Home / Gas boilers

Back

Published: 05/22/2019

Reading time: 2 min

16

60401

Gas boilers are designed to create comfortable living conditions. Double-circuit units provide the living space with heat and hot water at the tap. But it happens that a working boiler does not heat the water well and does not provide the necessary comfort.

The efficiency of the entire heating system depends on how the boiler operates. If there is a problem in the gas boiler itself, this can negatively affect the efficiency of the entire system and cause excessive consumption of energy resources. What happens when the boiler stops heating water? Let's look at the reasons and ways to solve this problem.

- 1 How does a boiler work?

- 2 The boiler does not heat water for heating

- 3 The boiler does not heat water for hot water supply

Operating principle of the boiler

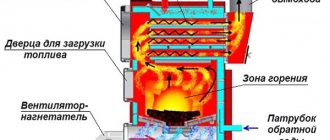

To understand the causes of the breakdown, you need to understand how the boiler works. Double-circuit devices “Ariston”, “Baksi” and other models have several blocks. In the gas unit, ignition and combustion take place, the water unit is responsible for the water supply and pressure in the line. The smoke exhaust unit removes combustion products to the street.

As soon as you start the boiler, the pump is activated, which pumps water into the system. The gas valve opens. The liquid circulates through the tubes of the heat exchanger, and the burner evenly heats its body. Sensors control the heating process. As soon as the temperature reaches the set temperature, the gas supply is turned off and heating stops.

When the temperature begins to decrease, the sensors will send a signal to the control module - the heating cycle will start again.

When the mixer is opened, the flow sensor is activated. It signals the board to switch the three-way valve to DHW heating. When the mixer closes, the valve switches to the heating system. Some models are equipped with a “quick start” mode. Then the valve periodically switches, heating both the first and second heat exchangers.

Gas filter clogged

It is installed at the inlet of the boiler to further filter the incoming gas. Protects heating equipment from substances that cause malfunctions. A clogged gas filter delays the flow of gas, which reduces the combustion force, and accordingly the temperature in the house will drop.

The degree of contamination is assessed visually when the filter is unscrewed from the boiler. It is necessary to perform such a manipulation when the equipment is completely turned off.

Attention: A dirty filter must be replaced with a new one.

The main problems are why the boiler does not heat water

More often, boiler problems are detected during the heating season, when both circuits of the device are operating. There are two main problems that owners of wall-mounted gas boilers such as Ariston face:

- all boiler systems are working, the device turns on, but heats the water poorly or does not heat at all;

- the boiler does not start and, as a result, no hot water is supplied.

Each of these problems has its own causes and solutions. To troubleshoot problems, you need to figure out what caused them and what caused them.

Before finding out the reasons for the malfunction of the unit, you should look at the operating manual, read the instructions and check that the settings and connections of the device are correct.

Note! Modern gas boilers are equipped with a diagnostic system that detects faults and displays an error code on the display. The instructions for the unit will help you decipher the codes.

If all requirements and conditions are met, the most common causes of malfunctions should be considered:

- Blockage. Experts say that using unfiltered working fluid increases the risk of clogging the heat exchanger pipes. The resulting scale reduces its thermal conductivity, which causes the unit to operate with excessive energy consumption. In this case, the optimal temperature regime is not achieved even with continuous operation of the device. Due to limescale deposited inside the heat exchanger pipes, the metal is subject to corrosive changes, which can lead to its rupture.

- Faulty pump. The circulation of the coolant may be stopped due to the accumulation of air, the so-called air lock in the pump. The second cause of a pump malfunction may be a rotor that is jammed. A circulation pump that stops functioning can lead to overheating of the gas boiler.

- The flow sensor is stuck. Inside the boiler there is a sensor in the form of a turbine, resembling a small fan. When the turbine rotates inside the sensor, an electrical pulse is generated due to the fluid flow, which is supplied to the control unit. This way the electrical system understands that it needs to warm up the coolant.

- The three-way valve is stuck. Such a malfunction will not allow you to switch the water supply from heating to DHW. Valve stoppage can occur due to blockage, either in the part itself or in the gas hose or filter.

- Insufficient pressure. If the volume of liquid in the system does not create the required pressure, the water supply valve does not open, which leads to burner ignition failure.

When you know the reason why the boiler does not heat the water, you can try to eliminate it yourself. Manufacturers often make mechanical components available for self-service.

Important! When troubleshooting problems on your own, before starting work, you must disconnect the unit from the electrical power supply and free the internal components from the coolant.

Further on the situation:

- If the heat exchanger is clogged, you can clean it using special liquids, or using proven home remedies for descaling. In the future, it is better to use filter devices at the coolant inlet to the boiler.

- If the cause is a faulty pump, you should disassemble it and inspect the rotor. If foreign particles are found that block free movement, they must be removed. The filter should also be inspected for clogging.

- When the cause of the malfunction is the water flow sensor, it is necessary to remove from it the part containing the turbine inside. If, when rotating with your finger, it begins to click or slow down as it moves, this means that there are foreign particles in the body. You should try to flush the turbine and clean each of its blades using a cotton swab dipped in cleaning fluid.

- The three-way valve, if it caused a boiler malfunction, also needs to be cleaned, and at the same time check the gas hose and filter.

- If the pressure is low, you should check all fittings and valves on the device, the pressure with which water flows from the mixer. If there are no leaks and the pressure is weak or absent, then simply replenishing water in the expansion tank will help solve the problem.

One of the main tips is to follow the operating rules and follow the manufacturers' recommendations.

It is important to remember that prevention is always more profitable and better than repair. Timely maintenance and checking of the main components of the system will extend the service life of the autonomous heating device

As you know, the boiler is filtered from various impurities using a mesh filter that traps debris with rust particles. The lattice top gasket becomes clogged, and a lump of debris prevents the fluid from flowing freely. Therefore, it can end at one moment.

To resume normal boiler filling, you need to remove the plug, wash the mesh and return everything back. There are replaceable types of filters that are filled with helium or air. Bad material leaks out and clogs the water pipes. Buying a normal water supply filter or cleaning the water intake pipes with a brush will help save the situation.

Three-way valve

A three-way valve is installed in boilers with two heat exchangers. When a signal is received from the flow sensor, the electronics gives a signal to the valve and the heated water from the first heat exchanger is sent to the second heat exchanger, where the heat is transferred to the passing tap water. If, for example, no actual switching occurs (the valve is faulty), then the coolant will continue to circulate in the heating circuit and no heat transfer to the hot water circuit will occur.

If, for example, a valve only partially closes the heating circuit due to a malfunction, then there will be problems with insufficient heating of hot water, since part of the heat will go to the heating system.

DHW does not heat up - causes and troubleshooting.

The most common reason why DHW does not heat up is severe scale formation inside the heat exchanger. Scale not only narrows the water flow in the heat exchanger, it significantly reduces the water temperature.

The reason for this is that the thermal conductivity of scale salts is many times less than the thermal conductivity of the metal from which the heat exchanger is made. The unit does not produce (does not supply) hot water or it flows poorly if a piece of plaque has broken off and blocked the flow of liquid.

Hot water does not flow into the tap when the flow sensor does not work. It is a fan that works when water flows through it. in this case, the signal from it is sent to the control board, which gives a command to heat the water. The sensor may become clogged; it can be cleaned without dismantling it.

The sensor is a cylinder located near the circulation pump. To clean, simply open and close the tap in front of the device. If this procedure does not produce results, you will have to dismantle it, clean it and put it in its original place. If the sensor is not working, you will have to replace it.

If the three-way valve is faulty, the unit will not produce hot water. The purpose of the three-way valve is to shut off the heating system when the hot water tap opens. When the valve does not switch, the boiler continues to heat water for heating.

The cause of a valve malfunction may be a simple blockage, for example, a piece of rust. If the problem is more serious, replace the valve with a new one. In addition, one of the simple reasons why hot water does not flow from the tap may be a clogged gas hose or gas filter.

Sectional view of a three-way valve

With heating this will not be so noticeable, but at the temperature of the water from the tap it will be more noticeable. Clean the hose and filters. Some of the points listed above may also be the causes of problems with heating and hot water in wood, electric and solid fuel (ST) boilers, provided the design details are similar.

Problems with the Navien gas boiler and methods for solving them

Navien boilers are gas water heating equipment from a manufacturer from South Korea, widely used among consumers in our country. When the heating boiler does not heat well, the reasons may be one of the following situations:

- If the Navien equipment does not start, the problems may be hidden in the lack of electricity in the network or in a malfunction of the gas supply line. If such a situation occurs, it is worth checking the voltage, and, if the reason is the gas supply, contact specialized services.

- If the boiler has stopped heating hot water, you should clean the heat exchanger following the algorithm described above.

The video explains how to clean the internal parts of the unit from scale.

- If the internal parts of the unit are cleared of scale and other deposits, but the boiler still does not heat, it is necessary to look at the condition of the strainers, the performance and settings of the pump group, and also check the system for the formation of an air lock. As a rule, when airing, the device first gains temperature, but then slowly drops it to its original values.

Gas boiler equipment "Navien" https://otoplenie-expert.com/wp-content/uploads/2019/03/kotel-gazovyy-dvuxkonturnyy-nastennyy-6.jpg

- If the boiler does not heat the water, the reasons may lie in a malfunction of the turbocharging in a closed combustion chamber. In such cases, you should check the fan, replace the bearings, clean the axle, and, if necessary, buy a new device.

The video lists the probable reasons why boiler equipment does not heat water

Any water heating unit that is used in a heating system must be in good working order and sealed. If the Baksi boiler does not heat the water, or the same problem occurs with Navien or another brand of equipment, but the tank leaks when the lid is opened, you should look for the reasons in the device itself. As a rule, the problem is solved by calling the service department using the warranty card.

When the Solly gas boiler does not turn on hot water, it is necessary to additionally examine its built-in circulation pump. If solid sediment is found on the impeller of the device when opening the housing, it should be cleaned or the pump replaced.

Gas boiler equipment Baxi https:///upload/iblock/4ea/4ead7eb3e4d52cffa45b3b226c346cd6.jpg

In the video about problems that may arise during operation of the Navien boiler

Vaillant boiler does not heat hot water due to blockages

This is one of the most common problems. Most often, the reason is poor water quality - scale appears, units, filters and pipes become clogged.

If the flame does not light up in the boiler, start checking with the flow sensor. Finding this cylindrical device is quite simple. The flow sensor is located near the pump; the wires go to it. There are two sensors installed near the pump:

- Pressure sensor in the heating system.

- Flow sensor.

The flow sensor looks like a small fan; it begins to rotate as water moves through the pipes. If the flow sensor detects the movement of water, the automation receives a signal to turn on the gas and heat the water. If the flow sensor is clogged, water will flow but the fan will not move. Accordingly, the signal to turn on the heating is not received. There are two ways to solve the problem:

- Don’t rush to disassemble the boiler and try to “blow out” the system first. Turn off the main water supply valve to the house. Open the hot water tap and drain the system. Now the percentage of air in the pipes has increased. Start sharply opening and closing the water tap immediately in front of the boiler. These simple manipulations will help create pressure and clear the flow sensor fan of debris.

- If “blowing” does not solve the problem, you need to open the boiler, unscrew the flow sensor and clean it manually.

If the Vaillant boiler does not heat hot water, you should check the secondary heat exchanger. It also tends to get clogged quickly. But, fortunately, it can be easily removed, cleaned and reinstalled.

A clogged three-way valve can also cause the boiler to fail to heat water. And you can remove this unit yourself, clean it and install it back.

Having purchased a Vailant boiler, be sure to find out from the seller information about the places where the filters are installed. You can clean and change these components yourself.

Heating of water in a Vailant boiler largely depends on the operation of the pump. To repair or replace this unit, you must call a specialist. But, you can check for yourself whether this is the reason for the boiler’s failure to work.

Set the water temperature on the boiler to 0 °C and turn on the water heating mode. During this time, monitor the operation of the pump. If after 20 minutes of operation it does not heat up, then the problem is with the pump.

The reason for the boiler’s failure to heat water may also be due to a simple loosening of the bolts at the connection areas. Carefully examine the boiler diagram and check that all connections fit tightly. Perhaps simply tightening the bolts will solve your problem.

Use a recirculation pump

The best option is that the water heater is located in close proximity to the hot water intake points. The closer it is, the faster the hot water enters the tap, the more efficiently it is used. If this option for installing a water heater is not possible, then it is recommended to install a recirculation pump.

The pump is installed in the section between the water heater and the hot water intake points, ensuring the slow movement of hot water through the pipes. In addition, if you install a heated towel rail in this section, it will perform its direct function at any time of the year, regardless of the operation of the heating circuit of the boiler.

Possible nuances

Today there are many gas wall-mounted boilers from various manufacturers on the market. The principle of operation of the units for all models is essentially the same, but each brand has its own nuances that may be related to the causes of malfunctions and, as a result, poor water heating.

- "Ariston" is an Italian brand that is distinguished by its reliability. The brand’s boilers are adapted to domestic utilities and operating conditions. The most common cause of malfunctions is hard water, which contributes to the formation of blockages in the heat exchanger and circulation pump.

- "Navien" - Korean autonomous gas boilers. They are easy to use and effective. A special feature of the modification is the presence of two heat exchangers and the absence of a control panel on the body. The reason why the Navien boiler does not heat hot water well may be a stop in the operation of the equipment. This is due to the air pressure sensor, which, in the presence of reverse draft in the smoke exhaust unit, sends a signal to the control board, which causes the gas supply valve to the burner to close.

- "Vailant." German quality is fully reflected in the units under this brand. Since the device is of European origin, its heat exchangers most often suffer, becoming clogged due to the poor quality of the conductive heat fluid.

- “Baksi” is another representative of Italian manufacturers of autonomous heating equipment. He has simple and reliable boilers. The main reason why the Baksi does not heat the water, as noted by specialists servicing such units, is a manufacturing defect, which is sometimes found in this model line - a South Korean manufacturer. He provided a certain algorithm for controlling heating equipment. Incorrect settings may be the answer to the question of why the boiler stopped heating water.

- Proterm is a subsidiary of the German company. When operating these boilers, you need to monitor the quality of the heat-conducting fluid and use cleaning filters to prevent clogging of the heat exchanger.

- “Buderus” is another “German” in the domestic market of autonomous heating equipment, which has proven itself on the positive side. Like all Europeans, malfunctions can be caused by the formation of limescale inside the heat exchange system, as well as clogging of the working fluid flow sensor.

Conclusions and useful video on the topic

The following video will show you how to clean the flow sensor:

A double-circuit gas boiler is a rather complex device, the repair of which is not always possible with your own hands. But if problems arise with the water supply, then, based on the material presented, you can independently identify the cause of the breakdown.

Knowing which components and parts affect the operation of the hot water supply and taking appropriate preventive measures in a timely manner, you can ensure long-term and uninterrupted operation of the equipment.

Would you like to tell us how you restored the operation of the hot water preparation circuit with your own hands? Do you have useful information on the topic of the article? Please write comments in the form below, ask questions, post photographs on the topic of the article.

Why there is no hot water coming from the boiler - a description of the reasons

The most common reasons why hot water does not come from the boiler:

- The coarse filter at the boiler inlet is clogged. If you have old pipes or the water is too dirty, the strainer will become clogged over time. You need to disassemble it and clean it or replace it with a new one. To do this, remove the plug from the flask using a key and remove the mesh. Installing an additional filter also solves the problem.

- The check valve is stuck. This can happen due to debris getting into it. You need to disassemble it and move the stem. Since it is connected directly without shut-off devices, all liquid is drained before this.

- Cold water does not flow from the tap. Even if the device is completely filled with liquid, if there is no pressure in the water supply, warm water will not flow out, since it is taken from above the tank and moves due to pressure. To check, open the cold tap and, if necessary, call the utility services.

- The pressure reducer is broken or incorrectly adjusted. The storage water heater produces the same pressure as it receives at the inlet. If there is pressure in the tap, but warm water flows poorly, check the pressure reducer and, if necessary, adjust it or replace it with a new one. Household pressure reducer

- A lot of scale has accumulated in the tank. If the water heater is equipped with an open heating element, for example Termex ER 80 H, then it must be cleaned regularly. If this is not done at least once a year, then salt deposits can block the hole through which cold water flows. You need to remove the protective cover, disconnect the wires, and pull out the heating element. Clean it by soaking it in a solution with citric acid and rinse the tank from the inside. To make scale easier to clean, magnesium anodes are installed inside.

- One of the input or output valves from the device is broken and does not open.

- The pipes are clogged. Poor quality water can clog water pipes. This happens especially often in places where they are folded. It is recommended to replace all old pipes with polypropylene ones.

- The mesh on the faucet spout may become dirty. In this case, the pressure will be weak for both cold and hot water. It is removed and cleaned or replaced with a new one.

Before carrying out repair work yourself, you should turn off the water supply valve to the room and disconnect the device from the network. If you cannot eliminate the cause of the breakdown yourself, contact a specialist.

How to descale a boiler

As stated above, the most common reason why a gas boiler does not heat water, although the heating is working, is a layer of scale that can accumulate on the internal contact surfaces of the storage part of the unit and the heat exchanger for years. In such cases, the following steps should be taken:

- The shut-off valves of the gas installation are closed, and the coolant remaining in the storage tank is drained through the drain valves.

- The front cover is removed, which opens access to a removable plate leading to the interior of the device.

Cleaning the heat exchanger https:///wp-content/uploads/2021/01/img_16120500346180-1-1024×576.jpg

- If boilers do not heat water, large amounts of lime and salts accumulate on their internal surfaces. Do not attempt to scrape off hard deposits, as sharp objects and abrasives can damage the soft metal of the heat exchanger.

- To clean metal and plastic parts from scale, use a 5%–10% solution of acetic or citric acids.

- This substance treats all elements covered with deposits. After 6–24 hours, depending on their thickness, the plaque softens and is easy to remove with a brush with soft polymer bristles.

If, even after cleaning, the boilers do not heat hot water, the cause of the malfunction should be looked for elsewhere. However, according to statistics, this is precisely the most likely cause of poor heating of the coolant or hot water supply.

Thermostat device

Another common reason for the heating boiler turning off and on frequently is the lack of a thermostat. This means that the device is regulated only by the temperature of the coolant. When the water is heated to the desired temperature, the boiler turns off. And after the water begins to cool, the boiler turns on again. But the problem is that the air in the room takes longer to cool than the coolant. With this method of controlling the device, fuel consumption increases significantly. And the air temperature in the room will be elevated, and it will be uncomfortable to be in it. Therefore, it is necessary to install a thermostat. With its help, the heating gas boiler will be automatically controlled. After installing a room thermostat, fuel consumption will decrease and heating will become more comfortable and efficient.

After the air temperature in the room becomes below comfortable, the gas boiler will turn on. Thus, the air in the room will always be comfortable, and fuel will not be consumed more than expected.

There are many thermostat options on the market that come with varying prices and features. Budget options would be mechanical room thermostats. But they are reliable and do not require special care during operation. Modern programmers have a more complex device. They can be given different options and set different temperatures.

In order for the heating system to function correctly and not consume excess fuel, it must be installed correctly. If the boiler is controlled by a room thermostat, then you will not need to monitor the device’s switching on and off. This way, you will save on fuel consumption, and the gas boiler will last longer.

Operating principle

The manufacturer uses metal to make the Baxi combustion chamber. On the outside it is covered with a layer of heat insulation. Above it there is a heat exchanger, which is made of copper. When there is a change in temperature in the room, the thermostat turns on. Please note that the launch is carried out automatically. From it the signal to turn on is transmitted to the pump. The latter creates a vacuum in the return pipeline. After this, heated water begins to flow into the heating system line under a pressure not exceeding 0.45 bar.

The boiler starts at low power. It gradually increases until the temperature of the coolant increases to a given value. After this, the mode changes - from heating to modulation mode . When the coolant temperature decreases, a signal is received from the temperature sensor, which leads to the opening of the inlet valve. After this, ignition occurs, and then the water is heated again.

If already at the beginning of the boiler operation its power is quite high, then the burner is switched off automatically. After three minutes, you can restart the system.

If there is no need for heating the room, then the boiler is turned on in DHW mode. In this case, cold water enters the secondary circuit through a three-way valve, through which the heating line is closed. supplied to the burner through a gas valve , which leads to a gradual increase in boiler power. After heating the water, the temperature control mode is activated.

BAXI Forum

The largest professional forum BAXI in Russia

- Unanswered topics

- Active topics

- Search

- Users

- our team

- Acknowledgments

- 08/30/2021 — The BAXI 3Q seminar book has been published. 2021 (18 MB). Download

- 04/16/2021 — The conference has been moved to a separate subdomain. Now we are at forum.baxi.ru.

- 11/15/2019 — A separate section on the forum has been allocated for discussion of the ZONT device.

- 07/19/2019 — The BAXI seminar book 3Q was published. 2019 (119 MB). Download

- 06/20/2019 — BAXI Energy voltage stabilizers are on sale.

- 04/16/2019 — Sales of BAXI Eco Nova boilers have started.

- 11/16/2018 — The BAXI 4Q seminar notebook was published. 2018 (8 MB). Download

Why do batteries warm up poorly in a private home?

Just as in the case of a high-rise building, there may be several reasons for the poor performance of heating batteries in a private house.

Reason 1: problems in the hydraulics of the heating system

The most common reason why radiators remain cold is due to the hydraulics of the heating system. In this case, one of the heating branches is working properly, and the second is intermittent. This picture is typical for a new heating system or when adding radiators to an existing one. If the hydraulics are incorrectly calculated, and in particular the diameters and lengths of pipes, some batteries may simply not heat up. You can adjust the hydraulics using special taps.

Reason 2: single-pipe heating system

In many private homes there are single-pipe heating systems. In such a system, batteries remote from the boiler often heat much worse than those nearby. This does not mean that there are problems; this is the nature of the operation of a single-pipe system. The only solution here can only be to replace the system with a two-pipe one.

Reason 3: boiler malfunction

The batteries may not warm up due to malfunctions in boilers with built-in automation, pumps and sensors, which is a typical problem for autonomous heating systems. In this case, you must contact a specialist who works with such equipment directly.

BAXI Forum

The largest professional forum BAXI in Russia

- Unanswered topics

- Active topics

- Search

- Users

- our team

- Acknowledgments

- 08/30/2021 — The BAXI 3Q seminar book has been published. 2021 (18 MB). Download

- 04/16/2021 — The conference has been moved to a separate subdomain. Now we are at forum.baxi.ru.

- 11/15/2019 — A separate section on the forum has been allocated for discussion of the ZONT device.

- 07/19/2019 — The BAXI seminar book 3Q was published. 2019 (119 MB). Download

- 06/20/2019 — BAXI Energy voltage stabilizers are on sale.

- 04/16/2019 — Sales of BAXI Eco Nova boilers have started.

- 11/16/2018 — The BAXI 4Q seminar notebook was published. 2018 (8 MB). Download

Modulation errors on the burner

To heat running water, in most cases a boiler power close to maximum is required. In modern boilers, the burner power is regulated over a wide range. The adjustment occurs by changing the amount of gas supplied by the gas valve. The amount of adjustment is determined by the control board depending on the operating logic and settings. The process can be observed visually by the height of the flames on the burner.

If the boiler settings are set to 100% boiler power in DHW mode, but visually the flames on the burner are weak, or obvious interruptions are visible, then you should check:

setting the gas valve (static and dynamic gas pressure)

Such checks should only be performed by a qualified person.

What to do if the engine overheats

First of all, it should be remembered that if the overheating is short-term (for example, the temperature needle rises in a traffic jam), then you should observe whether the temperature will drop after you start driving (counter air flow appears) or as a result of turning on the radiator fan.

If the car was already in motion and the engine temperature reached a critical level, you should not immediately turn off the engine. Also, you should not try to cool the engine by pouring water on it from outside, pouring cold water into the radiator, etc. Such actions will lead to the need to repair the internal combustion engine, and it may be necessary to change the BC and cylinder head.

To “cool down” the engine, you will need to pull off the road (if possible), stop the car and then turn the heater on to maximum, while the engine must continue to idle.

Next, you need to wait a few minutes, while simultaneously inspecting for obvious and strong signs of antifreeze/antifreeze leakage under the car or in the engine compartment. If no leaks are visible, but the temperature does not drop, the unit must be turned off.

Please note that you need to immediately turn off the engine when steam starts coming out from under the hood; traces of intense coolant leakage are clearly visible. In this case, the engine must be stopped, without expecting that turning on the stove will reduce the heating. https://youtube.com/watch?v=0swgbqh-RkU

https://youtube.com/watch?v=0swgbqh-RkU

BAXI Forum

The largest professional forum BAXI in Russia

- Unanswered topics

- Active topics

- Search

- Users

- our team

- Acknowledgments

- 08/30/2021 — The BAXI 3Q seminar book has been published. 2021 (18 MB). Download

- 04/16/2021 — The conference has been moved to a separate subdomain. Now we are at forum.baxi.ru.

- 11/15/2019 — A separate section on the forum has been allocated for discussion of the ZONT device.

- 07/19/2019 — The BAXI seminar book 3Q was published. 2019 (119 MB). Download

- 06/20/2019 — BAXI Energy voltage stabilizers are on sale.

- 04/16/2019 — Sales of BAXI Eco Nova boilers have started.

- 11/16/2018 — The BAXI 4Q seminar notebook was published. 2018 (8 MB). Download

Basic information about the design of the heating system

The heating system comes in two types: one-pipe, the so-called Leningradka, and two-pipe. In apartment buildings, single-pipe is predominantly used. The vast majority of individual properties and recent new buildings use a two-pipe system.

In a single-pipe system, the coolant enters a single riser, from where it is distributed to the radiators. Supply is carried out from the first or last floor, which is not of fundamental importance. Bypasses are used to ensure uniform water supply to all batteries. Thanks to them, the required amount of water enters the radiator, the rest moves to the next sections. The disadvantage of a one-pipe system is that batteries that are located closer to the inlet or boiler warm up better. The furthest ones in the system may not warm up enough.

In a two-pipe system, each radiator is independently connected to two risers. Hot water is supplied from one, cooled water goes to the other. Ignorance of the features of heating systems of various types sometimes leads to dire consequences, especially when unskilled workers are involved in repairs.

Infrequently, but there are cases when old batteries in a single-pipe system are replaced with modern aluminum ones. The expected effect does not occur, because aluminum appliances are designed for a two-pipe system, the coolant current weakens. Moreover, due to poor water circulation, they become clogged. There is only one way out - to repair old batteries or install new ones suitable for a single-pipe system.

BAXI Forum

The largest professional forum BAXI in Russia

- Unanswered topics

- Active topics

- Search

- Users

- our team

- Acknowledgments

- 08/30/2021 — The BAXI 3Q seminar book has been published. 2021 (18 MB). Download

- 04/16/2021 — The conference has been moved to a separate subdomain. Now we are at forum.baxi.ru.

- 11/15/2019 — A separate section on the forum has been allocated for discussion of the ZONT device.

- 07/19/2019 — The BAXI seminar book 3Q was published. 2019 (119 MB). Download

- 06/20/2019 — BAXI Energy voltage stabilizers are on sale.

- 04/16/2019 — Sales of BAXI Eco Nova boilers have started.

- 11/16/2018 — The BAXI 4Q seminar notebook was published. 2018 (8 MB). Download

Piping causes low heat

Failures in the heating mode are typical for a two-pipe heating system. In this case, the supply line that distributes the coolant to the radiators does not heat. Identification of the “problem” area can be done by measuring the temperature on the surface of the pipes or a thermal imager.

Natural circulation

What could cause such problems? If the heating does not heat well, the slope of the line may not be observed. This only applies to natural circulation systems. According to the standards, the slope of the pipes should be 10 mm per 1 m.p. In addition, the direction is taken into account - from the accelerating riser to the radiators. For the return pipe, the slope must be towards the boiler.

At the first stage, it is necessary to measure this indicator using a building level. If it meets the standard, but the heating radiator does not heat, there is a possibility of air pockets forming. In this case, an integrated approach is recommended, which includes the following steps:

- Measuring the angle of inclination. If necessary, change it to the required value;

- Flushing pipes to remove limescale;

- Filling the system with coolant with open Mayevsky taps on the radiators.

This technique will eliminate the low heat transfer rate of the heating system.

Forced coolant circulation

For a system with forced movement of water in pipes, the formation of air locks can be avoided by using an air vent installed at the top of the system. In part, it performs the functions of an open expansion tank, but it does not reduce the pressure in the pipes to a critical level. Its absence is an indirect cause of poor heating of the radiator.

The specificity of closed heating systems is that it is not necessary to comply with the installation level of the pipes. However, when the critical heating level of the coolant is exceeded, steam is released, which is the main cause of air locks. Since air has a lower density than water, it will concentrate in the upper region of the pipeline sections. If heating radiators in a closed system do not heat well, the reason may be a decrease in the volume of coolant in the pipes due to air resistance.

What needs to be done in this case? First of all, check the functionality of the air vents. If the valve is idle for a long time, it may become covered with limescale, which makes it impossible to open it under air pressure.

In addition to this factor, it is necessary to take into account the excess of hydraulic resistance in the system. This is why the heating battery does not heat if the initial calculation is incorrect. Therefore, before you begin installing a new system or upgrading an old one, you should perform the calculation of the operational and technical parameters:

- Selection of pipes of the appropriate diameter - the larger it is, the lower the hydrodynamic resistance. However, this increases the volume of water;

- The likelihood that a two-pipe heating system will not heat is significantly less than that of a single-pipe one. Therefore, it is preferable to install radiators with parallel connections;

- Heating of the heating circulation pump occurs due to incorrectly selected power. It directly depends on the calculated hydrodynamic parameters.

The video shows the main reasons for poor radiator heating for a single-pipe heating system: