The appearance on the domestic market and active popularization of such an energy carrier as fuel briquettes poses some difficulties for users of boiler equipment that runs on coal and wood. In order to make a choice, you should understand in detail what briquettes for heating (or Euro-firewood) are.

Fuel briquettes are used as fuel for solid fuel boilers, stoves and fireplaces

What are fuel briquettes?

Fuel briquettes are a relatively new type of solid fuel. They are made by pressing fine-grained raw materials of natural origin. Sawdust, wheat, rice or buckwheat husks, and sunflower husks can be used as such raw materials. In addition, fuel briquettes are pressed from leaves, straw, reeds, tree bark, and pine needles. Pellets are also made from reeds.

During the pressing process, strong pressure is applied to the raw materials from which wood briquettes are made, resulting in the release of a special substance - lignin. It acts as a connecting component. Thus, no additional chemicals are used in the production of wood pellets, which makes such fuel environmentally friendly.

Various types of raw materials can be used for the production of fuel briquettes

The release of lignin is only possible in cases where significant pressure is applied to the raw materials from which wood briquettes are made. It is quite difficult to fulfill this condition when making fuel briquettes with your own hands using homemade equipment, so in such cases binders are added to the raw material mixture. Clay, wallpaper glue, soaked paper or cardboard can be used as the latter.

Pressed briquettes for combustion can differ not only in the material of manufacture and the degree of density of the internal structure, but also in their geometric parameters, in particular shape and size.

Scheme of the technological process for producing briquettes

Business planning

It is advisable to start opening a mini-factory for the production of fuel briquettes by drawing up a business plan. It is better to order a full feasibility study of the project from specialists. You can also make an approximate calculation of economic indicators yourself by collecting certain data for your region: prices for equipment and its technical characteristics, the cost of raw materials, the cost of utilities, etc.

The main goal of developing a business plan for the production of fuel briquettes is to draw up a program of economic activity of the enterprise, within the framework of which it is optimal to distribute available resources to achieve the set goals. During its development, it is necessary to find out the degree of reality of achieving the intended results. It must reflect the reasonableness of the costs and profitability of the project. It is useful to learn how to write a proper business plan. Approximate data for calculating the profit and payback period of the project are given in the following table:

| Costs for production of 1 ton of briquettes | ||

| 1. | Raw materials (2 tons) | 400 rub. |

| 2. | Electricity (100 kW/hour) | 550 rub. |

| 3. | Thermal energy (1 MW/hour) + price of dry wood waste | 100 rub. |

| 4. | Salary (2 employees per shift at a rate of 20,000 rubles/month with taxes) | 360 rub. |

| Total: | 1410 rub. | |

| Income | ||

| 1. | Productivity per month for single-shift work (0.5 t/hour × 8 hours × 21 days) | 84 tons |

| 2. | Capacity per year (84 tons × 12 months) | 1008 tons |

| 3. | Minimum selling price | 5000 rub./t |

| 4. | Revenue per month | 420,000 rub. |

| 5. | Revenue per year | RUB 5,040,000 |

| 6. | Profit per month | RUB 301,560 |

| 7. | Profit per year | RUB 3,618,720 |

This table shows only direct costs; packaging, delivery, taxes and other mandatory payments are not taken into account. In addition, productivity largely depends on the quality of equipment and the level of qualifications of personnel. But, as practice shows, such productions pay for themselves in an average of two years of operation.

Main varieties

There are three main types of Euro firewood offered on the modern market, which, while not having any fundamental differences in composition, differ from each other in the density of the internal structure and geometric shape:

- fuel briquettes RUF (RUF);

- European firewood Pini Kay (Pini Kay);

- fuel briquettes Nestro (Nestro).

Fuel briquettes Ruf

RUF wood briquettes, for the production of which sawdust, small chips or shavings are used, have the shape of a rectangle. They are distinguished by the lowest price when compared with other types of pellets. When using such fuel briquettes, it should be borne in mind that the heating boiler must be equipped with a forced ventilation system.

Fuel briquettes "Pini Kay"

Pini Kay fuel briquettes are fired at the final stage of production, which makes them more resistant to high humidity. Pellets of this type differ from RUF fuel briquettes in their geometric shape: in cross section they can have the shape of a cylinder or hexagon with a hole in the central part. Thanks to this hole, they can be successfully used even in ovens that are not equipped with a forced ventilation system. The cost of pellets of this type, which can be easily distinguished from RUF fuel briquettes even from a photo, is higher, which is explained by the more complex technology of their production.

Round fuel briquettes Nestro

House heating

Fuel briquettes are probably ideal for heating a home. The ability to light the stove once and maintain the fire and heat for a long time without additional tossing allows us to talk about the good characteristics of Eurobriquettes. Let's look at how to heat a brick stove with fuel briquettes within the house.

Of course, pressed bricks will not burn immediately, so let’s figure out how to light fuel briquettes. This is quite simple to do; first of all, you should put tree bark, wood chips, and some dry newspapers in the oven, and then place alternative firewood on top. During kindling, while the wood chips are actively igniting, we adjust the airflow. As soon as the fire starts on the first briquettes, you can add the rest.

Another option is to heat the stove with fuel briquettes after the first batch of wood has burned and decent coals have appeared. In such a firebox, the fire can quickly be caught on Eurobriquettes.

Preparing to light the stove

Depending on your needs, we choose the tactics for filling the stove with fuel:

- If you stack the fuel briquettes loosely, at a short distance from each other, the fire in the stove will be quite intense and will generate a lot of heat, which will allow you to quickly heat the house.

- If you stack alternative firewood tightly to each other and cover the vent, the firewood will smolder for a longer time, which is perfect for heating a house at night. At the same time, the consumption of fuel briquettes per day will be several times less than firewood.

In order to roughly understand how many eurobriquettes will be required to heat a house, you should conduct several experiments, each time finding out this parameter in practice. There are too many nuances in this matter.

It is worth noting that fuel briquettes have a specific purpose - to create heat, while firewood can be considered for the purpose of creating a comfortable and cozy environment. For example, is it possible to light a fireplace with fuel briquettes - well, of course, yes, but they will not create the same atmosphere as firewood with its pleasant crackling and uneven fire. By the way, the smell from burning wood is stronger and more pleasant.

In conclusion, I would like to say a little about the storage of Eurobriquettes and compare it with the preparation and storage of firewood. Fuel briquettes are sold in separate packages wrapped in cellophane. In this state, they are not afraid of moisture, which means they can be placed in a utility room, attic, basement or shed. Eurobriquettes look like bricks or tubes, all of the same shape, which is very convenient for storage. In addition, they take up much less space, since for the winter they will be needed several times less than firewood.

If we remember what difficulties await us when collecting firewood, there is food for thought when choosing the appropriate fuel. Eurobriquettes do not need to be sawed, split, stored and dried throughout the year; they are already ready for use.

Fuel briquettes or regular firewood: what to choose?

What to give preference to: regular firewood or fuel briquettes? To answer this question, we need to study the advantages and disadvantages of both.

Let us list the most important advantages of fuel briquettes:

- A fuel briquette, when compared with conventional firewood, burns 4 times longer than the latter, which contributes to the economical consumption of such fuel.

- After combustion of pellets, very little ash remains - about 1% of the total mass of fuel used. When using conventional firewood, this figure can reach up to 20% of the total mass of fuel used. The ash remaining after the combustion of wood or any other type of briquettes can be used as a fertilizer containing a large amount of potassium.

- The amount of thermal energy released when burning Eurowood is almost twice as much as when using conventional firewood.

- During combustion, fuel briquettes emit heat almost all the time, which cannot be said about ordinary firewood, the heat transfer of which decreases rapidly as it burns.

- When burned, fuel briquettes practically do not spark and emit a minimal amount of smoke and odor. Thus, this type of fuel does not create discomfort and does not harm the environment. In addition, when burning firewood contaminated with mold or mildew, toxic smoke is generated, which is excluded when using Euro firewood, for the production of which carefully dried sawdust or shavings are used.

- When using wood briquettes as fuel, significantly less soot is deposited on the walls of chimneys than when using conventional firewood.

- The compact dimensions that distinguish Eurowood allow for more economical use of the space for storing such fuel. Moreover, when storing fuel briquettes, which are usually placed in neat packaging, no debris and wood dust are generated, which are necessarily present in places where ordinary firewood is stored.

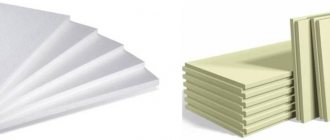

Compact storage is the indisputable advantage of fuel briquettes

Naturally, this type of fuel also has certain disadvantages:

- Due to the high density of the internal structure, fuel briquettes take a long time to flare up; it will not be possible to quickly warm up a room using such fuel.

- The low moisture resistance of Euro firewood can cause it to simply deteriorate if the required storage conditions are not provided.

- Fuel briquettes, which are compressed sawdust, are characterized by fairly low resistance to mechanical damage.

- When burning fuel briquettes, there is no such beautiful flame as when using conventional firewood, which somewhat limits the use of pellets as fuel for fireplaces, where the aesthetic component of the combustion process is also very important.

Comparison of the main parameters of various types of solid fuel

To decide between fuel briquettes and regular firewood, you should take into account the advantages of the latter.

- When burning ordinary firewood, as mentioned above, more heat is generated; accordingly, with the help of such fuel you can quickly warm up a heated room.

- The cost of ordinary firewood in comparison with fuel briquettes is much lower.

- Firewood is more resistant to mechanical damage.

- When burning wood, a beautiful flame is formed, which is a particularly important quality for fireplace fuel. In addition, when wood burns, essential oils contained in wood are released into the surrounding air, which has a beneficial effect on the nervous and respiratory systems of a person in a heated room.

- The characteristic crackling sound that firewood makes when burning also has a beneficial effect on the nervous system.

- The ash remaining after burning conventional firewood does not have such a tart smell as the product of pellet combustion.

What if this doesn't help?

Even when laid correctly, briquettes may not live up to expectations: they burn too quickly and do not provide enough heat. Such situations occur rarely and are mainly associated with:

- The quality of specific briquettes. Try analogues from other manufacturers; you may have stumbled upon low-quality products with a large number of impurities.

- Feature of the oven. Not all designs work well with briquettes, which is why they burn out too quickly and are inferior to conventional firewood in terms of heat production.

Yes, briquettes can easily replace firewood and will be easier to use, but in practice their effectiveness depends on a number of factors. They cannot always reveal themselves 100% and show those beautiful numbers that manufacturers lure with. Therefore, we recommend that you first simply check the briquettes with your stove, especially since for this you do not have to buy a ton of briquettes at once, one package will be enough.

Most modern stoves do not have problems loading briquettes, for example, the Butakov stove

Economic component

When deciding between regular firewood and fuel briquettes, you should also take into account the cost of both types of solid fuel. Euro firewood, which is produced today by many domestic manufacturers, on average costs 2–3 times more than regular firewood. Meanwhile, inexpensive ordinary firewood is rarely of uniform quality.

Most often, the total mass of firewood contains only 20–30% of well-dried logs, while up to 50% of the total mass of purchased firewood can be logs with high humidity, and 20–30% may be stale firewood of not very high quality. If we talk about fuel briquettes, then the moisture content of such fuel, for the production of which well-dried sawdust is used, does not exceed 9%.

Briquettes clearly outperform firewood in terms of transportation

When making a choice between fuel briquettes and firewood, you can also take into account the following facts.

- The burning time of fuel briquettes, which is about two hours, is almost twice the period during which ordinary firewood burns.

- The heat transfer of firewood, which is especially noticeable when located in close proximity to a heating boiler, is significantly higher than that of fuel briquettes.

- The amount of ash remaining after burning fuel briquettes is approximately ¼ less than the amount of combustion products remaining after burning conventional firewood.

Thus, pellets are better used as fuel for long-burning boilers, and ordinary firewood is more suitable for lighting fireplaces. In any case, when making a choice in favor of one or another type of solid fuel, you should be guided by all of the above facts, and also take into account the type of heating equipment.

Financial plan

Drawing up a financial plan will help determine the amount of necessary investments, further monthly expenses and income, as well as the payback period of the enterprise. In each individual case, these amounts can vary significantly, but it should be borne in mind that the initial investment will always be quite high.

Starting investments

The main costs at the start will be associated with the purchase of equipment. To create a production line you will need:

| Name | Average cost, rubles |

| Crushing apparatus | 100000 |

| Aerodynamic dryer | 800000 |

| Press shock-mechanical screw | 1500000 500000 |

| Feed auger | 80000 |

| Cyclone filter | 35000 |

| Heat generator | 150000 |

| Remote controller | 15000 |

| Band conveyer | 200000 |

| Packing machine | 400000 |

The total cost of equipment with a screw press will be 2,280,000 rubles, and with a mechanical impact press - 3,200,000 rubles. It should be taken into account that the first has a productivity of about 250–300 kg/hour, and the second – 1000–2000 kg/hour, depending on the model.

If we take equipment costs to a minimum (with the purchase of a screw press), then taking into account other costs, the initial investment will be approximately as follows:

| Article | Amount, rub. |

| State registration: payment of duty paperwork | 5000 4000 1000 |

| Arrangement of the premises: Repair Furniture for office and service premises Warehouse equipment | 300000 100000 100000 100000 |

| Purchase of equipment | 22800000 |

| Purchase of raw materials | 10000 |

| Advertising campaign | 45000 |

| Unexpected expenses | 50000 |

In total, starting a business will require 2,420,000 rubles.

Monthly expenses

In the course of business, costs are significantly reduced. First of all, you will need to pay employee salaries, which will be:

| Job title | Salary | Number of staff units | Total monthly payroll |

| Director | 35000 | 1 | 35000 |

| Accountant | 30000 | 0,5 | 15000 |

| Operator | 25000 | 4 | 100000 |

| Equipment adjuster | 25000 | 1 | 25000 |

| Helper worker | 20000 | 4 | 80000 |

| Driver | 20000 | 1 | 20000 |

| Office cleaner | 20000 | 0,5 | 10000 |

The entire monthly wage fund will be 285,000 rubles.

