It’s good when heating equipment provides uninterrupted heating throughout the winter. You don’t have to interfere with your work, all you have to do is enjoy the warmth and comfort. But it happens that during the coldest period the heating stops. Why does the gas boiler turn off? The reason may be a malfunction of one of the nodes, causing the automation to block its operation. You have two options: call a specialist or help yourself. Since the wait for a specialist may be lengthy, use our recommendations.

Reasons for clocking

Clocking indicates the frequency of switching on of the device that provides heating of the thermal fluid. In the absence of external control devices connected to the equipment, most often the time interval between turning on the boiler does not exceed 10 minutes, and by default such indicators are only three minutes. Frequent switching on and off is not a recommended mode for operating a gas boiler.

In order to maximize the economical consumption of blue fuel, it is advisable to choose the option of continuous operation of equipment with compensation for heat losses. Among the main problems that provoke the clocking of the unit, the following can be noted:

- overheating of the device under high power conditions;

- insufficient gas supply pressure;

- incorrect installation of the thermostat;

- various pump breakdowns;

- filter clogging.

In small rooms, excessive gas consumption is common, so when choosing equipment it is very important to correctly calculate its technical indicators and basic operational characteristics. Among other things, the configuration parameters of different models often differ significantly, which requires a mandatory and very careful study of the instructions before configuring the equipment.

Let's look at the main reasons for the boiler constantly turning on and off.

What to do when a malfunction occurs?

Gas consumers should understand that they do not have the right, but the obligation, to repair their home or apartment equipment. Moreover, in a timely manner and with high quality.

And since frequent shutdown of the boiler is potentially a malfunction, this legal requirement cannot be ignored. Since for this, according to Art. 9.23 of the Administrative Code faces a fine.

Repairing any gas equipment is a responsible procedure, as it significantly affects safety. Therefore, you should not overestimate your capabilities or try to save money, risking the lives and health of people nearby, including relatives and friends.

The size is 1-2 thousand rubles. And, if suddenly the situation, through the fault of the user, becomes dangerous to the life and health of people or an accident occurs, then you will have to part with 10-30 thousand rubles (Article 9.23 of the Administrative Code).

It is easier and more reliable to contact the gas company with which the contract has been signed. And all the risks will fall on their shoulders. As well as responsibility for the timeliness and quality of repairs. And for violations the company will be held liable in accordance with Art. 9.23 Code of Administrative Offences. Where is it said that penalties can reach an impressive 200 thousand rubles

You should also remember that you should not take responsibility for yourself by trying to eliminate the cause of switching on/off yourself. Especially against the backdrop of the fact that problems with equipment inoperability must be resolved by specialists from companies with which the gas consumer has signed an agreement. And for ignoring such a rule, additional sanctions in the amount of 1-2 thousand rubles are threatened - this is also stated in Art. 9.23 Code of Administrative Offences.

Any repeated violation of the above norms will be the reason for punishment in the form of a fine, the amount of which will be 2-5 thousand. The basis for this is the corresponding norm in the above article of the Code of Administrative Offenses.

High boiler power

Operating a gas boiler at maximum power levels causes rapid heating, as well as pulsed operation of the unit. The heating level is determined by the modulation of the gas burner. When receiving a heated return, the boiler goes into standby mode, and as the return cools down, the boiler turns on again. Due to the high starting power of the boiler in the off-season, the problem of turning the gas boiler on and off occurs most often.

A room thermostat can solve the problem. In this case, regulation is carried out automatically. If the room temperature is reached, the thermostat will signal the boiler to turn off. The heating system cools down faster than the air temperature. Therefore, the boiler will turn on less often and work longer.

It is of no small importance to determine the optimal power of the equipment, taking into account the region of residence, the total area of the heated room and the degree of insulation of the building. Currently, condensing boilers used in low-temperature heating systems have proven themselves to be the best. This reliable option is characterized by heating the coolant in the return circuit within 60°C.

You asked, we answer

There are many nuances associated with the operation of boilers, and therefore many users ask questions regarding their correct operation.

