The appearance of air pockets in the heating system is accompanied by uneven heating of devices and alarming noise in the pipeline. The coolant moves jerkily along the circuit, increasing the likelihood of water hammer. Agree, any sensible owner would like to exclude these phenomena.

The listed negatives can be eliminated and prevented by a simple action - removing air pockets from the heating system. How to do it? How to correctly assemble the circuit, what devices should be installed so that the air is removed in a timely manner, you will learn from our proposed article.

The information presented for review is based on regulatory documentation. We have described all possible methods used against the formation of air jams. To optimize perception, the material is supplemented with photo selections, diagrams, and videos.

Removing air from systems in an apartment building

In order for all the batteries in a multi-storey building to be hot, the coolant must constantly move within them. In houses with centralized heating, water acts as a carrier of thermal energy.

The heating main consists of two threads - supply and return. In this case, in operating mode, the pressure difference between them is at least 2 kgf/cm2. The heated coolant from the supply enters the heating circuit not from the heating main, but after connecting with water flowing through the return line. The function of obtaining mixed liquid is assigned to a water-jet elevator, which is a tee made of steel or cast iron with a nozzle located inside it.

Thanks to partial recirculation of water, the highest speed of its movement in the circuit and the minimum temperature difference between the first and last radiator in the building heating system along the movement of the coolant are ensured.

The difference in pressure between the supply pipe and the return pipe in the battery is 0.2 kgf/cm2. This indicator corresponds to the pressure of a two-meter water column. The presence of air does not allow water to circulate, so information on how to remove an air lock from a heating system will not be superfluous for many property owners.

The fact is that the presence of a small difference prevents the plug from being pushed down due to a significant difference in the density of the air and the working environment. To remove air from the heating system, the hydraulic pressure expressed in meters must exceed the height of the bottling risers.

How to bleed air in autonomous systems

For autonomous heat supply systems with forced circulation of the working environment, everything is different. Typically, the pressure created by pumping equipment exceeds the height of the heating circuit and it can function even if the pipes are airy.

But as air bubbles move in pipes and batteries, extraneous sounds arise - hydraulic noise. If they are distributed continuously, this will cause a lot of unpleasant moments for residents.

In addition, air contributes to the formation of corrosion processes in steel parts of the heating circuit, such as panel radiators, pipes made of black steel, and cores of bimetallic devices.

When there is no oxygen, it does not come into contact with the coolant and rust does not appear. Now it’s clear why an air lock in the heating system of a private home is such a nuisance.

Preventive measures

The most effective and accessible preventive measures aimed at preventing network airing include:

- compliance with the installation rules of all structural elements and components;

- installation of special devices that remove air manually or automatically;

- regular inspection of the tightness of joints and connection areas;

- bleeding air until the heating system is filled with water;

- monitoring the operation of water heating equipment;

- checking the characteristics of the thermal fluid for compliance with the requirements;

- monitoring of pressure gauge readings and pressure in pipelines;

- systematic visual inspection of pipelines and radiator batteries.

It is strongly recommended that during operation and maintenance periodically perform routine removal of air pockets.

Causes of airiness

Air plugs form in heating systems for a number of reasons:

- As a result of replacing radiators in the apartment. It is most often produced in the summer on the eve of the new heating season. After the pressure testing is completed, the risers are filled with water, and the bleeding of air from the heating system is postponed until the fall.

- After carrying out an inspection of the shut-off valves on the risers, which are needed to drain the circuit.

- As a result of checking the shut-off valves in the elevator unit. The circuit should be reset completely.

- From coolant leaks through battery intersections, threaded connections, fistulas formed in pipes, etc. If the valves in the elevator are in good condition and closed, the pressure in the circuit gradually begins to drop. In this case, you need to slightly open the Mayevsky tap or the flusher located on the top floor. As a result, the vacuum that arises at the top of the circuit sucks in air.

Signs of airing

Airing leads to inefficient operation of the heating system, as a result of which unnecessary resources are spent on heating the coolant. This leads to unjustified financial expenses and can significantly affect the family budget during the cold season. Signals if the heating system is airy are the following:

- No heating of heat exchangers. Air in the heating circuit in the form of a plug prevents the coolant from passing through the pipes, as a result of which it does not flow to the radiators or into the underfloor heating pipeline. If air gets into the supply pipes, the radiators and floors remain cold when the boiler is operating at full power.

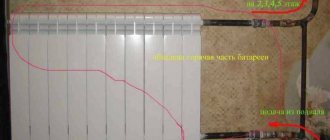

- Uneven heating of radiators. If there is air in the heating radiators, one of its parts will have a lower temperature, which can be easily determined by touching the surface of the sections with your palm.

- Increased noise. The movement of coolant in a pipeline circuit with air pockets is often accompanied by noise, which causes the movement of microbubbles.

- Vibrations. An increased concentration of air in the coolant leads to an acceleration of oxidative processes due to the oxygen contained in it, accompanied by the decomposition of metals with the formation of salts and carbon dioxide. Periodic emissions of insoluble metal oxides and carbon dioxide into the coolant can cause vibration processes in pipes.

Rice. 2 Air-filled radiators in a thermal imager

Bottom heating supply in a high-rise building

For modern buildings, the standard solution is a bottom filling scheme. In this case, both pipes - supply and return - are laid in the basement. The risers connected to the bottlings are combined in pairs using a jumper in the attic or upper floor.

Option No. 1 to solve the problem - start the elevator for dumping

Bleeding air from the heating system is carried out by housing and communal services specialists at the stage of starting the circuit, which is partially or completely vented. For this purpose, it is discharged: one valve is opened, and the second is left closed.

From the side of the heating circuit, up to the closed valve, open the vent, which is connected to the sewer. The fact that most of the air has escaped can be seen from the water flow in the discharge - it moves evenly and without bubbles.

Option No. 2 to solve the problem - installing an air vent

Before releasing air from the heating system, an air vent is installed in the upper part of all paired risers in the case of bottom filling. It can be not only a special Mayevsky tap, but also a screw valve, a water folding or ball valve mounted with the spout facing upward.

Venting air from the heating system is performed in a certain sequence:

- Open the tap more than one turn. The result should be a hiss of moving air.

- Place a wide container under the tap.

- They wait for water to flow instead of air.

- Close the tap. After 10 minutes the riser should warm up. If this does not happen, you need to bleed the plugs again.

Before getting rid of air in the heating system, you should remember these important rules:

- In the Mayevsky tap, you cannot unscrew the screw completely, since with a pressure of 5–6 atmospheres and boiling water pouring from the hole, it is impossible to return it to its place. The result of such actions may be flooding of your own apartment and that located below.

- There is no need to unscrew the air vent under pressure, even half a turn, since it is unknown what condition its thread is in. When a drain valve is faulty, before replacing or repairing it, you should shut off the two paired risers and ensure that their valves are holding water.

- If you live on the top floor, before the start of the heating season, you need to make sure that you have a tool that works with the air vent. Models of modern Mayevsky taps can be opened with a screwdriver or by hand, but in older buildings a special key will be required. It is easy to do - you just need to take a rod of the required diameter and make a cut at its end.

Option No. 3 to solve the problem - bypass the heating riser to discharge

With lower bottling, the main problem with air vents is that they are located on the upper floors of apartments. If their owners are constantly away from home, how to remove airiness from the heating system?

You can bypass the paired risers from the basement side, for which:

- They are examined for the presence of valves, after which plugs or vents can be installed. In the second case, there will be no costs, but in the first case, you need to buy a ball valve with a thread of the same size as the plugs.

- Shut off the valves on two risers.

- At one of them, unscrew the plug a few turns and wait for the pressure of the liquid that hits the thread to decrease. This way you can make sure that the valves on the floors are working properly.

- A ball valve is mounted in place of the plug, first winding up the threads.

- The mounted vent is opened completely.

- Now open the valve located on the second riser. When the pressure removes air from the heating system, close the vent and open another riser.

