Even if low-power heaters are used in the room, properly selected insulation will help maintain a comfortable temperature. When answering the question of what Izolon is, what first comes to mind is its improved capabilities in creating high-quality thermal insulation. Let's figure out what the features of the canvas are, what characteristics it has and how to choose the right option.

A popular variety is foil Izolon Source sevparitet.ru

Dimensions

To have a clear idea of what the material is, you should know what sizes the raw material can be.

The thickness of the products directly depends on the area of application of the isolon. To additionally insulate the floor, you can opt for products with a thickness of up to 5 mm; sound insulation of the roof should be done with sheets with a thickness of about 5-10 mm; interfloor ceilings require laying products with a thickness of 10-30 mm.

The size chart is very diverse: there are products with a thickness reaching up to 50 mm. Product lengths can range from 2 to 300 m; products with a length of 500 meters are not produced. The width of the isolon varies from half a meter to 2 m. Products in the form of slabs have the following dimensions - 1x1.11 m or 2x1.4 m.

How to choose?

The choice of material depends on the purpose. For sound insulation of interfloor ceilings and floor insulation, isolon with a thickness of 0.8 mm to 1 cm is most often used. When installing heated floors - from 2 to 4 mm, for laying laminate - from 2 to 3 mm.

Depending on the purpose, different types of insulating material are used:

- Isolon “Tape” or isolon in tape is used to insulate ceilings and cracks. This is an excellent sealant for insulating window niches and loggias;

- Isolon “Block” is a sheet material used for internal thermal insulation of premises, external thermal insulation of seasonal auxiliary buildings, interfloor ceilings, flat and pitched roofs, foundations;

- For insulation of heating mains and other pipelines, foil-coated isolon is preferred, the performance characteristics of which are an order of magnitude higher due to the reflective layer.

How much does isolon cost - review of prices per square meter

Izolon is a fairly affordable material , especially if you calculate the consumption and estimate the characteristics of other materials. Despite the apparent high cost, it will still justify the costs over time.

Here is the cost of the material as of autumn 2019 :

- an isolon block 5 cm thick and 1 m² in area will cost about a thousand rubles per piece;

- Isolon 500, sheet, 1 m², 5 cm thick – 1 thousand rubles;

- isolon 500, roll 60 m, width one and a half meters - 13 thousand rubles;

- the price of a 50-meter roll of foil isolon is 12 thousand rubles;

- self-adhesive isolon “Tape”, 20 m roll – about 3 thousand rubles.

What types of isolon are there?

How to properly lay laminate flooring with your own hands

When viewing this building material through a magnifying device, you can see what isolon is. The material has a foam base with closed cells.

- Based on the characteristics of the base, isolon is divided into two types:

- Polyethylene foam (PPE);

NPE, it has an unbound molecular structure, sometimes it is called non-crosslinked polyethylene foam Izolon.

Using a special technology called cross-linking, the service life of the product is significantly increased, thereby ensuring the constancy of the performance characteristics of this material. The type of a certain insulation can be easily determined by touching it or simply by assessing its appearance. For example, NPE has a larger cell structure and is not as elastic as the first type of isolon.

Advantages

Advantages of isolon:

- Thermal insulation. Indispensable in the construction field.

- Steam and moisture protection. Allows use in wet objects such as baths, swimming pools, saunas.

- Soundproofing isolon.

- UV resistance, which allows its use for external coatings;

- Fire safety.

- Light weight. Does not create additional load.

- Elasticity, which gives isolon its “flexible character”. It can easily take the shape of any object to which it is attached.

- Elasticity. Restores original shape. There is an opportunity to use it again.

- Rot resistant.

- Damping the force of blows.

- Easy installation.

- Safety for people. There are no releases of toxic materials.

- Environmentally friendly material.

- A thin layer of insulation does not reduce the internal dimensions of the insulated object.

The disadvantage of isolon is usually its cost. But if you consider that the service life is 90-100 years, then the investment in its purchase may not seem that big.

Characteristics and features of the material

Gap between the door and the interior door frame

What is Izolon? This is closed cell polyethylene foam. Depending on the type of production, there are two main types of this material: unstitched and stitched. Non-crosslinked is polyethylene foam whose molecular structure has few chemical compounds. The production process of this type is quite simple. This explains the low price of insulation. But its characteristics are slightly inferior to cross-linked Izolon, which is more resistant to temperature changes and the effects of various organic solvents.

