The secret of the popularity of bimetallic radiators is that their efficiency is not inferior to traditional cast-iron batteries, but at the same time they have better technical and operational characteristics. The undeniable advantages include:

- High heat transfer coefficient.

- Long service life of more than 20 years.

- Stylish and neat appearance.

- Relatively light weight, which greatly simplifies installation work.

- The presence of nipples provides the ability to connect sections, so that the radiator can be “extended”.

Note that often the need for expansion arises, for example, if a device with an inappropriate number of sections was selected during purchase or for other reasons. In order not to initially make a mistake in selecting the optimal model, you need to know how to calculate bimetallic heating radiators, that is, the optimal number of sections. By the way, you can do this yourself, without resorting to the help of professionals, and various methods are used for calculation.

Data preparation

To get an accurate result, the following parameters should be taken into account:

- climatic features of the region in which the building is located (humidity level, temperature fluctuations);

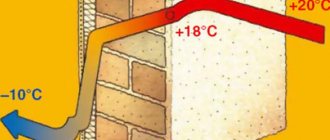

- building parameters (material used for construction, thickness and height of walls, number of external walls);

- size and types of windows to premises (residential, non-residential).

When calculating bimetallic heating radiators, 2 main values are taken as a basis: the thermal power of the battery section and the heat loss of the room. It must be remembered that most often the thermal power indicated by manufacturers in the technical data sheet of the product is the maximum value obtained under ideal conditions. The actual power of the battery installed indoors will be lower, so recalculation is done to obtain accurate data.

The simplest method

In this case, you will need to recalculate the number of installed batteries and rely on this data when replacing elements of the heating system. The difference between the heat transfer of bimetallic and cast iron batteries is not too big. In addition, over time, the heat transfer of the new radiator will decrease due to natural reasons (contamination of the internal surfaces of the battery), so if the old elements of the heating system coped with their task, the room was warm, you can use this data.

However, in order to reduce the cost of materials and eliminate the risk of the room freezing, it is worth using formulas that will allow you to calculate the sections quite accurately.

calculation of the number of sections of bimetallic radiators

How will we connect

The connection diagram for radiators may be different.

The level of heat transfer and the comfort of staying in the apartment depend on which option is preferred. Incorrectly selected wiring can reduce the power of the heating system by 50%. The most widespread is the one-sided side scheme, characterized by the highest heat transfer rate. In this case, the coolant supply pipe is connected to the upper pipe, and the outlet pipe to the lower one.

If you do the opposite, the efficiency of heating the room will decrease by almost 7%. For connecting multi-section radiators, such a scheme is not always justified, since insufficient heating of the last sections is possible. This can be avoided by installing a water flow extension.

In an apartment with pipes hidden in the floor or running under the baseboard, a bottom connection is used.

This is the most aesthetic option, in which the pipes for supplying and discharging coolant are located below in the floor, and therefore the lower holes are used for connection.

Diagonal

Batteries with twelve or more sections are installed in a diagonal pattern.

The coolant is supplied through the upper pipe located on one side of the radiator, and discharged through the lower pipe on the other side.

Sequential

This connection diagram assumes that there is sufficient pressure in the heating system for the coolant to move through the pipes.

In this case, it is worthwhile to provide a Mayevsky valve designed to remove excess air.

It is important to remember that repair and maintenance work will be accompanied by shutting down the entire heating system

Parallel

Parallel wiring assumes the presence of a special heat pipe built into the heating system, through which the coolant is supplied and discharged outside.

The presence of special taps at the inlet and outlet makes it possible to replace individual radiators without turning off the heat supply. However, the circuit may cause insufficient heating of the pipes at low pressure in the system.

Calculation by area

For each region of the country, there are SNiP standards, which stipulate the minimum power value of the heating device for each square meter of room area. To calculate the exact value according to this standard, you must determine the area of the existing room (a). To do this, the width of the room is multiplied by its length.

