness for use is issued.

Cleaning Guide

- Remove the nozzles and membranes from the hydraulic elevator, if present;

- Release the profile into the drain to drain the dirty liquid;

- Carry out a thermal imaging study of the internal planes of pipes, if special equipment is available;

- Block off the heat seal located on the return pipe;

- Fill the structure with water to remove the medium from it, with the air collector valve open. When the configuration is filled, the shutter closes;

- Connect the supercharger to the metering valve, open the release on the “return”;

- Open the valve when p reaches 0.6 MPa;

- Block off the risers and clean them one by one. Perform cleaning until the step until light water comes out of the pipe;

- Switch the heating profile from supply to “return”. Clean the risers in reverse order;

Washing equipment

- Station CILLIT–BOY

. This is a modern electronically controlled device. The cost of purchasing it can soon pay off, since such a unit can be used not only for flushing heating, but also for purifying drinking water from bacteria, as well as servicing the “warm floor” system. When used for heating, compressed air and water are uniformly supplied. Its washing power is enough not only to clean pipes and batteries, but also to remove scale from the inside of the heating boiler, which extends its service life and increases the heating level. - Rockal

. This compact compressor is mainly used for cleaning copper and steel pipes. It can clean systems with a capacity of no more than 300 liters. It maintains a constant pressure of 1 bar, and its productivity, despite its small dimensions, reaches 40 liters per minute. - Ropuls

. A powerful device that is used not only for flushing the heating system, but also for purifying water flowing through pipes into the house. It can be used for cleaning “warm floors” and cleaning solar collectors from silt deposits. When drinking water is purified with such a device, not only rust and debris are removed from it, but also bacteria. - Romantic 20

. It is suitable for removing scale from heating pipes. It provides automatic regulation of the pulse interval. The pressure height reaches 10 meters, the pressure is 1.5 bar, and the performance is the same as in the Rokal installation. It can be used for systems whose volume does not exceed 300 liters.

- the color screen displays an image at a viewing angle of 36 degrees;

- there is a focusing ring on the lens of the device;

- The shooting frequency reaches 9 Hz.

Advantages and disadvantages

Since the end of the 18th century, when Bonnemann proposed the prototype of modern heating systems, until now, the global industry has offered various means for effectively cleaning pipes and radiators. The industrial era has significantly changed approaches to the cleaning process. Manual work and labor-intensive operations have sunk into oblivion - flushing pumps have entered the service of specialists.

Over two and a half centuries, history has offered various ways to remove scale. But today the following operating principles are considered effective:

- Unit for flushing the system with chemical reagents.

- flushing pump for descaling using a pneumohydraulic method.

- Hydropneumatic shock devices for cleaning pipes and radiators.

Experts believe that there is no ideal method, since each method has unique advantages and disadvantages. For example, chemical cleaning is considered low-cost, so it is used most often. But the aggressive solution is not suitable for aluminum radiators, and used reagents need to be carefully disposed of.

Due to the kinetic impact at a speed of 1500 m/sec, the hydropneumatic impact type flushing pump copes well with scale and mud blockages. And, nevertheless, the device will not be able to clean a system with a length of more than 60 m. Specialists use similar units to clean the heating system of a cottage and risers in an apartment building.

The operating principle of a pneumohydraulic compressor is widely used to clean the system from rust, grease and scale. Such devices have excellent reviews for removing silt deposits, since they operate with water-air mixtures and loosen chemical formations at high pressure. However, buying such a flushing pump for the average person is an impossible task. The compressor has an impressive price tag, but pays off well for commercial enterprises.

How to find a leak

During air pressure testing, a leak can be detected by ear: a characteristic whistle of escaping air will be heard. But if you can’t find the place by ear, you should coat the joints with a soft brush and a solution of liquid soap. The air will blow up bubbles and you will find the source of the problem.

If the problem is in the joints, you can disassemble the joint and reseal it with fum tape.

PHOTO: zamena-radiatora.ru If the pipes are damaged, it is possible that the entire elbow will have to be replaced

With the hydraulic method, everything is much simpler - the leakage site will make itself known with a fountain of water or a puddle under the connection point.

conclusions

1. An analysis of the operating modes of hot water supply systems for residential buildings in Ulyanovsk was carried out. As a result of the survey, it was determined that in hot water supply systems there is a significant overconsumption of thermal energy and coolant, due to the unregulated circulation of the coolant and the lack of regulation of hot water temperature during periods of minimal water withdrawal.

2. Since 2006, the heat supply system of Ulyanovsk has implemented automatic control of hot water temperature with a standard temperature decrease during periods of minimal water withdrawal. An examination of the operating modes of the central heating station showed that due to the automatic decrease in the temperature of the hot water supply during periods of minimal water withdrawal, the heat consumption of the hot water supply system is reduced by more than 2.5%.

3. In the period from 2006 to 2012. automatic reduction of hot water temperature during periods of minimal water withdrawal was implemented at 25 central heating stations in the heat supply system of Ulyanovsk. The estimated annual savings of thermal energy at these central heating stations due to the nightly decrease in DHW temperature is more than 3.96 million rubles. with a weighted average tariff for the purchase of thermal energy in the amount of 1100 rubles/Gcal (including VAT).