Many visitors to the Technodom online store contact us with a request to select heating boilers online. We are always ready to help them in this matter, especially since our company’s range includes many different types and models of equipment suitable for literally any purpose. For example, if you need to select a gas boiler based on its parameters, our consultants will be happy to provide you with all the necessary information. Before you start choosing heating equipment, it is advisable to determine which criteria will be most important for you.

CONTENT

Introduction 1. Why a solid fuel boiler 2. How to choose the power of the boiler 3. Is the boiler only for heating or for heating and hot water (DHW)? 4. Dependence of power on the type of fuel 5. Steel or cast iron 6. Hot water or hot air

7. Features of choosing a boiler for industrial and non-residential premises

8. Features of choosing a boiler for greenhouses 9. Selection of boiler power for drying chambers 10. What parameters to pay attention to: 10.1. Power 10.2. Efficiency 10.3. In EU, dimensions 10.4. Fuel (including size of firewood) 10.5. Warranty period and service life 10.6. Price 10.7. Equipment

Types of electric boilers

When selecting the power of a heating boiler according to the area of the house, it is worth understanding the main types of such devices:

- heating elements . This is the traditional and most common version of electric boilers. Multi-stage units are considered more economical, since they are capable of operating in several modes. Among the disadvantages is low efficiency due to heat loss for heating heating elements. But the advantages include low prices for consumables (heating elements) and easy repairs.

- Induction . In such equipment, the coolant is heated at the moment water passes through the inductive coil. It is believed that induction boilers are more economical compared to heating elements, they have no heat loss and virtually no inertia. In addition, such boilers are very compact - they look like a piece of pipe from 35 cm to 1 m long. Among the disadvantages is the need for constant circulation of the coolant, otherwise the boilers overheat and burn out quickly.

- Electrode . Many buyers, when they want to choose a boiler according to its parameters, choose this type of equipment the least often. Although they are considered the most economical, in most cases consumers are stopped by the need to circulate electrolyte through the pipes as a coolant, that is, water with certain additives. This requirement is due to the fact that heating of the coolant occurs due to the passage of current between the electrodes. When operating boilers of this type, it is necessary to monitor the condition of the electrodes and electrolyte. In addition, the entire installation operates under voltage - this also somewhat frightens consumers.

Thus, if you don’t know how to choose a boiler based on the area of your house and which option to choose, then pay attention to induction and heating elements products.

Introduction

This instruction is written to help those people who are faced with the question of choosing a boiler for heating a room. has been producing and supplying heating boilers for 9 years, and during this time has accumulated considerable experience on this issue. Our boilers are installed in more than 10,000 premises throughout Russia and in the near abroad. In this manual, we will try to describe the process of selecting a boiler as clearly and completely as possible, while making it easy enough to understand. In addition to the issues of selecting a boiler for different premises - private houses, industrial buildings, greenhouses, drying chambers - we will consider additional issues that you should pay attention to when choosing a boiler. IMPORTANT! This instruction allows you to satisfy most requests for boiler selection. At the same time, there are situations when the production process (for example, for growing a certain type of plant, obtaining wood of a certain degree of moisture) requires a stable set temperature throughout the entire operation. In this case, the materials in this manual may not be enough. We strongly recommend that you contact specialized organizations for a full thermal calculation of your premises.

Selection of an electric heating boiler

In addition to selecting a gas boiler for a private home according to its parameters, our clients are also interested in other types of these devices. For example, electric models are very popular. Such boilers must be selected according to their power (this is a universal parameter for any model), type of connection (220V or 380V), principle of power control (stepped or smooth), as well as heating method (heating element or electrode). Each of the listed criteria can play a rather important role, therefore, we recommend paying increased attention to all of them.

WHY SOLID FUEL BOILER?

All recommendations for selecting a boiler in this manual will primarily concern solid fuel boilers, i.e. boilers operating on wood, coal, peat, fuel briquettes, pellets. Why is that? Firstly, the selection technique itself is suitable for boilers using other types of fuel. Secondly, as practice shows, solid fuel boilers confidently occupy second place in terms of heating costs after mains gas (and in some cases even first). Thirdly, this is a classic type of heating for our country. Fourthly, it specializes in the production of solid fuel heating pyrolysis* (please read about this word in the link below) boilers and has extensive experience in their correct selection. Fifthly, and this is IMPORTANT! In conditions of periodic accidents on electrical networks, decreases in pressure in the gas line and gas quality, and constant growth in tariffs, solid fuel boilers are increasingly being installed as a backup source of heating in many rooms where there is already another source of heat. Therefore, we are sure that this instruction will be useful to a large circle of readers.

