In order for the fireplace to take its rightful central place in the house, you need to seriously think about its decoration. After all, he should attract household members with his beauty and comfort. But in addition to aesthetics, the fireplace lining must also have a practical component. An open fire in the hearth is not only comfort and luxury. But also danger. As well as soot and soot from combustion products.

Cladding a fireplace with tiles Source ceramicadecor.ru

Choosing a finishing method

Just the mention of a fireplace in a casual conversation can make a person feel warm. And all because an island of comfort with tongues of living flame immediately appears before your eyes. Where it is very pleasant to while away the cold winter evenings.

Previously, it was believed that only owners of private houses could afford such luxury. Since safety requirements are fully implemented only in such buildings. But with the advent of imitations, electric fireplaces and bio-fireplaces, it became possible to create a comfortable place to relax in any apartment in a multi-storey building.

Moreover, both a real working fireplace and a decorative stylization for it are subject to cladding. And if in ancient times only tiles were used to decorate the hearth, today the choice of materials is truly enormous. Therefore, the developer will involuntarily have to rack his brains about how to veneer the fireplace.

Since the range is really large, it is extremely difficult to name the ideal material. After all, in addition to aesthetics, it is necessary to pay attention to the practical side. Find out how well the chosen option suits the existing design. Because you will need to take into account a lot of factors.

Fireplace in the living room Source ceramicadecor.ru

For example, the type of fireplace and type of fuel. If wood burns in a real hearth, its walls will heat up to very high temperatures. Therefore, a special cladding is needed - heat-resistant. And it’s best to take the material with a margin to spare. Suddenly you want to heat the hearth with coal. And its combustion temperature is higher than that of firewood.

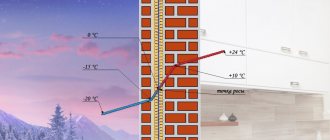

Or provide conditions at the location. It happens that a fireplace is installed on the terrace and used occasionally. The rest of the time the fireplace is in a cold room, where the ambient temperature can drop below zero. It goes without saying that the finishing material must be frost-resistant.

Any combustion releases products such as soot and soot. They settle on the surface and not only spoil the appearance of the room. If you want to lean your elbows on the mantelpiece, then this is fraught with damage to your clothes. Not to mention that you will have to wash it very carefully afterwards. Therefore, we need a cladding that is not afraid of water and is easy to clean regularly.

Fireplace lined with clinker tiles Source festima.ru

You also need to select a material that will fit perfectly into the overall design of the room. After all, no one has canceled simple design rules. And even if you involuntarily disturb the interior, then from the main accent of the room, the fireplace will literally turn into an eyesore.

But most often you have to take into account the weight of the materials. After all, finishing a fireplace with porcelain stoneware is completely impossible if it is a decorative imitation made of cardboard. And not every active fireplace can be covered with natural stone. The significant weight of these materials requires the construction of a reinforced foundation for the structure.

True, such difficulties await only those who want to decorate their recreation area with special luxury. But artificial stone or tiles are light enough to be glued even to a plasterboard frame. And the price will be much cheaper than natural materials.

And if you opt for plaster, you can save even more. And almost any conditions will suit her. And you don’t have to worry about the location, since this material is not afraid of temperature changes.

Plaster on the fireplace Source austroflamm.lv

Types of fireplaces and their features

Fireplaces are installed in different rooms. They can be active or decorative. The types of these devices depend on this. In village houses, wood-burning fireplaces are usually used, the design of which includes a major chimney. In this case, heating of such devices is carried out using firewood.

The firebox of such fireplaces is made of ceramic blocks and refractory bricks. They can be a finished cast iron structure or made of heat-resistant steel.

The outer part of the hearth is considered to be a portal, on which the appearance and decor depend. Brick, granite, and marble are suitable for decorating such a fireplace.

Another type of device is gas installations. They differ in the design of the firebox. In this case, the chimney is important, but its operation depends on the gas line. Such models are characterized by quiet operation and quickly heat the room. They are considered safer than wood-burning ones.

Electric fireplaces look more modern. They only require electricity to operate. They resemble the real ones solely in appearance. Such devices can be floor-mounted or suspended.

Eco-fireplaces are considered another constructive solution. To maintain them in working condition, substances that do not emit carbon dioxide are required. Such devices cannot heat a large room, but they can make the room temperature more comfortable.

There are designs that are open on three sides. Their use helps to heat the air in the room and performs decorative functions.

Eco-fireplaces are considered a trendy option.

Plaster

The method is considered the simplest, and also budget-friendly, since the raw materials and tools needed are not expensive. But meanwhile, sometimes the result exceeds all expectations. Because in addition to a smooth surface, you can also get a very beautiful textured one. And even put various designs on it.

Types of plaster

Compositions that were developed for brick stoves are suitable for fireplaces. And since the temperature regime of the latter is much higher, there are no problems. In addition, the manufacturer has already added all the necessary additives and additives to the dry mixture.

And those who like to do all the processes themselves need to be warned. Although the solution has only three components (clay, sand, lime), without gained experience it will not be possible to choose the correct proportions. The required fat content of the clay plays an important role, to which it is necessary to select the exact amount of sand.

Incorrectly mixed plaster cannot withstand strong heat and will immediately crack. Therefore, experiments will be very expensive. After all, after each unsuccessful kindling, the fireplace will have to be re-plastered, removing the old composition from the surface.

Classically plastered fireplace Source lg2.it

And the manufacturer offers two types of ready-made mixtures. The first composition is basic and is applied in a layer of up to 1 cm. The finishing mixture contains finely ground substances. It is layered with a thickness of only 3 mm onto a completely dry rough finish. The final layer can be left smooth or treated with techniques that will create different decorative textures on the surface.

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

Application technology

They say that plastering stoves and fireplaces is no different from working with ordinary walls. In general terms this is true. But there is one caveat. Before applying the base composition, it is necessary to heat the fireplace a little so that its walls warm up to 60 °C. This must be done so that the brick acquires its “working” parameters.

Step-by-step finishing of a fireplace using plaster:

- The old cladding is removed. The walls are cleaned of lime, clay or paint down to the brick itself.

- The seams are deepened to a distance of 1 to 1.5 cm. This will increase the adhesion of the mortar to the wall.

- Any cracks found in the masonry are filled with a heat-resistant sealant that can withstand heat up to 800 °C.

Filling cracks with a special sealant Source saznworld.com

- At the final stage of preparation, use a long-haired brush to sweep away all dust from the surface.

- A relatively flat wall can be moistened with water and immediately plastered with the base composition.

- If the differences in the plane are large, then the wall is reinforced with a metal mesh with a small cell and beacons are installed.

When performing the last point, preliminary jointing is not required. The mesh is fixed to the wall with nails, which are driven into the seams. And under the hats they put on a washer whose dimensions are larger than the mesh cell. The solution is applied with a spatula, leveling the surface along the beacons.

You can begin working with the finishing solution only after the base solution has completely dried. To speed up the process, it is allowed to create a draft in the room. But lighting a fireplace is strictly prohibited.

How to cover a fireplace with your own hands step by step

Finishing a fireplace with your own hands is not difficult. It is important to follow the step-by-step instructions and take into account a number of nuances. First, you need to decide how best to decorate the fireplace. Most often clay is used for this.

In most cases, the material is mined by hand. Therefore, it must be tested for suitability for use. To do this, you will need the clay itself and a clean container of water. The material must be placed in water and the contents mixed with a metal shovel. If the clay sticks to it, then the material cannot be used as a cladding. This sign indicates increased fat content of the substance.

The cladding material must be sufficiently elastic, withstand high temperatures and hold its shape well. Adding sand will help improve the structure of oily clay.

To veneer a fireplace, it is recommended to do the following:

- Mix the solution. This must be done in a clean container. To get the desired result, you should use clay and clean water. The number of components is selected taking into account the planned work.

- Tile the fireplace. In this case, it is permissible to use only certain types of tiles. These include majolica, porcelain stoneware, terracotta and clinker.

- Before carrying out work, the walls should be thoroughly cleaned of dust, old coating and dirt.

- Level the walls with putty using reinforcing mesh. In this case, it is necessary to increase the seams between the bricks to update them.

- Begin laying tiles by marking the floor and adjusting the dimensions using a grinder. The material must be laid from bottom to top. After each row, the uniformity of the laying should be assessed using a level.

- After completing the work, wipe the tiles with a damp cloth to remove the mortar.

When finishing work with stone, it is better to give preference to artificial varieties. It is important to choose shades, textures and monitor the location.

It is quite possible to decorate a fireplace with your own hands.

Tiling

A couple of decades ago, many home craftsmen used ordinary ceramic tiles for facing the fireplace. And the result was very similar to a lottery. With a probability of 50%, after some time the glaze was covered with a network of tiny cracks.

Tiling a fireplace Source pechki.su

The appearance of the fireplace was hopelessly ruined. Moreover, it is not even possible to simply wash off the contamination. Although in those days there were special materials. For example, tiles. But they were expensive. True, even today good tiles for finishing a fireplace have a high price. But you always have to pay for quality and beauty.

