Author: Yuriy Fedorovich Kolesnikov, thermal power engineer

The term lining comes from the German futter - lining. In technology and construction, lining means a finish that carries certain protective and, possibly, technological functions. There are no requirements for the appearance of the lining. For example, sections of newly laid pipelines, already covered with insulation, are additionally lined from the outside before being pulled under the existing ones. The furnace is lined from the inside, i.e. from the side of the greatest destructive influence.

Examples of lining furnaces for various purposes

According to the technology of work, the internal refractory lining of furnaces for various purposes is divided into:

- Overlay (overlay) - lining with piece or sheet fire-resistant materials.

- Pressed - by manually coating the masonry with viscous heat-resistant compounds.

- Shotcrete - spraying under fairly high pressure a fluid heat-resistant mixture from a special apparatus; As a rule, the lined surfaces are shotcrete with heat-resistant concrete.

Shotcrete is used to line furnaces, casting ladles, pipelines, chimneys, etc. a volume large enough so that a worker-operator with equipment can fit inside. Shotcrete is applicable for mobile equipment (casting ladles, thermoses for transporting molten metal, etc.), but requires solid professional training and special equipment, which is not applicable outside production conditions, so it is not discussed further in this article. Small furnaces are lined almost exclusively with overlay; Sometimes a rammed lining is used for repairs.

Note: the external lining of heating devices is called coating, because... very different from internal fire resistant. For example, steam boilers are often coated on the outside to reduce heat loss and the risk of superheated steam escaping during an accident.

What is a "lining"?

Furnace lining is the installation of a facing layer on the internal planes of the combustion chamber, which are in constant contact with open fire. Its function is to protect external walls from damage of a thermal, mechanical, chemical or physical nature. Lining is performed not only for heating devices for domestic use; this technology is used in the manufacture of metallurgical smelting furnaces, steam boilers, ladles, etc.

In addition to fire protection, heat-resistant material performs a thermal insulation function - reducing heat loss. However, there is some danger here: a lining layer that is too thick will lead to a decrease in the efficiency of the device, since the flow of thermal energy will “fly away” through the chimney to the street, rather than spreading inside the room.

Order lining work from professionals

During the existence of our company, we have repeatedly performed lining work for ferrous and non-ferrous metallurgy, engineering companies, petrochemical plants, steel and pipe rolling industries. They lined furnaces for melting non-ferrous metals, lined tunnel brick kilns, worked with ceramic kilns, steam boilers and other equipment. We independently select raw materials and technology for carrying out lining work, based on the type of equipment, operating temperatures and other parameters. By using our services, you will improve the performance characteristics of the structure.

Note! All our lining activities are accompanied by guarantees. If warping, cracking or peeling occurs, we will provide prompt maintenance. The client need not worry about this.

Do you have any questions? — Contact the manager by phone: you will receive a free consultation on lining work and can order services. We provide a guarantee for all lining work and cooperate under a contract.

Methods of execution

Furnace bunkers are lined, depending on the building material of the main structure, in several ways:

- installation of a facing layer made of materials with a low thermal conductivity coefficient: fireclay bricks or special panels. This work can be done both during the construction of the stove and after its construction is completed;

Fireclay brick - installation of protective screens that reflect thermal radiation. It is used for lining metal stoves - heaters, which are used to equip steam rooms in baths. The use of heat-reflecting screens for other designs of heating units is ineffective;

- coating the inside walls of the combustion chamber with a heat-resistant mixture of various types. You can apply the composition to the walls of the firebox at any time - during construction or in a ready-made unit.

External, internal protection

Protecting the internal walls of the firebox can be done in several ways:

- Firstly, you can use protective screens that can absorb most of the radiant fluxes. The screens installed inside the firebox affect the heating of the flue gases, so most of the heat will be removed through the chimney.

- Secondly, the inside of the firebox can be lined with fire-resistant, low-thermal conductivity material.

Thermal protection and thermal insulation - there is a difference

There is a huge difference between thermal protection and thermal insulation principles. With thermal insulation , the heat generated in the work area is not removed anywhere. This is what thermal insulation is for.

In contrast, thermal protection is designed to protect a specific area from the thermal radiation of the working area. From all that has been said, it becomes clear that thermal protection is not at all intended to preserve heat.