HOW TO SELECT BOILER POWER

By and large, power is the main parameter for choosing a boiler. It shows how much heat the boiler will produce, measured in kilowatts (kW). The fact is that any house, building, room has heat loss. Heat escapes through windows, doors, walls, roof, basement, ventilation. And the boiler’s task is to produce enough heat to compensate for these losses and maintain a comfortable temperature inside. *Pyrolysis boilers are solid fuel heating boilers, the design of which includes special elements that make it possible to obtain heat not only from the combustion of solid fuel (firewood, briquettes, peat, coal), but also due to the additional combustion of gases that are released . These gases are called “pyrolysis” gases. Hence the name of the boilers. In other words, such boilers can operate as conventional solid fuel boilers (also called “direct combustion boilers”), or in a more economical and efficient mode of burning pyrolysis gases.

There are a large number of options for calculating power. And, of course, the most correct thing would be to contact specialists to carry out thermal engineering calculations. But such a calculation costs money, and usually not little. Therefore, we will try to calculate the boiler power ourselves. The simplest and most common formula:

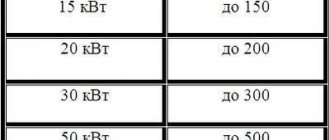

For every 10 m2 of room, 1 kW of heating power is required

Moreover, this calculation is correct for ceiling heights of up to 3 meters. Those. for a house, say, 150 sq.m. A boiler with a power of 15 kW is required. However, this formula is valid for new, residential, well-insulated premises. But what if the building has a different purpose? How to take into account the fact that in some regions the temperature can drop much lower than in others? In this case, you can use different formulas, sometimes so specific that only specialists with specialized education can figure it out. The experience of our company (to calculate the required power of solid fuel boilers) shows that in 95% of cases you can rely on the following formula:

W=(S*h*Δt*q)/0.86*1000, where W – boiler power, kW; S—room area, sq.m.; h – ceiling height, m; Δt—temperature difference inside and outside, degrees; q - correction factor is taken from the reference book depending on the type of building; 0.86 is the coefficient for converting calories to watts; 1000 is the conversion factor from watts to kilowatts. Let's assume that we need to heat a store in Vologda with an area of 250 sq.m. with a ceiling height of 3 meters. The store always requires a temperature of +20°C. 1) We calculate the volume of the room: V = 250*3=750 cubic meters. 2) We look in the directory (you can easily find it on the Internet by searching for “Climatic parameters of the cold period of the year”) for the lowest temperature in winter (there are several columns in the directory with similar names. You need the temperature of the coldest five-day period). For Vologda it is minus 42 degrees. If you want to have 20 degrees in the building, Δt=20+42=62 degrees. 3) Correction factor for stores with a volume of up to 5000 cubic meters = 0.38 kcal/m3*h*°C. Finding a good reference book is not easy. If you need it, send us a request by email [email protected] and we will send you the one we use ourselves.

4) Substitute the obtained values into the formula:

W=750m3*62°C*0.38 kcal/m3*h*°C/0.86*1000=20.5 kW.

We get the required power of 20.5 kW. Below we will separately consider the nuances of selecting boilers for industrial premises, greenhouses and drying chambers.

How much heat can be obtained from different types of fuel.

Depending on the type of heating boiler you choose, you will incur costs not only for creating a heating system, but also constant costs for fuel. We will look at what these costs will be in the following sections.

Natural gas.

One of the most popular and economical types of fuel. When burning 1 cubic. meters you can get up to 9.3 kW of thermal energy or 8,000 kcal. (without taking into account the energy of the phase transition of water vapor). Qnr=8.2…9.2 kW/N.m3. The efficiency of combustion in a conventional boiler is 85-90%. The total efficiency when burning in a condensing boiler is 110-115%. The average price of gas in the Republic of Belarus as of May 1, 2017 is 0.118 BYN. rub. for 1 cubic meter. This means that in order to get 100 kW of heat, we must spend only 1.26 rubles.

Liquefied gas.

The fuel is quite expensive and can be used when it is necessary to heat a dacha or for temporary heating during the planned transition to natural gas in the near future. Unit of measurement - l. or kg. Qнр=6.8 kW/l or 12.8 kW/kg (density 530 kg/m3, excluding the phase transition energy of water vapor). The efficiency of combustion in a conventional boiler is 85-90%. Cost 1 kg. liquefied gas approximately 0.5404 bel. ruble This means that in order to get 100 kW of heat, we must spend 4.22 rubles, i.e. 3.5 times more than when using natural gas for heating a home.

Diesel fuel.

Even more expensive fuel and rarely used in heating boilers. Unit of measurement - l. Qнр=10.2 kW/l (density 860 kg/m3, excluding the energy of the phase transition of water vapor). The efficiency when burned in a conventional boiler with a liquid fuel burner is 85-90%. The cost in the Republic of Belarus as of May 1, 2017 is 1.27 BYN. rub. for 1 liter. This means that in order to get 100 kW of heat, we must spend 12.45 rubles, i.e. 10 times more than when using natural gas to heat a home.

Firewood.

The unit of measurement is kg or m3. It should be noted that the heat released during the combustion of wood is very dependent on the moisture content of the wood. The fresher the wood you use, the higher its humidity and the less heat you will receive. In addition, the heat of combustion also depends on the type of wood. The most commonly used firewood is pine and birch. Average dryness of firewood can be considered with the following calorific value - Qнр = 3 kW/kg or 1421 kW/m3 (density 480 kg/m3, humidity 30%, excluding the phase transition energy of water vapor). The efficiency when burning in a solid fuel boiler is 65-80%. The average cost is 50 rubles per 1 cubic meter. Taking into account the low efficiency of wood-burning boilers, we can calculate that in order to get 100 kW of heat, we must spend about 3.5 rubles, i.e. 3 times more than when using natural gas to heat a home.

Pellets.

A modern type of fuel for pellet boilers, which allows you to create a relatively autonomous heating system. Unit of measurement is kg. The calorific value depends on the manufacturer and on average will be equal to Qнр = 4.2 kW/kg (density 680 kg/m3, humidity 10%, excluding the phase transition energy of water vapor). The efficiency when burning in a pellet boiler is 70-80%. The average cost is 0.3 rubles per 1 kg. Taking into account the low efficiency of pellet boilers, we can calculate that in order to get 100 kW of heat, we must spend about 7.14 rubles, i.e. 5 times more than when using natural gas to heat a home.

Electricity.

A fairly affordable type of fuel. Modern electric heating boilers have high efficiency and reduce home heating costs. The unit of measurement is kWh. Qnr= 1 kW. The efficiency of electric boilers is 98-99%. The average cost is 0.12 rubles/1 kWh. You can calculate that in order to get 100 kW of heat, we must spend about 12 rubles, i.e. 10 times more than when using natural gas to heat a home.

Calculations show that the most economical type of fuel in our country is natural gas and firewood. The most expensive fuels are electricity, diesel and pellets.

So, in order to select and buy a boiler for heating your home, you need to find out about the possibility of laying a natural gas line to your home. If possible, it is better to choose a gas boiler. If gas tariffs rise and the cost of electricity falls, then perhaps, as in Europe, a transition to heating with an electric boiler is possible in the future.

IS THE BOILER FOR HEATING ONLY OR FOR HEATING AND HOT WATER?

Practice shows that in approximately 30% of cases, users use the boiler not only for heating, but also for heating hot water in the water supply system. If you also heat water “at the tap” with a boiler, then you need to take into account the following points. Firstly, it does not matter how your boiler will transfer heat to the water - through the DHW circuit built into the boiler or through an indirect heating boiler. What kind of devices these are, you can always consult our managers using the contacts listed at the end of the instructions. Secondly, you need to understand that at the moment when water is heated for the water supply system, this heat is taken from the heating system. Therefore, a boiler must be selected with a power reserve specifically for heating water. In general, the formula is not that complicated. From experience, you just need to add about 25-30% of the power to the boiler power that you obtained using the formula from point 2. In most cases, this completely covers the need for additional power to heat hot water.

Selection of gas heating boiler

For many of those who select a gas boiler based on parameters, the cost of this equipment can be very important, but far from the only factor. In addition, it is worth determining its location - whether it will be wall-mounted or floor-mounted. An equally significant factor is its energy dependence; the equipment can be autonomous or must be connected to the mains. Finally, these models are single-circuit and double-circuit, the first provide only heating, and the second provide heating and hot water heating. The staff will be happy to help you understand all these subtleties.

DEPENDENCE OF POWER ON FUEL TYPE

Another important parameter that can affect the calculation of boiler power for your premises is the fuel with which you will heat the boiler. And this is a nuance in selecting power specifically for solid fuel boilers. Everyone has encountered a situation where some firewood cannot be lit, and some burn out like matches. The correct moisture content of the wood is necessary. Damp firewood and firewood with natural moisture do not burn well; during combustion, heat transfer is also lost due to internal moisture. Part of the boiler's power is simply used to evaporate moisture. According to various estimates, fresh firewood contains from 80 to 35-45% water. The optimal humidity for the firebox is about 20-25%. This drying out usually occurs during the summer. Today, the bulk of firewood sold is firewood with natural moisture. Chamber-dried firewood exists and is sold, but it is much more expensive. If you were unable to prepare, or you consciously make a choice in favor of “heating with anything,” then when selecting a boiler, you should put at least 20-30% of the power on top.

What to look for when choosing a boiler

To make the right choice of heating boiler for a private home, it is worth considering several fundamental points.

First of all, you should pay attention to the types of fuel available in a particular region. Both the cost of fuel and the ability to easily purchase it if necessary will matter.

The next important point is the presence of automation, that is, the ability to work without operator intervention. This condition becomes especially relevant if there is no one in the house during the day, and the equipment must work continuously.

When selecting a heating boiler, you need to consider how simple and easy to use this or that option is, as well as what kind of maintenance it requires. If you do not want to regularly clean the boiler, then it is better to opt for an automated product, although it will cost significantly more.

It is worth noting that all solid fuel boilers require periodic cleaning of burners and combustion chambers. Gas and electric appliances require much less maintenance.

STEEL OR CAST IRON

Well, we figured out the boiler power. Now you can move on to the next selection points. Often future users choose for comparison such a parameter as the boiler firebox material. And here there are two options - steel or cast iron. At first glance, cast iron boilers seem more reliable and durable. This is partly true. And if these parameters come first in your values, then you should first take a closer look at cast iron boilers. Additional advantages include smaller dimensions with the same power as steel boilers. But it is necessary to take into account several nuances: 1) cast iron is a fairly fragile material, so it can be relatively easily damaged during transportation, impacts, temperature changes (when, for example, in emergency mode the boiler was extinguished not with sand, but with water); 2) cast iron is poorly repairable, and the proposal to replace individual elements of the firebox (they are also called “sections”) in practice turns out to be very labor-intensive, because During operation, these elements become overgrown with combustion products, “sinter” and become almost a single whole. Steel boilers do not have these disadvantages. 1) They, on the contrary, are easier to repair, and in case of emergency conditions (pah-pah, of course) “any person with a welding machine” can restore them. 2) Due to the plastic characteristics of steel, these boilers are impact-resistant. 3) The ratio of the volume of the loading chamber to the power of the boiler is greater for steel stakes, which means that you will have to approach the boiler less often to add fuel. 4) These boilers are more resistant to pressure increases in the boiler, because less sensitive to temperature changes. 5) Plus, steel boilers are often much cheaper than cast iron ones. And they weigh less, which will reduce both delivery and installation costs. You will be able to save about 15-20%. Well, durability is ensured by proper heat removal. Now manufacturers of steel boilers claim a service life of 10-15 years, which is quite enough. For cast iron boilers, this parameter is usually 25 years. The only thing worth paying attention to is the thickness and grade of steel from which steel boilers are made. , for example, manufactures its Bourgeois-K boilers from special corrosion-resistant heat-resistant steel grade 09g2s with a thickness of 5 mm. By the way, you can judge the thickness of the steel by the weight of the boiler. If two boilers of the same power have a weight difference of about 50 kg, guess where thicker metal is used and which boiler will last longer?

Selecting a heating boiler

Considering the wide variety of heating devices on the market, many consumers do not know how to choose the power of a heating boiler and which type to choose.

Here are the basic requirements for such devices:

- Saving money . The optimal types of fuel are wood, coal and natural gas. At the next level in terms of cost are pellets, liquid fuel and electricity. However, it is worth taking into account the specific situation in each region and the availability of a particular type of fuel.

- Autonomy . Gas, pellet and electric boilers can operate without operator intervention. Such devices do not require constant supervision. Some control is necessary on oil boilers. But solid fuel ones have a minimal level of automation.

- Easy to connect . The most problematic is the process of designing and connecting a gas boiler to the main pipeline. If there is an electric boiler, the substation must allocate a powerful heating line if they have a reserve. All other equipment is connected much easier, but in compliance with safety measures.

Thus, taking these factors into account, it will be much easier for you to decide on the type and power of the boiler for your private home.

WATER HEATING OR AIR HEATING

Most heating boilers are hot water boilers that heat the coolant (water or special antifreeze for heating systems). And it, in turn, enters the premises through pipes to radiators (batteries), where it gives off heat. These are the most popular and familiar boiler models, so we will not dwell on them in detail. At the same time, there are also so-called air-heating boilers. Air passes through their surfaces around the outer walls of the firebox (either independently or pumped by fans). The air is heated and supplied directly to the room. Air-heating boilers are more convenient because there is no need to spend money on a heating system (pipes, radiators, boiler “piping” elements). There is no coolant in them, which means there is nothing to freeze if, for example, firewood was not added to the boiler in time. Such a boiler can easily be stopped when there are no people in the room (nights, weekends, holidays), without fear of defrosting the system and spending a lot of money on its restoration. True, there are several nuances. Firstly, such boilers are not suitable for residential premises. Perhaps these will be some kind of stoves for country houses where you are not constantly present. The fact is that they: a) dry the air; b) dust from your premises burns on them, and the substances obtained from this are not the most useful; c) in the case of boilers with fans (more efficient models), they also make noise. Secondly, by their design, these boilers heat the air in only one room. In order to heat the neighboring ones, this air must be transferred there, and this is already an air duct system. And even though it turns out to be cheaper than hot water heating, it is clearly inferior in appearance. Therefore, air-heating boilers are mainly used in large industrial premises, greenhouses, garages, workshops, car washes, drying chambers, etc. If this is your option, then take a closer look at air-heating boilers, they may turn out to be very suitable.

Solid fuel boilers

Often, when selecting a heating boiler based on area, consumers choose solid fuel equipment. Although it has a number of disadvantages, it is still the most popular.

As a rule, coal and firewood are used to fire solid fuel boilers. The final choice depends on which raw materials are more available in a given region. It is worth noting that coal and wood boilers differ from each other. Wood-burning boilers have a large loading chamber that can hold a lot of firewood. Coal chambers have a smaller firebox with thicker walls to withstand high combustion temperatures.

The advantages of solid fuel boilers are:

- saving money on heating;

- reliability and prostate structure;

- ability to work regardless of the availability of electricity.

It is worth mentioning significant disadvantages:

- Due to the cyclical operation of boilers, the air temperature in the house is not constant, it becomes either cold or hot. To solve this problem, heat accumulators are installed, that is, containers with water, which allow you to maintain an optimal microclimate constantly - during the combustion process, heat is accumulated, which is then used to warm up the house.

- Need for maintenance. Any solid fuel will first have to be loaded, ignited, the intensity of its combustion must be monitored, and upon completion of the process, the firebox must be cleaned and the boiler re-ignited.

- The system cannot work offline. As it burns out, it is necessary to periodically add a new portion of fuel so that the system does not freeze.

- Since a lot of dirt is formed during the process of filling fuel and cleaning the boiler, it is advisable to install the boiler as close to the entrance as possible so as not to spread it everywhere.

In general, a solid fuel boiler in the heating system of a private house does not seem very convenient. Despite the fact that fuel for them can be easily obtained and is relatively cheap, it takes a lot of time to kindle, so the savings are not always justified.

FEATURES OF CHOOSING A BOILER FOR INDUSTRIAL AND NON-RESIDENTIAL PREMISES

In general, the formula specified in paragraph 2 is suitable for selecting boiler power for industrial premises. Here it is: W=(S*h*Δt*q)/0.86*1000, where W is the boiler power, kW;

S—room area, sq.m.; h – ceiling height, m; Δt—temperature difference inside and outside, degrees; q - correction factor is taken from the reference book depending on the type of building; 0.86 is the coefficient for converting calories to watts; 1000 is the conversion factor from watts to kilowatts. A detailed description of how to use it is given in paragraph 2. THE TABLE WITH THE Q COEFFICIENT (SPECIFIC THERMAL CHARACTERISTIC) WILL BE TO HELP YOU:

| Name of buildings | Volume of buildings, m3 | Specific thermal characteristic, kcal/m3h°C |

| Administrative buildings, offices | up to 5,000 | 0,43 |

| up to 10,000 | 0,38 | |

| up to 15,000 | 0,35 | |

| more than 15,000 | 0,32 | |

| Clubs | up to 5,000 | 0,37 |

| up to 10,000 | 0,33 | |

| more than 10,000 | 0,3 | |

| Cinemas | up to 5,000 | 0,36 |

| up to 10,000 | 0,32 | |

| more than 10,000 | 0,3 | |

| Theaters | up to 10,000 | 0,29 |

| up to 15,000 | 0,27 | |

| up to 20,000 | 0,22 | |

| up to 30,000 | 0,2 | |

| more than 30,000 | 0,18 | |

| The shops | up to 5,000 | 0,38 |

| up to 10,000 | 0,33 | |

| more than 10,000 | 0,31 | |

| Kindergartens and nurseries | up to 5,000 | 0,38 |

| more than 5,000 | 0,34 | |

| Schools and higher education institutions | up to 5,000 | 0,39 |

| up to 10,000 | 0,35 | |

| more than 10,000 | 0,33 | |

| Hospitals | up to 5,000 | 0,4 |

| up to 10,000 | 0,36 | |

| up to 15,000 | 0,32 | |

| more than 15,000 | 0,3 | |

| Baths | up to 5,000 | 0,28 |

| up to 10,000 | 0,25 | |

| more than 10,000 | 0,23 | |

| Laundries | up to 5,000 | 0,38 |

| up to 10,000 | 0,33 | |

| more than 10,000 | 0,31 | |

| Catering establishments, canteens, factory kitchens | up to 5,000 | 0,35 |

| up to 10,000 | 0,33 | |

| more than 10,000 | 0,3 | |

| Laboratories | up to 5,000 | 0,37 |

| up to 10,000 | 0,35 | |

| more than 10,000 | 0,33 | |

| Fire stations | up to 2,000 | 0,48 |

| up to 5,000 | 0,46 | |

| more than 5,000 | 0,45 | |

| Garages | up to 2,000 | 0,7 |

| up to 3,000 | 0,6 | |

| up to 5,000 | 0,55 | |

| more than 5,000 | 0,5 |

It should be borne in mind that this formula is designed for new buildings in which a standard number of windows (new), doors, the building was originally intended for a certain type of activity and the corresponding production processes. Practice shows that often buildings are already “aged”, have poor insulation in some places, cracks in window frames and doors, and the roof. It happens that buildings have stood for an impressive period of time without heating, when the heat-saving properties of materials deteriorate significantly, etc. If this is your case, then the result that you obtained from the formula should be multiplied by a number of coefficients. 1) Building age factor. If your building is up to 10 years old, then the coefficient is 1. If it is from 10 to 30 years old – 1.3. If the building is older than 30 years, feel free to multiply the calculated capacity by 1.5. 2) Building insulation coefficient. If the building is well insulated, there are no gaps in the windows, doors, gates, coefficient = 1. If at least one of the surfaces (walls, ceiling, floor) or elements (windows, doors, gates) are poorly insulated, take coefficient = 1.3. If two or more elements leave much to be desired, your coefficient = 1.5. Thus, for an old building with poor insulation, the required boiler power may be 1.5 * 1.5 = 2.25 times greater.

FEATURES OF CHOOSING A BOILER FOR GREENHOUSES

To calculate the boiler power for heating a greenhouse, you need to know the heat loss of your greenhouse.

The heat loss itself can be calculated using the following formula: Heat loss = Surface area * K * Temperature difference (°C)

, where:

Surface area (sq.m) - the entire external surface of the greenhouse (roof, walls).

IMPORTANT! For greenhouses, unlike other objects, they take not the area of land that is located under the greenhouse, but the area of all EXTERNAL SURFACES. Temperature difference (degrees) – the maximum temperature difference between the temperature outside and inside the greenhouse. You know the temperature needed to grow certain plants, and the minimum outside temperature can be easily found on the Internet (you need the temperature of the coldest five-day period for your region) K (Watt/sq.m*deg) - the thermal conductivity coefficient of the material. For materials used in the construction of greenhouses, the thermal conductivity coefficient has the following values: Single-chamber cellular polycarbonate 4mm - 3.9 / 6mm - 3.6 / 8mm - 3.3 / 10mm - 3.0 Double-chamber cellular polycarbonate 16mm - 2.3 Glass 3mm - 6.0 Single-chamber double-glazed window 4mm - 1.9 Polyethylene film 1 80 -200 mkm — 7.5 Two-layer inflated polyethylene film 180-200 mkm — 3.5

Separately, I would like to write a little about such a material as polycarbonate. The structure of polycarbonate sheets provides significant advantages where thermal insulation is important. The hollow form provides higher thermal insulation properties with lower heat losses than solid glazing materials. Heat loss is characterized by the thermal conductivity coefficient - this is the amount of heat passing through 1 m2 of glazed area material in 1 hour when the temperature changes by 1°C. The insulating properties of polycarbonate sheets will also help reduce the penetration of cold into the building. The lower the thermal conductivity coefficient, the higher the temperature is maintained on the inner surface of the sheet in winter. Below is an example of the temperature process through a 6 mm thick polycarbonate sheet, at an outside temperature of -10°C and an indoor air temperature of +20°C. If compared with single glass, the inner surface of the glass under the same conditions will have a temperature much below zero, which will affect the overall temperature in the room and will create discomfort near the windows.

Heating devices operating in long-burning mode

Long-burning boilers have been designed to maximize combustion efficiency and the time between loads.

There are two options for such equipment.

- Pyrolysis boilers . Such devices have two or even three combustion chambers. In this case, fuel combustion occurs with a lack of oxygen. As a result, a large volume of flue gases is released, most of them very flammable. These gases enter the next chamber, into which air is supplied. When mixed with oxygen, flammable gases ignite again and produce even more heat than the solid fuel itself.

- Devices with top combustion type . In conventional solid fuel boilers, combustion propagates from bottom to top, that is, most of the load is burned at the same time. Due to too intense combustion, the system quickly overheats, which is not very effective and is uncomfortable for residents. If the top combustion principle is applied, then ignition is carried out only in the upper part of the loaded fuel. In this case, only a small part of them lights up, which significantly extends the combustion life of the fuel. Thus, the temperature in the room is equalized.

The efficiency of long-burning solid fuel boilers is quite high - various designs with wood can operate from 6-8 hours to a day on one load, and with coal - from 10-12 hours to several days. However, such results can only be achieved if very high-quality fuel materials are available. The main thing is that they are dry. Wet coal or firewood will not even be able to smolder, that is, such a boiler will not warm. It is advisable to equip a coal storage shed or wood shed with a supply of 2-3 years. In this case, a long-burning solid fuel boiler will truly be a worthy choice.

SELECTION OF BOILER POWER FOR DRYING CHAMBERS

When selecting boiler power for drying chambers, they are based either on the volume of the drying chamber, or on the volume of raw materials that are to be dried. To select power, you can focus on the following ratios: 1) “Raw materials usually occupy about 20% of the total volume of the drying chamber” 2) “For drying 1 cubic meter. raw materials, about 5 kW of thermal energy is required.” Thus, for a drying chamber, for example, with a volume of 50 cubic meters. meters we need a boiler with a capacity of W=50 cubic meters*20%*5 kW/cub.m = 50 kW. This formula is simplified, although it allows you to quite accurately select the required boiler power. At the same time, if there are strict requirements for the production process, it is necessary to confirm the calculations with the help of a specialized organization.

Liquid fuel equipment

It is worth noting that when selecting a boiler by area, liquid fuel equipment is rarely preferred.

The low popularity of such boilers is due to the following factors:

- high price of fuel;

- the need for a place to store diesel fuel, that is, a large container located close to the house;

- the need to provide heating for the tank so that diesel fuel does not thicken at low temperatures and clog the burner;

- Since the operation of the equipment is accompanied by a high level of noise and an unpleasant odor, it must be installed either in a well-ventilated extension or in a separate boiler room.

