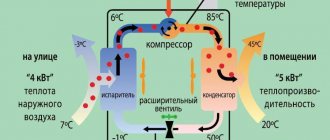

Few residents of apartment buildings are well aware of the rules for flushing heating pipelines. Meanwhile, this operation can extend the service life of the entire system, and, what is important for each of the residents of the house, improve the efficiency of its operation. After all, everyone wants their apartment to be warm and cozy in winter! And the temperature in the apartment in the winter cold directly depends on timely and high-quality washing.

With the onset of cold weather, many note that the heating in the apartment does not work very well, to put it mildly. Utility workers, in turn, assure that everything on their part complies with the standards, the temperature of the coolant is sufficient to keep the house warm. Everything is correct, everything corresponds - but in the bedroom no higher than +17! Residents buy heaters and curse in their hearts both careless utility workers and standards that do not correspond to the real climate.

However, the problem often lies elsewhere. Simply, the pipes are clogged, the passage of coolant is difficult, and the bulk of the heat goes to heating solid deposits in the pipes, and not the radiators in the rooms. It's time to flush your home heating system! Naturally, residents cannot do this on their own. And they shouldn't!

Necessity

Despite the fact that most consumers who have a centralized heating system in their homes are accustomed to the fact that pressure testing is carried out in the summer, it is recommended to carry it out twice a year.

In addition, crimping is carried out in the following cases:

- Do-it-yourself pressure testing can be carried out at any time if there are suspicions about the integrity of the system, for example, rust on the pipes, their bending, etc.

- According to the rules of SNIP, pressure testing of the heating system is necessary when putting it into operation, for example, in new buildings or after major repairs with the replacement of pipes.

- If necessary, sewer risers can be pressure tested to identify defects. Considering that the sewer system is usually gravity-fed, a small leak does not cause problems until the riser becomes clogged or the water intake level is exceeded.

- In some cases, control pressure testing is carried out to resolve controversial issues, for example, when filing a civil lawsuit against neighbors who flooded as a result of burst pipes. In this case, a pressure test certificate for the heating system is issued, the form of which is certified by specialists and handed over to the judicial commission.

Who is to blame for the system malfunction?

All accidents associated with the heating system can be divided into intra-apartment and intra-house. This separation allows you to determine who is to blame for the problems.

Legally, responsibility for the heating system rests with consumers of services and the companies that provide them. The management company is fully responsible for the in-house system, so the blame for the accident falls on this organization.

Limits of responsibility between owners and management companies

Owners of housing in apartment buildings must ensure the safety of not only their apartment, but also common property. By signing the contract, each tenant agrees to these conditions of living in the apartment building.

And yet, many people believe that since the batteries are in their apartment, they belong to them by right of ownership. However, the heating system along with the radiators is included in the structure of the common property of the house. Therefore, only management companies are involved in their repair and replacement.

Crimping methods

Pressure testing, according to OKPD, is carried out before the start of the heating season in order to identify and eliminate possible breakdowns and leaks in the heating system. Otherwise, during the heating season, if serious leaks occur, you have to stop the entire system, reduce the pressure, and only then fix the problem. In addition to such a check, it is recommended to flush the system, according to OKVED, to maintain the working condition of the pipes, which quickly oxidize and become overgrown with lime deposits from the inside.

Currently, this procedure is carried out in two ways:

- Air pressure testing of the heating system. To carry out this procedure, a pump is connected to a closed heating system, which creates critical pressure. You can check the pressure level using a pressure gauge installed on the pump compressor. According to SNIP standards, pressure testing of the system is carried out at a pressure exceeding the working pressure by at least 1.25-1.5 times; in reality, when checking the system, the pressure is raised significantly higher. The operating pressure is regulated for each individual heating system.

- The second method of crimping, according to SNIP, is with water. In fact, the method differs from air pressure testing only in that water is pumped into the system under pressure several times higher than the working pressure. Experts believe that, in accordance with the OKPD code, pressure testing of heating systems with water is more effective, as it allows you to quickly identify even minor leaks and microcracks in pipes. In addition, after air pressure testing, the pipes must be washed, and in cases with water pressure testing, this process can be combined.