Materials used

Refractory materials for lining furnaces, depending on the ingredients included in the raw material composition, are divided into the following classes:

- A - products based on materials of natural origin or a synthetic composition with the addition of an organosilicon binder;

- B - a special type of clay (fireclay) is used as the main ingredient;

- C - other components of refractory substances.

Products and compositions for lining a class B furnace (bricks, blocks, mastics, etc.), the basis of which is fired fireclay clay, are available, inexpensive, and therefore are most popular. To increase heat resistance, portions of quartz sand, sandstone and other types of rocks, the strength of which remains unchanged at any heating temperature, can be introduced into the raw materials during their production.

As additional protection, materials in the form of a roll, plate or sheet are used for fireclay products. They are laid between layers of masonry made of heat-resistant and ceramic products. The list of such materials for furnace lining, which are based on white clay, includes:

- basalt wool;

- dense kaolin;

- mullite - siliceous mats;

- vermiculite and a number of other products.

Dry mixtures are used to make fire-resistant mortar, which is used to coat the surfaces of the combustion bunker and other masonry elements. They fill the cavities of technological clearances and gaps that compensate for the linear expansion of the structural parts of the metal furnace.

Refractory materials for lining furnaces also include heat-resistant aluminosilicate adhesive mass, which is used to glue refractories in sheet or roll form. This glue is also used for fireclay masonry and for coating walls made of bricks with low heat resistance with a thin layer.

Features of protective finishing of furnaces

When using the oven regularly, all materials from which it is made are exposed to very high temperatures. They depend on the combustion temperatures of specific substances that are used as fuel. Of course, the walls of the stove are made of refractory materials, but extreme thermal effects change their structure and properties, which leads to gradual destruction. It is to protect against such influences that the lining is used.

The lining will be the best internal protection of your fireplace from burnout and other damage.

About glue and mortar

In addition to the quality and technical characteristics of the materials, the durability and efficiency of the furnace lining is influenced by their correct installation. Any violations in the technology of internal cladding of the firebox can lead to a change in the properties and structure of the surrounding building materials, and the release of carbon monoxide into living rooms.

Solution

When the firebox is coated with heat-resistant solutions, a monolithic, very thin protective layer is formed on the walls, which is the best protection for the working surface from the effects of fire. However, such a monolith will require repairs faster than masonry made from piece products.

There are several rules for making linings using this technology:

- Prepare a solution from dry mixtures of fireclay, mullite or corundum type, diluted with water to the consistency of thick sour cream. They are usually sold in paper packaging, which contains information about the proportions of the components, the characteristics of the mixture, and the manufacturer’s instructions for use.

Consistency of lining solution - The applied layer of solution is first burned with a blowtorch or by briefly heating the oven until a hard crust is formed.

- When lining a furnace with fireclay bricks, the joints must be filled to the full height of the masonry.

The consumption of the finished mortar per 1 m³ of brickwork is approximately 100 kg.

Fireproof glue

Fireproof adhesive for lining is sold in plastic containers weighing 2 - 50 kg. Before starting lining work, the bucket of glue must be opened and the contents mixed until completely homogeneous.

Further:

- The adhesive mass is applied only to the pre-moistened surface with a spatula. The layer thickness should not exceed 3 mm.

- If you plan to coat the entire firebox cavity with glue, then the coating is done in layers with a time interval between applications of at least 15 minutes.

- To glue basalt cardboard to horizontal sections, the adhesive composition can be diluted with water by 15%, but no later than 12 hours before starting to work with the glue.

- Depending on the structure of the surface being treated and the thickness of the adhesive layer, from 1 to 4 kg of glue is consumed per 1 m².

- The time for complete hardening of a layer of adhesive mass with a thickness of 3 mm at temperatures above 25ºC is 24 hours, at temperatures above 90ºC - 6 hours.

Do-it-yourself stove repair - we repair the firebox and remove the soot layer in the pass

It’s not enough to build a stove with your own hands - it will continue to require careful treatment of itself, removing soot from pipes and chimneys, cleaning soot from glass fire doors (especially if you are a big fan of burning all the garbage from the site in a sauna stove - from leaves to torn galoshes), there is always something somewhere that needs to be tinkered with, coated and repaired.

All this, of course, is rewarded with the warmth of the hearth or a Saturday bath, but it also takes a lot of effort and time (and if you don’t do it yourself, then of course, too, finances).

Therefore, folk ingenuity could not be more valuable here - we present to you two options for solving frequently encountered “stove problems”, the second of which the author treated with truly folk ingenuity and got rid of the tedious dismantling and disassembly of the stove at (that’s for sure) the speed of sound .