There are also some nuances to this:

- When all the batteries are installed on the supply riser, but there are none on the return riser, the dumper needs to be mounted on the return and then the problem of how to remove the air lock from the heating system will be solved. If radiators are located on paired risers, it is not always possible to remove the air.

- If it is not possible to bypass the risers in the same direction, then the vent is moved to the second riser and the coolant is transferred in the opposite direction.

- If there are screw valves on risers, it is necessary to avoid moving water through them in the direction opposite to the arrow on the body. The desire to slightly open the valve with the valve pressed down may result in its separation from the stem. To fix the problem of how to bleed air from a heating system, it is quite common to reset the building's heating system.

Installation of air vents

At all upper points of the system, be it pipeline bends or radiators, you need to install air vents - the main weapon in the fight against traffic jams. The air vent can be automatic (valve) or manual (Maevsky valve). The automatic valve will do everything itself, unnoticed by the owner.

In order for the automatic air release valve to work properly, you need to ensure that the coolant is clean at all times.

Internal structure of an automatic air vent

In manual mode, if signs of airiness occur (decrease in temperature in the area, gurgling, drop in pressure), you need to immediately take care of bleeding the air.

When replacing a radiator, they buy an installation kit, which contains everything necessary for installation, including the Mayevsky tap. But air vents are also sold separately. They are placed in the upper fitting of the radiator, on the opposite side from the supply inlet.

Top supply in an apartment building - how to release air

Buildings with a top spill have the following characteristics:

- The supply bottling is located on the technical floor, and the return bottling is in the basement;

- each riser is a jumper between them, disconnection is possible both from below and from above;

- the feeding bottling is done with a slight slope;

- at the very top there is an expansion device with a discharge outlet, while the discharge is often discharged through all floors to the elevator unit in the basement or at most close to it.

The function of the air vents is assigned to the vent on the expansion device. Thanks to the discharge to the basement, the start of heat supply in the fall is simplified.

Option No. 4 to solve the problem - sump on the expansion tank

To fix the problem, before pushing through the air lock in the heating system, the top filling must be put into working condition.

To do this you should:

- Slowly fill the system to prevent water hammer. It is necessary to slightly open the house valve on the supply or return, located between the elevator unit and the heating circuit.

- After filling the system, open the second valve completely.

- After 5 - 10 minutes, open the vent on the expansion device and wait until the air is replaced by water.

Open heating system in a private house

Such a system operates when the pressure and height of the water column formed by the lower and upper points of the heating circuit correspond. In this case, the bottling is arranged at a constant slope, and an open expansion device is located at its highest point.

It combines a number of functions:

- expansion tank, which compensates for the increase in liquid volume when heated;

- a safety valve that serves to relieve excess pressure in the event of water boiling in the heat exchanger of the heating unit;

- an air vent, thanks to which the problem of how to expel air from the heating system is solved - it must be forced into the upper part of the circuit, or rather into the expansion tank, from where it is sent into the atmosphere.

With this scheme, no additional installation of air vents is required. But they can be individually supplied to radiators located above the spill: the Mayevsky valve allows air to be removed from the radiator and forces the working medium to circulate through both collectors.

Closed system of a private house - how to remove an airlock

An automatic air vent is placed in the circuit through which the coolant is forced to move, operating at excess pressure. It is an element of the safety group of the heating unit and is mounted at the outlet of the heat exchanger.

Some boiler models have their own safety group installed inside the housing. All batteries located above the bottling points are equipped with Mayevsky taps or air vents. The latter are certainly needed when connecting devices diagonally or sideways. In the case of a lower two-way connection, the operation of an air-filled radiator is possible. The following method is used to bleed air from the heating system: it is forced into the upper collector, and the coolant is released through the lower one. The battery sections are heated in height due to the thermal conductivity of the metal.

Draining through expansion tank

In households with an individual heating system, expansion tanks of closed and open type are installed. In open structures, the level of water or other heat carrier naturally drops.

It is advisable to top up the system through the lower radiator valve, but it is possible to pour coolant directly into the tank. The running system should be allowed to run for several minutes, which will allow the plug to be pushed out. Otherwise, a standard drain through the radiator is used.