Foil backing

Such technical characteristics are made possible as a result of cross-linking of molecules, which changes the structure of polyethylene. Also relatively recently, foil-coated Izolon appeared in construction stores. Foamed polyethylene has low thermal conductivity, and the reflective properties of aluminum foil provide additional thermal insulation.

The substrate for the laminate is produced with one-sided or double-sided lamination with polished foil. Also, a special adhesive composition can be applied to the insulating coating, which is protected on top by a coating material. Foil-coated Izolon has a fairly high level of thermal resistance, provides protection from moisture, steam and creates an additional barrier against radon.

Briefly about the main thing

Isolon is a universal insulation material that is widely used not only in construction, but also in other areas of the economy. Thanks to its closed porous structure, it has improved performance characteristics: plasticity, minimal water absorption, high levels of noise and heat protection.

The chemically neutral material is produced in the form of canvas (roll), plates and construction tape; There are colored varieties for creative needs. The canvas may have an adhesive and/or foil layer. The choice of the appropriate PPE option depends on the type of work to be done.

Tips and tricks

How to glue fallen tiles on the floor

When choosing isolon, you should adhere to the following recommendations:

The cost of thermal insulation products does not always determine its quality, so you should pay attention to the manufacturer of the product, as well as its technical characteristics, in order to choose a product that is ideal for insulating a particular surface. Installation and fixation of seams cannot be done with ordinary tape; there are specialized adhesive aluminum tapes for such purposes.

- During the installation process, do not forget about the ventilation layer, which must be formed near the walls.

- Products, especially products with a foil layer, require compliance with the specified storage conditions, as well as care during transportation of the goods.

- Violations made during the installation of heat-insulating material can damage the integrity and structure of the isolon, as a result - the product will lose its properties.

A very important parameter of isolon is the thickness of the products. It is this indicator that determines the scope of product operation.

To help make the right choice, manufacturers classify products based on thickness and area of installation.

- To carry out work on thermal insulation of pipes located directly underground, it is necessary to use PPE with a thickness of 15 to 45 mm with a foil layer for work.

- Sound insulation in multi-storey buildings between floors will have a high level of quality if you use isolon of 8-10 mm thickness. Such material will be enough to reduce noise from the movement of people living above, as well as to eliminate the audibility of low-volume music from neighbors. But for buildings where the top floor, for example, will be used as a gym, you need to purchase products with greater thickness.

- Floor coverings, for example, laminate, can be insulated with high-quality 3-5 mm products. For a “warm floor” system, preference should be given to products with a minimum thickness. Based on the type of floor screed, it is recommended to use different types of isolon: for a dry screed - foil material, for a wet screed - you need to lay products with a metallized layer.

- Thermal insulation of wood and concrete bases is carried out with products with a product thickness of up to 10 mm.

You will learn more about the material in the following video.

Cost criteria

The price is directly affected by the following qualities and characteristics of the product:

- Quantity (footage).

- Sheet width.

- Thickness.

- Type of raw materials.

- Manufacturer's brand.

- Surface quality (smooth, embossed, foil-coated).

- Color (white or colored).

- Presence of an adhesive layer.

Isolon foil where it is used

The use of foil-coated isolon is not limited to construction - it can be found literally everywhere where maintaining a certain temperature regime for a long time is involved. It is widely used in the automotive industry (noise and heat insulation of bodies), used in shipbuilding and even in medicine. Moreover, various types of packaging and even elements of sports equipment are made from it. As for construction, here it acts as an effective and reliable insulation material. It is used to insulate the following building elements.

- Roof. The main advantage of using isolon as roofing insulation is that its use allows for effective thermal insulation without increasing the thickness of the roof.

- Walls. This material turned out to be especially in demand in severe frost conditions - using it in tandem with standard mineral wool in frame or log houses, again, it becomes possible not to increase the thickness of the wall. This is a thin material, which is one of its main advantages.

- Floors.

The effect is still the same - instead of the standard 50mm polystyrene foam, there is a maximum of 5mm isolon under the screed. As a result, the screed lays more rigidly and during operation practically does not collapse under loads. Izolon foil photo

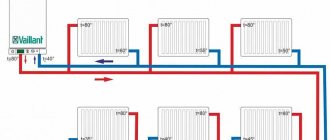

In apartment renovations, foil insulation isolon is most often used for thermal insulation of balconies and loggias. As a rule, it is laid under water and electric heated floors. It is also pasted behind standard heating radiators, directing the heat from them not to the outer walls of the house, but to the interior of the room. As you can see, the thing is very useful and, most importantly, effective, which we will try to verify further.