Regardless of the method of pressure testing and flushing, the system must be left under pressure for at least a day to identify hidden breakdowns and leaks.

Types of system maintenance work

According to Appendix 1 to the Methodological Manual for the Maintenance and Repair of Housing Stock MDK 2-04.2004, maintenance of communications, technical devices and premises consists of the following list of works:

- conservation and re-preservation;

- adjustment of taps, valves, gate valves;

- adjustment and packing of oil seals;

- compaction of squeegees;

- system check;

- descaling;

- turning off radiators in case of leakage;

- washing and cleaning of constituent components;

- draining/filling the system with water;

- eliminating air jams;

- strengthening pipelines.

If an accident is detected, the damaged fittings are repaired and replaced.

Crimping services

Despite the fact that most objects on the state balance must undergo this procedure centrally, quite a few companies offer this service on a commercial basis. In order to confirm the quality of the work performed, the company must issue a heating system pressure test certificate, a sample of which can be found in official sources. In addition, the customer is issued certificates that confirm that the heating system has been pressure tested and flushed in accordance with SNIP standards and in accordance with legalized OKPD codes.

The price for providing such a service will depend on several factors, the first of which is the length of pipes and heating elements. Other factors influencing the final cost of the service will be the complexity of the work performed and the availability of pump connection points. It plays a role whether the pressure test is performed with water or with air.

The price for providing such a service will depend on several factors, the first of which is the length of pipes and heating elements.

Professional equipment for washing and crimping

DIY crimping

In general, flushing and pressure testing the heating system is a relatively simple procedure that you can do on your own. To carry out quality work yourself, you need to follow a few simple steps:

- Do-it-yourself pressure testing of a heating system begins with removing all the coolant from it; in some complex designs, the coolant must be removed using a pump.

- The second step is to fill the system with water. This can usually be done with the simplest pump, throwing it into a sufficiently large container filled with water. Water is pumped into the system through the drain valve, which must be in the open position. While pouring water, it is necessary to monitor the pressure in the system and continue to pump water until it exceeds 2 atm.

- Once the system pressure reaches the desired level, it is necessary to bleed the air from the batteries unless automatic bleed valves are provided.

- The last step is to inspect all pipes, especially their joints, for water leaks.

To solve the question of how to pressurize a heating system with air yourself, almost the same algorithm is performed, only instead of liquid, air is pumped into the pipes. Joints and suspected leak points are lubricated with a soap solution, which begins to bubble in case of damage.

A professional pump for pressure testing a heating system is quite expensive and it is unprofitable to use it for domestic purposes. Basically, such equipment is purchased by companies that offer services in the field of pressure testing and flushing of systems, in accordance with the regulations of SNIP and OKVED.

In everyday life, a press is often used for crimping heating systems, which implements a mechanical operating principle and is also capable of increasing pressure in closed systems, while its cost is quite reasonable. A number of hand press models can be equipped with a pressure gauge. If it is not included in the design, it is necessary to connect a separate device in order to control the pressure in the system if the work is done with your own hands.

In everyday life, a press is often used for crimping heating systems, which implements a mechanical operating principle and is also capable of increasing pressure in closed systems, while its cost is quite reasonable.

Pressure testing of the heating system at the repair stage

Do-it-yourself washing

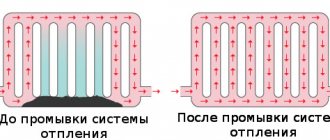

Flushing heating systems is necessary to eliminate excess debris inside it. Recommendations, according to SNIP, suggest flushing the system at least once per heating season. This allows you to keep the inner surface of pipes and radiators clean and, as a result, improve their thermal conductivity and coolant circulation. Ideally, it is recommended to remove them to wash the batteries, but in extreme cases, you can use a pump. It is not difficult to assemble a pump for pressure testing the system with your own hands; in general, you can use any circulation pump that works with liquid, and a pressure gauge measuring pressure is not needed for flushing.

Flushing heating systems is necessary to eliminate excess debris inside it. Recommendations, according to SNIP, suggest flushing the system at least once per heating season.

Dirty pipes in the heating system

For flushing, the pump is connected on the back side of the battery against the normal circulation of the coolant; this improves the flushing results due to the fact that the scale formed inside the pipe is deposited in the form of scales directed along the flow of the coolant.

Methods

Currently, washing is carried out in several ways according to OKPD:

- The chemical cleaning method involves the use of acids and alkaline solutions.

- Electric pulse cleaning - electrical discharge occurs in the water, which leads to the destruction of scale and its subsequent removal by regular washing.

- OKPD provides for washing batteries with water hammer, which is created by a special apparatus.

Why is this necessary?

In the vast majority of old houses, the filling, risers and heating connections are installed with steel pipes. Black steel has an unpleasant feature: the rough walls of pipes tend to collect dirt, gradually becoming overgrown with scale. The build-up is formed mainly from rust and calcium salts.

Rust is a product of corrosion of pipe walls. The source of calcium is sedimentary rocks, which are eroded by water on the way to the water intake.

Not only that: over time, spills, hoses and radiators become clogged with silt - suspended matter that settles in them, which enters the heating devices along with the coolant and settles in areas with a minimum speed of its movement.

The consequences of decreased pipe flow and the appearance of sludge deposits in radiators are very predictable:

- Reduced circulation rate . It leads to a drop in the temperature of the return pipeline and, accordingly, to a decrease in the temperature in residential premises;

- Cooling of the last sections of sectional batteries. It is there that the water speed is minimal, so silt begins to accumulate in the lower collector of the outer sections and over time completely blocks the circulation in them;

- In the most advanced cases, defrosting of the heating system or its individual sections. If the coolant circulation stops in cold weather, the water in the pipes and radiators will freeze very quickly. Since when the state of aggregation changes to solid, it increases in volume, pipelines and heating devices will be torn.

Crimping. Video

A video about pressure testing of an air heating system is presented below.

Cleaning batteries with air is usually not done, as it does not bring great results. It is also worth noting that the use of alkalis and acids is allowed only for cleaning batteries and pipes made of ferrous metals; it is prohibited for use in metal-plastic or plastic plumbing.

Based on the regulatory documentation given below, a pressure testing certificate has been developed, which is one of the main documents when handing over work to the Customer at the site.

Heating networks must undergo annual hydraulic tests for strength and density (pressure tests) to identify defects after the end of the heating season and carry out repair work. Pressure testing of pipelines accessible for inspection during operation may be performed once after completion of installation.

Hydraulic pressure testing is carried out with a test pressure of 1.25 working pressure, but not less than 1.6 MPa (16 kgf/cm2). The pipelines are maintained under test pressure for at least 5 minutes, after which the pressure is reduced to operating pressure. At operating pressure, a thorough inspection of pipelines is carried out along their entire length. The results of pressure testing are considered satisfactory if during its implementation there is no drop in pressure and no signs of rupture, leakage or fogging are found in valve bodies and seals, in flange connections, etc.

Before the start of the heating season, after the end of the hot water supply, the following must be subjected to hydraulic pressure testing for strength and density:

Elevator units, heaters and water heaters for heating and hot water supply - pressure 1.25 working, but not lower than 1 MPa (10 kgf/cm2);

Heating systems with cast iron heating devices - pressure 1.25 working, but not more than 0.6 MPa (6 kgf/cm2);

Panel and convector heating systems - pressure 1 MPa (10 kgf/cm2);

Hot water supply systems - pressure equal to the working pressure in the system plus 0.5 MPa (5 kgf/cm2), but not more than 1 MPa (10 kgf/cm2).

The hydraulic test must be carried out at positive outside temperatures. When the outside air temperature is below zero, checking the density is possible only in exceptional cases.

Systems are considered to have passed the test if, during testing:

No “sweating” of welds or leaks from heating devices, pipelines, fittings and other equipment were detected;

When testing water and steam heat consumption systems for 5 minutes. the pressure drop did not exceed 0.02 MPa (0.2 kgf/cm2);

When testing surface heating systems, the pressure drops within 15 minutes. did not exceed 0.01 MPa (0.1 kgf/cm2);

When testing hot water supply systems, the pressure drops within 10 minutes. did not exceed 0.05 MPa (0.5 kgf/cm2).

The results of the inspection are documented in a test certificate. If the results of pressure testing do not meet the specified conditions, it is necessary to identify and eliminate leaks, and then recheck the tightness of the system. During hydraulic testing, spring pressure gauges must be used with an accuracy class of at least 1.5, with a body diameter of at least 160 mm, a scale for a nominal pressure of about 4/3 of the measured pressure, a division value of 0.01 MPa (0.1 kgf/cm2), verified and sealed by the state verifier.

The heating system is one of the engineering systems that allows the building to be operated in winter. It is a misconception that the heating system will work on its own without interruption if it has been installed correctly.

To identify problem areas or to confirm operability in operating mode, it is necessary to conduct hydraulic tests. What pressure testing of the system looks like is shown in the photo.

What is crimping? This is a set of standard measures for checking heating equipment for operation.

When is pressure testing carried out?

Work related to testing and checking the system is carried out in the following cases:

- upon completion of installation and commissioning of the system;

- after repair of any heating device;

- when replacing parts of the pipeline;

- in preparation for the heating season.

By the nature of the test work, crimping is a leak test. What it is?

Let's say that this procedure involves the following actions:

- supplying the system with water or air under pressure using a hydraulic or pneumatic pump;

upon completion of installation and commissioning of the system; after repair of any heating device; when replacing parts of the pipeline; in preparation for the heating season.

- identification of system leaks;

- determining where water or air has penetrated the system.

Modern systems make it possible to carry out such tests without involving a large number of personnel. Violations of tightness are determined by special equipment.

When excess pressure is created inside the system, faulty devices, components and emergency areas will become unusable. The performance of suitable system elements does not suffer from such testing.

Sequence of work

Pressure testing and flushing of heating systems is carried out after turning off the entire system and removing the coolant (water or antifreeze) from it. When carrying out such a check, it becomes necessary to monitor pressure indicators to prevent rupture of the main pipeline.

Pressure testing and flushing of heating systems is carried out after turning off the entire system and removing the coolant (water or antifreeze) from it.

What features of the heating system are taken into account when determining specific test parameters:

- pipeline characteristics (material, wall thickness);

- characteristics of fittings;

- number of floors;

- type of wiring.

Pressure testing and flushing of the heating system includes the following preparatory work:

- prevention and preparation of the system;

- directly carrying out work to create pressure inside the system;

- preparation of documentation on the work performed;

- flushing the entire heating system.

Important!

If, during leakage testing, defects, damaged components or malfunctions are discovered, they must be eliminated. After the required repairs or troubleshooting, the entire set of measures is carried out again. If there are no violations, such a system is recognized as one that has passed the tests.

How to flush cast iron radiators ms140

Cast iron radiators are most susceptible to clogging. Due to their large volume, insoluble substances are much more likely to form in them, settling to the bottom, turning into dense plugs. Some residents, due to the ineffectiveness of the system, are replacing the main components. However, cast iron radiators can be cleaned yourself.

They will have to be first removed from the brackets by shutting off the coolant supply. All work is carried out in non-residential premises or outside. Moreover, it is desirable to provide sufficient pressure for flushing. If necessary, it can also be done in the bathroom. However, it is necessary to protect the drain from clogging with insoluble substances. Therefore, be sure to install a grille. Additionally, cover the bathtub enamel with a rag.

- Remove all plugs from the batteries. Additionally, clean the cavities with a piece of reinforcement.

- Place no-flow plugs on the upper and lower manifolds that do not allow liquid to pass through. Install the radiator with the open holes facing up.

- It is advisable to rinse the pipes with a soda solution. You can also pour it down the drain. Concentration 20g per liter.

- Caustic soda is poured into the liquid, then hot water is poured into the container. Mix until dissolved.

- Then, the radiator is filled with solution to the maximum.

- You need to leave the battery for 2 hours until completely dissolved.

- Flush any residue from the pipe using a hose or faucet.

- Significant volumes of dirt flakes may come out of the lower parts. It is advisable to rinse until clear liquid comes out of the neck.

Regulatory rules for conducting hydropneumatic tests

The rules for carrying out such work are determined by regulatory documents - SNiP (building codes and regulations).

These standards regulate certain technological schemes and instructions, taking into account the specifics of work from the point of view of compliance with safety regulations, and also define equipment for pressure testing of the heating system.

These standards regulate certain technological schemes and instructions, taking into account the specifics of work from the point of view of compliance with safety regulations, and also define equipment for pressure testing of the heating system.

Hydraulic tests must be preceded by flushing and preparation of the main pipeline of the heating system. Flushing is carried out in various ways and aims to remove scale and deposits of various salts and other chemical compounds from the internal walls of pipes in the system. A compressor is used for this.

Composition of deposits on the walls of pipes of heating systems (in decreasing order):

- ferrous oxide;

- magnesium oxide;

- calcium oxide;

- copper oxide;

- zinc oxide;

- trivalent sulfur oxide.

Important! Flushing should be carried out every 5-7 years of operation of the heating system. This will make the operation of the entire system more reliable and of higher quality.

What is the practical meaning of such a flush? During operation, heating efficiency is significantly reduced due to plaque and deposits on the pipes.

The flow diameter of pipes is reduced by almost half due to deposits and scale. This all leads to breakdowns and disruptions to proper operation. Due to scale and deposits, the quality of water circulation decreases.

The flow diameter of pipes is reduced by almost half due to deposits and scale. This all leads to breakdowns and disruptions to proper operation.

Flushing the heating system of an apartment building: instructions, rules and cleaning methods

Flushing the heating system of an apartment building

How often is a procedure such as flushing the heating system of an apartment building performed, and why is there a need for flushing? Let's try to answer these questions in this article.

When does it become necessary to flush the heating system in residential buildings?

The answer to the question of when heating systems are flushed lies on the surface when a significant decrease in the efficiency of its operation is detected. And the latter decreases significantly over time due to the fact that processes such as silting continuously occur in them (especially when it comes to heating systems of apartment buildings).

First of all, this occurs in areas of heating systems through which the coolant moves at minimal speeds: heating radiators, connections to them and bottling.

It should be remembered that these processes occur most intensively in radiators made of cast iron, since they have large intra-sectional volumes. This is explained by elementary physics. With fixed diameters of the connections and risers, the speed of water movement is inversely proportional to the internal volume of the heating device. And the lower the speed, the more deposits.

Basic methods for flushing the heating system of a residential building

The method for flushing the heating system of an apartment building may be different, but, in any case, flushing, confirmed by the relevant Act, is designed to restore the efficiency of your system.

The rules and procedure for flushing the heating system of an apartment building depend on the time period that has passed since the date of major repairs of the heating systems (HS), the materials from which the pipelines are made, etc.

The sediment in the CO is formed due to scale formed during installation of the system during welding, sand and other solid suspensions entering the main line from the heating main. The fact is that the thermal power plant takes in water around the clock and heats large volumes; it is technically impossible to filter them with proper purity.

If the CO line is made of steel pipes that have not undergone special anti-corrosion treatment, then flushing the heating system of a residential building is required due to another problem - mineral deposits. Mg and Ca salts settle on the inside of the pipes and the internal diameter, due to this, constantly decreases. This problem can be solved simply; instead of pipes made of ordinary steel, galvanized pipes or pipes with an internal polymer coating are used.

The presence of solid suspensions in the coolant becomes the reason leading to complete blocking of movement through the entire radiator. Water moves only through a number of outer sections. Things can get to the point where the circuit completely overlaps and falls out of the CO (when the internal hole is completely silted up).

Chemical flushing of the heating system

Flushing heating in an apartment building using this method is considered the most effective and efficient and is chosen in cases where:

- Work is being carried out to restore CO in an old apartment building that has been in operation for several decades without replacing the pipelines. Flushing of intra-house heating systems, in this situation, is carried out only after calculating the economic feasibility of the operation. Often it is completely absent, since the pipeline is so destroyed that after cleaning, dozens of leakage points appear.

- Work is being carried out to remove deposits formed in it from the system. But only in cases where the owner of the specified object refuses to completely change it to a modern one. In this case, the overwhelming majority of precipitation is concentrated in the boiler heat exchanger, and the sludge lies evenly over the entire surface (mainly in the lower parts).

Flushing the heating system of an apartment building, in these cases, consists of pouring a special solution (reagent) into the flushed circuit instead of the water present there. As a rule, the reagent is an alkaline solution (sodium hydroxide, NaOH) or phosphoric acids (general formula P2O5•nh3O).

Equipment for flushing the heating system of an apartment building, specially used for these purposes, in this case is a pump that performs bubbling and circulation in the flushed circuit. The process continues continuously for at least two hours. Then the reagent is drained and the CO is pressurized, after successful completion of which it is put into operation again.

The technique for flushing the heating system of an apartment building strictly prohibits pouring waste solutions into the sewer. But, if there is no other disposal option, then this is possible provided that you have a neutralizing solution.

Hydropneumatic cleaning of the system

Flushing heating in an apartment building using the specified method is most often used by all housing and communal services since the times of the USSR, because demonstrated its high efficiency at relatively low cost of work.

In different organizations it is called differently: pneumopulse flushing of the home heating system, hydrodynamic flushing method, etc. But this does not change the essence of the technology.

The above work is performed very simply. The heating system circuit is closed to discharge into the sewer at the first stage from the supply line to the return line, and in the second - vice versa. The passing water, in these cases, is “adjusted” by a compressor (pneumatic pump), which supplies air under pressure into the main line.

The resulting pulp is driven along the contour of the entire CO. At the same time, it partially breaks up the scale and loosens the silt deposits and takes it all with it into the sewer.

The step-by-step sequence of work such as flushing in-house heating systems looks like this:

- The valve on the return supply line is closed (common house);

- After it, there is a metering valve in the system, to which the compressor is connected;

- A discharge on the common house return line opens;

- We raise the pressure in a special container of the connected compressor to 6 kgf/sq. cm, then open the valve;

The instructions for flushing the heating system of a residential building provide for the sequential closing of a group of risers, selected in such a way that no more than ten of them are opened at a time. With this approach, washing is as efficient and effective as possible.

The time during which flushing should be performed is easily determined by the state of the discharged liquid. It has reached a transparent state, we move on to the next group of risers.

After complete flushing of all risers, the heating system is reconnected so that the discharge is directed in the opposite direction.

- The valve to which the compressor was connected shuts off the discharge;

- then the supply line to the house is closed with a valve and the house return is opened;

- The supply opens the reset;

- The compressor is docked to the valve on the return, after which this valve opens;

- The risers are being flushed. Only in reverse order.

The frequency of flushing the heating system can be significantly reduced if a recurring problem is solved, when it is enough to flush not the entire system, but only one heating device (radiator).

For this procedure, you can purchase a special flushing tap. But it is better to use a self-made structure for this, consisting of a ball valve and a radiator plug.

It should be installed in the system with the coolant discharged from the riser. Then, when the CO starts working, the specified device can be successfully used to remove any contaminants (slag, silt, etc.). Moreover, not only from the radiator, but also from the supply pipes to it.

In addition to the previously mentioned tap, you will need a hose equipped with a fitting. Moreover, the latter must have a thread that matches the one on the tap we installed for flushing.

Article rating: (total 1 votes, rating: 5.00 out of 5)

Heating schemes for a private house, the pipe routing of which is carried out according to one of the above options, requires the contractor to carry out high-quality preliminary calculations.

- Insulation for chimney pipes

Today, there are several most popular ways to insulate the chimneys of residential buildings. - Insulation of a brick chimney

Brick chimneys necessarily require additional insulation. High-quality insulation of a brick chimney means significantly extending its service life. - Replacing heating risers in an apartment

The most optimal solution when performing the above work is a one-time replacement of the heating riser with polypropylene on all floors at once (the entire span).https://vse-otoplenie.ru

legkoe-delo.ru

Hydropneumatic testing process

How to pressurize a heating system? The following procedure for pressure testing and flushing primarily applies to the prevention and testing of heating systems in residential apartment buildings.

Pressure testing of heating systems is carried out after completion of heating operation at the end of the heating season. As a rule, in our area the heating season ends in April. At the same time, the condition of shut-off valves, riser pipelines, thermal and elevator units is checked.