The next major cost will be related to electricity bills. Given the high power of the equipment, on average you will have to pay about 50,000 rubles per month for utilities. In addition, it is necessary to take into account the cost of raw materials and other expenses, which in general will cost the following amounts:

| Articles | Cost, rubles |

| Rent | 70000 |

| Payroll | 285000 |

| Payment of utility services | 50000 |

| Administrative expenses | 10000 |

| Tax payments | 80000 |

| Purchase of raw materials | 10000 |

| Unexpected expenses | 20000 |

The total amount of all monthly expenses will be 525,000 rubles, of which more than half will go to wages. Therefore, as production expands, it is recommended to take care of its maximum automation.

Income

The income of an enterprise producing fuel briquettes using the auger method is calculated according to the following scheme:

- number of working hours for 2 shifts – 16;

- number of working days per month – 30;

- equipment productivity – 300 kg/hour.

It turns out that the workshop will produce about 150 tons of products per month. The average market price of 1 ton of fuel briquettes is 6,000 rubles. Consequently, the monthly revenue will be 900,000, and the net profit will be 375,000 rubles.

As a result, the initial investment will pay off in 6–7 months of full-time work. But since it will be possible to reach the indicated volumes at least 3 months from the start of production activities, we should expect that the payback period will be about 1 year.

The business of producing fuel briquettes is a profitable and very promising direction. The main thing is to find the necessary financial resources to launch it, to properly organize work and sales of finished products. The activity itself is simple and highly profitable, so it can be an excellent startup for the future development of your business.

How to make using pellets more profitable

You can make the use of pellet fuel economically profitable if you make briquettes yourself. By creating equipment that can be operated either manually or through a hydraulic mechanism, you can independently produce fuel briquettes for your needs from straw, wood waste, as well as fuel briquettes from sunflower husks and other waste remaining after processing agricultural raw materials. Naturally, you can organize your own production of fuel briquettes only if you have access to a sufficient amount of cheap raw materials.

Homemade manual briquette press with two dies

Homemade equipment for making fuel briquettes, as mentioned above, can be operated manually, using a lever or screw mechanism, or operated through a hydraulic mechanism, which can be used as a car jack. Regardless of the type of drive, the main design elements of a device intended for the production of pellets are:

- a matrix in the working cavity of which the formation of a fuel briquette occurs;

- a punch, which, by exerting pressure on bulk raw materials, compresses it;

- a mixing drum, where the components from which the fuel briquette will be formed are mixed;

- loading and unloading trays;

- a powerful frame on which all structural elements of the device are fixed.

When making pellets using homemade equipment, you should keep in mind that a binder must be added to the mixture from which fuel briquettes will be formed. As such a substance, ordinary clay, wallpaper glue, soaked paper and cardboard can be used.

Types of LED lamps

There are special designs of LED lamps, the appearance of which resembles a fluorescent lamp and other lighting devices of this type.

They are a tube with a power supply and can be manufactured in the following options, depending on the material:

- Tube with a diameter of 26 mm made of solid transparent or matte polycarbonate. Due to their strong glow, such LEDs are placed in closed lampshades. Matte coatings partially absorb the light flux, and this factor should be taken into account when calculating power.

- Double-sided design. On the outside there is a part of the body made of a chemical alloy, and on the rear there is a round aluminum profile. Matte or transparent material is used as a diffuser.

Some types of lighting fixtures are equipped with a rotating mechanism that allows you to adjust and direct the light flux in the desired direction at a given angle. All tubes have standard lengths of 600, 900, 1200 and 1500 mm.

In residential premises, instead of a fluorescent lighting system, it is recommended to install lamps with a length of 600 and 1200 mm, which have sufficient power and optimal luminous flux. The power of the lamps varies between 9-25 W, including 18 W, and the light emitted can be cold or warm.

The LEDs and power supply are located inside the tube on a special getinax strip. Such lamps do not require an external source, and are connected directly to the electrical network. Power is supplied to pins located in the base and connected by copper wire. The T8 design practically does not need to be modified and the problem of how to remake it needs to be solved. After removing unnecessary parts, the device can be immediately connected and put into operation.

Conclusion

Thanks to modern technologies, we can use alternative fuel - briquettes. These are compressed particles of various materials. The most common briquettes are made from sawdust, but similar products can be purchased from straw, peat or coal.

With the help of fuel briquettes you can heat a bathhouse, a summer house and a private house. Their main advantages are environmental friendliness and high heat transfer at an affordable price. Disadvantages include the long time it takes to ignite the fuel and the pungent smell of ash, which is uncharacteristic of firewood.