In this regard, it is advisable to install an oil-fuel boiler only if you have constant access to cheap fuel.

WHAT OTHER PARAMETERS TO PAY ATTENTION TO?

In general, above we have described quite fully how to choose a heating boiler for you. In this section we will tell you what else you should pay attention to when choosing a boiler.

10.1. Power

Manufacturers often label their boiler models using numbers in the names to indicate the boiler's power. For example, our boiler has a power of 24 kW. But there are also manufacturers who put increased numbers in their models. For example, the model name contains the number 30, and the technical specifications indicate the boiler power of 25 kW. Be carefull.

10.2. Efficiency (coefficient of efficiency)

This indicator lets us understand what percentage of benefit we can get from fuel. The higher this coefficient, the less you will “drown the street” in the future. What you should pay attention to is that manufacturers often indicate maximum efficiency in the technical specifications. In practice, the following results: by reducing the boiler power (when raw wood is used or there is simply no need to heat the boiler to full capacity), in some boiler models (usually these are ordinary direct combustion boilers), the efficiency decreases sharply. In other boiler models (for example, pyrolysis), the efficiency is constantly high.

10.3. Weight, dimensions

These characteristics are worth paying attention to in two cases. First, they directly affect the cost and convenience of delivery and transportation. In particular, be sure to pay attention to the dimensions if your building has already been built and you are limited in the area for installing the boiler. In addition, the dimensions of the boiler are important in order to provide for its transportation through doorways in advance. It would seem that in this case, you need to choose a lighter and smaller boiler. But it is not always the case. A “golden mean” is needed, because The weight of the boiler is often proportional to the thickness of the steel from which it is made, which means reliability and durability. Plus, the dimensions affect the amount of fuel you will put in. But more on that later.

10.4. Fuel

We wrote in paragraph 4 how the quality of fuel affects the required power. Here I would like to note that for users who will heat the boiler with wood, an important parameter is the size of the firewood that can be placed in the firebox. Standard firewood has a size of 48-52 cm. So, a good indicator for the boiler would be the ability to lay firewood from 50 cm or more. In this case, you will save a lot of time and effort.

10.5. Warranty period and service life

Two more indicators that are worth paying attention to. Boilers with a 1-year warranty should alert you. Well, the service life for such a serious purchase as a boiler should be at least 10 years.

10.6. Price

Everything seems to be simple here. Whatever budget we have allocated, we will buy such a boiler. The only thing you should always take into account is that in addition to the boiler, you will need to purchase a chimney, piping elements, and materials for the heating system. Plus, investments will be required to install the boiler and heating system. Typically, these costs are several times higher than the cost of the boiler. And one more thing... a good practice when choosing a boiler is the following: look not at the price of the boiler, but at the difference in price of the selected boilers, and what benefits the manufacturer offers you for this difference. Sometimes it happens that the difference in price is 5,000 rubles, but for this money you won’t have to go to the boiler every night to add firewood. And this is over 10 years of boiler service. Are you ready to pay 5,000 rubles for 10 years of good nights?

10.7. Equipment

The boiler is fully equipped if it is supplied with: grates, measuring instruments, automation devices, chimney adapter, gaskets, fasteners, technical data sheet, warranty card. In other words, the boiler should be sold in such a way that you don’t have to buy anything for it except the chimney and elements of the heating system. Some suppliers sin by reducing the cost of the boiler to attract a buyer, but will charge money for additional equipment, as a result of which the total cost may be more expensive. Pay attention to this.

Pellet boilers for home

Due to the design features of pellet boilers, they are classified as a separate class. The fuel for such devices is sawdust compressed into granules. As a rule, a special shed or bunker is allocated for storing pellets near the boiler. The length of independent operation of the equipment depends on the size of such a bunker. Typically, about two buckets of pellets are required per day of work.

A special burner is installed in a pellet boiler, which allows you to burn fuel almost completely. If the granules are of high quality, then about 3-5% of ash is formed as a result of combustion. Therefore, cleaning the firebox is required only once a week or even several weeks. Thanks to the automation of the equipment, it can work autonomously for several weeks.

Among the disadvantages of modern pellet boilers are the high price and sensitivity to fuel quality. Pellets must be durable, not crumble or break, have low ash content and good calorific value.

In general, when selecting a boiler based on the area of the house, a pellet appliance can be a good option if there is enough fuel for it.