ISOLON® in production

Izolon in production is an indispensable material for the manufacture of a wide range of everyday goods. Buoyancy inserts in life jackets; gasket and sealing technical elements; gaskets for bottle caps and canisters; supports, elements for rigidity and elements for softness of suitcases, bags, bondages; high-quality packaging; insoles and shoe elements, children's toys; elements for sports gloves, makivara, shields, and much more. A separate, very popular topic is the Isolon Color line as a material for creativity. Isolon Color of different shades is used to produce life-size flowers, lamps, souvenirs, window dressing, photo zones, weddings and much more.

Types of foil isolon and their features

This material is not very diverse in variety - besides the fact that it can have different thicknesses and sizes, be produced in rolls or in mats, it can also differ in different types of base. In this regard, it can be divided into a couple of subspecies.

- Self-adhesive foil insulation. Without human intervention, it, of course, will not stick - it received this name because on its back side it has an adhesive base, protected by a thin layer of paper. The master simply removes the protection and glues the isolon to the right place - as they say, easily and simply, which is the main advantage of this type of insulation. Naturally, you will have to pay more money for additional amenities.

- Classic foil isolon. Unlike self-adhesive material, classic isolon provides the master with a choice of fastening methods - it can be glued with a special glue, nailed with nails or a stapler, and even simply laid on a horizontal surface, connecting its individual parts with special tape. This approach to the matter expands the scope of application of the material - if self-adhesive can only be installed on a plane, then the classic material can even be attached to a frame, which is what craftsmen use by laying it under drywall or panels installed on the frame.

In principle, these are all types of material. Not a lot, but they are quite enough for construction needs, and in particular, for thermal insulation of houses and apartments.

Insulation with foil isolon photo

Areas of application of isolon.

Izolon is a reflective insulation material, its base is foamed polyethylene, on which polished aluminum foil is applied. Foil increases the thermal insulation effect by 25-80% depending on the conditions of use. Foil-coated isolon is successfully used in construction, be it civil, industrial or the construction of private houses and buildings. The use of isolon is ideal for insulating and insulating walls, floors, ceilings, basements, roofs, garages and even baths and saunas. Due to its small thickness, isolon reduces the complexity of the design.

Application of isolon in construction

One of the main areas of application of isolon is civil engineering. This material is used for floor insulation, laying it under laminate, parquet or carpeting. Thus, ideal sound and waterproofing is achieved, and the cost of heating the room is significantly reduced. Izolon insulates the walls of rooms, balconies and loggias. Both internal and external insulation are possible. At the same time, the material is absolutely safe for humans and the environment.

Recently, artificial ponds have become an integral part of landscape design when arranging country houses. And in this case, you cannot do without isolon - the material does not absorb moisture and is ideal for waterproofing.

For ideal waterproofing of a small pond or lake, it is better to use PPE grade isolon 1504, 3005,3008.

Because of its unique properties, isolon is indispensable when building a bathhouse or sauna. When the steam room is sheathed, a layer of foil insulation is placed under the tree. It is necessary to carefully handle the joints of the ceiling and walls; if necessary, use aluminum tape. The ceiling of the bathhouse is also sheathed with isolon.

If the cladding with isolon is done correctly, then due to the vapor barrier and waterproofing properties of the material, a thermos effect is created, which promotes rapid heating and long-term retention of warm air inside the bathhouse or sauna.

Izolon is successfully used as seals for windows and doors, which will allow you to get rid of drafts, noise and dust.

If you plan to use isolon during construction or renovation, you need to prepare the room. Determine the places where the most noise or vibration occurs, and clean them. Measure the area to be covered with isolon. Then the material should be cut into pieces of the required size. Remove the protective film and stick the isolon on, avoiding bubbles. Avoid any gaps.

It must be said that isolon has a long service life and by using it, you are making an investment in the future. You will forget about the cold, drafts, noise and sounds from the outside for a long time.

Use of isolon in everyday life

In addition to construction, isolon is also used in other areas due to its unique properties. For example, rugs for tourists, various seats, heat-reflecting screens for radiators, and for car windshields are made from it.

You may not believe it, but even toys for children are made from isolon. After all, the material is pleasant to the touch, elastic, but soft and absolutely safe for humans.

It does not break, is easy to cut with scissors, and easy to glue. Izolon in colored sheets is ideal for labor lessons in schools.

Since the material does not sink, it is used to make life jackets, swimming boards, various toys, such as boats, ducks, which will not drown, but will bring a lot of joy to children.

As you can see, izolon has a wide range of applications from construction to medicine and light industry. With the development of production and human imagination, we are confident that its use will expand.

You can buy isolon wholesale from the manufacturer at NPO GEOstandart.

Installation technology

The main feature of the product is to ensure tightness, so all joints between products should be sealed. The working surface must be dry and free of various contaminants.

Experts say that one layer of 3-5 mm will be enough to provide high-quality insulation for the room. But the coldest places need to be insulated in several layers, or purchase a material with greater thickness and combine insulation with glass wool, forming a thermal insulation sandwich.

Thermal insulation of the subfloor includes the necessary list of works.

- After purchasing a material of appropriate thickness, the first step is to prepare the surface. If there is an old coating on it, it is dismantled and the floor is leveled.

- If necessary, products are cut to the required length and width; for this you need to take measurements of the working base. It is best to cut products with an ordinary knife.

- If self-adhesive material is used, then before installing it, the protective film is removed, and then the raw materials are laid. During work, the products must be lightly pressed against the surface to ensure better fixation.

- Work with conventional products is carried out using acrylic adhesive compounds.

- Following the instructions for laying isolon on the base of the floor, before installing the raw materials, you need to apply waterproofing. However, in most cases, the flooring is not provided with additional protection from moisture.

- A polyethylene film is laid on top of the thermal insulation, since isolon does not absorb moisture.

- The material is fixed at the seams with tape, a construction stapler, or the products are welded to each other;

Insulation of the first floor floor

To carry out this type of work, inexpensive expanded clay is required. In terms of its qualities, it is not inferior to expensive insulation materials. Expanded clay is made from clay compounds and is environmentally friendly. 100 mm of expanded clay layer has the same characteristics as 1 m of brickwork and 250 mm of boards.

The use of other materials for insulating a wooden floor on the first floor imposes restrictions on the use of silicate, polymer and wood-shaving insulation. Unlike expanded clay, these materials are susceptible to destruction by rodents and accumulate moisture. Therefore, expanded clay looks much better against their background.

Expanded clay must be laid on a previously laid layer of waterproofing. Polyethylene film can act as a waterproofing material; the thicker the better. After laying, the edges of the film should protrude 10 cm above the joists along the perimeter of the walls. The technology of expanded clay insulation is simple, but quite labor-intensive.

Before pouring expanded clay, it is necessary to prepare a mixture of different fractions. The main size of the filler should be 10 mm, but it is advisable to add a larger or smaller size to it, since when shrinking, small granules wedge larger ones. Thanks to this, the overall level of insulation does not drop.

Expanded clay is poured in a layer of 15 cm, since with a smaller thickness it is not able to provide reliable thermal insulation. Therefore, control beacons are installed and the insulation layer is leveled along them. The finished layers are checked using a beacon (stretched fishing line).

After the expanded clay has been laid correctly, you can begin laying the finished floor.

Moisture insulation

By not laying the underlayment, or by doing it incorrectly, you may encounter a problem such as swelling of the floors. Swelling usually occurs because moisture or simply water has gotten into the substrate. The unique closed-pore structure of the ISOLON PPE substrate provides a water absorption coefficient of less than 1%. This means that the substrate does not allow moisture and water vapor from the concrete screed to pass into the laminate plates, and when the floor above gets wet, it keeps the concrete screed dry. Therefore, when laying the ISOLON PPE substrate, unlike laying conventional substrates, the use of polyethylene films for waterproofing is not required. The physical cross-linking of the structure of the ISOLON PPE material excludes the presence of gases other than atmospheric air. ISOLON PPE is used for the production of products in contact with food and alcoholic beverages, human skin and perfumes and cosmetics, in pharmacy and for the production of children's products. And this list is far from complete. By choosing ISOLON PPE, you can be calm about your health and the health of your loved ones.

Among other things, ISOLON PPE tolerates contact well with building materials that have an alkaline environment (cement, concrete), is resistant to most solvents, gasoline and oils, and is not susceptible to insects, as well as bacteria, fungus and mold. A special place is occupied by ISOLON PPE, backed with foil or metallized PET film. It is widely used in systems of so-called “warm floors” - floors with heating pipes and ducts. It performs the functions of a sound insulator and a reflector of thermal energy, that is, heat flows, reflected from the foil layer, do not enter the supporting structures under the floor. It is also worth noting that the metallized film, unlike foil, does not corrode when interacting with cement. Thus, ISOLON is ideal for use in the construction of “floating floors” and as a substrate for floor coverings. “IZOLON PPE” IS AN IDEAL SUBSTANCE FOR FLOOR COVERINGS!

- It has a fairly high compressive strength with a small thickness;

- Has high impact insulation properties;

- Has a low thermal conductivity coefficient;

- Practically does not absorb or allow moisture to pass through, due to the closed-cell structure of the material;

- Is an excellent barrier to water vapor;

- Has low residual deformation;

- Environmentally friendly, safe, durable, rot-resistant material;

- Easily subjected to mechanical processing (cutting with a knife, welding with a construction hair dryer, fastening with a construction stapler, etc.);

- Provides minimum cost of work.

HAVING MADE THE RIGHT CHOICE, YOU WILL GET WHAT YOU WANTED – A REALLY “QUIET FLOOR”.

Kinds

The material manufacturing technology includes three main stages, on the basis of which products are divided into types:

- mixing components, including granulated polyethylene, foaming agent and other components;

- extrusion;

- foaming due to which the foaming agent begins to “work”, which provides a specific structure to the material - as a result, it looks like a porous sheet.

Foil products require another process - during lamination, aluminum foil is fixed to polyethylene.

Taking into account the production method, two types of material can be distinguished

Cross-linked – PPE

During production, changes occur in components at the molecular level. This group includes products with a cross-ligament and mesh molecular base. The specificity of the composition increases the resistance of the material to aggressive environments, and also increases moisture resistance.

Unstitched – NPE

This variety is distinguished by the almost complete absence of connections between the molecules of the components. Essentially, this is a gas-filled raw material with a closed cell structure. Even at the foaming stage during the heat treatment of the substance, carbon dioxide is added to it. It fills pores that are larger than other materials. In addition, NPE has less flexibility.

Based on the crosslinking method, it is possible to select materials with a chemical or physical option for performing this task.

Taking into account the structure, isolon can be foil or uncoated

Foil

Its composition is similar to the standard type, the only difference is the presence of film on one or both sides. The film can be made of aluminum or have a metallized composition. The products have high performance characteristics and are therefore recommended for use inside and outside buildings. The choice of products depends on the scope of application, for example, if Izolon is needed for flooring, they prefer to purchase products with heat-reflecting film, positioning it so that the side with the film is at the top.

Uncoated Products

The material does not contain additional layers, due to which its properties are slightly reduced. The cost of such products is an order of magnitude lower.

Depending on the fastening technology, certain types of raw materials are distinguished.

Covering

The material can be glued to the base overlapping if the thickness is small, or end-to-end if you plan to use large sheets. For installation, construction tape is used, which is responsible for the tightness of the seams between the products.

Self-adhesive material

Its installation is carried out to the enclosed base; fastening is carried out only after the protective film has been removed from the side that has the adhesive layer.

In addition to the main varieties, several more types of products can be distinguished, which are marked using a special abbreviation:

- Izolon “A” – products with an aluminum layer on one side, its thickness can reach 10 mm;

- brand “B” – products with closed foil on both sides;

- “C” is a type of thermal insulation that has a self-adhesive base;

- ALP is a self-adhesive raw material having a white film on foil, the thickness of which is 3 mm.

What it is?

The term isolon appeared thanks to the developments of the Izhevsk Plastics Plant. The material is foamed polyethylene with a porous structure. This feature provides isolon with high quality heat and sound insulation. It should be noted that the material is quite elastic, which greatly simplifies the installation process.

How polyethylene foam with a uniform cell structure is produced

The technological process of isolon production can be divided into three stages:

- All components involved in the process are mixed in one container, adhesion agents and foaming agents are added.

- The finished mass is heated to high temperatures, melts, forming finished sheets.

- The material is sent to the oven, where it undergoes additional heat treatment. At certain temperatures, foaming agents react, creating pores on the surface of the sheets.

If we are talking about the production of foil material, at the final stage, one side of the sheet is covered with thin aluminum foil. Lamination technology is used here.