Among them:

- Which brand is best? – some of the best models are Vaillant, Protherm devices, Bosch gaz 6000W double-circuit boilers. They are distinguished by high productivity, long service life, efficient heating of rooms up to 200 m², and can withstand power surges well;

- Which heat exchanger is better to install? – the cast iron heat exchanger is considered the most durable;

- Why does a wall-mounted gas boiler often turn off? – the cycle is provoked by incorrect installation;

- Does the boiler make noise during operation? – heating systems operate almost silently;

- How to calculate power? – power is considered 1 kW per 10 m2, + 20%. If a double-circuit boiler is selected, add 5 kW per tap, 10 kW per bathroom, 7 kW per shower to the calculation;

- Why is a floor-standing boiler more expensive than a wall-mounted one? – simple floor-standing units have a thick cast-iron heat exchanger, which itself is quite expensive. However, its advantage is the possible partial replacement of a separate section, which is much cheaper than replacing the entire heat exchanger.

Should a gas boiler turn off during normal operation?

The boilers are equipped with electronics. After connection, the temperature is set. Upon reaching the set point, the boiler turns off and lights up again when the system cools down. This is an absolutely normal process. You can only suspect something is wrong if it happens too often. In this case, you need to look for the problem or call a specialist to determine the reasons why the gas boiler constantly turns on and off.

Why does a gas boiler often turn on and off in heating mode?

A situation where a gas boiler gains temperature and quickly turns off will indicate a problem with the equipment. If it was just purchased, then there may be several reasons - factory defects, installation errors, improper operation.

In the first case, the breakdown is detected immediately after installation. The second and third options are discovered only during use. Then you notice the gas boiler turning on frequently. A lot depends on the design of the heating system. A well-installed boiler will provide warmth, coziness and comfort in the home.

Weak gas pressure

The level of fuel pressure in the gas line undergoes significant changes at different times of the year. With the onset of winter, as a rule, the maximum number of users is connected to the centralized gas pipeline, so the pressure in the system decreases to a minimum. In this case, the burner without modulation continues to function, but the operation of the device is noticeably reduced. Today, various flame modulation options are used:

- hydraulic type - direct relationship between flow and constant temperature;

- electronic type – indirect relationship based on a temperature sensor;

- ionization type - current in a closed circuit with a signal to the control unit.

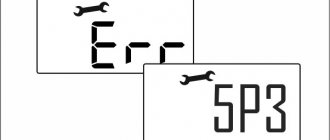

At low gas pressure, the boiler may turn off and turn on again due to the fact that the system is not warmed up. But most often today, gas boilers simply go into error states and do not work until you reset it.

Troubleshooting new equipment

New equipment may also experience various problems. Most often they manifest themselves in the operation of the flow sensor, in the operation of the candle, or in the power system. Let's take a closer look at these problems.

Column microswitch failure

Often the problem with a loud bang during ignition is the insufficient discharge of batteries, which provokes the inability to instantly ignite the gas-air mixture.

The power supply is connected to the control unit via special microswitches, which are responsible for generating a signal to activate the ignition when the DHW tap is opened. If the signal arrives at the wrong time, this causes the problem. This malfunction occurs most often due to oxidized contacts. The microswitch cannot be repaired; it will need to be replaced.

If the microswitch breaks down, repairs cannot be carried out, since this system will have to be completely replaced

Flow sensor malfunction

Often the problem with popping is the flow sensor. It is located in the input circuit. A signal is sent to the control unit controller indicating the presence of liquid in the pipe. The data instantly activates the ignition system. Intensive use of this element creates an increased risk of breakdowns. For example, contact groups can be oxidized.

Such sensors are most often manufactured in a non-separable design, therefore, if a problem occurs, they cannot be repaired and must be replaced.

Working candle offset

The problem may be with the spark plug. After applying voltage, it provokes the formation of an electric spark. Modern candles are made in such a way that they can last for a long time. Element failures are rare, but they do happen.

The most common occurrence is that the ignition device is displaced relative to its nominal position. It can occur as a result of repeated heating and cooling. Such processes are associated with changes in the dimensions of individual structural elements. As a result of adjusting the position of the spark plug, the spark parameters become normal, and extraneous noise completely disappears.

Incorrect operation of the ignition retarder

A rare breakdown is considered to be incorrect operation of the ignition retarder. When disassembling the column, you need to remove the water regulator. On its cover there is a hole in the bypass channel, in this hole the ball is located. The adjusting screw determines the position of the ball.

If, when shaking the lid, you hear the sound of a moving ball, then you should not manipulate this part further. If there is no knocking, then you can move the ball using a thin copper or aluminum wire through the passage channel hole, which is located in the regulator cover.

Most often, the retarder is a ball of metal or plastic that blocks part of the bypass channel in the water regulator. In most column designs, this moderator is located in the boss of the water regulator cover.

As a last resort, you will have to resort to the procedure of parsing the element. It must be said right away that the external screw does not affect the position of the ball in any way.

The inner screw must be removed very carefully. You should first remember its initial position, and also clearly determine the number of revolutions by which this screw is screwed in

This will allow you to maintain the required location of the element (ball) during subsequent assembly.

After repair work, be sure to check all connections to completely eliminate leaks of both water and gas. All connections must be treated with a sealant to ensure tightness. After which you can put the casing in place and use the column as usual.

Incorrectly installed thermostat

In practice, two types of thermostats are used: built-in and remote type. The first option does not involve transfer. Remote models require proper installation. The installation should be carried out in the fastest cooling room, which allows the heating system to operate normally. Installation prohibited:

- in basements;

- near window and door openings;

- next to household appliances;

- very close to the surface of the ceiling, floor;

- under direct exposure to sunlight.

- Installation in kitchens is not recommended

Particular attention is paid to proper connection in accordance with the circuits recommended by the manufacturers, in accordance with the technical characteristics of the device.

How to avoid subsequent breakdowns after repair

Sometimes it makes more sense to buy a new, modern refrigerator than to spend money on repairing a cheap but old one. Here's what experts advise on how to extend the life of a refrigerator:

the instructions for the equipment are a useful document, and not waste paper, as they treat it. Before turning on the refrigerator, study the operating features of the device. Unfortunately, most people only pick up the instructions after something has gone wrong; When installing the unit, you must adhere to the level. It happens that the floor in the selected place has unevenness

Then a stand is placed under the refrigerator; It is also important where the equipment is located. There should be no sinks, stoves or heat sources (radiators, microwaves) near it. It’s also better not to place it close to the wall

For normal air circulation and, accordingly, normal operation, at least 3 - 5 cm is required; The refrigerator should be connected to a separate, not a shared outlet. This is a large household appliance that consumes a lot of light, so it must have a separate power source; Do not leave the door open for a long time. Because of this, increased loads are placed on the motor. It’s easier with modern refrigerator models - if the door is open for a long time, they beep; if the refrigerator does not have the “No Frost” function, then it will have to be defrosted every month; The rubber gasket in the door area must be clean. Contamination will lead to depressurization; Do not put hot food in the refrigerator; There is no need to fill departments with products to capacity. Air must circulate freely in the chambers.

It’s also better not to place it close to the wall. For normal air circulation and, accordingly, normal operation, at least 3 - 5 cm is required; The refrigerator should be connected to a separate, not a shared outlet. This is a large household appliance that consumes a lot of light, so it must have a separate power source; Do not leave the door open for a long time. Because of this, increased loads are placed on the motor. It’s easier with modern refrigerator models - if the door is open for a long time, they beep; if the refrigerator does not have the “No Frost” function, then it will have to be defrosted every month; The rubber gasket in the door area must be clean. Contamination will lead to depressurization; Do not put hot food in the refrigerator; There is no need to fill departments with products to capacity. Air must circulate freely in the chambers.

These are simple recommendations, but they should be followed constantly. And then the refrigerator will delight you with a long service life and will not cause difficulties during operation.

There are several reasons why a refrigerator turns on and then turns off after a while. Some are diagnosed on their own and eliminated without much difficulty. In other situations, it is necessary to replace the part with a new one or even have to buy a new refrigerator. To avoid these troubles, read the instructions before using the equipment.

The filter is clogged

When the filter system is clogged, the filling of the system with coolant decreases, resulting in too rapid heating of the small volume of water inside the boiler. The boiler turns off and waits for the system to cool down. Then it turns on again, realizing that the return line is still cool. The thermal fluid supplied to the heating system through public pipelines is capable of carrying a huge amount of dirt and all kinds of impurities. Therefore, a water strainer must be installed in front of the circulation pump.

This mesh-type device most effectively retains various mechanical contaminants. The lack of complete protection causes contaminants to enter the pump and cause rotor failure. Filters must be cleaned periodically. For this purpose, the valves that are located in front of the filter and behind it are closed, after which the plug above the liner is unscrewed using a key. The filter mesh is washed with running water and carefully installed in its original place.

Leakage in the system

Logically, if the station does not turn off, it means that there is not enough water in the tank. There are two options: the pump does not have the ability to pump water, or water leaves the system. In the second case, you need to check all pipes and taps, as well as the drain tank. If the pipes are metal, a leak may occur if the metal rusts or corrodes. Here you need to replace the segment that has become unusable. If it leaks in the place where the parts are twisted, it is necessary to use a rewind. Well, every man can deal with a leaking faucet.

House plumbing diagram. During installation, it should be taken into account that there is free access to all elements

It has become fashionable to hide pipes in walls. But even plastic pipes can leak when twisted. It is very difficult to detect a water leak behind a wall. In addition, in private homes it often happens that pipes are damaged by freezing, which can also cause leaks. To avoid this, insulate pipes that are located outside.

Narrowing of pipe diameters

As a rule, blockages cause narrowing of the lumen in the pipeline system. When the riser is clogged, there is an increase in the resistance of sections of the heating system and a reduction in the flow rate of the circulating coolant. After identifying the blockage, hydraulic, pneumatic flushing or cleaning is used to narrow the diameter of the pipes.

Before performing this procedure, leaks are checked, disassembled and cleaned. Hydraulic flushing involves creating a high flow rate of water through the pipeline system. The used liquid with contaminants is discharged into the drain. In order to increase speed, pumping equipment of network, circulation or other types is used.

Pipeline cleaning is carried out in cases where it is impossible to remove the blockage using standard flushing. For this purpose, the clogged narrowed section of the pipeline is turned off, after which the coolant is drained. To clean disconnected pipes, a thick and fairly elastic wire with a fixed brush is used. At the final stage of getting rid of pipes from narrowings, the heating system is assembled in the reverse order.

Problems with the control unit

If you have a modern refrigerator at home, then check its electronic board (control unit). She is responsible for turning the refrigerator on and off. When it fails, commands to stop and resume work are issued chaotically.

The refrigerator control board is responsible for turning the device off and on.

Unfortunately, it is not possible to diagnose such a breakdown without specialized equipment. The unit can be repaired by reprogramming, or it may need to be completely replaced. Both can be done only in repair shops.

The pump is not working well

Users of gas boilers sometimes encounter various problems with the operation of the pumping unit. Such equipment stops pumping water if the rotor fails or a significant amount of air has accumulated in the internal part. To prevent such a breakdown, it is necessary to unscrew the nut from the unit and drain the water, after which the axle is forced to rotate using a flat screwdriver.

Pump in a gas boiler

Free-standing equipment requires compliance with installation rules. It is advisable to install the pump before the gas boiler, which will extend the life of the heating system. This rule is due to the presence of high temperature conditions at the boiler outlet, which can cause damage to the device. Of course, the design characteristics of the circulation pump must also be taken into account, as well as the need to mount a filter or sump directly in front of the pump.

Prevention measures

Breakdowns of gas equipment happen to everyone; it is impossible to insure against this.

However, there are a number of ways to reduce the risk of breakdowns:

- Scheduled diagnostics of gas equipment before the start of the heating season - a specialist will conduct an inspection, do a test run and tell you about all the nuances of this boiler.

- Selection of the correct operating mode of the boiler and pump.

- Periodic cleaning of all combustion chamber elements is carried out only by a specialist.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

You should always pay attention to whether the boiler is easy to ignite and whether it can always be done the first time. If there is any suspicion of a malfunction, it is better to call a technician and carry out an unscheduled diagnosis.

Drawing conclusions

The frequency of turning on and off the burner of a gas heating boiler is a very variable and very individual value, directly dependent on a large number of factors. Manufacturers guarantee that the boiler will provide the specified temperature range, regardless of whether the burner is turned on or off. At the same time, the intensity of fuel combustion helps prevent its overconsumption due to clocking.

The operating mode of the gas boiler is selected strictly in accordance with the time of year and the required thermal index in the room. To avoid very frequent switching on and off of equipment, you need to determine the correct location for installing the thermostat, stabilize temperature intervals, as well as adjust the gas burner and resolve the issue with the thermal capacity of the heating circuit.

Reasons for the attenuation of turbocharged gas boilers with a closed combustion chamber

Turbocharged models of gas boilers have additional equipment, so in addition to the above-mentioned problems, there may be other difficulties with them:

- ice formation inside and outside the chimney;

- malfunction of the built-in air blower.

Despite the fact that such devices have a complex design, all manipulations with checking traction, pressure, contacts, etc. are still relevant.

Icing of the cap or chimney pipes

If a gas boiler goes out mainly in cold weather, then perhaps its chimney opening is blocked by an ice mass. This happens for two reasons:

- accumulation of condensate on the walls of the air duct;

- snow sticking to the outside of the chimney.

The first situation is typical for convection boilers, usually with a coaxial chimney. In them, hot exhaust gases, when cooled outside, form condensate, which settles in the pipes. Therefore, when the thermostat turns off the heating after reaching the set temperature, all this moisture freezes. Over time, plugs form, blocking access to air.

As a rule, the problem can be determined visually: the surface of the pipe begins to get wet, and the wall at the level of the ice becomes covered with frost on the outside.

It’s not always possible to simply knock off the ice, so it’s worth buying a disposable construction torch with a can in advance so that you can use it to defrost the air duct. When it warms up, the boiler will be ready for operation again, but to prevent this from happening again, it is recommended to insulate the pipes.

The second situation arises when installing a coaxial pipe or cornice-type caps: the desire to protect the chimney from precipitation is understandable, but using them for gas equipment, as mentioned earlier, is extremely undesirable. Instead, it is recommended to use open tapering attachments on the headband.

It is impossible to knock off the ice crust from the top or remove it like ice - it tightly covers the entire structure. Therefore, the outer part of the chimney will have to be dismantled and placed in hot water until completely defrosted. The boiler can function without this part, but it must be monitored at all times.

Fan or turbine malfunction

When the igniter suddenly goes out in a unit with a built-in supercharger, you should listen to its operation: the turbocharging system or fan should emit a measured hum, so if extraneous noise appears (creaking, crackling, whistling) or the sound comes out intermittently, you should think about their malfunction.

If they stop making any sounds, the breakdown is obvious: the automation does not allow the safety valve to open and the igniter does not light up at all.

You can try to repair broken equipment, but, as practice shows, it is difficult to repair. In any case, the work should only be performed by specialists, because without the necessary skills, all manipulations with the supercharger are associated with a high risk of carbon monoxide entering the room.

Additional factors

Hidden leaks in the water supply pipe system can also cause unstable operation of the complex. The situation is complicated, since pipe damage can also occur underground. It is quite difficult to detect such a breakdown.

If the question arises how often the pumping station should be turned on, then you should pay attention to the calculations of water consumption. It is possible that your demands for water have increased, and you need to think about installing another tank in parallel or replacing it with a more capacious receiver

It doesn't hurt to take a few more factors into account:

- The check valve is clogged - the water flow does not stop, it leaves the system, the pressure decreases, and the pump constantly turns on. There are two options: remove and clean the valve or replace it with a new one.

- The capacitor in the terminal box has failed - in this case, the pump will not start at all. The part is checked with a tester and changed if necessary.

- The spool valve is faulty - air from the tank escapes into the atmosphere and its pressure drops, which leads to increased operation of the pump. To eliminate the malfunction, the hydraulic accumulator must be dismantled, the membrane removed, and the nipple replaced.

Why might the burner go out at all?

- the draft in the chimney has decreased or disappeared;

- the gas pressure in the supply line has dropped;

- The flame in the burner has gone out.

Moreover, these processes can occur both due to internal failure and due to the influence of external factors.

If we consider floor-standing models (manufacturers: Danko, Aton, ROSS, Zhitomir), then they have a primitive internal design. Therefore, if you look into them, there is nothing special to break in them. Attenuation in this case occurs most often due to strong wind outside or other external factors.

Floor-standing gas boilers are simple in design, so eliminating the cause of their attenuation will not be so difficult

But wall-mounted gas boilers in their design already resemble an autonomous mini-boiler room, and therefore there may be more options for stopping the operation of a gas boiler:

- the coolant circulation was interrupted or did not start after repairing the circuit (the flow sensor reacts);

- The air supply has decreased/stopped (the pressure switch is triggered);

- voltage drops occur;

- power outage.

If a mounted heat generator goes out, it is not easy to restore its operation. However, it is still quite possible to eliminate some malfunctions on your own. Find out how to do this below.