To eliminate problematic blockages in risers, flushing is carried out. Before this, the following preparatory work is performed:

- checking the elevator, risers and main pipeline;

- inspection of all elements of the heating system to identify leaks and eliminate them;

- checking thermal insulation on risers, highways and basements.

Important! At the thermal unit, preparatory work should be carried out after the system has been prepared, since hydrotesting of the thermal unit is carried out at a pressure higher than in the system.

Important! At the thermal unit, preparatory work should be carried out after the system has been prepared, since hydrotesting of the thermal unit is carried out at a pressure higher than in the system.

Sequence of hydropneumatic tests:

- filling the system with water;

- a press is connected for crimping heating systems;

- checking the pressure gauge readings.

If within half an hour after the pump for pressure testing heating systems has been connected, the pressure readings do not change, this means that the system is sealed and can be considered pressure tested. If the pressure reading on the pressure gauge decreases, there is a leak in the system. It is searched for, eliminated, and the process repeats.

Crimping of the input unit is carried out separately under a pressure of 1 MPa. Pumps for pressure testing heating systems can be manual or electric.

Crimping of the input unit is carried out separately under a pressure of 1 MPa. Pumps for pressure testing heating systems can be manual or electric.

After this, a representative of the organization that provides heat supply and a representative of heating networks fills out the report form. A representative of the heating service has a sample of the heating system pressure test report.

After this, a representative of the organization that provides heat supply and a representative of heating networks fills out the report form. A representative of the heating service has a sample of the heating system pressure test report.

The inspector also checks the system for rigidity. To do this, a sample of network water is taken from any tap and the content of magnesium and calcium salts in it is determined in a laboratory method. The standard water hardness is 75-95 units. If all parameters are normal, this means that the system is ready for operation.

Non-standard methods

Elevator without nozzle

How and with what to flush the heating system of an apartment building in the absence of a compressor and a control campaign? Unfortunately, this also happens far from large cities.

In this case, running the elevator unit without a nozzle for two to three days often helps. When the inlet, house and domestic hot water valves are turned off, the water-jet elevator is removed, the nozzle is removed from it, and the suction (the bottom flange of the elevator) is muffled with a steel pancake.

- of the coolant in the heating circuit increases

- Circulation accelerates . The nozzle no longer restricts the flow of water from the supply thread of the heating main. The difference between the beginning and end of the circuit is not the standard 0.2 kgf/cm2, but 2-3 atmospheres.

Why is this procedure abnormal? Because in this mode:

- Heat consumption increases many times (that is, its supplier incurs losses);

- The temperature regime of the heating main operation is disrupted. Excessively hot water enters the return line. Due to the technological cycle of the CHP plant, before a new circulation cycle, it has to be cooled to the required temperature.

Who carries out the pressure testing

The next logical question is: who carries out pressure testing of the building’s heating system?

The responsibility for the prevention of heating systems rests with the enterprises, institutions and organizations that operate it.

For example, in residential buildings, pressure testing is carried out by utility workers, administrative and production premises are tested by services that carry out maintenance of these premises.

For example, in residential buildings, pressure testing is carried out by utility workers, administrative and production premises are tested by services that carry out maintenance of these premises.

In principle, such work can only be carried out by certified personnel (heating system pressure testers) using special equipment. You should not carry out crimping yourself.

At the elevator and heating unit in each building, a drain valve is installed on the main line, through which the system is filled with coolant, and then it is drained. Air vents release air from the highest points of the system. After this, a pressure test pump is connected to this tap.

Pressure under which the system is tested

The pressure under which the tightness of the system is checked depends on its operating pressure. For example, in a system with cast iron batteries in an apartment building, the pressure usually reaches 2-5 atmospheres. But in a country house or cottage, the operating pressure is set to no more than 2 atmospheres. When it increases above this value, excess pressure is released through the emergency relief valve.

The procedure for crimping can be found in the video:

When performing pressure testing of new systems, the pressure is increased twice as much as the working pressure. During repeated checks, it is enough to increase the pressure in the system by 20-50%

from a worker.

Based on the list of work performed, an estimate is drawn up for pressure testing of the heating system. In this case, data from the directory-classifier of types of economic activities, products and services (OKDP) is taken into account.