Types of tiles

The main material for decorating fireplaces is terracotta. Literally translated, the word means “burnt earth (clay).” This ceramic becomes brown in color after pre-treatment in the kiln. There is no glazed layer, and the surface remains matte and slightly porous. The tile looks like burnt red brick.

But if you apply a pattern to terracotta and cover the tiles with glaze, you get majolica. The word is of Italian origin, since such technology was first used in this country in the fourteenth century. And after a couple of centuries, the production method was copied in Russia. And stove tiles are essentially the same majolica, but only of Russian origin.

Majolica on the fireplace Source timepad.ru

Use of thermal insulation materials

Thermal insulation is necessary if the combustion chamber will perform a purely decorative function. The main requirements for thermal insulation include the following:

- The presence of slight hygroscopicity. Such a composition should not absorb or absorb moisture. Make sure that condensation does not form inside the material. This may lead to loss of filler performance;

- Melting occurs exclusively under the influence of very high temperatures. The use of such a base with a high melting point is necessary to comply with fire safety standards and regulations.

Zones with insulation

Performing thermal insulation of a heating installation

Mineral wool for thermal insulation of fireplaces

Of course, facing fireplace inserts can also be done using other coatings. In this article, we have collected the most common materials, which are recommended to be used by leading experts and professionals. When making a choice, consider the cost, quality and operational features of the coating. This will allow the cladding to be completed with the highest possible quality, ensuring the structure’s efficiency and durability.

Stone cladding

Stone finishing of the fireplace is made from both natural materials and artificial analogues. Moreover, the latter are produced in the form of tiles. Therefore, the technology for their installation is no different. Yes, and natural stone for work is pre-cut into thin plates.

True, some types of stone still retain significant weight. In addition, elements often come in different configurations. And this complicates the installation process. It is necessary to first assemble the mosaic on the floor, and then transfer it to the surface of the fireplace. But otherwise, the technology for installing stone is no different from gluing tiles.

Cladding a fireplace with stone Source dompechey.ru

Tips and tricks from professionals

To make the fireplace cladding look attractive, the following nuances should be taken into account:

- When constructing and finishing a structure, it is important to use a building level.

- After creating a fireplace with your own hands, irregularities often appear. They definitely need to be removed.

- When decorating the surface, you need to use a spatula and a sponge. This will help you achieve better results.

- It is recommended to plaster the fireplace using a small brush and trowel.

- For high-quality cladding you will need good equipment.

- To get a unique design, you should use different shades of tiles. They can be combined in different ways.

- To retain heat as much as possible, it is better to use tiles. They have a large thickness and relief structure.

- To make the marble pattern monolithic, you must first lay out the tiles on the floor.

Tiles retain heat best.

Less popular methods

It’s worth talking right away about decorating the fireplace with tiles. The method is quite old, but today it is very rarely used. Firstly, such finishing is possible only when constructing a fireplace. You cannot cover an already finished hearth with real tiles.

Secondly, the installation is so complicated that it requires a highly specialized specialist. Tiles are already a very expensive pleasure. And the involvement of a master in the work makes such a fireplace truly “golden”.

You can line the fireplace with brick. In this case, there are two ways. They take plastic molded ceramic bricks and lay out the external walls. In the second case, the main masonry is refined. The seams are deepened and cleared. Then they are filled with special compounds.

The brick itself is also subjected to various treatments. Hydrochloric acid solution for color saturation. And before that, each element is polished or chamfered. The complexity of such finishing is so great that not every stove maker will take on the job.

Video description

The video will show how to line a fireplace with artificial stone:

But a fireplace trimmed with wood looks most original. Some might say that this is a complete violation of fire safety. But if you follow certain rules, you can get a chic fireplace for your living room in a classic style.

Firstly, it is necessary to select wood that will maintain its structure at periodically changing temperatures. And you only need to consider oak, hornbeam, maple or cherry. The density of other breeds is much worse.

Secondly, the material is generously treated with fire retardants. And even after this, it is necessary to move the wooden frame ten centimeters away from the bricks of the hearth. Only in this case will the heating of the wood not exceed permissible limits.

Thirdly, the firebox itself must be covered with a protective screen. To protect the tree from accidentally flying sparks from the hearth. And as a result, you can get an aesthetic finish from natural materials that will last for an extremely long time. Moreover, the type of cladding will not change over time.

Briefly about the main thing

When choosing materials for cladding a fireplace, you first need to pay attention to their weight. Natural stone or porcelain tiles have a very large mass. Therefore, they are suitable only for a private house, in which it is possible to strengthen the foundation of an existing fireplace.

In all other cases, it is better to stick to tiles. It weighs little and is easy to attach to the surface of the fireplace with glue. Moreover, its range is so wide that there is an imitation of almost all natural materials. From natural stone to wood of any species.