The power per square meter is taken into account. Most often it is 100 W.

Having determined the area of the room, the data must be multiplied by 100. The result is divided by the power of one section of the bimetallic radiator (b). This value must be looked at in the technical specifications of the device - depending on the model, the numbers may differ.

A ready-made formula into which you should substitute your own values: (a*100): b= required quantity.

Let's look at an example. Calculation for a room with an area of 20 m², while the power of one section of the selected radiator is 180 W.

We substitute the required values into the formula: (20*100)/180 = 11.1.

However, this formula for calculating heating by area can only be used when calculating values for a room whose ceiling height is less than 3 m. In addition, this method does not take into account heat loss through windows, and the thickness and quality of wall insulation are also not considered. To make the calculation more accurate, for the second and subsequent windows in the room you need to add 2 to 3 additional radiator sections to the final figure.

calculation of sections of bimetallic heating radiators by area

Standard sizes and diameters

Today, bimetallic radiators are produced in generally accepted standard sizes:

- thickness indicators - 9 centimeters;

- width indicators - at least 40 centimeters;

- height indicators - 76, 94 or 112 centimeters.

It should be borne in mind that the linear parameters of heating devices can vary significantly and depend on the materials used and design features:

- if it is necessary to install thinner devices , it is not advisable to use a bimetallic type of equipment, which is due to the double metal layer;

- The panel version belongs to the category of the thinnest devices .

Calculation by volume

Calculation of the number of sections of bimetallic radiators using this method is carried out, taking into account not only the area, but also the height of the room.

Having received the exact volume, calculations are made. Power is calculated in m³. SNiP standards for this value are 41 W.

For example, we take the same values, but add the height of the walls - it will be 2.7 cm.

Let's find out the volume of the room (we multiply the already calculated area by the height of the walls): 20 * 2.7 = 54 m³.

Next, we determine the required battery power (we multiply the volume of the room by SNiP standards): 54*41 = 2214.

The next step is to calculate the exact number of sections based on this value (we divide the total power by the power of one section): 2214/180 = 12.3.

The final result differs from that obtained when calculating by area, so the method taking into account the volume of the room allows you to get a more accurate result.

Terminology

The main selection parameters are the width and height of the radiator.

Documentation discussing the dimensions of heating radiators often talks about the center-to-center distance. This parameter indicates the length of the gap from the center point of one connecting hole to a similar place in the other. Sometimes this value is called the center-to-center or inter-nipple distance. If the pipelines supplying the radiator are in working condition and there are no plans to change them, the new heater purchased should have the same center-to-center indicator as the old one, so that changes to the connections do not have to be made. Sometimes the names of models - both Russian and foreign - contain three-digit numbers. They indicate this parameter in millimeters (for example, Modern 500).

Linear dimensions include:

- installation height of the radiator - it must be selected so as to ensure the required distances to the window sill and floor;

- depth;

- width - for models with a sectional design, it, like the previous parameter, also refers to the dimensions of the elements, but if the depth of the radiator and its individual sections is the same, to calculate the total width you need to multiply the indicator of an individual unit by their number and add approximately 1-2 cm, attributable to sealing gaskets.

Heat transfer analysis of radiator sections

Despite the external similarity, the technical characteristics of radiators of the same type can differ significantly. The power of the section is affected by the type of material used to make the battery, the size of the section, the design of the device, and the thickness of the walls.

To simplify preliminary calculations, you can use the average number of radiator sections per 1 m², derived by SNiP: • cast iron can heat approximately 1.5 m²; • aluminum battery – 1.9 m²; • bimetallic – 1.8 m².

How can you use this data? From them you can calculate the approximate number of sections, knowing only the area of the room. To do this, the area of the room is divided by the specified indicator.

For a room of 20 m² you will need 11 sections (20/1.8 = 11.1). The result approximately coincides with that obtained by calculating the area of the room.

Calculation using this method can be carried out at the stage of drawing up an approximate estimate - this will help to roughly determine the costs of organizing the heating system. And more accurate formulas can be used when a specific radiator model is selected.

Selecting the distance between the axes

The functionality of different models of bimetal radiators is usually equivalent. But they differ in the distance between the axes of the collectors.

There are models with both standard values (50 and 35 centimeters) and non-standard ones. For example, if radiators of minimum or maximum height are suitable for your purposes, then keep in mind the following points:

- A small distance between the axles (20 centimeters) is found only in models from BiLUX, RIFAR and Sira.

- A large distance between the axles (about 80 centimeters) occurs only in models made by the Italian company Sira.

We can note some advantages of the products of our manufacturer – RIFAR. He makes a line of RIFAR MONOLIT radiators, which have a solid core. Another line - RIFAR FLEX - can be rounded in accordance with the wishes of the customer.

This is convenient in an apartment where the corners are not straight, but rounded.

Such a radiator will fit into the design most optimally and will fit perfectly into the wiring. Date: September 25, 2022

Calculation of the number of sections taking into account climatic conditions

The manufacturer indicates the thermal power value of one radiator section under optimal conditions. Climatic conditions, system pressure, boiler power and other parameters can significantly reduce its efficiency.

Therefore, when calculating, these parameters should be taken into account:

- If the room is corner, then the value calculated using any of the formulas should be multiplied by 1.3.

- For every second and subsequent windows you need to add 100 W, and for a door - 200 W.

- Each region has its own additional coefficient.

- When calculating the number of sections for installation in a private house, the resulting value is multiplied by 1.5. This is due to the presence of an unheated attic and the external walls of the building.

Design of bimetallic heaters

The body of these radiators is figured-ribbed, made of aluminum alloy, which is distinguished by excellent heat transfer. Under the housing there is a heating circuit made of pipes (copper or steel).

This “filling” helps the battery adequately withstand the attack of chemical and mechanical impurities present in hot water for heating.

The steel from which the core tubes are made is very strong. Therefore, the radiator will withstand even under high pressure. This can be 20, or even 40 atmospheres (some models up to 100 atmospheres). And the temperature of the coolant can rise to 110 or 130 degrees. If you need more specific numbers, you need to look at the passport of a specific radiator. Aluminum not only increases heat transfer, but also significantly makes the device lighter. In addition, the complex shaped housing has a very attractive design, giving the radiators an excellent appearance.

According to their characteristics, these radiators are quite suitable both for apartments in buildings of various heights, and for individual cottages with autonomous heating systems. But don’t rush to the store right away - first we’ll tell you how to intelligently approach the issue of choosing them.

Battery power recalculation

In order to obtain the real, and not specified in the technical specifications for the heating device, power of the heating radiator section, it is necessary to make a recalculation, taking into account the existing external conditions.

To do this, first determine the temperature pressure of the heating system. If the supply turns out to be +70°C, and the output is 60°C, while the desired temperature maintained in the room should be about 23°C, it is necessary to calculate the system delta.

To do this, use the formula: the outlet temperature (60) is added to the inlet temperature (70), the resulting value is divided by 2, and the room temperature is subtracted (23). The result will be a temperature difference (42°C).

The desired value - delta - will be equal to 42°C. Using the table, they find out the coefficient (0.51), which is multiplied by the power specified by the manufacturer. They obtain the real power that the section will produce under given conditions.

| Delta | Coef. | Delta | Coef. | Delta | Coef. | Delta | Coef. | Delta | Coef. |

| 40 | 0,48 | 47 | 0,60 | 54 | 0,71 | 61 | 0,84 | 68 | 0,96 |

| 41 | 0,50 | 48 | 0,61 | 55 | 0,73 | 62 | 0,85 | 69 | 0,98 |

| 42 | 0,51 | 49 | 0,65 | 56 | 0,75 | 63 | 0,87 | 70 | 1 |

| 43 | 0,53 | 50 | 0,66 | 57 | 0,77 | 64 | 0,89 | 71 | 1,02 |

| 44 | 0,55 | 51 | 0,68 | 58 | 0,78 | 65 | 0,91 | 72 | 1,04 |

| 45 | 0,53 | 52 | 0,70 | 59 | 0,80 | 66 | 0,93 | 73 | 1,06 |

| 46 | 0,58 | 53 | 0,71 | 60 | 0,82 | 67 | 0,94 | 74/75 | 1,07/1,09 |

Additional recommendations

To give batteries an aesthetic appearance, they are often masked with special screens or curtains. In this case, the heating device reduces heat transfer, and when calculating the required number of sections, another 10% is added to the final result. Since most modern radiator models have a certain number of sections, it is not always possible to select batteries taking into account the calculations performed. In this case, it is recommended to purchase a product whose number of sections is as close as possible to the desired one or slightly more than the calculated value.

From “cast iron” classics to modern bimetal: which is better to choose?

To choose the right radiator, pay attention to the material from which the heating devices are made. Not so long ago, only cast iron radiators were available to consumers; there are other models on the modern market that differ in technical parameters, appearance, and service life

Cast iron

The metal has low thermal conductivity and therefore heats up slowly. To heat the radiator surface to 40–45 °C, the water in the system must correspond to 70 °C. The advantages include the slow cooling of the batteries after the boiler is turned off, resistance to aggressive environments and rust.

Photo 1. A cast iron radiator with low thermal conductivity and heavy weight is suitable for country houses.

Such heating devices do not require additional water treatment. Service life - more than 50 years. They can be installed both in spacious cottages and small private houses.

Radiators made of cast iron have a number of disadvantages related to heavy weight and appearance. Batteries must be periodically painted with durable paints. They are difficult to keep clean. Often, due to their unpresentable appearance, cast iron classics are hidden behind screens, which leads to heat loss.

If you have installed protective screens, add another 20% when calculating power.

Aluminum

Aluminum radiators are made by casting or extrusion with the addition of silicon. Unlike the classics, they are light in weight and installation, and have good thermal conductivity. Pleasant appearance excludes protective screens.

Photo 2. An aluminum radiator in a private house has good thermal conductivity and is easy to install.

These are the cheapest heating devices. But they have serious disadvantages: water preparation is necessary. The owner must install cartridges and filters and monitor the pH level. Otherwise, the protection of the inner layer of the devices will be compromised. The joints between the links may leak.

Attention! These radiators cannot be supplied with water through copper pipes - oxidation processes will begin. The product will last less than 15 years, allotted to it by the technical certificate

Steel

Reliable heating radiators with high thermal conductivity are made of steel. Lightweight, convenient for self-installation. Unpretentious products at an affordable price are chosen by owners of any type of housing construction. Attractive appearance, possibility of mounting options: horizontal and vertical, angular design.

The main disadvantage of steel panels is that they are subject to mechanical stress. Careless handling of the device reduces the service life from the stated 20 years.

Photo 3. Steel battery with high thermal conductivity, side connection method, suitable for any house construction.

Steel radiators are connected to the heating system using the bottom or side method. The bottom connection will cost the householder more than the side connection. Steel radiators should always be filled with water.

Bimetallic

In the manufacture of heat exchangers, two types of metal are used: steel pipes are placed in an aluminum body. The result is a more reliable design than devices made from one type of metal. They heat up quickly and transfer heat well. High-strength steel of the heat exchanger protects the system from corrosion. The radiators are light and aesthetic. They will create a comfortable environment in any type of private household.

The disadvantages include the high price, cracking during operation, since the two metals have different coefficients of thermal expansion.

Reference! Experts advise installing a venting valve on bimetallic radiators, and shut-off valves on the pipes. The service life in this case will be maintained: 25 years.