Instead of water or antifreeze, pour oil into the system, for example transformer oil, or some other kind.

Is this how it's generally done?

Theoretically it is possible, but in practice this is not done and there are many reasons for this:

Oil viscosity, the first reason is antifreeze, or water, more fluid liquids.

It is necessary to install a circulation pump in the heating system of greater power.

There are no methods for calculating a heating system that uses oil as a coolant.

That is, everything is at your discretion, it is not a fact that such a system will work effectively.

Oil is a flammable material, the use of a flammable coolant is strictly prohibited, that is, everything here is at your responsibility.

All gaskets in fittings, pumps, and other shut-off valves used in the heating system must be replaced with oil-resistant gaskets; “ordinary” ones will not withstand operation in such an environment.

That is, all the “rubber” must be replaced with paronite.

Oil is tens of times more expensive than water and much more expensive than antifreeze, that is, at the end you will get an extremely expensive heating system with a very expensive coolant.

Plus, there are not isolated cases of fire precisely because of such a heating system with a coolant in the form of oil.

Many manufacturers of heating radiators clearly exclude the possibility of using oil as a coolant, that is, either water or antifreeze, and not oil.

The oil takes longer to warm up, but it also retains heat longer.

If you still decide on oil, then it’s better to take this

In this article we will talk about what heating with waste oil is and how to implement it in a country house. In addition, we will consider the most common misconceptions associated with the use of this type of fuel and explain why they are false.

But first, let’s define what this fuel product is and what its main characteristics are.

Mining is a cheap fuel whose value is obvious

Waste oil, or technical oil as it is also called, is fuel and lubricants (machine, transformer or motor oils) that have been used. The product, in accordance with GOST 26098-84, is fuel and lubricants that have been drained from working systems, have expired and have lost their original performance qualities established by regulatory and technical documentation.

Transformer oil in the heating system allows increasing the heat transfer of batteries

Waste is a liquid synthetic petroleum product suitable for use as a lubricant, as an impregnation of wood and other porous materials subject to decay. But the main area of application for mining is its use as an energy carrier in the operation of liquid fuel heating boilers.

Features of operation of heating equipment

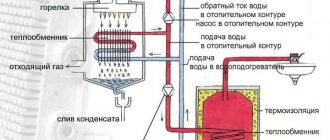

Diagram of a factory-assembled boiler

Modern waste oil heaters are liquid fuel hot water boilers, which, if necessary, can be powered with other types of energy carriers.

Structurally, the equipment is a combination of the following elements:

- fuel supply pipe;

- preheating chamber;

- compressed air supply pipe with air mixture blower;

- burner with nozzle and blower;

- heat exchanger for one circuit or two heat exchangers for a double-circuit installation;

- exhaust gas removal system.

Diagram of a homemade burner for burning waste

The design of the device does not have a combustion chamber with an open flame. Moreover, the device does not contain elements that are subject to strong heating, which ensures an acceptable level of safety.

Among the advantages of the equipment, the following points should be noted:

- Affordable energy price, since waste can be purchased inexpensively at most car repair shops, service stations, etc.;

- High efficiency of the equipment and, as a result, the ability to heat both small dachas and full-fledged country houses;

- High fire safety of the heating process, since waste oil is characterized by mediocre flammability in comparison with other types of fuels and lubricants.

A more complex version of the previous scheme

Among the disadvantages of this heating method, we note the following points:

- Lack of fully automated equipment on the market;

- The need to build a special storage facility for fuels and lubricants;

- The need to arrange a special room for the boiler room;

- The need to establish contacts with organizations where you can purchase fuel.

Top 6 ways to soften water for a heating system

In the country

For heating the boiler room, water comes from the water supply. It is usually not cleaned because it does not contain sand, stones and other large pieces of debris.

But the water coming from the water supply has the property of hardness. That is, it contains a small amount of small particles of a substance that are invisible to the eye. These substances: calcium, iron and magnesium are contained in limescale on the walls of the heating system.

Conclusion

Now you know what heating systems are based on boilers running on waste oil. Moreover, you could get acquainted with general information about the profitability of using such systems.

All that remains is to consider the prospect of using this equipment in your country house and make the appropriate choice, which the video in this article will certainly help you with.

Heating is an important issue that every home or cottage owner faces. In addition to choosing equipment, you need to decide on the heating fluid. More and more people are thinking about using oil rather than water for their home heating system. There are many opinions regarding this issue, which we will try to understand.

Step-by-step instruction

The coolant replacement process begins with draining the used composition. To do this, you must wait until the engine cools down; the pressure in the system must drop to safe values. Next, you need to place a container of sufficient volume under the radiator and unscrew the drain plug, having first removed the cap at the top of the radiator. To remove all remnants of old antifreeze from the system, you should also drain it from the cylinder block (if this is provided for by the design of the car and there is a corresponding neck on the BC).

Next, you need to screw the drain plug back and pour the required amount of coolant through the filler neck on the radiator. In some cars, it is possible to fill directly into the expansion tank. The required amount of antifreeze can be found by reading the technical documentation for the vehicle.

Heating is important

The issue of heating arises even during the design of a new house. Sometimes it appears when the operating mode changes. So, for example, a person could buy himself a country house, which the previous owners visited only in warm weather. Now he intends to visit it in late autumn and winter. What to do? Shouldn't you stay in a cold room? The answer is obvious - heating. It is important to choose which one and with what coolant. It depends on many factors.

Most people try to use water in their system, since it is the cheapest and most energy-intensive coolant. Moreover, if the temperature drops below zero, it will freeze. As a result, the system will have to be heated, and, at best, some burst pipes will have to be welded. At worst, you need to change the entire system, including the boiler. This situation is not only unpleasant, but also costly.

Therefore, in winter, special additives are used for water to prevent freezing. They come in different varieties, ranging from liquids with mineral salt to alcoholic ones. Each has its own positive and negative qualities. But still, none of them can be called ideal. It is in this regard that many people think not about what to add to the water, but what to replace it with.

Rating of the best coolants

Having seen the key parameters for choosing a product, let’s move on to the rating of coolants based on the characteristics and user reviews. This will help you find out in advance the pros and cons of antifreeze for heating in a house, country house or enterprise, and choose the best one for specific operating conditions.

DIXIS-65

A universal tool for working with gas and electric boilers of any type of installation. Optimally transfers heat at ambient temperatures from -65 to +95º C. Suitable for heating with pipes made of cast iron, copper, aluminum, brass. Does not damage solder joints or harm plastic pipes and containers. Along with the product, a sticker for the boiler is provided, which contains fields for recording the date of refueling, volume and other important details, which will be very useful years later when servicing the heating.

Our experts awarded this coolant first place in the ranking due to its high crystallization temperature of -66 degrees. This is the best product for heating systems in the Far North and other cold regions, which will withstand severe frosts and keep pipes and radiators intact. If used in areas where the winter temperature does not drop below -20º C, antifreeze can be diluted with water in a 1:1 ratio, which will significantly save money.

Advantages

- fireproof;

- the highest antifreeze rate;

- guaranteed service life 5 years;

- protection of the container from unauthorized opening.

Flaws

- heat capacity is 10% less than that of water;

- strong viscosity;

- not suitable for galvanized pipes;

- cannot be poured into boilers with an electrode operating principle.

Warm House Eco

This is a domestic coolant based on propylene glycol, which is supplemented with a pigment additive to give it a green color to make it easier to detect leaks. Available in containers of 10 and 20 kg with convenient handles for transportation. The product is fireproof and has been tested, therefore it is accompanied by a certificate and is designed for widespread use in heating and air conditioning systems. The service life of the substance is 5 years, after which it retains all its antifreeze properties, but loses the package of additives that prevent corrosion. Users in their reviews share that if the heat exchanger in the boiler is copper and the pipes are plastic, then it can be used for up to 10 years.

In our opinion, the coolant should be included in the rating due to its elevated boiling point of 106º C, which is 11 degrees higher than most products. This is useful if the system frequently overheats, especially if it is rarely looked after. The thermal destruction point of the product is 170º C, so antifreeze is not in danger.

Advantages

- does not destroy flax tow;

- can be used with sealants;

- does not expand when frozen, but turns into jelly;

- the vapors are harmless to humans.

Flaws

- when used with galvanized communications, it produces sediment;

- not for electrolysis boilers;

- high fluidity when heated requires careful sealing and preliminary crimping;

- you need a powerful circulation pump.

THERMAGENT-65

The product is manufactured in Russia, but from raw materials imported from Germany. The production uses a special technology called Organic Acid Technology. But organic additives do not contain amines and other harmful substances. The coolant is compatible with boilers operating on liquid fuel, gas and electricity. Judging by the reviews, the liquid does not harm rubber gaskets, sealants and paranitis. The manufacturer has added anti-foam and antibacterial additives to the composition, so the system will remain clean and with high permeability.

Our experts included the coolant in the rating, because in addition to a very low freezing point of -65º C, it has a long service life. The liquid retains its anti-corrosion properties for up to 10 years, and can be used for up to 20 seasons continuously, without losing its freezing resistance characteristics. This is beneficial in terms of system maintenance costs and does not require frequent intervention.

Advantages

Used oil in the heating system has many advantages:

- In winter, the liquid will not freeze. Unless the temperature in the house drops to -35 degrees Celsius. Agree, this is unlikely to happen.

- It doesn’t matter how long the negative temperature lasts, it does not affect the oil in any way. You can turn on the boiler and start heating the room at any time.

- Low volatility due to the structure.

- There is no need to additionally pour in any additives to prevent the coolant from freezing.

- The oil has high anti-corrosion properties. Therefore, there is no need to flush the system frequently.

- Has high thermal stability.

Antifreeze for a country house

With the arrival of cold weather, summer residents solve the problem: should they change the water in the heating system to an antifreeze liquid or not? And which one - prescribed by the manufacturer or any other? And also: is it possible to fill in car antifreeze, transformer oil or ethyl alcohol? In general, they save the dacha from possible freezing of the heating when you rarely have to go outside the city.

— In modern dacha heating systems, you can use both water and antifreeze. The choice depends on specific conditions,” says Alexander Milov, head of a company that selects equipment for heating and water supply. — But it should be taken into account that in Russia electricity or gas is turned off often and for a long time. Heating water can freeze and burst pipes. Therefore, it is better to fill in a low-freezing liquid - antifreeze.

Antifreezes are also preferable because in most regions of Russia the water is hard and contains a large amount of salts, foreign inclusions and additives. As a result, during operation, scale, sediment, and corrosion quickly form in the heating system. Pipes and equipment have to be replaced every five to seven years. It should also be taken into account that water begins to boil already at 96-98 degrees, accelerating negative processes in the system, while antifreezes last at 160-180 degrees. However, if antifreeze reaches such temperatures (this is possible in case of abnormal heating operation), it will lose its properties due to thermal decomposition. The liquid acquires a characteristic unpleasant odor. Therefore, reliable circulation must be ensured for antifreeze.

What experts do not recommend using for heating is transformer oil, car antifreeze or ethyl alcohol. “They create unpleasant odors and contain substances harmful to breathing. In addition, the liquid must be fireproof,” says Vadim Pogorelov, head of the certification laboratory.

Most antifreezes are based on ethylene glycol. Thanks to it, the liquid based on it does not freeze at minus 65 degrees. But a mixture of ethylene glycol and water is even more corrosive than just water, so additives are added to antifreezes to prevent the appearance of rust, and at the same time the formation of foam and scale. Since all antifreezes are essentially the same (they differ only in the additive package), experts say that any antifreeze, including domestic ones, can be used in heating systems. Of the Russian brands, the most popular are Dixis, Hot Blood, Nord, Teply Dom and some others. However, when giving priority to domestic antifreezes, it should be borne in mind that among them there are many counterfeits and low-quality liquids. “Unfortunately, not all Russian antifreezes comply with GOST, and this is the cause of many problems,” says Vadim Pogorelov. — Increased foaming leads to “airing” of the system and reduced heat transfer. Heat exchangers often become clogged with corrosion products, and build-up forms on the heating elements. Russian antifreezes, as a rule, do not work well at high temperatures.

As for imported liquids, they, as a rule, are not designed for temperatures below minus 25-30 degrees. In addition, they often delaminate when diluted with hard water. Experts advise using water with a hardness of no higher than 7 units. Among the imported ones, the most famous brands are Antifrogen N, Inibahel, Feetherm.

Flaws

Despite the obvious advantages of this type of coolant, there are still a number of disadvantages:

- The need for filtration before injecting into the system. The fact is that usually the oil is a mixture of many oils of different brands and viscosity. In addition, it contains third-party components in the form of dirt and metal. The process of cleaning a considerable volume can cost a large sum.

- Availability of the required quantity. At the moment, there are no companies that are engaged in the targeted collection and purification of oil for future infusion into heating systems. Therefore, finding a sufficient amount of the desired consistency will be problematic.

- High fire hazard. In the event of a leak, there is a risk of fire. True, for this the liquid must come into direct contact with an open source of fire.

- It is not permissible to use a boiler with direct heating.

- Replacing all rubber gaskets and connectors with oil-resistant ones, which will be more difficult to find, since conventional heating systems are not equipped with them. In addition, their purchase can cost a large sum.

How to properly clean the engine cooling system

You should strictly observe the maintenance periods prescribed by the regulations, change the coolant, belts, pumps on time, and monitor the tightness and cleanliness of the cooling system.

Kuhler-Reiniger Cooling System Cleaner

Cooling circuit cleaner. Effectively dissolves scale and contaminants in radiators, pipes and engine water jacket, ensures normal engine temperature and reliable operation. Suitable for all cooling and heating systems. The product does not contain aggressive acids or alkalis. Recommended for every coolant change.

Popular models

Equipment using waste oil is more expensive than equipment using diesel. Reality:

this is wrong. Although mining equipment has a higher cost, heating at mining is much cheaper to operate due to the low cost of fuel. By the end of the first year of operation, the cost of the boiler and the fuel consumed during exhaust operation will be equal to the cost of a boiler using diesel fuel + fuel, and with further operation you will receive significant savings. In addition, exhaust burners, as a rule, are universal, i.e. They work on both OM and diesel.

Due to its complexity and the specific nature of burning waste oil, the equipment is less reliable than diesel equipment. Reality:

the reliability coefficient of equipment using OM is higher than that of diesel equipment due to the higher requirements placed on units using OM. Any equipment often fails due to improper operation and negligence.

equipment using waste oil requires constant maintenance (cleaning, adjustment). Reality:

if the equipment is installed correctly (tank, fuel line, chimney), then the OM burner requires maintenance no more than once a year, similar to any heating equipment. But, as with any heating equipment, fuel contamination has a great influence on the frequency of maintenance.

Since the equipment is not as widespread on the market as diesel, there is a problem with spare parts and service. Reality:

Of course, it is important to make sure that there is a representative office and service center of the equipment manufacturer in your city.

Timing for oil changes

During operation of the transformer, an oil oxidation reaction occurs, dirt accumulates and the viscosity of the oil increases, which reduces its ability to cool the operating transformer. If the oil is not changed on time, the service life of the equipment is significantly reduced.

The average time to replace transformer oil is 1 year. And no more than after 5 years it is necessary to carry out drying and regeneration work. To extend the life of oil and equipment, you need to follow some rules:

Popular models

When used oil is used as fuel, the amount of harmful emissions into the atmosphere increases. Reality:

Remember the truck or bus driving ahead of you with a smoky diesel engine and a foreign car with a modern diesel engine overtaking you. Indeed, some modern imported burners and boilers and air heaters specially designed for them completely burn fuel, do not smoke, and are environmentally friendly. Burning OM in modern heating systems is even more environmentally friendly than gas, coal, diesel, etc.

In the fight for environmental cleanliness, used oil must be recycled and not burned. Reality:

If you consider in detail the entire chain of processing and regeneration of used oils, you can come to an unexpected conclusion: emissions from burning OM in special equipment (boilers and air heaters with forced-air burners) are significantly less than the amount of harmful substances when processing OM. In the process of mechanical and chemical purification of OM, many different toxic compounds are used and formed, which are subject to special burial or high-temperature oxidation (i.e., the same combustion). Also, when cleaning and processing oils, huge energy resources are consumed (heating during oil sublimation (cracking), centrifugation, filtration, pumping, transportation, etc.). Thus, as a rule, in the absence of selective collection (each type of oil is collected in a separate container), it is economically and environmentally more profitable to use it locally as fuel in special boilers and air heaters.

operation of a boiler or air heater using waste oil is subject to licensing. Reality:

operation of a boiler or air heater does not require licensing or special permits in the same way as for any equipment operating on liquid fuel.

What should I do if I run out of used oil, because the equipment will then stop? Reality:

Everything can run out or shut down: gas, coal, firewood, diesel, fuel oil, electricity. A huge advantage of modern OM burners is that they also operate on diesel fuel without special adjustments. In the event of interruptions in the supply of OM, diesel and/or a mixture of it and waste can be used as fuel.

Recommended Posts

Recently viewed by 0 users

No registered user is viewing this page.

The best articles on the IVD website

Are you a professional architect or designer?

IVD. Repair and finishing

Are you a professional architect or designer?

The IVD.ru website is a leading Internet project dedicated to the issues of reconstruction and interior design of residential premises. The main content of the site is the archive of the magazine “Ideas for Your Home” - exclusive author’s articles, high-quality illustrations, practical tips and lessons. A team of professionals is working on the project in close collaboration with famous designers, architects and leading publishing experts.