Choosing a gas boiler for a heating system is a responsible task.

The continuity of the heating process depends on the efficiency and reliability of its design, which is very important in the cold season.

Incorrect selection of unit parameters can cause the temperature in the house to be insufficiently high, or cause abnormal operation of the boiler.

In addition, it is necessary to select a unit design that matches the needs and capabilities of the home.

Condensing boilers appeared relatively recently, so we need to talk about them in more detail.

What is a condensing gas boiler?

The usual design of gas boilers involves single-stage heating of the coolant. It enters the primary heat exchanger and receives the temperature set by the operating mode. A condensing gas boiler is more complex.

Heating of the coolant in it occurs in two stages:

- primary preparation of liquid in the condensation chamber;

- final heating in the primary heat exchanger (in the usual way).

Thermal energy for heating the first stage arises from the condensation of water vapor from their smoke and exhaust combustion products. The point of the procedure is that this heat usually disappears .

If the coolant is warmed up even a little, the load on the main heat exchanger will drop. There is a positive dynamics in the operating mode, which makes it possible to reduce gas consumption, reduce wear on the main components of the boiler and obtain an increased effect from its operation.

Fuel savings are about 20%, but prices for condensing models are almost twice as high as those for convection designs.

According to manufacturers, the efficiency of such devices is 107-109%, which is impossible from the standpoint of physics. This is a very clumsy marketing ploy, since it is incorrect to rely on an illiterate buyer from manufacturers of heating equipment.

They simply added the efficiency of the condensing chamber to the efficiency level of the base model on which the design was based.

NOTE!

For full operation of the unit, a specific operating mode is required. It is capable of demonstrating positive results only on low-temperature heating systems such as underfloor heating, and with radiator circuits it most often functions as a regular convection unit.

Price

Technically improved boilers are more complex, and it becomes clear why their cost is higher. But most of all, the surcharge is provided for the additional percentage of thermal energy. Keep in mind that the equipment will last for several decades, so you can overpay to get a high-quality heating device, on which you will be able to save money when using it.

All condensing boilers can be divided into 3 categories according to prices:

- Premium class. This category has the fewest buyers, because boilers are more expensive. This includes models of the German brand, which are distinguished by high quality, attractive appearance, due to durable materials. Such boiler models meet European quality standards and therefore can last for several decades. Due to the high price, the equipment is equipped with many useful functions that make use as comfortable as possible. They can be used to program operating modes even when the owners are absent from the house, or reduce the temperature level at night, and adapt to weather changes.

- Middle class. This class of heating equipment includes boilers with a modest set of functions. The boilers provide high performance and, like premium equipment, can adjust the temperature to weather changes. These are the most popular models that people choose for their home.

- Economy class. Such boilers also save fuel, but they are not equipped with the functions described above. Budget models are produced by Korean companies. The cost of such heating elements is half that of a premium product. But such devices are maximally adapted to the climatic conditions in Russia.

When choosing a boiler for your home, you need to consider the cost of installation and further maintenance of the equipment. Before purchasing, keep in mind that modern equipment saves gas. Such boilers are only suitable for places with permanent residence. The more cold days there are in the region where you live, the more advisable it is to install such equipment in your home.

Advantages and disadvantages

The advantages of condensing boilers include:

- high performance heating system;

- fuel savings reaches 20%;

- the load on all main components of the boiler is reduced, which increases the service life of the unit;

- in the absence of the necessary conditions, the work does not stop, the boiler functions as a conventional convection-type device.

The disadvantages of such designs are:

- for work it is necessary to create specific conditions, which is not always possible;

- To dispose of condensate, it is necessary to take special measures - it contains a large amount of acid, so it is prohibited to drain it into the sewer;

- the cost of condensing units is much higher, and repairs will be more expensive than traditional models.

The disadvantages are few, but they are quite significant. For normal operation of a condensing boiler with a radiator system, it is necessary that the difference in temperature outside and indoors does not exceed 20°.

Otherwise, there will be no conditions for condensation of water vapor. But the use of heated floors is not always possible and advisable. These features significantly limit the demand for such designs .

Perhaps this is where the attempt of manufacturers to intensify sales begins, indicating obviously impossible efficiency.

Statement No. 4. Condensate can be drained into a septic tank or directly onto the ground

This is not just a consumer misconception. This advice is often given by sellers and installers if the owner of a property does not want to spend money on an expensive condensate neutralization and removal system.

A household condensing boiler produces up to 15–20 liters of condensate per day with a pH level of 3–5, which is comparable to an acetic acid solution. Such liquid must be passed through a neutralizer filter to reduce its acidity. Otherwise, it can destroy bioactive sludge in the septic tank, cause corrosion of metal sewer pipes, or simply kill the fertile layer of soil if the acidic solution is poured onto the ground.

There is one more nuance. Installers can neglect the condensate removal and neutralization system if they know for sure that, due to the configuration of the heating system, the boiler will only operate in an ineffective high-temperature mode in which condensate does not form.

Conclusion: not true!

Device

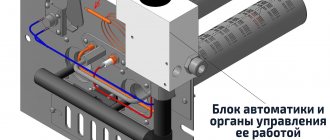

The design of condensing boilers completely replicates the design of basic convection models. The only difference is the presence of a condensation chamber.

It does double duty:

- ensures the deposition of water vapor on the walls of a special container with the release of thermal energy;

- transfers heat to the reverse flow of the coolant, acting as a kind of heat exchanger.

From the condensation chamber, the coolant immediately enters the primary heat exchanger, where it receives the maximum temperature set by the mode.

It then enters the secondary (plate) heat exchanger and helps heat water for domestic use. After this, the liquid enters a three-way valve, where it finally reaches the temperature required by operating conditions by mixing a certain amount of cooled “return” into the hot flow .

The finished coolant is removed from the boiler and completes another cycle of circulation, after which the entire cycle is repeated again.

High cost of the heat exchanger used

The heat exchanger itself is complex and expensive equipment, and if it breaks, the owner will have to spend a lot of money to restore it. Sometimes purchasing a new heat exchanger and installing it is more expensive than purchasing a new boiler.

But to prevent such situations from happening, it is necessary to constantly maintain the heat exchanger and monitor its condition. Do not allow it to become clogged, as it is extremely difficult to flush the equipment. Also, before installing a condensing boiler, it is necessary to update all pipes and get rid of rusty elements.

The durability of the heat exchanger depends on the quality of the coolant. The water must be soft so that scale does not form inside the pipes, which will be difficult to get rid of. It is unacceptable to use water containing impurities of rust, salts, suspended matter and iron.

Due to the acids in the composition, the heat exchanger must be susceptible to such compositions. It is worth choosing designs made of stainless steel and silumin. The second material is cheaper, but it is less resistant to aggressive environments than steel. If you want the equipment to last for several years, you need to purchase heat exchangers made of more durable material, despite their cost.

Kinds

The design of condensing boilers was created on the basis of conventional models.

There are different species that have typical characteristics:

- single-circuit. They only heat the coolant for the heating circuit;

- double-circuit. Together with the preparation of the heating agent, they are capable of heating water for domestic needs.

By installation type:

- floor Installed on the floor or a special non-flammable stand. They have no restrictions on weight and power;

- wall-mounted For installation, strong load-bearing walls are used. This imposes restrictions on the weight and power of the boiler. The limit is usually 45-50 kW.

All condensing boilers have a closed burner, since the operation requires strict regulation at all stages and does not allow the use of natural processes.

They are unstable and cannot be the basis for fine tuning.

Sensitivity to intake air quality

In order for the boiler to operate without complaints, it is necessary to pay attention to the access of combustion air and the removal of combustion products. Condensing boilers take air from the street, and so that the fan does not become unusable in the shortest possible time, the quality of the air taken in must be high. It is also important to maintain the optimal temperature of the intake air so that the air duct does not freeze. To avoid problems with servicing the boiler, its connection and configuration should be done by professionals. A trained person with a license and permission must set the parameter responsible for the incoming air.

Gas analyzers are most often used for this purpose. In the absence of equipment and incorrect settings, it is not possible to achieve the maximum efficiency value, and can also damage the boiler.

Principle of operation

The unit operates in two stages:

- the return flow of coolant enters the condensation chamber . It is a heat exchanger in which the energy from the settling water vapor from the flue gases is transferred to the heating water (heating water). This causes the temperature of the coolant to rise slightly, which makes the heating mode of the gas burner more economical and gentle;

- From the condensation chamber, the OM enters the primary heat exchanger and then the whole process occurs according to the usual traditional method . Having received full heating, the liquid enters the secondary heat exchanger, giving up part of the energy for the preparation of hot water. It then enters the heating circuit or underfloor heating system.

For efficient operation of a radiator-type thermal circuit, it is necessary that the return temperature is not higher than the degree of heating of the condensation chamber heat exchanger, otherwise the operation of the first stage will become impossible.

IMPORTANT!

In Russian conditions, it is physically impossible to provide such conditions, so all that remains is to use condensing models to power the heated floor circuits. Such a limitation calls into question the feasibility of using these units in unsuitable conditions, since the difference in cost destroys all the benefits of fuel economy.

Myth 2. Problems with condensation

Yes, condensation forms during boiler operation, but there are several ways to eliminate it. If it is produced in small quantities, you can use the services of local services or install neutralizers.

Few people know that when a conventional unit operates, condensate also forms, which needs to be disposed of. When the chimney is stopped, condensate flows to the boiler and is later drained into the sewer pipe through a condensate drain. But to minimize the impact on the environment, the condensate must first be neutralized.

Rating of TOP 5 condensing gas boilers

Let's look at several of the most popular models of gas condensing boilers from different manufacturers:

BAXI LUNA Platinum+ 1.32

Gas condensing unit from Italian manufacturers. The boiler is single-circuit, designed for heating only. The power is 35 kW, which will allow heating a house with an area of 350 sq.m.

Advantages:

- high efficiency - 105.7%;

- at a fairly high power, gas consumption does not exceed 3.49 m3/hour;

- it is possible to reconfigure the power supply with liquefied gas, and no reinstallation of nozzles is required for this - everything is done using the software method;

- complete protection from external influences;

- built-in water filter.

Flaws:

- Only low temperature systems must be used;

- the cost of the boiler is significantly higher than that of convection models of the same power;

- The boiler is delivered only to order, so you have to wait a long time for delivery.

BAXI Duo-tec Compact 1.24

Another condensing boiler from an Italian company. A single-circuit model with a power of 24 kW will allow you to heat 240 sq.m. usable area.

Its virtues:

- economical, high efficiency;

- reliability, durability of main components and parts;

- full control over all areas of the structure;

- Ease of Management.

Disadvantages of the unit:

- the ability to only heat the house, without supplying hot water;

- high cost of the boiler and repair work.

Protherm Lynx condensation 25/30 MKV

Double-circuit gas boiler made in Slovakia. With a power of 25 kW, it is suitable for heating 250 sq.m. residential or public area.

Advantages of the boiler:

- aluminum primary heat exchanger, resistant to operating loads;

- built-in 8-liter expansion tank allows you to compensate for pressure drops in the heating circuit;

- high DHW productivity - 14 l/min;

- Full-featured protection against all influences.

Flaws:

- relatively high cost;

- specific working conditions;

- there is no possibility of reconfiguring the liquefied gas supply.

Vaillant ecoTEC plus VU INT IV 246/5-5

The German company Vaillant is one of the leaders in the production of heating equipment. The single-circuit condensing model ecoTEC plus VU INT IV 246/5-5 has a steel heat exchanger. The power of the unit is 20 kW, designed for a room up to 200 sq.m.

Advantages:

- high efficiency - 108%;

- the volume of the expansion tank is 10 l;

- gas consumption is only 2.6 m3/hour;

- there is a possibility of remote control;

- multi-stage protection against overloads or malfunctions.

Flaws:

- excessively high price, which significantly limits the possibilities of the mass buyer.

Viessmann Vitodens 100-W B1HC043

Another German condensing boiler. Single-circuit powerful model - develops up to 35 kW and is capable of heating 350 sq.m. Designed for wall mounting.

Advantages:

- high efficiency - 108.7%;

- gas consumption is 3.46 m3/hour;

- electronic control with the ability to connect remote control;

- durable heat exchanger made of stainless steel.

Flaws:

- specific operating mode;

- high price.

Fuel savings when used in low temperature systems

The main advantage is efficiency, approximately 20-35% compared to traditional equipment. Fuel consumption is determined by the power of the unit and the area of the room. If you have a country cottage of 200-250 m2, then a 28 kW boiler is sufficient for heating, which will consume a maximum of 2.85 m3/h. A regular boiler will consume 3.25 m3/h.

If we take into account that a person uses heating appliances for 6 months a year, the approximate savings per year will be 3,000 rubles. But if we talk about regions where the average temperature in winter is -30 degrees, then these savings will be several times greater, because there the heating works constantly. And if we take into account that the cost of gas increases every year, then the savings will increase when using a condensing boiler.

Converting the boiler unit to bottled gas

Theoretically, converting the boiler to liquefied gas is not difficult: the most important thing is to replace the nozzles responsible for fuel consumption, or the entire burner. This is followed by alteration of the gas valve (in accordance with the attached operating instructions) and reconfiguration of the electronic board if the unit is automated.

But you shouldn’t interfere with the internal structure of the boiler yourself; it’s better to contact a licensed gas company. Specially trained personnel will complete the task in half an hour - maximum, while the cost of work with the purchase of all consumables will cost approximately 2.5-3.5 thousand rubles.

Where to buy a gas boiler using liquefied gas

In Moscow and Moscow Region

- MirCli (mircli.ru/kotly-otopleniya/nastennye-gazovye-kotly/odnokoturnye-kotly) – Leningradsky Ave., 80, building G, tel. +7 (863) 303–35–06, +7 (800) 775–29–90.

- IM “Gas Boilers” (https://msk.kotel-gazoviy.ru/na-szhizhennom-gaze/) – Moscow, st. Podolskikh Kursantov, 22, tel..

In St. Petersburg

- ProTeplo (https://www.proteplo-spb.ru/products/kotly-na-szhizhennom-gaze) – st. Chugunnaya, 14, lit. K (entrance from Mendeleevskaya 5), tel. +7 (812) 241–12–06.

- TechnoDOM (https://www.teh-dom.ru/gazovye_kotly_na_sgigennom_gaze#0) – Marshal Govorova Ave., 35, BC Yellow Corner, p. 119, tel. +7 (812) 671–00–88.

In conclusion, I would like to remind you that, despite all its advantages, liquefied fuel is not a competitor to natural gas. However, if connection to the pipeline is not available, then it can be argued that an LPG boiler is the most profitable and convenient option for organizing heating of a country house.

Gas boilersBoilers

Liquefied gas consumption

The amount of fuel spent on heating depends on the operating conditions of the device and its technical characteristics, usually power and efficiency. So, for example, according to the passport data, for the boiler JSC Zhukovsky AOGV-17.4-3 with a power of 17 kW with an efficiency of 90%, the consumption of liquefied gas is 0.7 kg/h or 1.3 l/h.

Knowing that the cost of refueling in 2022 is 12-23 rubles/l, taking the average value, you can roughly calculate the cost of heating a house over a certain period of time:

- per day (24 hours) – 1.3 × 24 = 31 l × 17 ≈ 527–558 rubles;

- per month (30 days) – 31 × 30 = 930 l × 17 ≈ 15810–16740 rubles;

- for a season (six months) – 930 × 6 = 5580 l × 17 ≈ 94860–100440 rubles.

It must be taken into account that a 50 liter cylinder actually contains 40–42 liters of propane-butane mixture: about 15–20% of the free volume is used to increase the area of gas evaporation, and overfilling leads to a decrease in its production. This means that with a flow rate of 1.3 l/h, one cylinder is enough for approximately 1.5 days.

But not everything is so bad: the numbers in the passport are given on the basis that the unit will always operate at maximum power 24/7, but in reality this only happens in severe frost. In warm weather, the boiler is active only 10–14 hours daily, i.e. the result obtained can be safely reduced by 30–50%.

How to choose a room thermostat and save up to 30% per month on heating

Myth 3. Complex chimney

A feature of the equipment is that during operation of the boiler a large volume of condensate accumulates. And many people think that the chimney must be made of lead or a more durable material. But chimneys are practically no different. Combustion products are removed forcibly, so the boiler can be connected to different smoke removal systems. Chimneys must be airtight, and to connect the boiler it is not necessary to build a chimney.