Stove firebox repair

In the furnace of one of my friends, quite unexpectedly, the bricks in the firebox began to deteriorate intensively, especially in its lower, most thermally stressed zone (Drawing 1).

Most likely, the problem arose due to the poor quality of the brick used.

Having a large number of lime inclusions, this material could not withstand intense periodic heating and cooling and began to crumble after just a couple of years of operation of the furnace. Moreover, the spalling occurred not in small, but in very large fragments - the size of some fallen pieces of masonry reached 5 cm.

Everything you need for this article is here >>>

Just before the start of the third heating season, the spalling had already become dangerous, as it could lead to a breakthrough and release of hot gases directly into the room through the front wall of the stove and into the last vertical channel through the rear wall of the firebox.

It was necessary to take urgent measures, but there was no time for repairs with complete or even partial disassembly of the stove - it was the end of October. There was only one way out: to select a protective coating composition such that it could be used not only to restore the damaged part of the masonry, but also to prevent further destruction of the firebox at least until the end of the heating season.

After experiments with several coating compositions based on various binders and fillers, the following composition was selected:

- purchased fireclay mixture;

- fireclay brick crumbs;

- asbestos crumbs soaked in water;

- wood ash, sifted.

When choosing the composition, I reasoned as follows. During operation, sifted ash will certainly burn out inside the coating, resulting in the formation of a porous structure with increased thermal insulation properties. The fibrous structure of asbestos will give the coating the ability to resist cracking. The fireclay mixture, which has a very high sintering temperature (about 1000°C), will serve as a binder, and its increased fat content will be compensated by ground brick chips.

I coated the damaged areas in several stages, in thin layers with intermediate drying. I managed to apply 2-3 layers a day, no more. Noticed defects were immediately eliminated with additional grout before applying the next layer.

Also from the section “Stoves, fireplaces and barbecues”: Laying a beautiful garden barbecue stove with your own hands (+ 95 photos) Just in case, I kept a small (emergency) supply of coating, but it was never needed. After the repair, the stove worked safely through the entire winter season until the summer of next year without any problems.

Removing soot in the stove pass (roof)

When dismantling old furnaces, I more than once found loose growths of soot in the pass area (Fig. 2). Stove makers call these growths a beard, which settles on the inner surface of the roof and grows from top to bottom. In some cases, the “beard” grows so much that it significantly narrows the internal cross-section of the canal, or even can completely clog it.

The reasons for the appearance and growth of a “beard” may be insufficient heating of the roof (soot likes to settle on cold surfaces), as well as an oversized channel cross-section, leading to a decrease in the flow rate of flue gases.

Older furnaces rarely have special cleaning doors. In ancient times, stove makers did not install them, most likely to save money. Therefore, getting rid of such soot deposits is often not so easy. They say this can be done using potato peels or damp aspen firewood. Maybe it helps, but somehow it’s not very effective. I have not been able to achieve a noticeable improvement in the draft in the furnace using these means.

Source: https://kak-svoimi-rukami.com/2012/08/remont-pechki-svoimi-rukami-remontiruem-toplivnik-i-ustranyaem-sloj-sazhi-v-perevale/

Is it necessary to soak fireclay bricks before laying?

Even experienced stove makers do not have a clear answer to this question. However, having studied the physical properties of fireclay, you can be convinced that in some cases, before making the furnace lining, it is simply necessary to moisten the masonry material:

- when the masonry is done with used bricks. During previous use, the pores of the material became clogged with particles of dust and masonry mixture, and in order to open the capillaries in its structure, the brick is soaked. After the brick is removed from the container with water, you should wait until all the liquid has drained from it, and only then use it for masonry work;

- when building a heating device in the summer heat, but with high humidity in the fall or spring, it is better not to soak the brick.

Reflection of light

If you want to enjoy the sight of a live fire in the dark, with the lights turned off, then you need to keep in mind that a light lining will reflect more light from the flame into the room than a dark one. This is good for romantic evenings.

On a dark lining, the flames look more clear and contrasting than on a light one. This option is better suited for meditation, concentrated observation of the play of fire, when nothing should distract attention.

View of a fire with light and dark lining against the background when lighting a wood-burning fireplace.

We hope that taking these nuances into account will help you. We wish you a good choice!

Lining Instructions

To install the lining of a home stove, it is better to use the services of specialists, but if you have at least minimal skills and diligence, this type of work of a stove master can be done with your own hands.

Brick kiln

The lining of a brick kiln firebox using fireclay is performed as follows:

- First row. Fireclay bricks are laid edgewise around the grates. It is preferable that the brick product have an inclined edge to ensure a slope towards the grate.

- The second row of rear and side walls rises simultaneously. The brick is also laid edgewise with a shift of ½ length relative to the block in the bottom row. The seam is reinforced with steel wire with a diameter of 3 mm or 5 mm.

- Subsequent rows are performed in the same way up to the top of the combustion chamber. Reinforce the seams through one row of masonry.

- Lastly, the upper surface of the firebox is lined, laying the brick flat. Between the layers of lining and the main masonry, thermal insulation is made of asbestos. If the vault has a convex shape, the masonry is carried out using shaped (three-sided wedge or pentagonal) bricks.

Example of lining with fireclay bricks

Example 2

Example 3

Example 4

In this case, it must be taken into account that the lining layer and the main masonry of the walls must coincide in the location of the vertical seams and not have any bandaging.

Metal furnaces

The lining of the fireboxes of metal furnaces is carried out in the same way as in brick chambers (instructions above), but with one difference: there should be a small gap between the walls made of metal and fireclay bricks to compensate for linear expansion. Basalt or kaolin slabs and asbestos sheets are laid in this space. External cladding is not recommended with brick due to its low thermal conductivity.

Metal furnace lining

One more example

Solid fuel boiler

In boilers, the coolant passes through heat exchange channels and loses almost no energy to heat the walls of the housing. This feature of solid fuel equipment is taken into account when constructing the lining.

This is done in one of three ways:

- Heavy lining. Used for devices with weak shielding. With this method, the internal lining of the firebox is made of two or three layers of fireclay masonry.

- Lightweight lining. Single-layer brickwork is placed inside the combustion chamber. The outside of the boiler is lined with heat-insulating products that can withstand high temperatures and sheathed with sheet steel.

- Pipe lining. The boiler pipes are coated on the outside with fire-resistant glue and mortar in 3-4 layers reinforced with fiberglass mesh. After hardening, a monolithic thick layer is formed, protecting against unnecessary heat loss.

Clay ovens

The lining of the fireboxes of molded clay furnaces is carried out with fireclay bricks. The exception is a stove made of a clay-sand mixture and reinforced with stone. It can be coated with plastic refractories: aluminosilicate glue or mastic. After hardening, a layer of such lining material forms a continuous shell that reliably protects the clay walls from overheating.

Large industrial

In all large industrial furnaces, the purpose of the lining is to reduce heat loss and the effect of high temperatures on the furnace body (casing). In firing kilns, the lining also serves as a heat accumulator, providing an optimal firing mode (smooth increase in temperature), as well as an infrared (IR) emitter that uniformly heats the firing chamber.

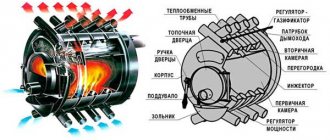

The task of lining metal smelting furnaces is much more complex. Here, too, it should emit IR well in order to heat the slag more strongly. High-quality metal is smelted only when the layer of molten slag is heated significantly higher than the liquid metal. But at the same time, the lining of industrial furnaces for smelting metal should not be wetted by molten slag and the metal itself, be chemically inert towards them and not release harmful impurities from the melt. Additionally, be strong enough to withstand your own enormous weight, because... The economic efficiency of metal smelting furnaces increases with increasing size. Therefore, for example, at least 7 types of lining materials are used for lining various parts of blast furnaces and steel-smelting furnaces (see figure).

Blast furnace and steel smelting furnace lining diagrams

Lining an industrial furnace is a complex and responsible job. Even with 3-4 years of vocational education in this specialty, you need to work in a brigade for several more years as a student or (informally) journeyman, i.e. at lower grades before being allowed to work independently. Therefore, if you are interested in what and how industrial metal smelting furnaces are lined, you can start with Wikipedia (wikipedia.org/wiki/Lining), where it is explained quite clearly, or Metallopedia. As for small kilns, they are lined like metal technological ones (see below), and we will go further - to the lining, which you can make yourself.

Note: in ultra-small metal smelting furnaces, e.g. jewelry, the lining can make up the entire structure (body) of the furnace or most of it, see video: