Is it possible to make heating using a water heater?

Initially, the idea seems difficult to implement, but with proper calculation and proper implementation, it is quite possible to heat a house using a boiler. It is important to consider several nuances here

- the capabilities of this equipment will be sufficient to service small areas on average from 30-100 m2

- A prerequisite for the operation of such a system is the connection of a circulation pump

- in some cases, it will not be possible to provide both hot water supply (DHW) and heating from a boiler made by yourself due to the limited resource of this device

- special attention should be paid to the issues of thermal insulation of the storage tank, as well as the heated room

For the most efficient operation of the complex, it is important to accurately calculate all the parameters of the future homemade boiler, additional devices, and the engineering system itself.

Main technical characteristics

- Power. Its choice depends on the heated area. On average, the calculation is taken from the ratio of 1 kW boiler – 1 m2 of room area.

- Storage tank volume. The amount of coolant in the system directly depends on this indicator, so the larger it is, the more productive it will be. The best option is to choose a container of 300 liters or more.

- Location of pipes. It is advisable that the cold water inlet be at the bottom and the hot water outlet at the top of the housing. In this case, heating from the boiler will be effective since the scheme with opposite placement of connections implies the impossibility of mixing flows with different temperatures. As a result, the maximum heated coolant will flow from the device into the system.

- Diameter of connections. Most often, ¾-inch pipes or flexible connections are used to install a water heater. To install a heating complex, it is recommended to use wiring with a diameter of 2 inches.

- The degree of branching of the complex. The fewer circuits and consumers, the easier it will be to maintain a comfortable temperature.

- Circulation pump flow. Determines the ability to pass a certain volume of working medium per unit of time. The larger it is, the faster the coolant will move through the pipeline.

What will you need?

You will need a small set of tools, materials, diagrams, and design sketches of heating boilers.

Tools

The issue of tools is not as important as the level of skill of the master. The simple skills of a novice welder in a garage workshop will not be enough. Above average level required. The reason for the requirements is work at high temperatures and hot water pressure. If the welds are not of sufficient quality, leakage and rupture are likely.

The following tools will be required:

- Inverter welding machine

- Semi-automatic welding machine

- Angle Grinder

- High speed drill, metal drill set

- Devices for fixing parts during welding - clamps, clamps

- Welding table

- Welder mask

- Pneumatic spray gun

Materials

If you do not pay due attention to the quality of materials, the structure made as a result of many hours of labor will not live up to expectations and will fail after several days of use. Leaks in the water jacket appear more often, and the smoke circulation system begins to pass smoke through the welds.

Problems can only be avoided by using high-quality materials:

- Sheet steel of heat-resistant grades

- Seamless pipes

- Construction fittings

- Asbestos sheets, sealing cords

- Gas, water fittings, pressure gauges, bimetallic thermometers

- FOM tape

- Heat resistant paint

Project

A number of operating diagrams and sketches with dimensions of the most practical, technologically simple heating structures are presented.

Solid fuel boiler - diagram, main dimensions Diagram with dimensions of the simplest heating boiler

Advantages and disadvantages of heating using a water heater

Like any system, this one has its pros and cons. Let's consider the benefits

- reduction of cash costs for the purchase of equipment. Boilers are an order of magnitude more expensive than heaters, and using an old tank will generally reduce costs to a minimum

- ease of installation. Installing heating from a water boiler only with your own hands without involving third-party specialists is a completely solvable task

- minimal energy loss. Any heater model includes a thermal insulation layer, which is almost always absent from the boiler.

The disadvantages of such a complex include the low power level. It will not be possible to achieve high performance, even if you use a device with a high-performance heating element and a significant tank capacity. The maximum that the design is capable of is the preparation of coolant for hot water supply and heating of a small private house, cottage, or apartment. In addition, the life of the boiler is not designed for uninterrupted operation, which is necessary to maintain a comfortable temperature in the premises. Operating at maximum capacity can lead to a significant reduction in its service life.

Boiler based systems

For those who do not have the opportunity to purchase a boiler, there is an alternative option - a water heating device. Electric heating of a private house based on a boiler will cost a little less, but it will also have more disadvantages. Also, the boiler cannot be used in every situation; for this, certain conditions must be met. However, there are a number of cases when heating a private house with electricity based on a water heater will be no less functional than a system based on a boiler.

Heating a house using a boiler

Selection of design and materials for installation

First of all, you need to decide on the type of water heater that will act as a boiler. This characteristic will largely affect the installation and connection algorithm. Here you can use one of three types of equipment

- Gas. In order for heating from a water heater equipped with your own hands to be energy efficient, it is recommended to use flow-through devices that operate online. They usually have sufficient power and performance, in addition, gas as a fuel is economical. When organizing such a system, it is important to pay special attention to safety issues, since overheating, burner extinguishing or lack of draft in the chimney can lead to emergency situations.

- Electric. In this case, the heat generator is created on the basis of a storage tank with a heating element. It is better to choose models with a “dry” heating element, as they are less susceptible to corrosion. It is also necessary to take into account its power, which should be from 8 kW. It makes no sense to install devices with smaller parameters in the heating system. It is also important to pay attention to the condition of the wiring, which must be able to withstand peak loads. It would be a good idea to calculate the operating costs of the complex, since electrical equipment is more expensive than fuel-powered units.

- Indirect heating. Such equipment is a storage tank equipped with a coil that is connected to the boiler. The heated working medium circulates inside this tube. In this scheme, the boiler acts as an energy accumulator, which, after turning off the main unit, heats the coolant in the coil. Here, heating from a water heater is created with your own hands to increase the power of an existing complex. At the same time, it is possible to provide hot water supply in full. The main thing is to correctly calculate the tank capacity.

Boiler as a boiler. Boiler design features

In order to correctly organize the electric heating of a private house, operating on the basis of a boiler, you must first study its design features. The main element of a water heating device is a storage tank. The process of heating the coolant occurs in it.

In order for such a heating system to be more efficient and to be able to set the most optimal temperature conditions in the room, it is necessary that the storage tank be as large as possible.

The tank contains a device called a heating element. It is necessary for the water in the tank to heat up to the required temperature. Such a device operates in autonomous mode, and as soon as the water in the storage tank heats up to a certain temperature, the heating element will automatically turn off. Most modern boilers are distinguished by the fact that the storage tank is additionally placed in a special protective housing. Between the walls of this housing and the walls of the tank, material is placed that is necessary to provide thermal insulation. Thanks to it, heat loss that goes outside is prevented.

Boiler device

How to make your own heating

Depending on what type of boiler: gas, electric or indirect was chosen, the connection algorithm is slightly different

Scheme with a gas water heater

To adapt the device to new operating conditions, it is necessary to take a number of measures

- install a circulation pump into the supply line of the system, which will regulate the speed of the coolant

- install a hydraulic arrow. Then the heating from a water heater assembled with your own hands will be more balanced. In addition, it will ensure the safe operation of the complex in the event of all radiators being turned off.

- organize fresh ventilation in the boiler room, which will ensure the presence of a sufficient amount of air for burning gas in the burner

System with indirect water boiler

This option is the easiest to implement, as it requires minimal system reorganization. In this case, the device simply cuts into the supply line as close as possible to the boiler in order to avoid heat loss as much as possible. The coil of the main energy source passes through the tank, is heated by the hot water accumulated in it and is discharged further into the heating network. Additionally, the boiler is connected to the DHW to meet its needs.

Electric boiler from a water heater

Equipment calculated based on power and tank volume must first be connected to the network. To do this, it is recommended to draw a separate grounding line from the panel, which must have an RCD (residual current device) on it. The boiler is connected to the heating pipe of the house by the corresponding pipes: the inlet for the return line, the outlet for the supply. The forced movement of the working medium through the system will be provided by a circulation pump.

Although it is possible to construct an electric boiler from a water heater with your own hands, it is unlikely to be able to ensure that it covers the needs of the hot water supply. The reason for this is the limited resource of the equipment. If you use the boiler as a double-circuit boiler, its service life will be reduced to a minimum.

Flow type devices

Electric heaters of this type belong to a separate category. In their design features, they differ significantly from storage water heating devices. The flow-through device has a more compact size, since it does not have a hot water storage tank. Water enters the heater through the inlet pipe, and then it is heated.

Instantaneous water heater

Heating occurs in a copper flask, and rather powerful heating elements serve as heating devices. Typically, flow-through devices use heating elements with a power of 5 to 25 kW. After the liquid is heated, it immediately enters the heating of a private house with electricity, and its flow is regulated by means of special valves.

Installation of a heating water heater

The body of the unit is placed on the floor, as it has significant weight. The equipment may include height-adjustable legs. If they are not available, to install it, it is recommended to pour a separate concrete platform and put a layer of thermal insulation on it. It is important that the tank is positioned strictly vertically, which must be checked for level.

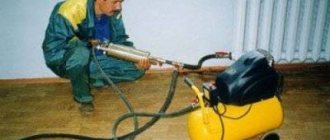

Do-it-yourself heating from a water heater is installed in a standard manner, for which the diagram is shown in Figure 1. A safety valve is installed at the inlet to regulate the pressure, and at the point of supply from the cold water complex, a shut-off valve is connected to prevent the reverse movement of the coolant.

A circulation pump is installed on the supply line after the hot water supply comb, ensuring forced movement of the working medium through the heating system. If DHW is not provided for in the engineering complex plan, the boiler is connected directly to the heating distribution.

Required Tools

In order for the scheme to connect the boiler to the water supply to be implemented without problems, it is necessary to prepare everything necessary in advance.

The list of tools and materials includes:

- measuring devices (ruler or tape measure),

- impact tool for drilling and drill bits in a set (you can use a hammer drill or a drill with an impact function),

- fastening elements for mounting the unit on the wall (brackets, anchors),

- mounting keys for connecting elements (it is optimal to supplement the kit with pliers and an adjustable wrench),

- tees (fittings designed for insertion into water pipes),

- shut-off valves (they should be installed at the entrances to the boilers to ensure that the equipment can be turned off, for example, for repairs)

- materials to ensure the tightness of connections (tow, special paste, sealing tape),

- flexible hoses (with their help, liquid is introduced into and out of the heater).

When preparing materials and tools, take into account the individual characteristics of connecting the water heater to the water supply system - the scheme may involve extending pipes or creating a bypass line. In this case, you need to purchase pipes, choosing them according to their technical characteristics (it is important to remember that not all materials are resistant to high temperatures).

Find out what rules exist for installing water meters in an apartment. The article also describes the sequence of installation of devices.

Recommendations for use

Ensuring long-term and uninterrupted operation of the heater is possible with systematic maintenance, which includes

- Cleaning the storage tank. If this is an electrical device, then so is the heating element. It is necessary to remove scale, which quickly corrodes metal walls.

- Timely replacement of the magnesium anode. This point also applies to electric boilers.

- Check the integrity of the thermal insulation layer, as damage to it will cause serious heat loss.

- Checking pipe connections and fittings for leaks. A leak that is not detected in time can cause a decrease in the efficiency of the entire system.