Almost every summer cottage and garden in the private sector has a greenhouse. They are used mainly in the spring and summer for growing seedlings and summer heat-loving vegetables. And sooner or later, every greenhouse owner begins to think about its profitability. You can increase its efficiency only when you use it all year round, or when growing very early products, when everything is very expensive on the market and in the store. Now it has become fashionable to create winter gardens and grow greens, radishes, cucumbers for the New Year and flowers for March 8 during the cold season. Of course, it’s great to have fresh produce from your greenhouse for the holidays in winter, but for this you need to make it heated, because our winters are long and harsh.

Heating a greenhouse means increasing its efficiency

But for early or year-round use of a greenhouse, heating is needed, because there are severe frosts outside in winter, and in early spring, sub-zero air temperatures are not uncommon. And then the question arises of which heating to choose, which is personally acceptable for your household, because any of them requires a financial investment. Here you need to figure out what you have enough money for and which heating will be less expensive to maintain. In addition, it is necessary to take into account the durability and efficiency of the selected type of heating.

Heating a greenhouse is the most important part of the microclimate in the life of plants, as is watering. It is advisable to think about what it will be like before construction begins. It’s better to do it right away, as it should be, so as not to have to redo it later. Let's consider different heating methods, the pros and cons of the selected options and choose what is most convenient and least expensive.

Reduced heat loss

With any heating method, overheating is possible during the day, and hypothermia at night. Therefore, in hot weather, it is sometimes worth leaving the doors open, and at night additionally covering the greenhouse with an awning or mats made of reeds or straw.

To retain heat, the familiar double window system is used - the walls are covered with another layer of insulation from the inside. For example, film. An air layer is created between the layers, which retains heat.

Outside the greenhouse, foam blocks are dug into the ground in a vertical position along the entire perimeter. However, it is worth considering that in this case less light will enter the greenhouse or greenhouse.

The joints and seams of the greenhouse are treated with sealant or lined with rubberized inserts. The foundation, or at least the part of the greenhouse adjacent to the ground, is also subject to insulation. Styrofoam packed in plastic film is well suited for this.

A rational solution would be to attach a vestibule to the entrance to the inside of the greenhouse - this is called an air curtain; the average temperature between the greenhouse and the outside world minimizes heat loss when entering inside.

For several decades, our summer residents and gardeners have been using mulching film. This is a type of thick plastic film with holes made in it for fruits, which is used to cover plants.

Before covering, biofuel is placed on the soil and then covered with film. This technique improves crop growth and stabilizes the temperature inside the shelter, reduces the outflow of moisture and heat, prevents the development of weeds, promotes the development of the root system, and the fruits remain clean.

How to heat a greenhouse in early spring?

It is not necessary to use any heating to grow seedlings and early summer produce. To do this, it is enough to make greenhouse beds on rotted manure. It is necessary to remove the fertile layer of soil; instead of beds, you will get trenches. It is advisable to make sides for future warm beds from boards or other available materials. Place a thick layer of rotted manure mixed with straw or peat on the bottom. Pour a fertile layer of soil on top. Manure rotting below will release heat and moisture. Plants planted on high, warm ridges will feel comfortable.

When it’s still cold outside, you can put a second layer of film over the greenhouse. An air pocket is formed between the main layer and the additional layer, which will also retain heat. The greenhouse should be positioned so that it is exposed to the sun as long as possible. The sun's rays will penetrate the film or cellular polycarbonate and heat the surface of the earth in the greenhouse. Thus, natural heat will condense in it. This is how you can “naturally” heat a greenhouse, just don’t make the roof too high, then it will warm up more. Experience has shown that greenhouses with an arched structure have the highest efficiency in terms of heat retention.

But there are some disadvantages. If you don’t have your own manure, you will have to buy it, and this is now quite expensive. In addition, it must be stocked in the fall. And make the ridges anew every spring. This is a very labor-intensive process. Making heated greenhouses with your own hands is not easy. And in winter such “heating” will not be enough.

What should a winter greenhouse be like?

Winter greenhouses are permanent structures built on a foundation that can withstand both wind and snow loads. These can be either free-standing buildings or extensions with one blank wall. For example, to the utility block, if the orientation of the structure allows.

Foundation

The foundation of a greenhouse can be strip or made of separate blocks; columnar and slab foundations are less common. USPs are usually not made under free-standing greenhouses, but if this is a winter garden within a permanent building, then such a foundation is quite justified. In terms of cost, a slight expansion of the building area against the general background is not critical, and the heating circuit installed when pouring the slab will simplify the further arrangement of the greenhouse.

To prevent the outflow of far from free heat through the base of the greenhouse, extruded polystyrene foam can be used when building the foundation. The most effective is comprehensive insulation of both the foundation strip and the soil under the greenhouse, on the site of future beds. The use of insulation is especially important if soil heating is planned; EPS will prevent unnecessary consumption of thermal energy for heating the lower, unused layers of the soil. You can also use insulation to protect the north side.

Frame

Like seasonal, year-round greenhouses, mainly of the frame type, the frame comes in two types:

- metal;

- wood.

These materials are comparable in strength; In addition, wood does not overheat in summer and gives off much less heat to the outside in winter. Considering that winter greenhouses are built on a foundation, and there will be no direct contact with moisture at the racks, the service life of the wooden frame is quite decent. Naturally, when calculating the parameters of all elements, the expected loads must be taken into account.

Alla Ivanova

I prefer to build only wooden winter greenhouses - cheaper, simpler, and simple - I love wood. In our steppe there are such hurricane winds - don’t worry, mother, but nothing has ever been torn down, we always do it conscientiously.

A frame made of HDPE (low-density polyethylene) pipes is increasingly in demand for seasonal greenhouses; if used for winter ones, it is in regions where heavy snowfall is very rare.

The shape of the greenhouse largely depends on the frame material, climatic conditions and personal preferences. Most often they build:

- arched;

- single-pitched;

- gable.

Due to the shape, it is problematic to make a wooden frame for arched structures; technically this is possible, but it will require much more effort and time than rectangular options. Therefore, such greenhouses are usually on a metal frame, while a wooden one is more in demand for single-pitch or gable structures. Although some still prefer to combine wood with the arch.

Sheathing

As for the frame sheathing, the era of polyethylene film in several layers is gradually disappearing; today, in most cases, cellular polycarbonate (SP) is used. Glass, also used as cladding for winter greenhouses, is significantly inferior in thermal conductivity, although it is superior in durability (if treated with care) and light transmittance. From the point of view of heat conservation, the optimal greenhouse-thermos for cold regions is considered to be double cladding with SP sheets with an air gap, similar to double-glazed windows. In this case, the thickness of the outer layer is at least 6 mm; for the inner layer, a thickness of 4 mm is acceptable. But the thicker the sheets in the layers, the lower the thermal conductivity, therefore, when creating a sealed circuit (using end caps), the lower the heat outflow. In the summer months, the effect of a thermos will help prevent overheating without the need for partial dismantling of the casing.

Anchor PlusModerator FORUMHOUSE

Possible combinations of layers (external plus internal, distance everywhere - from 20 to 50 mm):

- 6/4 – 1.8 W/(m•⁰С);

- 10/6 – 1.61 W/(m•⁰С);

- 16/6 – 1.42 W/(m•⁰С);

- 16/10 – 1.27 W/(m•⁰С);

- 20/6 – 1.19 W/(m•⁰С).

However, you should not get too carried away with thicknesses, especially when the greenhouse is of an arched type. The thicker the sheet, the greater the minimum permissible radius with which it can be bent without loss of characteristics. Yes, and problems may arise with the purchase of components, since for sheets thicker than 16 mm they are rarely found on sale, and if they are, the price is prohibitive. While for most regions, 10 mm on the top layer is sufficient for snow loads, the main thing is to correctly calculate the pitch of the racks.

One of the portal users has a winter garden (extension), on USP, with two layers of joint venture cladding.

Arkhipov I

I plan to install a greenhouse as an extension to the boiler room on one USHP - a wooden frame, polycarbonate walls in two layers, with an air gap. Height – 2.5 m, covering – single-pitched polycarbonate roofing.

Stove heating

How to heat a greenhouse without gas and electricity? One such method is stove heating. They make an ordinary stove, and from it run a chimney horizontally along the walls of the greenhouse. It should gradually rise up and finally come out. This way the greenhouse will be heated. The firebox must be made so that it opens outside the greenhouse, because soot and smoke cannot penetrate into it. Then the quality of vegetables will suffer.

You can install a stove with a boiler in which water will be heated, and then it will circulate through pipes that will be laid on the ground along the length of the greenhouse. Hot water will heat the air.

While the efficiency of such systems can satisfy the user, the complexity of the process is very tiring. The point is that you need to constantly monitor the temperature and add solid fuel often. Not everyone can quit their job and be a fireman in their greenhouse all winter. And is it worth it?

When building heated greenhouses with your own hands, you should keep in mind that film and glass do not retain heat well, and therefore they need to be heated better. Cellular polycarbonate, due to its design, retains heat well, and therefore heating costs will be lower.

Heating with heat generator boilers is also a good option. Unlike simple stoves, a heat generator with solid fuel needs to be charged no more than 2 times a day. Diesel fuel systems are available. The efficiency of such heating is not the highest.

Arrangement of winter greenhouses

In order to engage in crop production when nature does not provide for it, the winter greenhouse must maintain the temperature, light and humidity conditions necessary for the crops.

Heating

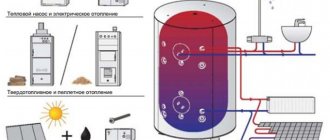

Even thermos greenhouses with two layers of SP as cladding for year-round operation in regions with temperate and cold climates, first of all, need an effective heating system. Another thing is that a sealed circuit with minimal heat losses will save on energy. With a lot of design options and types of fuel used, the heating itself comes in several types:

- Air - warm air is supplied through air ducts at different levels or heated and maintained directly by a furnace installed in the room itself.

- Contour - a thermal contour is created along the edges, and if necessary, along the middle part, pipes and radiators are used, the boiler can be installed both in the greenhouse and remotely.

- Subsoil - in regions with a mild climate, where severe frosts are rare, a thermos greenhouse will maintain heat with minimal heating. In this case, a water heated floor circuit or electric cables/mats designed for this specific application are laid in the ground.

- Combined - they combine air or contour heating with subsoil heating for growing crops that are demanding in terms of soil temperature.

Ruslan N

Subsoil heating is not suitable for all crops; in my greenhouse I made a hydraulic system (gravity) using coal with the possibility of attaching a subsoil circuit to it (for growing cucumbers), but for other crops a good subsoil heating system is sufficient.

Or for insurance purposes.

Alla Ivanova

The main heating is contour, pipe, the subsoil circuit is deepened by 30 cm so that it is not damaged when processed with a walk-behind tractor. If the soil is loose, it works well. But for me it’s not so important for lettuce - 14⁰C heat in the soil is enough, but other crops need higher temperatures. I have subsurface heating as an insurance policy; there are very frosty winters.

Which energy carrier to use depends on many factors - cost-effectiveness, availability, and the possibility of automating the process.

- Electricity is one of the most expensive energy sources, but with minimal heat loss it can become the basis of the system. Especially if there is a night tariff and a TA (heat accumulator).

- Mains gas is cheaper than electricity and is not inferior to electrical equipment in terms of the possibility of automating the process, but it is not available in all areas.

- Solid fuel boilers - previously the biggest problem was the need for regular loading, today there are long-lasting models, including homemade ones.

DVAL

I heat a winter greenhouse (100 m²), covered with two layers of film, with a distance of 30-40 cm, with a homemade wood-burning boiler. The set temperature (+20⁰С) is maintained automatically. Adding firewood to the boiler lasted for a day when the temperature dropped to 20-25⁰С below zero, and on “warm days” (5-10⁰С below zero) it lasted up to two days or more if the firewood was oak or acacia. The boiler heats the air - a heat generator (without a water jacket). It’s not particularly annoying, just put it on and sleep peacefully (but the signal about the boiler going out or the wood burning is sent into the house). The cost of making the boiler is insignificant, I made it from what was lying around the yard, I spent only on electrodes (10 kg) and on circles for the grinder. I tried IR gas burners - they are ineffective, they require a lot of air, and when the windows are opened frequently, the heat evaporates.

As DVAL notes, you can heat it however you like and with whatever you want, everyone chooses their own option, which they choose as the optimal one in terms of the combination of costs and returns. Here viktor50 prefers the Bubafonya boiler, and although he has a seasonal greenhouse, such experience can be taken into account.

Lighting and Humidity

Winter days are short, especially in the northern regions, so even with the correct orientation of the greenhouse, for full growth, most crops require additional lighting with special lamps that generate the required spectrum. HPS (sodium arc tube lamps) or LED lamps are used. This is one of the most consumable items in winter crop production, especially on a large scale.

Alla Ivanova

Heat is only one of the conditions, the main thing is light, photosynthesis, however. In the same Novosibirsk region in winter you can only do forcing. Or lamps - for 200 m², about 40 pieces of 400 W each, that’s 18 kW/hour and for 12-16 hours a day.

Of course, when we are talking not about two hundred, but about twenty squares for personal use, the costs are much lower, and many are willing to pay for the opportunity to eat fresh herbs all year round.

Thanks to regular watering, additional air humidification in the winter greenhouse is usually not required. And to prevent it from becoming oversaturated, which is also not good for plants, greenhouses are either ventilated through vents installed in the roof, or a forced ventilation system with a recuperator is created. The second option cannot be called budgetary, and in small greenhouses it is practically not in demand. The irrigation itself is organized on the basis of an insulated underground water supply system or through storage tanks or a root system (drip irrigation).

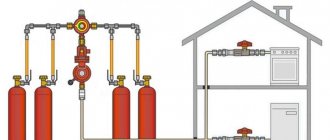

Gas heating

Gardeners are interested in how to make a heated greenhouse using gas. If it is small, then you can use bottled gas. If the greenhouse is of an industrial scale, then you need to take a permit and use a natural one. For gas heating, conventional and infrared burners are used. A conventional water heating system based on AGW is also used. Gas, of course, is profitable because it is cheaper than electricity.

When using such heating with burners, it is necessary to provide ventilation, and this already reduces the heating efficiency. If you make water heating based on heating water with gas, then the system can be fully automated. Without constant human control, the microclimate in the greenhouse will be maintained. The main thing is that it is profitable from a financial point of view, and the costs can soon be recouped.

Heating a greenhouse with underground pipes

A universal way to maintain soil and air temperatures within normal limits in the spring in a greenhouse is heating with pipes using a water system. The main advantages of this method include:

- low cost of maintaining a water heating system;

- condensate collecting on the pipes additionally moistens the ground;

- the system does not affect air humidity;

- uniform heating of the soil and air space.

Plastic pipes are currently used to install the water system. They are more affordable than metal ones, moreover, they are light in weight, do not rust and are easy to install. A do-it-yourself greenhouse with earth heating involves creating a system of water pipes.

Installation of water heating with pipes consists of the following steps:

- Remove the soil in a layer of 25–40 cm.

- At the bottom of the dug trench, lay a material that has good thermal insulation properties, for example, penoplex or polystyrene foam.

- Lay plastic pipes and connect them to the heating system.

- Install a water pump that will control the draft and circulation of water.

- Cover the pipes with a layer of fertile soil.

The complexity of this method of heating a greenhouse in the spring lies in the need to maintain the temperature inside the pipes at a level of no more than 40 0 C. Otherwise, the root system of the plants will suffer from burns, which will be reflected in the withering of the above-ground parts.

Convectors will also work

You can heat the greenhouse with electric convectors. They are installed on the walls of the structure and on the floor. Convectors heat the air well, they have timers that can be set to a certain temperature, and they will turn on and off themselves. One drawback is that they are quite energy-consuming, and electricity is now expensive.

Rating of heaters for greenhouses

You can heat a greenhouse in different ways. When compiling the rating, our team studied the main options for heating rooms, from primitive and low-cost to technically complex and expensive. Each of them has its own advantages and disadvantages. Water heating, heat guns, electric panels and infrared emitters - all of the heating methods listed have their own characteristics, advantages and disadvantages.

Some are highly effective, but their implementation is associated with serious costs of labor and material resources, and they will pay for themselves only in reputable and profitable farms. Others do not require special material costs, can be installed within a few hours, but are ineffective and consume a significant amount of energy resources. Our task is to select inexpensive, effective and economical devices that do not require complex installation and the constant presence of the owner during operation, such as when using a potbelly stove.

When selecting nominees for the rating, our experts paid special attention to the following characteristics and functions of the devices:

- Model sizes. The heater should not clutter up the work space;

- Weight. Lightweight greenhouse structures will not withstand heavy equipment;

- Power. It should be enough to effectively heat the soil and plants;

- Cost-effective – The model must provide the desired effect with minimal costs;

- Autonomy. Preference was given to devices whose operation can be programmed to automatically maintain a set temperature in the room around the clock.

- Price. Nominees with the best price-quality ratio were selected;

- Safety. Models that meet all electrical safety requirements were selected.

A team of experts took part in compiling the rating, which included experienced gardeners who have been using heaters of various designs for many years, electricians with extensive experience, and sales consultants in specialized stores. Considering their competence and high level of professionalism, we can confidently recommend any of the seven nominees presented to customers.

Warm floors in a greenhouse

A do-it-yourself heated polycarbonate greenhouse can be made with complex heating. After all, it is necessary to heat not only the air, but also the soil in which the plants grow. To do this, some use the “warm floors” design. A sand cushion is laid, a protective mesh is placed on it, then a heating element or cable, then a protective mesh again and a sand cushion on top. Then the soil is poured in a layer of up to 20 cm. It is necessary to install a thermostat so that the soil does not warm up more than 45 degrees, otherwise the roots of the plants may be damaged. This method of electric heating is very economical, with high efficiency. The sun warms the greenhouse from above, and the cellular polycarbonate retains heat. The soil below is also warmed up, and the heat from it rises.

Solar heating

The most affordable option for maintaining heat is solar energy. Environmentally friendly heating and absolutely free, does not require human intervention. Sunlight, heating the greenhouse body and penetrating through the transparent walls, gives the soil warmth. The soil also warms up the air inside the structure, due to which the desired effect is achieved.

It is advisable to build the walls of greenhouses from glass. You can create greenhouses from film, but in any case, take care to insulate the seams and stabilize the film in the wind, otherwise heat loss is inevitable.

It has been experimentally established that in small greenhouses in sunny times the temperature inside is 10-15 degrees higher, and in cloudy times - by 2-3 degrees.

The most efficient heating method

There is another way to heat a polycarbonate greenhouse in winter. These are infrared electric lamps and heaters. These devices are good because they do not dry out the air and act like solar energy. As is known, the sun's rays, reaching the surface of the Earth, heat objects and are reflected by heat. Lamps and heaters with infrared radiation also work. If they are placed along the entire length of the greenhouse, under the ceiling, then they will heat the soil, plants, walls, and, being reflected, the heat will accumulate in the room. They are absolutely harmless, with very high efficiency. Because they provide a lot of heat, but the energy consumption is small. Such heating can be very easily adjusted to create the desired microclimate in the greenhouse.

Perhaps, today this is the safest and most profitable method of heating a greenhouse in winter.

Heat accumulation using bottles and water containers

A folk method, simple and no less ingenious. Bottles with water are placed with their necks in the soil, the cork is not tightly closed. During the day, water is heated by the sun and, under pressure, little by little penetrates the soil, moistening it and protecting plants from sunburn.

At the same time, condensation forms on the walls of the greenhouse at night, which additionally moistens the soil, and wet walls transmit heat less well. Water needs to be added every 3 days: the lower the ambient temperature, the more bottles need to be placed inside the greenhouse or greenhouse. The bottles should be placed evenly between the bushes throughout the free space. Small bottles should be preferred as they heat up faster. Do not forget that when using bottles in greenhouses, for better heating, an additional layer under the main film is required - a cover made of non-woven material is best.

It also makes sense to use water accumulators - basins, buckets or barrels of water accumulate heat during the day and release it into the greenhouse at night.

It is important not only to heat the greenhouse, but also to save heat

In order for the greenhouse business to be profitable, it is necessary not only to heat the greenhouse well, but also to use all possible means to retain this heat as best as possible.

To do this, it is good to apply all knowledge in a complex. A well-chosen place to build a greenhouse, no shade, all day under sunlight. The greenhouse should be located so that the wind does not blow away the heat. Good, warm foundation. The greenhouse covering is better made of cellular polycarbonate. There should be no gaps in the structure: in the cold winter, any draft is destructive.

You can use warm, high beds with manure, which will also accumulate heat. You can grow seedlings on shelves. It is good to combine heating of the greenhouse: increasing the temperature of the air and soil. By the way, you can use waterproof mats to create the effect of warm floors. They are convenient to use in greenhouses with shelving, placing heating mats underneath them. Heat always rises from below, heating the trays with plants and the air.

Biological heating

An additional and environmentally friendly way of natural heating. Based on the decomposition of organic matter, which releases heat. In addition to heat, carbon dioxide enters the air, which is useful for the ripening of crops. Under suitable conditions, microorganisms heat such biofuel to 60-70 degrees, which is enough for the entire growing season. The process is conventionally called “combustion”.

The traditional material for biofuel is horse manure (according to summer residents, it is the most effective), beef, and pork. You can mix with them fallen leaves, which are harvested in the fall. You can use slightly decomposed peat with the addition of mullein. Straw with a small addition of urea warms well.

Household waste - food from the kitchen, sawdust, paper, rag materials, various non-chemical waste - will wonderfully heat the greenhouse. 30-40% of paper and rags in the fuel is enough for a good reaction.

Biofuels need to be properly stored. Manure is piled up to two meters high and compacted with shovels. After this, they are covered with peat, sawdust, leaves or straw.

Should you make the heating yourself or order a ready-made one?

You don’t have to invent a bicycle at all, but when ordering a greenhouse, immediately buy a heating system and fully maintain the microclimate. Specialists will deliver the structure and install it in the shortest possible time. They will equip it with all the necessary options, which is called “turnkey”, and will also give a guarantee.

Everything, of course, depends on your financial capabilities and desires. Every year, new products appear on the market that will help make the greenhouse pay for itself all year round. What kind of heating you want depends, of course, on how you want to use it: to grow something all year round or in the early spring and summer.

Frost protection

Evening watering of the soil is an effective way to protect against frost down to -5-6 degrees. There is no need to pour in a lot of water; a medium static spill from a hose or watering can will suffice.

Smoke – several piles of garbage, rotten firewood and sawdust are piled up on the leeward side. A peg is stuck into the middle of the future fire. At night, such piles are set on fire and with their smoke screen they will protect your garden from frost down to -4 degrees. Unfortunately, in strong winds this method is ineffective.

Plastic opaque bottles are filled with hot water and evenly laid out inside the desired room. It is advisable to dig them a little into the ground.

As we can see, the process of retaining heat turned out to be not such a difficult task. For the most part, a positive effect can be achieved using improvised means and household materials, showing cunning and ingenuity. And at the end of the season, your greenhouses and greenhouses will become real islands of abundance!

Features of installation of warm greenhouses

Depending on the purpose of the greenhouse, the method of its heating, the level of illumination and other technical characteristics are selected. Winter greenhouse structures are buildings on a foundation that can withstand strong gusts of wind and snow loads.

First, you need to decide on the place where the winter greenhouse with heating will be installed with your own hands. It could be a hillock or a hill. If the terrain is flat, then it is advisable to create an earthen embankment. This method contributes to additional heating of the greenhouse building due to the sun.

It is advisable to allocate an area for a vestibule within the building area. It will create a transition zone and cold air will not penetrate to the planted plants.

Rating of greenhouse heating options

In conclusion, we will make a comparative analysis of the considered options for heating greenhouses.

The easiest way to organize heating is with gas boilers and stoves running on solid fuel. Gas installations are easy to automate and create a comfortable microclimate for plants without auxiliary heat sources.

Buleryan stoves are not very convenient to use (the need for periodic manual loading of firewood). Their main advantages are low fuel cost and high heat transfer.

In second place you can put infrared emitters, cable heating systems and solar collectors. They are relatively inexpensive, easy to install and operate automatically. However, in terms of the cost of energy spent on generating a unit of heat, they are significantly inferior to gas and wood.

Heat guns occupy the third step in our rating. They are easy to maintain, can operate automatically, but are not economical. Heat pumps are located in the same niche. Despite the minimal cost of energy, the price of these installations is high and pays off for a very long time (8-12 years).

Emergency heating

The method is necessary in case of force majeure, in order to protect the future harvest in the event of equipment failure or severe frosts.

For this it is better to use:

- a metal pipe placed in one piece in a container;

- bricks that retain heat;

- flammable mixture.

We recommend that you learn how to heat the soil in a greenhouse.

Construction of the structure does not require a lot of labor and skills and includes the following steps:

- Placing the free part of the pipe inside the greenhouse - the container must be outside.

- Insulation of the hole for the pipe in polycarbonate film.

- Placing porous bricks inside a metal container.

- Treating bricks with a flammable mixture, often kerosene.

- Ignition of the flammable mixture inside the container.

Video: emergency heating of a greenhouse

Choosing materials for the greenhouse

The frame of a winter greenhouse can be made of wood or metal. The first one is cheaper, but it is less durable and not as strong, despite all sorts of modern impregnations that can be used to coat it. Although metal is more expensive, it can withstand heavy loads and can last for quite a long time.

It is best to use

cellular polycarbonate for coating, since it has high thermal insulation and transmits light well. True, its transparency decreases over time, but over the course of 6-7 years it demonstrates fairly high light transmittance. In addition, polycarbonate is durable and, at the same time, lightweight.

It is very convenient to cut and install on the frame. Of course, glass is much more transparent, but its main drawback is its fragility. In addition, it is a rather heavy material. For a winter greenhouse, glass is not the best option, since in especially snowy times it may not withstand the snow cover and simply crumble under its weight. However, if there is no particular choice, then you can use a glass roof, but it must be installed at a sharp slope to avoid snow accumulation. In addition, when building a greenhouse, you can resort to different combinations, for example, making the walls glass and the roof made of film or polycarbonate.