The boiler starts up independently after a long period of inactivity outside the heating season, the burner is turned off automatically or goes out during wind (if there is no automatic start), also after any repair work. The initial commissioning of a new gas boiler should be carried out exclusively by a specialist who will put the appropriate mark in the boiler unit’s passport. Without it, the boiler warranty is void.

However, even starting a previously configured boiler is not such a short process; according to the operating rules for hot water boilers, it requires a more thorough approach: proper filling of the system, bleeding of air, pressure testing and monitoring of indicators. All this is done to avoid problems and emergency situations during the heating season.

How to light a flame on a gas boiler

When you purchase and install gas equipment, the first question that arises is how to light a gas boiler. The first start-up of a gas boiler is carried out by a specialist, from whom you can get recommendations on the use of the equipment. During subsequent starts, you can also set the required temperature using the coolant heating level control knob.

Read more about the procedure for starting gas equipment in the material: Starting gas into a private house. Primary requirements

At the same time, the circulation pump is connected. Excessive noise indicates stagnant air in the pump. To release it, you need to remove the boiler cover, then unscrew the pump cover. When water appears from under the lid, screw it back on. As soon as the pump starts, automatic ignition occurs and the boiler operates normally.

The feed tap is of great importance for the operation of double-circuit boilers. Due to it, pressure is maintained so that the equipment operates without interruption.

Circulation pump

The boiler circulation pump requires special attention during startup.

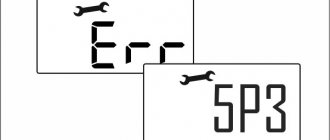

Air often accumulates in it, and its blades sometimes seem to get stuck (the boiler will display a corresponding error).

To do this, you need to remove the front panel of the housing, unscrew the central bolt on the pump and use a straight-bladed screwdriver to turn the shaft in the direction indicated by the arrow.

An air vent is installed above the pump. You need to pull the bright lid up and let the air escape.

Floor-standing boilers are usually more powerful than wall-mounted ones. If you need to heat a large room, it is better to choose this option. — overview of design options and models.

Conclusion

At first, the system may make gurgling sounds, all because during startup it is impossible to bleed air down to the last atom. It will gradually be removed through the expansion tank valve. Periodically check the pressure on the pressure gauge - it should be within the operating range.

Temperature adjustment and other boiler settings are described in the instructions for each model.

If the gas boiler does not ignite the first time

In order to determine why the gas boiler does not turn on, you should pay attention to the following important points:

If your device's piezo element runs on batteries, try replacing them. As a rule, they last for 6-8 months, then a lack of power appears, which leads to the fact that the burner on the gas boiler does not light. The “syndrome” of low batteries sometimes manifests itself in such a way that the gas boiler does not light up the first time, but lights up on the second or third attempt. In modern gas boilers, batteries are practically not used to ignite the gas burner, and the problem when turning on can be of the same nature. Below we will look at the reasons.

Recommended reading: Why does a gas boiler often turn on and off?

Recommendations for use

- If the gas valve malfunctions, it is necessary to check it and adjust the settings. If the heat exchanger is covered with a large layer of scale, this greatly reduces heat transfer and significantly increases fuel consumption. In such a situation, the boiler makes a cracking or noise. This occurs due to the accumulation of salts, which slowly fall off the surface over time, which is why the noise is heard. They can be removed using special reagents.

- Often you have to deal with components wearing out too quickly. The main reason for this is timing. In this case, the gas boiler can automatically turn on and off. When the water in the circuit cools down, a signal is received from the thermostat that the water has cooled, in which case the boiler turns on.

To learn how to choose a gas boiler, see the following video.

What to do if a gas boiler with automatic ignition does not light up

Reason 1. Reduced network voltage

If the gas boiler does not start, then the problem may lie in the power supply from the household network. It is recommended to install a voltage stabilizer, which can significantly reduce the risk of consequences of power outages.

It protects the electronic component of the boiler during power failures. A decrease in voltage may affect the operation of other elements of the gas heating system. First, check the serviceability of the outlet and inspect the condition of the electrical wiring.

Reason 2. The ignition unit has failed

When the equipment does not want to ignite, check how the ignition unit works. To do this, you can take a multimeter. Switch it to ohmmeter mode. Measure the resistance at the output of the contacts of the electronic unit, which are responsible for ignition. A level of 650-750 Ohms means that the unit is functioning normally. If the value is different, the tester will show an open (the electronics will show a value of 1) or a short circuit (the electronics will show a value of 0). Replacing the part will solve this problem.

Reason 3: Gas valve malfunction

Gas burners tend to let debris into the valve, as a result of which the valve fails because the inductor burns out. And she is responsible for the operation of the valve. To check this malfunction, you can also use an electronic tester in the “ohmmeter” mode. To do this, be sure to first turn off the power to the boiler. Readings of 80-90 Ohms can be considered normal. If the value is different, the gas valve must be cleaned. First you need to unscrew the side of the housing in which the valve is located and clean it inside. If the equipment has fasteners with a rarer head profile, you will have to select a suitable screwdriver or sharpen the one that is available.

Reason 4: Flame electrode needs cleaning

Another reason when the gas boiler does not turn on and there is no heating is contamination of the electrode. The soot remaining after fuel combustion causes the flame control electrode to malfunction. Cleaning with fine-grained sandpaper will help. If the gas boiler still does not turn on, you need to turn off the heating and wait until the circulation pump stops. Next, you need to turn off the instrument panel, remove the plug from the socket, and turn it 180 degrees. Then insert it into its original place and turn on the boiler. This rephasing helps restore the sensitivity of the gas ions necessary for normal operation of the system.

Features of filling the system with water

To turn on the heating system, you must first fill it with coolant, i.e. water, which, after heating, will begin to circulate. A feature of modern equipment is that special manual recharge is not needed. During the first launch, you need to carefully check everything so that further work proceeds smoothly and accurately. Not only a pump is built into the boiler body, but a special tap near the pipe for supplying cold water to the system. When cold water is supplied, noise is heard, this is quite normal, there is no need to panic.

During filling, you need to monitor the pressure in the system; special sensors and pressure gauges are provided for this. Modern equipment necessarily has such additional elements, so there is no need to purchase them separately. As the gas boiler fills, the mark on the sensor rises. When it reaches 1.5-2 atmospheres, it is necessary to stop the supply of cold water, i.e., filling is completed. The pressure parameter may be different, since everything depends on the equipment manufacturer and its requirements for the operating pressure in the system. But this is not the final filling; replenishment is necessary as the heating system is freed from air pockets.

Return to contents

There is no spark and the flame does not light up on boilers with semi-automatic mode

The gas supply system is not adjusted

This problem on heating devices can lead to the following consequences:

- When fuel is supplied at low pressure, the system may experience constant malfunctions. The gas boiler may turn off, and the automation will not allow it to ignite when the coolant temperature drops and will generate an error. The consequences of low gas pressure, especially in winter, can be detrimental to the entire heating system. If the device generates this particular error, check the gas supply valve, as well as the fuel supply pipes at their connections for leaks. Call your gas company to see if they have reduced the pressure due to any work. If the cause cannot be determined, contact a specialist.

- gas pressure too high. This can lead to increased fuel consumption and rapid wear of all equipment. Check the gas supply valve, you can close it a little.

However, first, contact the gas workers and find out if there were any failures on their part. accompanied by movement of the coolant along the system circuit. To resolve the issue, it is recommended to contact a specialist.

Read more: How to properly set up and adjust a heating boiler

The emergency electrical circuit is broken

The emergency electrical circuit includes connecting wires and bimetallic sensors in the chimney, which are triggered when 75-80 degrees Celsius are reached. The circuit also includes a thermocouple that produces a voltage of 10-20 mV, a draft breaker and an electric valve, which consists of an inductor, a rod and a valve.

If the emergency circuit is broken, the electric valve does not open, which may be the reason why the gas boiler does not ignite. A special multimeter tester will help you check all elements of the circuit. A value of 0.3-0.5 Ohm is considered normal. There should be no oxidized or loose contacts. If there is no such device, we adjust the temperature to about 0 and at the same time connect the piezoelectric element. The pilot light should light up. Release the temperature control button.

If it goes out, you need to carry out the entire cycle again, closing the contacts of the traction breaker in order to check the integrity of the installation and boiler sensors. If the pilot light is on, it is due to poor contact in the circuit or one of the sensors is not working. The thermocouple may also be faulty. Non-working elements require replacement.

The piezoelectric element has failed

This part is usually mounted next to the temperature setting, but is sometimes located separately. To check whether the piezoelectric element is working properly, try disconnecting the wire through which the generated voltage flows from the electrode and bring it 4-8 mm closer to the valve body.

After that, click on the launch element button. When a spark appears, the piezoelectric element is working, you need to check the electrode itself (its body is made of ceramics, it must be dry and clean). Remember that the fastening nut must be tightened by hand.

The valve or torch tube is clogged

This problem often occurs in the summer when the boiler is rarely used. In summer, the valve and flare tube become filled with insects, which prevent further gas movement. Also, the reason that the gas boiler does not turn on may lie in rust and the combustion products themselves. The tube and valve must be cleaned to continue proper operation of the equipment.

Ignition

On the eve of putting the unit into operation, you need to fill the heating system with coolant, preferably soft water. After this, the temperature is brought to 90 C several times in order to extract dissolved oxygen from it as much as possible.

Filling is carried out very slowly without interruptions in order to prevent the formation of air jams in the network.

The procedure for igniting the Danko boiler unit:

- Check the draft in the chimney system and the absence of gas contamination in the room.

- Ventilate the furnace room for at least 10 minutes, the valve at the entrance to the boiler must be closed.

- Check the gas fuel pressure in front of the boiler - less than 3000 Pa.

- Using the automatic “KARE” system, with the boiler valve on the gas pipeline closed, turn the handle of the temperature sensor all the way counterclockwise.

- Open the gas tap.

- Press the start button of the thermoelectromagnetic valve and, holding it, press the piezo button until the burner device begins to burn steadily.

- Heat the water to 80C, while monitoring the pressure in the water network, checking the quality of the burner, the torch should be bluish in color.

The flame does not ignite (general faults)

Pipe burnout

To organize the safe operation of the chimney, a steel pipe is used. However, it can overheat when interacting with combustion products and burn out. To avoid this problem, it is recommended to use a sandwich pipe, which will protect against overheated gases.

Chimney problems

There may be several problems associated with the chimney design. So, fallen leaves, snow can get into it, and the mouth can freeze over (in this case, the frequency of occurrence depends on the deflector, umbrella or other end). This requires cleaning the chimney or reshaping its fungus to allow smoke to escape unhindered. Below in the picture are options for “fungi” deflectors.

In addition, if the chimney is poorly insulated, the gases in it can form an air lock, since the cooled, cold gas is more dense and does not allow hotter gases to escape freely.

If the chimney is not insulated, strong condensation may settle inside it and freeze up during the cold season. Insulating the chimney will help solve the problem.

If foreign objects (house, tree) interfere with the mouth of the chimney, you will need to increase its height, cut off interfering branches, or otherwise remove the obstacle to the exit of smoke.

Weak supply ventilation

Organizing normal supply ventilation is very important for the proper operation of gas equipment. Thus, combustion requires oxygen, and combustion of 1 m3 of gas uses 10 m3 of air. If this air is not enough, then backdraft may form in the chimney, and ventilation will not be enough. The exhaust hood in the kitchen also contributes to weak supply ventilation if the boiler is installed in this room. Also, due to plastic windows there may not be enough air. The problem needs to be solved by proper installation of gas equipment and proper ventilation.

Pressure testing and washing

Pressure testing of the system is not the most necessary preparatory stage, but it is desirable, since it will show defects and leaks in advance, if any.

Pressure testing is not always done due to the lack of a special pump and the reluctance to call a team, but if the heating fails in the midst of cold weather, the costs can be much higher!

It is especially important to check a new system and one that, on the contrary, has been in use for several years.

The cost of crimping in construction companies is from 3,000 rubles.

Additionally, they may charge a fee for visiting the site (about 2 thousand rubles). By the way, a manual pressure testing pump will cost 4.5 – 6 thousand rubles.

The principle of operation of a gas burner

It consists of the following: air and fuel are mixed, and the combustion products must go through the entire combustion process.

We can conditionally distinguish three tasks in the operation of this element of the system:

- preparing air and fuel for combustion by determining temperature, speed and direction;

- mixing these elements;

- combustion, that is, oxidation of combustible elements with the help of oxygen, combustion due to the nozzle at the end point of the tube.

The reasons that the burner does not light up must be sought in the principle of its operation.

The burner itself is essentially a metal tube that is hollow inside and has several holes called nozzles. The gas burns in it, heading towards the combustion chamber. The mixture of combustion products is discharged outside. And if the air is collected by natural injection, then the gas is distributed and directed inside thanks to the system of indicated holes.

If the gas boiler does not ignite, it means that the combustion conditions are not met: there is no gas, no air is supplied, and combustion products do not come out. Understanding the cause of problems allows you to eliminate them in a timely manner and restore system operation. When lighting a gas boiler, be careful. This equipment requires special care.

Launch

This stage is especially important for creating a home in the house. In order for the AGV to serve for a long time and work without breakdowns, it is necessary to correctly organize the startup process the very first time. During this procedure, the entire system is filled with water and air is removed from the pump and all heating radiators. To facilitate this work, Mayevsky cranes are used. They must be opened until all the air has left the system and water flows out of them.

To check whether there is air left in the pump, you need to remove its panel from the front side. If there is still air, then the necessary adjustment work must be performed automatically. When the air pockets are removed, the pump should start working immediately.

Before starting the boiler, you need to make sure that it is installed correctly and securely. It must be installed in accordance with safety requirements. It should be no closer than twenty centimeters from any gas appliances. The same goes for flammable items.

Model range of Mimax equipment

The mimax company offers the consumer the following products of its own production:

VEGA Series

This floor-standing gas boiler is available in two variations:

In addition to the high efficiency of 92% for this type of boiler, the operating instructions contain the following technical characteristics:

Devices MIMAX KSG and KSGV

In this model of gas heating apparatus, the Mimax company installs open burners of its own production and automatic equipment from the Italian company Optima. The attached instructions contain the following technical characteristics and design features:

Mimax parapet models

The heating boiler of this series has the following features:

READ How to install a YouTube icon on your desktop if it is not there anywhere

All these design features of Mimax parapet boilers have received approval and positive feedback from consumers.

The worthy technical and operational characteristics of gas units of the Mimax brand are deservedly in demand among domestic consumers. A low price with excellent quality, reliability and safety is another advantage of this equipment, which is confirmed by numerous reviews on the manufacturer’s website.

Source

Varieties of classic style

The concept of classical style unites a number of trends that have a common basis, but different means of expression. Let us next consider the two most popular trends in interior design.

IMPORTANT: do not skimp on purchasing high-quality materials and interior items - it depends on how the room will look - cheap and pretentious or dignified and elegant.

American classic style in the interior

This style came to us from across the sea from colonial settlers. In pursuit of a better life in the New World, they furnished their homes as best they could - so by the end of the 20th century, by intertwining European and local country styles with a touch of Art Deco, an elegant American classic style was formed, which has several characteristic features:

- The center of the house is the living room, usually with a fireplace and combined with the dining room. Upholstered furniture is concentrated in the center, wood predominates in materials;

- The rooms flow into one another - the doors close only to private rooms;

- Photos of kitchen interiors in a classic American style usually have one common and integral detail - a bar or kitchen island, which is also sometimes a dining table;

- Lighting is another characteristic feature. It divides the room into zones: a large chandelier and additional floor lamps and sconces - everything is like in ordinary classicism. However, additional light sources are turned on only when necessary - a tribute to the economy and thrift of the inhabitants of the New World.

Interior style: modern classic

If in the photo the classic style in the interiors of apartments or houses seems to you too oppressive, “smells of mothballs” and deliberately pretentious, but you still want something timeless and sophisticated, a more modern neoclassical style in the interior (or modern classics, as it is sometimes called) just for you. Here, too, typically classical decorative techniques are used - stucco molding and gypsum rosettes, patina and pilasters, Greek columns and complex relief patterns. However, the overall impression of the interior is lighter and unobtrusive - this effect is achieved by intertwining classic features with modern laconicism.

The neoclassical style in the interior also supports the principle of symmetry - there are no random or disordered things here. The color scheme is predominantly light, pastel tones. The main colors are still white, beige and gray, but unlike the classic interior, color accents are increasingly found here, albeit muted, in textiles and furniture upholstery - azure, green, red, pink, blue, etc.

Characteristics

| Basic | |

| Type | gas, convection |

| Burner | gas |

| Number of circuits | single-circuit |

| Max. thermal power | 10 kW |

| Max. thermal load | 12.50 kW |

| Non-volatile | Yes |

| The combustion chamber | open |

| Heated area | 100 sq.m |

| Efficiency | 90 % |

| Control | mechanical |

| Installation | floor |

| Built-in circulation pump | No |

| Built-in expansion tank | No |

| Fuel | natural gas |

| Natural gas consumption | 1.32 cu. m/hour |

| Nominal pressure of natural gas | 13 mbar |

| Coolant temperature | 50 – 95 °C |

| Max. water pressure in the heating circuit | 2 bar |

| Comfort | |

| Functions | thermometer |

| Peculiarities | external control connection |

| Safety | |

| Protection | gas control |

| Connection | |

| Gas connection pipe | 1/2″ |

| Heating circuit connection pipe | 1 ½” |

| Chimney diameter | 120 mm |

| Dimensions (WxHxD) | 300x650x490 mm |

| Weight | 44 kg |

The homeland of the brand is Russia, the place of production is Taganrog.